Documente Academic

Documente Profesional

Documente Cultură

7-Civil - Ijcseierd - Comparative - S. P. Dalal

Încărcat de

TJPRC PublicationsTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

7-Civil - Ijcseierd - Comparative - S. P. Dalal

Încărcat de

TJPRC PublicationsDrepturi de autor:

Formate disponibile

COMPARATIVE EVALUATION OF ELASTIC DESIGN AND

PERFORMANCE BASED PLASTIC DESIGN METHOD FOR A STEEL

MOMENT RESISTING FRAME

1

SEJAL P. DALAL,

2

ANDEEP A. VASANWALA

&

2

ATUL K. DESAI

1

Assistant Professor, Civil Engineering Department SVIT, Vasad, Gujarat, India

2,2

Associate Professor Applied Mechanics Department, SVNIT, Surat, Gujarat, India

ABSTRACT

Presented in this paper is the comparative evaluation of Performance Based Plastic Design

(PBPD) method Elastic Design (ED) method in terms of lateral force distribution, design, strength and

economy. For this, a steel moment resisting frame is first designed using the Elastic Design method and

then using the Performance Based Plastic Design Method. The Lateral forces in the Elastic Design

method are calculated using the Elastic Design Spectra and all the structural members are designed as

elastic beam-columns based on Limit State Design Philosophy. The Lateral forces in the Performance

Based Plastic Design Method are calculated using the inelastic spectral acceleration which is obtained by

applying proper reduction factors. Results prove the superiority of the PBPD method over the Elastic

Design method in terms of safety and overall economy.

KEYWORDS: Elastic Design Method, Performance Based Plastic Design Method, Target and Yield

Mechanism.

INTRODUCTION

When struck by severe ground motions, the structures designed by elastic design procedures

have been found to undergo inelastic deformations in a somewhat uncontrolled manner. The inelastic

activity, which may include severe yielding and buckling of structural members and connections, can be

unevenly and widely distributed in the structure. This may result in a rather undesirable and

unpredictable response, sometimes total collapse, or difficult and costly repair work at best. While the

elastic design practice has served the profession rather well in the past, societal demands are pushing the

practice to achieving higher levels of performance, safety and economy, including life-cycle costs. For

the practice to move in that direction, design factors, such as determination of appropriate design lateral

forces and member strength hierarchy, selection of desirable yield mechanism, structure strength and

drift, etc., for specified hazard levels should become part of the design process right from the start.

One such method known as the PBPD method for Earthquake Resistant Design of Structures,

which accounts for inelastic structural behavior directly, has been developed by Goel et al, 2001. The

PBPD method is a displacement based method in which a predetermined failure pattern is used at certain

International Journal of Civil, Structural,

Environmental and Infrastructure Engineering

Research and Development (IJCSEIERD)

ISSN 2249-6866

Vol.2, Issue 3, Sep 2012 76-97

TJPRC Pvt. Ltd.,

77 Comparative Evaluation of Elastic Design and Performance Based

Plastic Design Method for A Steel Moment Resisting Frame

points of a structure based on strong column weak beam concept. Results of extensive inelastic static

and dynamic analyses have proven the validity of the method. The method has been successfully applied

to steel Moment Frame (Goel et al , 2008,2010 ), Eccentrically Braced Frame (Chao and Goel, 2006a) ,

Composite buckling restrained braced frame (Dasgupta,2004),Concentrically Braced Frame (Chao and

Goel, 2006b) and Special Truss Moment Frame (Goel and Chao, 2008). In all cases, the frames

developed the desired strong columnweak beam yield mechanisms as intended, and the storey

drifts/ductility demands were well within the selected design values, thus meeting the selected

performance objectives. An excellent literature review of the method has been done by Dalal et al

(2010).

The PBPD method is a direct design method that uses pre-selected target drift and yield

mechanisms as key performance objectives that determine the degree and distribution of expected

structural damage. It is based on the formulations derived from the capacity-spectrum method using

NewmarkHall (1982) reduction factors for the inelastic demand spectrum. The design base shear for a

specified hazard level is calculated by equating the work needed to push the structure monotonically up

to the target drift to the energy required by an equivalent Elasto Plastic Single Degree of Freedom system

to achieve the same state. Plastic design is performed to detail the frame members and connections in

order to achieve the intended yield mechanism and behavior.

The current Indian Standard code (IS800:2007) uses the limit state procedure (which is a force

based design) for design of steel structures to ensure a good earthquake resistant design which at times

may fail in case of a severe earthquake as it is based on elastic analysis. The dead and imposed loads are

calculated using IS875, (parts I to V) and the seismic loads are calculated using IS1893:2002 based on

Elastic Design Spectrum. A steel moment resisting frame has been designed using the PBPD method in

accordance with the IS 800: 2007 code by Dalal et al (2011) in which the cross sections of beams have

been reduced at certain pre defined locations so that it forms the weak link during an earthquake and

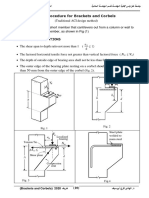

plastic hinges are formed. The steel moment resisting frame as shown in figure 1 has the parameters

given in the Table 1and is subjected to dead load and imposed load as given in Table 2.The gravity and

the seismic load calculations are shown in Section 1.1 and distributed as shown in figure 2.

Sejal P. Dalal, Andeep A. Vasanwala

& Atul K. Desai 78

Figure 1: Plan and Elevation of the Steel moment Resisting Frame

79 Comparative Evaluation of Elastic Design and Performance Based

Plastic Design Method for A Steel Moment Resisting Frame

Table 1:Design Parameters

Type of structure 4-Storey Steel Moment Frame.

Number of stories 4

Bays in X direction 6 bays at 9 m

Bays in Y direction 4 bays at 9 m

Floor height 4 m for all floors and 4.25 m for first floor

Building Height 16.25 m

Materials Structural steel with f

y

= 250 N/mm

2

Floor Seismic Weight for Roof 9720 KN

Floor Seismic Weight for Level

4

9331 KN

Floor Seismic Weight for Level

3

9429 KN

Floor Seismic Weight for Level

3

9525 KN

Seismic zone factor, Z Zone 4

Soil Profile Type Type 2 Medium

Importance factor, I 1

T 0.939 sec

Table 2:Design Loads

Typical Roof Level 4 Level 3 Level 2

Dead Load

(KN/m

2

)

4 4.5 4.5 4.5

Live Load

(KN/m

2

)

1 2.5 2.5 2.5

Mass Seismic

Load(KN/m

2

)

5 4.8 4.85 4.9

Dead Load due

to exterior

Curtain Wall

(KN/m)

3.75 ( 3 m Wall height) 4.5 ( 4 m

Wall

height)

4.5 ( 4 m

Wall height)

5 ( 4.25 m Wall

height)

Calculation Of Gravity Loads And Seismic Loads

1. Floor Seismic Dead Weight (full structure)

Roof = (5 x 54 x 36) = 9720 KN

Level 4 = (4.8 x 54 x 36) = 9331 KN

Level 3 = (4.85 x 54 x 36) = 9429 KN

Level 2 = (4.9 x 54 x 36) = 9525 KN

Sejal P. Dalal, Andeep A. Vasanwala

& Atul K. Desai 80

Full structure = 38005 KN

2. Beam Load Calculation (for exterior moment frame)

The exterior beams take the dead load from 4.8 meter of slab (which accounts for 0.3 meter of overhang.

The live load is calculated based on a 4.5 meter tributary width only.

Uniformly distributed loads on the exterior beams:

1. Roof

From slab (dead load) = 4 x 4.8 = 19.2 KN/m

From exterior curtain wall (dead load) = 3.75 KN/m

From slab (live load) = 1 x 4.5 = 4.5 KN/m

Total Load Combination w

3

(Clause 3.5.1 IS 800: 2007) = 1.4 DL + 0.35 LL = 1.4 x (19.2

+3.75) + 0.35 x 4.5 34 KN/m

2. Level 4 and 3

From slab (dead load) = 4.5 x 4.8 = 21.6 KN/m

From exterior curtain wall (dead load) = 4.5 KN/m

From slab (live load) = 2.5 x 4.5 = 11.25 KN/m

Total Load Combination w

2

(Clause 3.5.1 IS 800: 2007) = 1.4 DL + 0.35 LL = 1.4 x (21.6 +4.5)

+ 0.35 x 11.25 40 KN/m

3. Level 2

From slab (dead load) = 4.5 x 4.8 = 21.6 KN/m

From exterior curtain wall (dead load) = 5 KN/m

From slab (live load) = 2.5 x 4.5 = 11.25 KN/m

Total Load Combination w

1

(Clause 3.5.1 IS 800: 2007) = 1.4 DL + 0.35 LL = 1.4 x (21.6 +5) +

0.35 x 11.25 41 KN/m

3. Concentrated Load at Column Lines (values for one exterior moment frame)

4. Roof

Dead load (exterior column lines) = 4.8 x 1.56 x 4 + 2 x 4.8 x 3.75 x 1.2 = 73 KN

Live load (exterior column lines) = 4.5 x 1.2 x 1 = 5.4 KN

Dead load (interior column lines) = 0 + 9 x 3.75 x 1.2 = 40.5 KN

Live load (interior column lines) = 0 = 0 KN

Total Load Combination (Clause 3.5.1 IS 800: 2007) = 1.4 DL + 0.35 LL

L

5

(roof) = 1.4 (73) + 0.35(5.4) = 104 KN

L

6

(roof) = 1.4 (40.5) + 0.35(0) = 56.7 KN

5. Level 4 and 3

Dead load (exterior column lines) = 4.8 x 1.56 x 4.25 + 2 x 4.8 x 4 x 1.2 = 78 KN

Live load (exterior column lines) = 4.5 x 1.2 x 2.5 = 13.5 KN

Dead load (interior column lines) = 0 x 9 x 4 x 1.2 = 43.2 KN

81 Comparative Evaluation of Elastic Design and Performance Based

Plastic Design Method for A Steel Moment Resisting Frame

Live load (interior column lines) = 0 =0 KN

Total Load Combination (Clause 3.5.1 IS 800: 2007) = 1.4 DL + 0.35 LL

L

3

(level 3, 4) = 1.4(78) + 0.35(13.5) = 114 KN

L

4

(level 3, 4) = 1.4(43.2)+ 0.35(0) =60.48 KN

6. Level 2

Dead load (exterior column lines) =4.8 x 1.56 x 4.25 + 2 x 4.8 x4.25 x 1.2 = 80 KN

Live load (exterior column lines) =4.5 x 1.2 x 2.5 = 13.5 KN

Dead load (interior column lines) =0 x 9 x 4.25 x 1.2 = 46 KN

Live load (interior column lines)=0 =0 KN

Total Load Combination (Clause 3.5.1 IS 800: 2007) = 1.4 DL + 0.35 LL

L

1

(level 2) = 1.4 (80) + 0.35(13.5) = 114 KN

L

2

(level 2) = 1.4 (46) + 0.35(0) = 64.4 KN

DESIGN OF THE MOMENT RESISTING FRAME USING ELASTIC DESIGN

METHOD

The linear static procedure has been a traditional structural analysis method for earthquake

resistant design but it does not represent the nonlinear behavior of the dynamic response of a structure

caused by an earthquake ground motion. In the current Indian Standard Seismic design practice (IS1893-

2000), we first obtain design base shear from code-specified spectral acceleration assuming the structures

to behave elastically (which depends on the soil factors and the time period of the structure), and

reducing it by force reduction factor, R, depending upon available ductility of the structural system. The

design forces are also adjusted for the importance of specific structures by using an occupancy

importance factor, I. The step by step procedure of the elastic design of this frame is shown in the

following section.

Sejal P. Dalal, Andeep A. Vasanwala

& Atul K. Desai 82

Figure 2 : Distribution of gravity forces.

Step 1 : Calculation of Design Parameters

Based on the IS1893-2002, this frame is found having seismic design parameters as shown in Table 3

Table 3 : The seismic parameters of the frame as per IS1893-2002

Natural time Period "T" 0.939 seconds

Soil Type II

Elastic Spectral Acceleration " S

a

/ g" 1.448

Importance Factor "I" 1

Zone Factor " Z" 0.36

Response Reduction Factor "R" 5

Total Seismic Weight of the Building

"W" 38005

Step 2 : Calculation of design seismic base shear and lateral forces on each floor.

The total design lateral force or design seismic base shear ( V

b

) along any principal direction shall be

determined by the following expression

v

b

= A

h

W Equation 1

83 Comparative Evaluation of Elastic Design and Performance Based

Plastic Design Method for A Steel Moment Resisting Frame

v

b

= u.uS2 - S8uuS = 1981 KN

where

A

h

=

Z I S

a

2 R g

= u.uS2 Equation 2

This Base shear V

b

is distributed along the height of the Building as follows:

Q

I

= v

b

W

h

2

W

]

n

]=1

h

]

2

Equation 3

Where

V

b

= Base shear

A

h

= Design Horizontal Seismic Coefficient

W = Total seismic weight of the structure

Z = Zone factor

I = Importance factor

R = Response reduction factor

Sa/g = Average response acceleration coefficient

Q

i

= Design lateral force at floor i

W

i

= Seismic weight of floor i

h

i

= Height of floor i measured from base

n = Number of storeys in the building is the number of levels at which the masses are located.

Table 4 : Lateral force Distribution in floors

Roof

Level

4

Level

3 Level 2

Sum

Seismic Weight of floor i "W

i

" 9720 9331 9429 9525 38005

Design Lateral Force at Level i

"Q

i

" 1063.63 580.25 265.94 71.3 1981.1

Step 3: Static Analysis of the frame

The moment resisting frame was applied the above lateral forces along with gravity loads as

shown in figure 2 and static analysis was carried out. Based on the obtained values of axial force, shear

force and bending moment, all the structural members of this frame were designed using the elastic

design approach. As all the beams and columns have all the three components viz. shear, axial and

moment, they all need to be designed as beam-columns. The step by step procedure of design of the

structural members is shown in succeeding sections.

Sejal P. Dalal, Andeep A. Vasanwala

& Atul K. Desai 84

Step 4: Design Compressive Stress for axially loaded compression members (Member buckling

resistance in compression)

The buckling resistance in compression (or the Compressive Load Capacity) of all the members

should be less than the maximum value of axial force experienced by the member. Common hot rolled

members used for carrying axial compression usually fail by flexural buckling. The buckling strength of

these members is affected by residual stresses, initial bow and accidental eccentricities of load. To

account for all these factors, the strength of members subjected to axial compression is dependent on

Imperfection Factor "" defined by buckling class a, b, c or d as given in table 7 of IS800-2007 code

(Clause 7.1.2.1). To calculate buckling resistance in compression of members, following procedure

should be implemented.

=

_

I

y

[

KL

2

E

Equation 4

= u.S|1 +( -u.2) +

2

] Equation 5

=

1

j+(

2

-)

0.S

[

Equation 6

f

cd

=

I

y

mo

Equation 7

N

d

= f

cd

A

Where

= Non Dimensional Effective Slenderness ratio

KL/r = Effective slenderness ratio

= Stress Reduction factor for different buckling class, slenderness ratio and yield stress

f

cd

= Design Compressive Strength

A = Effective Sectional Area

N

d

= Design Compressive Load Capacity

Step 5 Safety against Shear

The Shear strength of all the members should be less than the maximum value of shear force.

This design shear resistance " V

n

" of members shall be calculated using Clause 6.4

v

n

=

d

secton

t

veb

I

y

3

Equation 8

85 Comparative Evaluation of Elastic Design and Performance Based

Plastic Design Method for A Steel Moment Resisting Frame

v

d

=

V

n

mo

Equation 9

Where

V

n

= shear resistance

d

section

= depth of the section

t

web

= thickness of web

V

d

= shear strength

Step 6 Safety against Flexure

To ensure safety of members against flexure, it is important that the flexural strength of members is

less than the maximum value of bending moment. The flexural strength of members can be calculated

using clause 8.2.There are two cases to be kept in mind while calculating the flexural strength

(i) When the factored shear force is less than 0.6 times Shear Resistance V

d

(ii) When the factored shear force is more than 0.6 times Shear Resistance V

d

(i)If, the factored shear force is less than 0.6 times the shear capacity then,

Design Flexural Strength shall be calculated as

N

d

=

Z

e

I

y

mo

Equation 10

Where

M

d

= Design Flexural Strength

Z

e

= Elastic Section Modulii of the section

(ii)If, the factored shear force is more than 0.6 times the shear capacity then, Clause 9.2.2 should be

satisfied. The Design Flexural Strength is dependent on whether the section is compact or semi compact.

When the ratio of width to thickness of flange is less than 15.7, the section is compact otherwise it is

semi compact.

(a)Section is semi compact

N

d Ior shcar

=

Z

e

I

y

mo

Equation 11

Where

M

d for shear

= Design moment capacity of section considering high shear force effect

(b) Section is Plastic or compact

N

d Ior shcar

= N

d cIastIc

-

shcar

(N

d cIastIc

- N

I pIastIc

) 1.2

Z

e

I

y

mo

Equation 12

Sejal P. Dalal, Andeep A. Vasanwala

& Atul K. Desai 86

N

d cIastIc

=

Z

e

I

y

mo

Equation 13

N

I pIastIc

=

Z

Iastc

I

y

mo

Equation 14

Where

M

d for shear

=Design moment capacity of the whole section considering high shear force effect

M

d elastic

=Design moment capacity of the whole section disregarding high shear force effect

M

d plastic

=Plastic Design strength of the area of the cross section excluding the shear area considering

partial safety factor

Where

shcar

= _

2v

v

d

- 1]

2

Step 7 Check for Combined effects

The members subjected to combined effect of axial force, shear force and bending moment need

to satisfy the following equation

N

N

d

+

M

y

M

ndy

1.u Equation 15

Where

N = Factored applied axial force

N

d

= Design Strength in Tension obtained as A

g

f

y

/mo

A

g

= Gross Cross Sectional Area

M

y

= Factored applied moments

M

dy

=Design reduced flexural strength obtained as

b

Z

p

f

y

mo

Step 8 Resistance to lateral torsional buckling

As the frame undergoes seismic forces, it is important to check its resistance to lateral torsional

buckling as per clause 8.2.2.1. The bending Moment capacity of the section against torsional effects "M

t

"

should be less than the maximum bending moment coming on the section. To calculate " M

t

" ,following

steps should be followed

f

cr b

=

1.1

2

E

(L

LT

r

y

)

2

_1 +

1

20

[

L

LT

r

y

h

I

t

I

2

_

0.5

Equation 16

LT

= _

I

y

I

c b

Equation 17

LT

= u.S|1 +

LT

(

LT

- u.2) +

LT

2

] Equation 18

87 Comparative Evaluation of Elastic Design and Performance Based

Plastic Design Method for A Steel Moment Resisting Frame

LT

=

1

_

LT

+|

LT

2

-

LT

2

]

0.S

_

1.u Equation 19

f

bd

=

LT

f

y

mo

Equation 20

N

t

=

Z

p

f

bd

Equation 21

Where

L

LT

= 0.9 L= Effective length for lateral torsional buckling

h

f

= centre to centre distance between flanges

t

f

= thickness of flanges

f

cr,b

= Extreme fibre bending compressive stress

LT

=Non dimensional slenderness ratio

LT

=the imperfection parameter =0.49 for welded section and 0.21 for rolled section

LT

= Bending stress reduction factor for lateral torsion buckling

f

bd

= Design bending compressive strength

M

t

= Bending Moment Capacity for torsional effects

Step 9 Check with Interaction Formula (should be less than 1)

Ratio of moments (negative /positive) "

y

"

Member resistance to combined bending and axial compression

K

y

= 1 + (

y

- u.2)

N

N

cd y

1 + u.8

N

N

cd y

Equation 22

C

my

= u.6 + u.4

y

u.4 Equation 23

N

N

cd y

+ K

y

C

my

M

M

d

1.u Equation 24

C

my

= Equivalent uniform moment factor ( as per clause 9.3.2.2 and table 18 of IS 800-2007)

The details of member sections thus obtained by the above mentioned steps of Elastic Design method as

done in the current design practice is briefed in Table 5.

Sejal P. Dalal, Andeep A. Vasanwala

& Atul K. Desai 88

Table 5 : The Design Sections obtained when the frame is designed by Elastic Design method

Sr. No. Level Section

Section

Modulus

(cm

3

)

Weight

( kg/m)

Beams

1 Roof ISMB600 with 320 x 32 mm cover plates 8930 313

2

Level

4

ISMB600 with 320 x 32 mm cover plates 8930 313

3

Level

3

ISMB600 with 320 x 32 mm cover plates 8930 313

4

Level

2

ISMB600 with 320 x 32 mm cover plates 8930 313

Exterior Columns

1 Roof ISWB600 3539 133.7

2

Level

4

ISWB600A with 400 x 16 mm cover plates 7502 245.6

3

Level

3

ISWB600A with 400 x 16 mm cover plates 7502 245.6

4

Level

2

ISWB600A with 400 x 16 mm cover plates 7502 245.6

Interior Columns

1 Roof ISMB600 with 320 x 32 mm cover plates 8930 313

2

Level

4

ISMB600 with 320 x 32 mm cover plates 8930 313

3

Level

3

ISWB600A with 400 x 16 mm cover plates 7502 245.6

4

Level

2

ISWB600A with 400 x 16 mm cover plates 7502 245.6

DESIGN OF THE MOMENT RESISTING FRAME USING THE PBPD METHOD

In this section, the steel moment frame building is designed using the Performance Based

Plastic Design Methodology in accordance with the IS 800:2007 code. The PBPD method is a direct

design method where drift and yield mechanism, e.g. strong columnweak beam condition, are built in

the design process from the very start.

The design base shear for a specified hazard is calculated based on the reduction factors

Rproposed by Newmark (1982). Also, a new distribution of lateral design forces is used that is based

on relative distribution of maximum storey shears consistent with inelastic dynamic response results

(Chao et al., 2007). Plastic design is then performed to detail the frame members and connections in

order to achieve the intended yield mechanism and behavior. Thus, determination of design base shear,

89 Comparative Evaluation of Elastic Design and Performance Based

Plastic Design Method for A Steel Moment Resisting Frame

lateral force distribution and plastic design are three main components of the PBPD method, which will

be discussed in the following sections. The step by step procedure of the design of the steel moment

resisting frame using the PBPD method is as follows

Step 1 : Calculate gravity loading and Seismic loading for the structure W.

Step 2 :Select an appropriate vertical distribution of forces based on the mode shapes obtained from

Modal Analysis.(usually mode shape 1 is chosen

Table 6 :The seismic Parameters of the frame for PBPD method

Seismic zone factor, Z 0.36

Soil Profile Type Type 2 Medium

Importance factor, I 1

S

a IncIastIc

0.64 g

T 0.939 sec

Yield drift ratio

y

1 %

Target drift ratio

u

2 %

Inelastic drift ratio

p

=

u

-

y

1%

Ductility factor

s

=

u

6

y

2.0

Reduction Factor due to Ductility R 2.0

Energy Modification Factor 0.75

0.942

Design Base shear V

b

8321 KN

Actual base shear for each floor 1040 KN

Sejal P. Dalal, Andeep A. Vasanwala

& Atul K. Desai 90

Step 3 : Select a desired Target Yield Mechanism for design earthquake hazard.

Figure 3 : The Target Yield Mechanism for the structure.

Step 4 : Calculate the shear distribution factor

i

of each floor.

I

= _

w

]

h

]

n

]=1

w

n

h

n

]

0.75T

-0.2

Equation 25

where

p

= The rotation at the plastic hinge [

p

= [

L

L

p

]

L'= The distance between the two plastic hinges of the beam = 0.8375L

i

= Shear distribution factor at level i

w

j

= seismic weight at level j

h

j

= height of level j from base

w

n

= seismic weight at the top level

h

n

= height of roof level from base

T = fundamental time period

Step 5 : Calculate .

o = ( ([

-[

+1

)

1

) _

=1

]

0.75

-0.2

[

Equation 26

p

p

p

Mpc

p

L'

L

p

p

p

Mpc

p

L'

L

p

p

p

Mpc

p

L'

L

p

p p

Mpc

p

L'

L

91 Comparative Evaluation of Elastic Design and Performance Based

Plastic Design Method for A Steel Moment Resisting Frame

Step 6 : Calculate Story shear V

=

-+_

2

+

2

2

Equation 27

Step 7 : Calculate the Lateral force F

n

of Roof Floor.

=

(

-

1

)

Equation 28

Step 8 : Calculate the Lateral force Fi of each level.

([

- [

+1

) Equation 29

Where

F

n

=Lateral Force at roof level ( n

th

level )

F

i

=Lateral Force at i

th

level

Step 9 : Calculate the required beam moment capacity Mu at each level

H

u

= [

H

pb

= [

- 2M

=1

2 [

L

L

,

=1

Equation 30

where

H

pc

=

1.1

1

4

M

pc

= required plastic moment of columns in the first story of the 1-bay model (V' =V/No. of bays)

M

pb

= required moment strengths at the top floor level

i

M

pb

= required moment strengths at level i.

Step 10: Calculate the design beam moment Mdesign by applying proper factors

M

design

= 1.1 M

u

/0.75 Equation 31

Step 11 : Calculate the section modulus Zp required.

Z

p

= M

design

/ f

y

Equation 32

Step 12 : Design of Beams using the Reduced Beam Section (RBS).

Select RBS dimensions a, b, and c (figure 4) subject to the following limits:

u.Sb

]

o u.7Sb

]

u.6SJ

b

b u.8SJ

b

u.1b

]

c u.2Sb

]

Where b

f

= width of beam flange

Sejal P. Dalal, Andeep A. Vasanwala

& Atul K. Desai 92

d

b

= depth of beam section

Z

RBS

= plastic section modulus at center of the reduced beam section,

Z

p

= plastic section modulus for full beam cross-section,

t

f

= thickness of beam flange.

a = distance from face of column to start of RBS cut

b = length of RBS cut

c = depth of cut at the center RBS section at the center of reduced beam section.

Step 13 : Check the compactness of the RBS

Z

RB

= Z

p

-2ct

]

(J

b

- t

]

) Equation 33

The ratio of Z

RBS

/Z

p

should be near to the assumption 0.75

The Moment Capacity M

RBS

of this RBS beam is calculated as

H

RB

=

z

RBS

]

j

mc

Equation 34

Step 14 : Checking the Moments and Shears of the beams

Checking Shear

Compute the probable maximum moment at the center of the RBS, M

prRBS

:

M

prRBS

= C

pr

R

y

f

y

Z

RBS

Equation 35

R

y

= ratio of the expected yield stress to the specified minimum yield stress (=1.1)

C

pr

= factor to account for the peak connection strength, including strain hardening, local restraint,

additional reinforcement, and other connection condition (=1.15)

RB

=

2M

rRBS

L

+

(udI)L

2

Equation 36

RB

=

2H

pRB

I

-

(uJl)I

2

V

RBS

= Probable Positive Shear Force at center of RBS

V'

RBS

= Probable Negative Shear Force at center of RBS

This shear V

RBS

or V'

RBS

should be less than V

n

as per the Clause 8.4.1 IS 800:2007

v

n

=

A

v

I

y

3

=

ht

v

I

y

3

=

d

b

t

v

I

y

3

Equation 37

Where

V

n

= nominal plastic shear resistance of section

93 Comparative Evaluation of Elastic Design and Performance Based

Plastic Design Method for A Steel Moment Resisting Frame

Figure 4: The details of the Reduced Beam Section

CHECKING MOMENTS

Compute the probable maximum moment, M

fcRBS

at the face of the column. If it is larger than

the expected moment capacity of the beam section at that location, the beam section will need to be

further reduced. The expected moment at the face of the column is computed as follows:

Sejal P. Dalal, Andeep A. Vasanwala

& Atul K. Desai 94

N

IcRBS

= N

prRBS

+ v

RBS

S

h

and Equation 38

N

IcRBS

= N

prRBS

+ v

RBS

S

h

The moment carrying capacity of the section is given by Clause 8.2.1.2 IS 800 : 2007

N

p

=

Z

p

f

y

mo

Where

b

=1.0 for plastic and compact sections

mo

= Partial safety factor = 1.0

S

h

=The distance from a column face to the center of RBS cut = a + b/2

This M

fcRBS

should not exceed M

p

.

Step 15: Calculation of Design Axial Force and Moments for the Exterior and Interior Columns

Exterior Column Tree

F

L

=

j (M

RE5

)

n

=1

[+j ](V

RE5

)[S

h

+

d

c

2

n

=1

[+|M

c

]

n

=1

Equation 39

Where

I

=

(

I

-

I+1

)

(

I

-

I+1

)

n

I1

F

L

= sum of lateral forces in columns

Interior Column Tree

F

L

=

j2 (M

RE5

)

n

=1

[+j ](V

RE5

+V

RE5

)[S

h

+

d

c

2

n

=1

[+|2M

c

]

n

=1

Equation 40

Step 16: Design of Exterior and Interior Columns

N

N

d

+

M

y

M

ndy

1.u Equation 41

Where

pi

= The rotation at the plastic hinge

L'= The distance between the two plastic hinges of the beam = 0.8375L

f

y

= tensile strength of steel

F

L

= sum of lateral forces in columns

95 Comparative Evaluation of Elastic Design and Performance Based

Plastic Design Method for A Steel Moment Resisting Frame

S

h

=The distance from a column face to the center of RBS cut = a + b/2

N = Factored applied axial force = (V rbs + V' rbs + Point load + load from upper floor)

N

d

= Design Strength in Tension obtained as A

g

f

y

/mo

A

g

= Gross Cross Sectional Area

M

y

= Factored applied moments = [(V

rbs

+ V'

rbs

)( S

h

+ d

c

/ 2 ) +2 M

prbs

]

M

ndy

=Design reduced flexural strength obtained as

b

Z

p

f

y

mo

The details of member sections thus obtained by the above mentioned steps of PBPD method are briefed

in Table 6.

Table 6 : The Design Sections obtained when the frame is designed by PBPD method

Sr.

No.

Level Section

Section

Modulus (cm

3

)

Weight

( kg/m)

Beams

1 Roof

ISWB600 B

and RBS at 400 mm from column face

with a = 150 mm b = 500 mm c = 40 mm

Z

p

= 4341

Z

RBS

= 3252

145

2 Level 4

ISWB600 A with 400 x 10 mm cover plates

and RBS at 400 mm from column face

with a = 150 mm b = 500 mm c = 40 mm

Z

p

= 6426

Z

RBS

= 4863

197

3 Level 3

ISMB600 with 320 x 20 mm cover plates

and RBS at 400 mm from column face

with a = 150 mm b = 500 mm c = 40 mm

Z

p

= 7478

Z

RBS

= 4963

223

4 Level 2

ISMB600 with 320 x 25 mm cover plates

and RBS at 400 mm from column face

with a = 150 mm b = 500 mm c = 40 mm

Z

p

= 8510

Z

RBS

= 5526

248

Exterior Columns

1 Roof ISWB600 A with 400 x 10 mm cover plates 6130 207

2 Level 4 ISWB600 A with 400 x 20 mm cover plates 8420 270

3 Level 3 ISWB600 A with 400 x 20 mm cover plates 8420 270

4 Level 2 ISWB600 A with 400 x 20 mm cover plates 8420 270

Interior Columns

1 Roof ISWB600 A with 400 x 25 mm cover plates 10591 302

2 Level 4 ISWB600 A with 400 x 40 mm cover plates 14581 397

3 Level 3 ISWB600 A with 400 x 40 mm cover plates 14581 397

4 Level 2 ISWB600 A with 400 x 40 mm cover plates 14581 397

Sejal P. Dalal, Andeep A. Vasanwala

& Atul K. Desai 96

CONCLUSIONS

1. In the Elastic Design method as all the structural members (i.e. both beams and columns) have

all the three components viz. shear, axial and moment, they are all designed as beam-columns.

The design is simple and hassle free.Whereas in the PBPD method, the beams are provided with

hinges (weak links) at predetermined points. The beams are to be designed for flexure and

shear. In addition these, weak links are also to be designed separately and checked. This makes

the design lengthy.

2. The failure pattern and failure points in the PBPD method are predetermined and fixed prior to

the design whereas in the elastic design method, the failure can occur anywhere in the structure.

3. For the same values of dead and live load, the values of shear force, axial force and bending

moment in the PBPD and elastic design frame is totally different. This is probably due to the

variation in lateral force. Also, there is 35 % decrease in weight of beams, 17 % increase in

weight of exterior columns and 33 % increase in weight of interior columns of PBPD method as

compared to Elastic Design method. Hence, it could be seen that the strong column weak

beam concept is satisfied in PBPD method.

4. The overall cost of the structure remains same because in the PBPD method, even if the

reduction in weights due to RBS is not considered, still the overall weight of the structure is just

15% higher than Elastic Design Method. This fact can make the PBPD method more acceptable

and admirable to designers.

REFERENCES

1. Chao S H, Goel S C, Lee S S (2007) : A seismic design lateral force distribution based on

inelastic state of structures, Earthquake Spectra 23: 3, 547569.

2. Chao S H, Goel S C. (2006a) : Performance-based design of eccentrically braced frames using

target drift and yield mechanism, AISC Engineering Journal Third quarter: 173200.

3. Chao S H, Goel S C. (2006b): A seismic design method for steel concentric braced frames

(CBF) for enhanced performance. In Proceedings of Fourth International Conference on

Earthquake Engineering, Taipei, Taiwan, 1213 October, Paper No. 227

4. Chao S H, Goel S C. (2008): Performance-based plastic design of seismic resistant special

truss moment frames, AISC Engineering Journal Second quarter: 127150.

5. Dalal S P , Vasanwala S A , Desai A K : (2011) , Performance based Plastic Design of

Structure : A Review in International Journal of Civil and Structural Engineering , Volume

1 No. 4 -2011 , pp 795-803.

6. Dalal S P , Vasanwala S A , Desai A K : (2012) , Applying Performance based Plastic

Design method to steel moment resisting frame in accordance with the Indian Standard Code

in International Journal of Engineering and Technology , Volume 2 No.3 March 2012 , pp

409-418, IJET publications, United Kingdom.

97 Comparative Evaluation of Elastic Design and Performance Based

Plastic Design Method for A Steel Moment Resisting Frame

7. Dasgupta P, Goel SC, Parra-Montesinos G. (2004): Performance-based seismic design and

behavior of a composite buckling restrained braced frame (BRBF). In Proceedings of

Thirteenth World Conference on Earthquake Engineering, Vancouver, Canada, 16 August

2004, Paper No. 497

8. IS-1893:2000: Criteria for Earthquake Resistant Design of Structures.

9. IS-800:2007: General Construction in Steel Code of Practice.

10. IS-875 Parts I to V: Indian Standard Code of Practice for design loads other than earthquake)

for buildings and structures.

11. Lee S S, Goel S C. (2001): Performance-Based design of steel moment frames using target

drift and yield mechanism. Research Report no. UMCEE 01-17, Dept. of Civil and

Environmental Engineering, University of Michigan, Ann Arbor, MI.

12. Newmark N M, Hall WJ. (1982): Earthquake Spectra and Design, Engineering Monographs

on Earthquake Criteria, Structural Design, and Strong Motion Records, Vol 3, Earthquake

Engineering Research Institute, University of California, Berkeley, CA.

S-ar putea să vă placă și

- Comparative Study of Original Paithani & Duplicate Paithani: Shubha MahajanDocument8 paginiComparative Study of Original Paithani & Duplicate Paithani: Shubha MahajanTJPRC PublicationsÎncă nu există evaluări

- 2 29 1645708157 2ijtftjun20222Document8 pagini2 29 1645708157 2ijtftjun20222TJPRC PublicationsÎncă nu există evaluări

- 2 33 1641272961 1ijsmmrdjun20221Document16 pagini2 33 1641272961 1ijsmmrdjun20221TJPRC PublicationsÎncă nu există evaluări

- Baluchari As The Cultural Icon of West Bengal: Reminding The Glorious Heritage of IndiaDocument14 paginiBaluchari As The Cultural Icon of West Bengal: Reminding The Glorious Heritage of IndiaTJPRC PublicationsÎncă nu există evaluări

- Flame Retardant Textiles For Electric Arc Flash Hazards: A ReviewDocument18 paginiFlame Retardant Textiles For Electric Arc Flash Hazards: A ReviewTJPRC PublicationsÎncă nu există evaluări

- Development and Assessment of Appropriate Safety Playground Apparel For School Age Children in Rivers StateDocument10 paginiDevelopment and Assessment of Appropriate Safety Playground Apparel For School Age Children in Rivers StateTJPRC PublicationsÎncă nu există evaluări

- 2 52 1649841354 2ijpslirjun20222Document12 pagini2 52 1649841354 2ijpslirjun20222TJPRC PublicationsÎncă nu există evaluări

- Covid-19: The Indian Healthcare Perspective: Meghna Mishra, Dr. Mamta Bansal & Mandeep NarangDocument8 paginiCovid-19: The Indian Healthcare Perspective: Meghna Mishra, Dr. Mamta Bansal & Mandeep NarangTJPRC PublicationsÎncă nu există evaluări

- 2 51 1651909513 9ijmpsjun202209Document8 pagini2 51 1651909513 9ijmpsjun202209TJPRC PublicationsÎncă nu există evaluări

- Using Nanoclay To Manufacture Engineered Wood Products-A ReviewDocument14 paginiUsing Nanoclay To Manufacture Engineered Wood Products-A ReviewTJPRC PublicationsÎncă nu există evaluări

- 2 67 1653022679 1ijmperdjun202201Document12 pagini2 67 1653022679 1ijmperdjun202201TJPRC PublicationsÎncă nu există evaluări

- 2 4 1644229496 Ijrrdjun20221Document10 pagini2 4 1644229496 Ijrrdjun20221TJPRC PublicationsÎncă nu există evaluări

- 2 44 1653632649 1ijprjun20221Document20 pagini2 44 1653632649 1ijprjun20221TJPRC PublicationsÎncă nu există evaluări

- An Observational Study On-Management of Anemia in CKD Using Erythropoietin AlphaDocument10 paginiAn Observational Study On-Management of Anemia in CKD Using Erythropoietin AlphaTJPRC PublicationsÎncă nu există evaluări

- 2 51 1656420123 1ijmpsdec20221Document4 pagini2 51 1656420123 1ijmpsdec20221TJPRC PublicationsÎncă nu există evaluări

- Vitamin D & Osteocalcin Levels in Children With Type 1 DM in Thi - Qar Province South of Iraq 2019Document16 paginiVitamin D & Osteocalcin Levels in Children With Type 1 DM in Thi - Qar Province South of Iraq 2019TJPRC PublicationsÎncă nu există evaluări

- Effectiveness of Reflexology On Post-Operative Outcomes Among Patients Undergoing Cardiac Surgery: A Systematic ReviewDocument14 paginiEffectiveness of Reflexology On Post-Operative Outcomes Among Patients Undergoing Cardiac Surgery: A Systematic ReviewTJPRC PublicationsÎncă nu există evaluări

- Dr. Gollavilli Sirisha, Dr. M. Rajani Cartor & Dr. V. Venkata RamaiahDocument12 paginiDr. Gollavilli Sirisha, Dr. M. Rajani Cartor & Dr. V. Venkata RamaiahTJPRC PublicationsÎncă nu există evaluări

- 2 51 1647598330 5ijmpsjun202205Document10 pagini2 51 1647598330 5ijmpsjun202205TJPRC PublicationsÎncă nu există evaluări

- Effect of Degassing Pressure Casting On Hardness, Density and Tear Strength of Silicone Rubber RTV 497 and RTV 00A With 30% Talc ReinforcementDocument8 paginiEffect of Degassing Pressure Casting On Hardness, Density and Tear Strength of Silicone Rubber RTV 497 and RTV 00A With 30% Talc ReinforcementTJPRC PublicationsÎncă nu există evaluări

- A Review of "Swarna Tantram"-A Textbook On Alchemy (Lohavedha)Document8 paginiA Review of "Swarna Tantram"-A Textbook On Alchemy (Lohavedha)TJPRC PublicationsÎncă nu există evaluări

- Self-Medication Prevalence and Related Factors Among Baccalaureate Nursing StudentsDocument8 paginiSelf-Medication Prevalence and Related Factors Among Baccalaureate Nursing StudentsTJPRC PublicationsÎncă nu există evaluări

- Comparative Fe Analysis of Automotive Leaf Spring Using Composite MaterialsDocument22 paginiComparative Fe Analysis of Automotive Leaf Spring Using Composite MaterialsTJPRC PublicationsÎncă nu există evaluări

- 2 67 1645871199 9ijmperdfeb202209Document8 pagini2 67 1645871199 9ijmperdfeb202209TJPRC PublicationsÎncă nu există evaluări

- Analysis of Bolted-Flange Joint Using Finite Element MethodDocument12 paginiAnalysis of Bolted-Flange Joint Using Finite Element MethodTJPRC PublicationsÎncă nu există evaluări

- Numerical Analysis of Intricate Aluminium Tube Al6061T4 Thickness Variation at Different Friction Coefficient and Internal Pressures During BendingDocument18 paginiNumerical Analysis of Intricate Aluminium Tube Al6061T4 Thickness Variation at Different Friction Coefficient and Internal Pressures During BendingTJPRC PublicationsÎncă nu există evaluări

- 2 67 1640070534 2ijmperdfeb202202Document14 pagini2 67 1640070534 2ijmperdfeb202202TJPRC PublicationsÎncă nu există evaluări

- 2 67 1641277669 4ijmperdfeb202204Document10 pagini2 67 1641277669 4ijmperdfeb202204TJPRC PublicationsÎncă nu există evaluări

- 2 67 1644220454 Ijmperdfeb202206Document9 pagini2 67 1644220454 Ijmperdfeb202206TJPRC PublicationsÎncă nu există evaluări

- Next Generation'S Energy and Time Efficient Novel Pressure CookerDocument16 paginiNext Generation'S Energy and Time Efficient Novel Pressure CookerTJPRC PublicationsÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Heat Transfer 2Document24 paginiHeat Transfer 2AshMere MontesinesÎncă nu există evaluări

- Vocabulary 1Document1 paginăVocabulary 1api-260932599Încă nu există evaluări

- Fabrication of Manual Roller Bending Machine-NEWDocument33 paginiFabrication of Manual Roller Bending Machine-NEWDinesh Kumar100% (1)

- Niloy GhoshDocument9 paginiNiloy GhoshNiloy GhoshÎncă nu există evaluări

- 4 - 6ميكانيك ت9Document15 pagini4 - 6ميكانيك ت9seifÎncă nu există evaluări

- Wien's LawDocument23 paginiWien's Lawpodinaf114Încă nu există evaluări

- A Computer Program For Designing Interplanetary Injection Trajectories (Fortran)Document22 paginiA Computer Program For Designing Interplanetary Injection Trajectories (Fortran)Anonymous REw1YIq4q7Încă nu există evaluări

- Implusive and Convective CalculationDocument140 paginiImplusive and Convective CalculationVISHAL GUPTAÎncă nu există evaluări

- 242 Wikarta Kuliah IV Keseimbangan Benda TegarDocument21 pagini242 Wikarta Kuliah IV Keseimbangan Benda TegarEffendi HabibieÎncă nu există evaluări

- Trans RotDocument5 paginiTrans RotFazriah UlfahÎncă nu există evaluări

- WDF14 4 2005DesignValuesDocument5 paginiWDF14 4 2005DesignValuesLutfur RahmanÎncă nu există evaluări

- Chapter 1Document17 paginiChapter 1SyahshaiÎncă nu există evaluări

- Motion Along A Straight LineDocument41 paginiMotion Along A Straight Linefitri dwi hartatiÎncă nu există evaluări

- Design of Gear BoxDocument26 paginiDesign of Gear BoxMKPashaPashaÎncă nu există evaluări

- Solutions Manual: Heat ExchangersDocument125 paginiSolutions Manual: Heat ExchangersRafael Rivera DelgadoÎncă nu există evaluări

- Stress Analysis NotesDocument127 paginiStress Analysis Notesreach_arindomÎncă nu există evaluări

- Aliha 2012Document12 paginiAliha 2012CHON SaophornÎncă nu există evaluări

- Optimizing The Design of A Helical SpringDocument4 paginiOptimizing The Design of A Helical SpringMartin VenichÎncă nu există evaluări

- Interphase Mass TransferDocument20 paginiInterphase Mass TransferDozdi0% (1)

- Circular SlabsDocument19 paginiCircular SlabsVarshith Reddy100% (1)

- H&MT - Lesson-21 Solid Angle and Intensity of Radiation, Radiation Heat Transfer Between Two Black BodiesDocument4 paginiH&MT - Lesson-21 Solid Angle and Intensity of Radiation, Radiation Heat Transfer Between Two Black Bodiesadimegha100% (1)

- Calculation Dilute Phase Pressure Drop Rhodes MethodDocument3 paginiCalculation Dilute Phase Pressure Drop Rhodes MethodBTEÎncă nu există evaluări

- 2.5.2 L C - D C: Fracture Mechanics: Fundamentals and ApplicationsDocument1 pagină2.5.2 L C - D C: Fracture Mechanics: Fundamentals and Applicationsahmed fayedÎncă nu există evaluări

- Brackets and Corbels ACI 318 L # 1Document7 paginiBrackets and Corbels ACI 318 L # 1soran azizÎncă nu există evaluări

- Aerodynamic Modeling & Simulation of HGVDocument26 paginiAerodynamic Modeling & Simulation of HGVManjunath PattarÎncă nu există evaluări

- Seismic Design Calculation p1 To p9Document9 paginiSeismic Design Calculation p1 To p9Ivan RocoÎncă nu există evaluări

- 06 Momentum 06Document4 pagini06 Momentum 06dil19860209100% (1)

- Lecture IX (Welded Joint - Eccentric Loading)Document13 paginiLecture IX (Welded Joint - Eccentric Loading)Bikalpa khadkaÎncă nu există evaluări

- Introduction to Quiz: Aerodynamics: = 8m/s V ρ = 1.225kg/mDocument4 paginiIntroduction to Quiz: Aerodynamics: = 8m/s V ρ = 1.225kg/mDaniel Alejandro Hernandez ToldoÎncă nu există evaluări