Documente Academic

Documente Profesional

Documente Cultură

Best Techniques For Batch Galvanizing

Încărcat de

Sreedhar Patnaik.MDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Best Techniques For Batch Galvanizing

Încărcat de

Sreedhar Patnaik.MDrepturi de autor:

Formate disponibile

Part C/Chapter 5

C.5. BEST AVAILABLE TECHNIQUES FOR BATCH GALVANIZING

In understanding this chapter and its contents, the attention of the reader is drawn back to the preface of this document and in particular the fifth section of the preface: How to understand and use this document. The techniques and associated emission and/or consumption levels, or ranges of levels, presented in this chapter have been assessed through an iterative process involving the following steps: Identification of the key environmental issues of batch galvanising. Among the important issues are: emissions to air (HCl from pickling and dust and gaseous compounds from the kettle); spent process solutions (degreasing solutions, pickling baths and flux baths); oily wastes (e.g. from cleaning of degreasing baths) and zinc-containing residues (filter dust, zinc ash, hard zinc). Examination of the techniques most relevant to address those key issues. Identification of the best environmental performance levels, on the basis of the available data in the European Union and world-wide. Examination of the conditions under which these performance levels were achieved; such as costs, cross-media effects, main driving forces involved in implementation of this techniques. Selection of the best available techniques (BAT) and the associated emission and/or consumption levels for this sector in a general sense all according to Article 2(11) and Annex IV of the Directive.

Expert judgement by the European IPPC Bureau and the relevant Technical Working Group (TWG) has played a key role in each of these steps and in the way in which the information is presented here. On the basis of this assessment, techniques, and as far as possible emission and consumption levels associated with the use of BAT, are presented in this chapter that are considered to be appropriate to the sector as a whole and in many cases reflect current performance of some installations within the sector. Where emission or consumption levels associated with best available techniques are presented, this is to be understood as meaning that those levels represent the environmental performance that could be anticipated as a result of the application, in this sector, of the techniques described, bearing in mind the balance of costs and advantages inherent within the definition of BAT. However, they are neither emission nor consumption limit values and should not be understood as such. In some cases it may be technically possible to achieve better emission or consumption levels but due to the costs involved or cross media considerations, they are not considered to be appropriate as BAT for the sector as a whole. However, such levels may be considered to be justified in more specific cases where there are special driving forces. The emission and consumption levels associated with the use of BAT have to be seen together with any specified reference conditions (e.g. averaging periods). The concept of levels associated with BAT described above is to be distinguished from the term achievable level used elsewhere in this document. Where a level is described as achievable using a particular technique or combination of techniques, this should be understood to mean that the level may be expected to be achieved over a substantial period of time in a well maintained and operated installation or process using those techniques.

Ferrous Metals Processing Industry

387

Part C/Chapter 5

Where available, data concerning costs have been given together with the description of the techniques presented in the previous chapter. These give a rough indication about the magnitude of costs involved. However, the actual cost of applying a technique will depend strongly on the specific situation regarding, for example, taxes, fees, and the technical characteristics of the installation concerned. It is not possible to evaluate such site-specific factors fully in this document. In the absence of data concerning costs, conclusions on economic viability of techniques are drawn from observations on existing installations. It is intended that the general BAT in this chapter are a reference point against which to judge the current performance of an existing installation or to judge a proposal for a new installation. In this way they will assist in the determination of appropriate "BAT-based" conditions for the installation or in the establishment of general binding rules under Article 9(8). It is foreseen that new installations can be designed to perform at or even better than the general BAT levels presented here. It is also considered that existing installations could move towards the general BAT levels or do better, subject to the technical and economic applicability of the techniques in each case. While the BREFs do not set legally binding standards, they are meant to give information for the guidance of industry, Member States and the public on achievable emission and consumption levels when using specified techniques. The appropriate limit values for any specific case will need to be determined taking into account the objectives of the IPPC Directive and the local considerations. This chapter discusses the best available techniques for reducing the environmental impacts from batch galvanising. Where possible, the structure follows the logic of the production line and identifies BAT for individual processing stages. However, some measures, especially primary or preventive measures, cannot be assigned to one single process step and have to be allocated to the plant as a whole. As far as possible and wherever the data available allowed, emission levels, efficiencies or recirculation rates are given an indication of the improvement that can be expected by implementation of the techniques. For a number of techniques, the obvious positive effect cannot be described by an exact number, but some of these techniques are nevertheless considered as BAT. Unless stated otherwise the emission figures presented in the following BAT chapters are daily mean values. For emissions to air they are based on standard conditions of 273 K, 101.3 kPa and dry gas. Discharges to water are indicated as daily mean value of a flow-rate-related 24-hour composite sample or a flow-rate-related composite sample over the actual operating time (for plants not operated in three shifts). For degreasing operations in batch galvanising plants, the following techniques are considered BAT: Installation of a degreasing step, unless items are totally grease-free which is rarely the case in job galvanizing. Optimum bath operation to enhance efficiency, e.g. by agitation. Cleaning of degreasing solutions to extend lifetime (by skimming, centrifuge, etc.) and recirculation; reuse of oily sludge, e.g. thermally. or 'Biological degreasing' with in situ cleaning (grease and oil removal from degreaser solution) by bacteria. A primary measure to minimize environmental impact from pickling and stripping is to operate both in separate treatment vessels, since mixed acids (with both high iron and zinc

388 Ferrous Metals Processing Industry

Part C/Chapter 5

contents) cause problems in regeneration or reuse. As long as there are no suitable treatment options for mixed acid, separate pickling and stripping and reuse of spent stripping liquor (external or internal e.g. to recover fluxing agent) are considered to be BAT for new and existing plants. If separation of pickling and stripping is not possible, e.g. when there is insufficient space to install additional pickling/stripping tanks, external reuse of the mixed acids for flux production is considered BAT. One central treatment plant for spent mixed pickle liquors using solvent-extraction and one galvanizing plant operating this process have been reported (see Chapter C.4.3.8). Where such (external) treatment plants are available, recovery of HCl from spent mixed pickle liquors using solvent-extraction may be considered a viable alternative to fluxing agent recovery (see above). For HCl pickling the following techniques are considered to be BAT to reduce environmental impacts: Close monitoring of bath temperature and concentration parameters: and operating within the limits given in Part D/Chapter D.6.1 Open Pickling Bath Operation. If operation outside the operational range given in D.6.1 is desired, e.g. if heated or higher concentrated HCl-baths are used, installation of an extraction unit and treatment of the extraction air (e.g. by scrubbing) are considered BAT. The associated HCl emission level is 2 30 mg/Nm. Special attention to the actual pickling effect of the bath and use of pickling inhibitors to avoid over-pickling. Recovery of free-acid fraction from spent pickle liquor. or External regeneration of pickling liquor. Zn removal from acid. Use of spent pickle liquor for flux production.

Neutralisation of spent pickle liquor and the use of spent pickling liquor for emulsion splitting are not considered BAT. Generally, good drainage between pre-treatment tanks is advocated. Furthermore, rinsing after degreasing and after pickling to avoid carry-over into subsequent process baths and thus to prolong the lifetime of these baths is essential. BAT is: Static rinsing or rinsing cascades. Reuse of rinse water to replenish preceding process baths. Waste water-free-operation (waste water may be generated in exceptional cases, in which waste water treatment is then required). For fluxing, control of bath parameters and the optimized amount of flux used are important to reduce emission further down the process line as well. For the flux bath itself, side-stream regeneration of the solution (using e.g. H2O2, electrolytic oxidation or ion exchange) or, if installation of a regeneration unit is not possible, regeneration by externals is possible. Both internal and external flux bath regeneration are considered BAT. The main problem arising from hot dipping is air emissions resulting from reaction of the flux agent during dipping. The following techniques are considered to be BAT:

Ferrous Metals Processing Industry 389

Part C/Chapter 5

Capture of emissions from hot dipping by enclosure of the pot or by lip extraction followed by dust abatement (e.g by fabric filters or wet scrubbers). The dust level associated with these techniques is < 5 mg/Nm. Internal or external reuse of collected dust for flux production. As this dust may occasionally contain dioxins at low concentration due to upset conditions in the plant (badly degreased items being galvanised), only recovery processes yielding fluxing agents free of dioxins are BAT.

Although the opportunities for energy saving by heat transfer from flue gases from the galvanizing kettles are limited due to low volumes and relatively low temperatures (450oC), it is good practice to recover heat from this source either to hot water used elsewhere in the plant or to air for drying. For all Zn-containing wastes (dross, hard zinc, and splashes/squirts), separate storage and protection from rain and wind, and reuse in the non-ferrous metals industry or other sectors to recover the valuable substances they contain are considered to be BAT.

390

Ferrous Metals Processing Industry

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Hand Book-GalvanizingDocument9 paginiHand Book-GalvanizingSreedhar Patnaik.M100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- What Is A Joint Health and Safety CommitteeDocument23 paginiWhat Is A Joint Health and Safety CommitteeSreedhar Patnaik.MÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Attachment - 1 Document No. 081113B-CL-303-R0 Permissible Elastic Bend Limit Calculation (48in Hassyan Gas Pipeline Location Class 4)Document4 paginiAttachment - 1 Document No. 081113B-CL-303-R0 Permissible Elastic Bend Limit Calculation (48in Hassyan Gas Pipeline Location Class 4)ISRAEL PORTILLOÎncă nu există evaluări

- White Rust PreventionDocument16 paginiWhite Rust PreventionSreedhar Patnaik.MÎncă nu există evaluări

- Salt Spray TestDocument13 paginiSalt Spray TestSreedhar Patnaik.M100% (1)

- Zinc Chloride Determination ProcedureDocument13 paginiZinc Chloride Determination ProcedureSreedhar Patnaik.MÎncă nu există evaluări

- Calculation of Liquid Heat Capacity of Petroleum Distillate FuelsDocument3 paginiCalculation of Liquid Heat Capacity of Petroleum Distillate Fuelsdennise8Încă nu există evaluări

- Chemical Analysis Procedures For Galvanizing PlantsDocument32 paginiChemical Analysis Procedures For Galvanizing PlantsSreedhar Patnaik.M100% (2)

- Microsoft Word - Slickline Mechanical CapibilitiesDocument7 paginiMicrosoft Word - Slickline Mechanical CapibilitiesRangga DraApÎncă nu există evaluări

- Flux - InformationDocument9 paginiFlux - InformationSreedhar Patnaik.M0% (1)

- ASTM B505-B505M-12 Standard Specification For Cooper Alloy Continuous CastingsDocument10 paginiASTM B505-B505M-12 Standard Specification For Cooper Alloy Continuous CastingsAarón Escorza MistránÎncă nu există evaluări

- Galvanizing Inspection Check PointsDocument2 paginiGalvanizing Inspection Check PointsSreedhar Patnaik.MÎncă nu există evaluări

- Inar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaDocument14 paginiInar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaSreedhar Patnaik.MÎncă nu există evaluări

- What ISO 9001, 9002, 9003,9004Document6 paginiWhat ISO 9001, 9002, 9003,9004Sreedhar Patnaik.M67% (3)

- Surface TreatmentDocument19 paginiSurface TreatmentSreedhar Patnaik.MÎncă nu există evaluări

- Machine Shop SafetyDocument9 paginiMachine Shop SafetySreedhar Patnaik.MÎncă nu există evaluări

- White-Rust On Galvanized SteelDocument2 paginiWhite-Rust On Galvanized SteelSreedhar Patnaik.MÎncă nu există evaluări

- Univan Hs PrimerDocument1 paginăUnivan Hs PrimerWorapat Puttakasem0% (1)

- Directory of Galvanizing Association DirectoryDocument8 paginiDirectory of Galvanizing Association DirectorySreedhar Patnaik.MÎncă nu există evaluări

- Avoid Surprises at The Kettle & Vents & Holes Desigine GuideDocument27 paginiAvoid Surprises at The Kettle & Vents & Holes Desigine GuideSreedhar Patnaik.MÎncă nu există evaluări

- Anti-Blast Preparation and Adding Procedure: Startup QuantitiesDocument2 paginiAnti-Blast Preparation and Adding Procedure: Startup QuantitiesSreedhar Patnaik.MÎncă nu există evaluări

- B-Gas-Question & Answer PaparsDocument62 paginiB-Gas-Question & Answer PaparsSreedhar Patnaik.MÎncă nu există evaluări

- HDG Steel Combined With Al-AlloyDocument9 paginiHDG Steel Combined With Al-AlloySreedhar Patnaik.MÎncă nu există evaluări

- What Is AnodisingDocument3 paginiWhat Is AnodisingSreedhar Patnaik.MÎncă nu există evaluări

- Surface Engineering For CorrosionDocument24 paginiSurface Engineering For CorrosionSreedhar Patnaik.MÎncă nu există evaluări

- Hot Dip GalvanizeDocument9 paginiHot Dip GalvanizeSreedhar Patnaik.MÎncă nu există evaluări

- Inspection & Testing of Galva-Products-Prepared by SreedharDocument5 paginiInspection & Testing of Galva-Products-Prepared by SreedharSreedhar Patnaik.MÎncă nu există evaluări

- Exp 10 - Exp 7 A Green Synthesis of Camphor UploadDocument4 paginiExp 10 - Exp 7 A Green Synthesis of Camphor UploadUyen V. NguyenÎncă nu există evaluări

- Carbon FoamDocument56 paginiCarbon FoamTam CheÎncă nu există evaluări

- HW 3Document2 paginiHW 3Christina HillÎncă nu există evaluări

- NiSlip 520ADocument8 paginiNiSlip 520ASTI InspiredÎncă nu există evaluări

- Antimicrobial FinishesDocument32 paginiAntimicrobial Finisheschahat anejaÎncă nu există evaluări

- Superoxide in Biology and MedicineDocument11 paginiSuperoxide in Biology and MedicineNvo SpektarÎncă nu există evaluări

- LOVIBOND Reagents Suited For HachDocument6 paginiLOVIBOND Reagents Suited For HachKacem BenaoumeurÎncă nu există evaluări

- MUY COMPLETO - CNC CNF Towards The Scale-Up Production of Cellulose Nanocomposites Using Melt ProcessingDocument63 paginiMUY COMPLETO - CNC CNF Towards The Scale-Up Production of Cellulose Nanocomposites Using Melt ProcessingDerek ZoolanderÎncă nu există evaluări

- CuproBraze 34Document2 paginiCuproBraze 34Vinod SaleÎncă nu există evaluări

- Tablas Lennar-JonesDocument3 paginiTablas Lennar-JonesMichel OrtegaÎncă nu există evaluări

- Industrial Manufacturing Process of Acrylonitrile: November 2014Document182 paginiIndustrial Manufacturing Process of Acrylonitrile: November 2014RasoulÎncă nu există evaluări

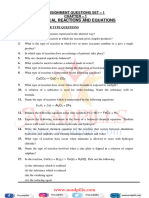

- Chemical Reactions and Equations Assignment Questions Set - 1Document6 paginiChemical Reactions and Equations Assignment Questions Set - 1kayace8055Încă nu există evaluări

- Spark TestingDocument23 paginiSpark TestingJad MacintoshÎncă nu există evaluări

- PH - Wikipedia, The Free EncyclopediaDocument11 paginiPH - Wikipedia, The Free EncyclopediaShikhar MahajanÎncă nu există evaluări

- 4 BrickDocument31 pagini4 BrickNardos GebruÎncă nu există evaluări

- Diffusiophoresis Migration of Colloidal Particles in Gradients of Solute ConcentrationDocument38 paginiDiffusiophoresis Migration of Colloidal Particles in Gradients of Solute ConcentrationPrateek DwivediÎncă nu există evaluări

- What Is A Pollen AllergyDocument13 paginiWhat Is A Pollen AllergyHuria MalikÎncă nu există evaluări

- PH Calculation With CO2 AdditionDocument12 paginiPH Calculation With CO2 AdditionPraveen KhatriÎncă nu există evaluări

- Introduction To Chemistry 4th Edition Bauer Birk Marks Test BankDocument52 paginiIntroduction To Chemistry 4th Edition Bauer Birk Marks Test Bankcasey100% (21)

- Production of X-RAYS Using X-RAY Tube: Journal of Physics: Conference SeriesDocument13 paginiProduction of X-RAYS Using X-RAY Tube: Journal of Physics: Conference SeriesATWIJUKIRE DICKENSÎncă nu există evaluări

- Mil-B-007883 Brazing - Cancelled - See Cancellation NoteDocument26 paginiMil-B-007883 Brazing - Cancelled - See Cancellation NoteChris NenovÎncă nu există evaluări

- TSC Lec Plan PCM - JEE MainDocument20 paginiTSC Lec Plan PCM - JEE MainrajÎncă nu există evaluări

- Pds Hempel's Silicone Acrylic 56940 En-GbDocument2 paginiPds Hempel's Silicone Acrylic 56940 En-GbsenthilkumarÎncă nu există evaluări

- 02.01.23 SR - Star Co-Sc (Model-A & B) Jee Main Ctm-2 QPDocument20 pagini02.01.23 SR - Star Co-Sc (Model-A & B) Jee Main Ctm-2 QPTanay1 MitraÎncă nu există evaluări

- Q4 COT - Chemical ReactionsDocument3 paginiQ4 COT - Chemical ReactionsGelli Jean Tortosa-LluparÎncă nu există evaluări