Documente Academic

Documente Profesional

Documente Cultură

How To Make A Rechargeable D Size 2 Cell Flashlight Using Laptop Batteries Rev1

Încărcat de

aarion5773Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

How To Make A Rechargeable D Size 2 Cell Flashlight Using Laptop Batteries Rev1

Încărcat de

aarion5773Drepturi de autor:

Formate disponibile

10-25-2011 4-08-2012 Rev.

1 How to make a rechargeable D size 2 cell flashlight using laptop batteries Disclaimer: If you dont know what you are doing, dont try this. Talk to someone who knows electricity and electronics and let them show you. Laptop batteries can be dangerous when used incorrectly. This document has no author or copyright. Please copy as much as you want and improve on the design. This is just one way. Start by taking apart a laptop battery. Ill use an old discarded Dell laptop battery.

Notice the label says it has lithium-ion batteries and its voltage is 14.8 and its capacity is 3.6 AH (ampere-hours). Youll need the following tools: scissors, sharp pointed instrument, side-cutters.

Take off the label and youll see this.

. Next stick the pointed instrument under the plastic. 1

This allows you to slide the side-cutters under the plastic and cut it. You are trying not to damage the batteries as you take it apart.

After you expose all the batteries, only a couple of double-stick tape is holding the battery pack in-place. Youll need a screw driver to carefully pry the battery off the tape.

Cut away any wires that are soldered to metal strips. Do not cut away the metal strips yet.

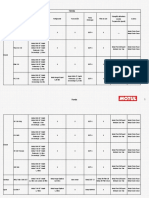

You will notice there are eight batteries that make up the laptop battery. Also notice that two batteries are in parallel and that there are four pairs of batteries in series. If you go back to the first picture it says a fully charged laptop battery will measure 14.8 volts. 14.8 volts divided by 4 equals 3.7 volts. So a fully charged individual battery will measure 3.7 volts and higher if left charging. The label also says it has a 3.6 AH capacity. That means each pair of batteries can put out 3.6 amps in one hour. If you use less current then the battery lasts longer. However, if there are numbers on the battery and you look up the specs, it will tell you that its capacity is 3.7 volts 1.2 AH which is typical. Two batteries in parallel will give 2.4 AH, not 3.6 as it say on the label. The newer laptop batteries they are making have square batteries inside. This cant be used for flashlight batteries. Begin cutting the metal strips so you end up with four pairs of batteries.

Dress up the pair of batteries by cutting any extra metal strips close to the terminals. File any sharp edges until they are smooth.

Next is the circuit well use to charge the batteries.

I use this circuit with a usb cable and a 5 volt usb source. The 2N5638 is a junction fet wired as a constant current source. With the 150 ohm resistor, the current is always 25 to 30 milliamps no matter what the load is and the input voltage can go up to 30 volts. Another junction fet is J105 with higher current spec but lower maximum voltage. This fet can handle higher currents with a different resistor.

The following circuit shows how the constant current device is wired to charge your laptop batteries.

I used the 2N5638 circuit because it can regulate current at 5 volts. Notice that the J105 does not begin regulating at about 7 volts. A note of CAUTION: Do not charge your laptop batteries at currents greater than 35 milliamps. There are not any over temperature protection built into the charging circuit like a regular laptop battery. It will take a couple of days to charge the battery to 3.7 4

volts at 35 milliamps. You can consider this a trickle charge circuit. If the battery feels warm when charging then something is wrong and you should stop. For that matter if the battery feels warm when you are using it then you are drawing a lot of power in a short time and should be careful. Even though it is a trickle charge, do not forget to stop charging after a couple days. Use a digital voltmeter to measure if the battery is at 3.7 volts. I have measured up to 4 volts when leaving it in the charger too long.

To be extra clear on how to hook up the constant current device, I have redrawn the circuit.

When you make the constant current device, you dont have to use a circuit board. Just twist the correct leads together and solder with wires. You can make more than one at a time.

Next, the pair of batteries tend to flop around when you put it in the D size flashlight, so I hot glued a piece of dowel to the batteries. One on each side. The dowel is 1/2 inch long and 7/16 inch in diameter.

I then solder a #6 zinc plated steel washer in the middle of the plus side of the battery.

Next, the pair of batteries are not as long as two D size cells, so I made a spacer to make up the difference. The wood dowel is 1 inch long and 1 inch in diameter. I used two flat head #8 x 5/8 sheet metal screws, 2 #10 brass washers and a straight piece of wire.

Screw in the #8 screws in the center at the two ends with the brass washer underneath. Drill a small hole through the dowel off to one side of the center and attach the straight piece of wire to the two screws.

This was the makeup of the spacer in the old revision. The new revision uses 3/16 x 1 inch fender washers on both sides and two flat head #8 x 5/8 sheet metal screws.

You can use a straight wire or a 2.2 ohm resistor depending on if you are using an incandescent bulb or led. Next is how I made up the charging circuit, you may want to do it differently. The difficulty is how do you attach the charging wirings to a flat surface? I had some cylindrical neodymium magnets so I thought I would use that. I also had some copper tape with conductive adhesive which I wound around the magnet.

The magnets were 3/16 inch in diameter and inch long.

I put solder on the end of the wrap of copper tape so it would not unravel and soldered wires to the magnets. Be very careful to not over-heat the magnet when soldering wires to it. If you do, it weakens the magnet and it stays weak. I leave the four magnets connected in a row to act as a heat sink while putting solder on the magnet .

Magnet and constant current device. I then use a usb cable from a discarded mouse or keyboard and an ac-to-usb adapter for the 5 volt source. I found this more convenient than using a transformer with a 5vdc output.

By the way, the black and red leads from a usb cable are always the power leads. Red for positive and black for negative. But always check by plugging into a usb port and test with a meter. Assemble the charging unit by soldering the wire from the constant current device to the red wire of the usb cable and the black wire to the black wire of the usb cable. I put shrink tubing over each solder joint, then shrink tubing over both wires.

I then use hot glue over the exposed solder joints like the magnet and constant current device so the wires dont break off from too much handling. The hot glue also protects the constant current device.

Assembled charging circuit.

Next buy the cheapest D size 2 cell flashlight you can find.

Revision 1: I no longer use masking tape around the batteries. I hot glue inch x 7/16 inch dowel to the batteries and solder a #6 zinc plated washer to the plus side. Also, the spacer has fender washers at the ends. Put the dowel in first and then the battery, plus side up. The spacer length was sized for an Eveready flashlight. Other models may require a longer length of dowel. Put in the spacer, battery plus side up and screw on the cap with the flashlight bulb. Turn it on and you will have a very bright light. If the light doesnt turn on, whack the flashlight on the side. Sometimes the battery doesnt make good contact with the flashlight bulb. If it does light up, the flashlight bulb will probably burnout in about 15 minutes. Every 2 cell flashlight comes with a PR2 incandescent bulb. This bulb cant 9

handle the current coming out of the lithium-ion batteries. You have to look for a replacement bulb named PR3. This will handle the current and probably be very bright for about 2 hours before you need to recharge the battery. You can find all the electronic parts from Mouser Electronics, even the PR3 bulb. Website is www.mouser.com. For the PR3 bulb you have to search for 606-PR3. Of course you can buy your parts from any electronic store. Let me backtrack a little. You have 4 pairs of batteries that you have recovered from the laptop battery. They all may be bad, either shorted or open. You may find some that are good. If you dont find a good battery, you need to open up more discarded laptop batteries. When you take out the batteries from the laptop battery and measure them, they usually will measure zero volts. Then you hook up your charging circuit and start charging them. Always measure the current first when you hook up the charging circuit. If the battery is open, there will be no current reading and you can discard (recycle) that battery. If you have current, you have a chance that the battery is good and will charge up to 3.7 volts. Let it charge a couple of hours, then take off the charging circuit and measure the battery voltage. If there is some voltage then you have a good chance that the battery is good. However, you are not done yet if it does charge up to 3.7 volts. When the battery charges to 3.7 volts, remove the charging circuit. Set the battery aside for several weeks, then measure the voltage again. If it still is at 3.7 volts, you probably have a good battery that will hold its charge for months and can be used as a flashlight battery. But if the voltage is less than 3.7 then eventually it will discharge to zero over time and this battery is not suitable for flashlights. Another thing to note is that if you look up the specs for the PR2 or PR3 bulbs, you will see that it is only rated for 15 hours of life! So the next part of this document is how to replace the incandescent bulb with a 1 watt white led. Revision 1: I have put together a new charging circuit. Use this charging circuit if you dont want to bother monitoring the voltage on the charging battery. This circuit will not overcharge your batteries no matter how long you leave it on the charger. It should fully charge your battery in two days. If you leave it charging longer, the battery voltage will be a little higher than 3.7 volts. It will not overcharge your battery to 4 volts. The maximum it can charge your battery to is about 3.875 volts. The following picture is the schematic and physical layout of the new charging circuit. It uses a chip TL431 which is a precision zener. The zener volt can be set where you want it and it is this chip that prevents the battery from overcharging.

10

Some pictures of the assembly of the charging circuit. Ive just replaced the constant current device with the TL431 chip. The wires to the usb cable is the same and the wires to the magnets is the same. I put a little more hot glue around the magnets.

Some pictures after soldering the wires.

Underneath look. 11

Device with wires attached.

Underneath view.

Wires cut for usb cable and magnets. White jewelry cord holding the wires together instead of plastic tyrap.

Hot glue covering the whole device and wires.

Magnets with hot glue all around. tubed.

Short wires soldered to usb cable and shrink 12

Shrink tubing over usb cable and wires. Assembled unit.

I put the charger in a zip lock bag with instructions on how to connect the charger.

Instructions for replacing the incandescent bulb with a one watt led. First buy some 1 watt white leds. However, dont buy the semi-hemisphere type.

There is a dark area in the center of the circle of illumination with this type of led. Buy the type that looks like an hourglass.

13

This is the underside of the hourglass led.

That round metal surface is the heatsink of the led. When you receive your led, the heatsink may be isolated from both the positive and negative lead. Or it may be tied to the positive lead or tied to the negative lead. I have received leds that fell into the three categories. Depending on the type you receive will change how the led is mounted on the metal case. Usually there are no instructions as to which lead is the positive and which is the negative. You can use a coin battery like the CR2032 or your digital multimeter. If using your multimeter, use it in the measuring ohms position, lowest setting. Make sure that plus voltage is really coming out of the red lead. You are looking for the led to light once the correct polarity is found. Do not power the led with double A batteries or the like. The coin battery like the CR2032 is current limited. Meaning it can put out only about 20 milliamps when shorted. Plus if you have the polarity reversed, the 3 volts out will not breakdown the led. We will be using the incandescent bulb metal case to hold the l watt led. So if you are willing to remove the bulb from the PR2 or PR3 lamp, try the following procedure. First tape the bulb with masking tape. This helps to wiggle the bulb and not burn your fingers if the bulb becomes hot.

Next use a solder sucker to remove the solder from the bottom of the bulb. There is a tiny wire that you must break free from the solder left on the bulb. Next you use your soldering iron to heat up the metal part of the bulb, put the soldering iron right where the solder is next to the flange of the bulb. This is where the other wire 14

is connected to the bulb. If you are lucky, the glue that holds the bulb to the metal case will melt and you can wiggle the bulb out.

Clean out as best you can the remaining glue in the case of the bulb. Especially the area opposite the V cut in the metal flange.

If you are unlucky and the glue does not melt no matter how hot or how long you leave your iron on the solder spot by the flange then its time for another method. It appears to be some type of epoxy holding the bulb to the metal case. What I do then is use a micro torch to heat the metal case, holding the masking tape with a long-nose plier. I see gas escaping from the bottom of the metal case where you sucked out the solder. The gas can burn. Let it burn until it stops burning. Then I put the bulb on a metal tray and break the glass. The I dig out the glass from the metal case. The glue looks carbonized and easy to scrape from the metal case. Next cut some copper strips from a piece of copper metal. I think the piece I had was one mil thick.

15

Tin in the center on both sides on the copper strip. We are going to solder the metal strip to the heatsink of the led. The width of the copper strip is the same as the diameter of the heatsink on the led.

Put a little solder on heatsink of the led.

Next solder the copper strip to the underside of the led.

This is why you put solder on both sides of the copper strip. Lay the copper strip on top of the heatsink of the led. Heat the solder of the copper strip, let the solder underneath melt along with the solder on the heatsink of the led, joining the two.

16

Soldering the copper strip only applies to leds with the heatsink tied to the negative lead or the heatsink is isolated from both the negative and positive leads. If you have an led with the heatsink tied to the positive lead, use a silicon compound/glue to attach the led to the copper strip. Do not solder the copper strip to leds with the heatsink tied to the positive lead. We will be using silicon compound/glue to electrically isolate the copper strip and still have heatsinking capacity with the silicon compound/glue. We want to mount the led to the metal case with the negative lead of the led touching the case always. The positive lead of the led will always be the wire at the tip of the metal case.

Picture of the silicon compound/glue and the led attached to the copper strip. You can see the white silicon compound/glue around the led and isolating the copper strip from the heatsink. After the silicon compound/glue has dried, test with an ohmmeter that the copper strip is electrically isolated from the positive lead. Next bend the leads of the led about 90 degrees.

Take an insulated #30 gauge wire and solder it to the inside of the positive lead of the led.

17

Solder only on the inside. Do not get any solder on the outside. Next you will put 3/64th inch shrink tubing over the connection.

Next you will put some solder on the negative lead of the led, both sides of the lead.

Next you file the flange where the v shape is cut out. File both sides so you can put a little solder there.

18

Then you place the led in the metal case. The negative lead of the led goes into the v cut in the flange. Try to center the led in the metal case and see where the negative lead of the led ends up. Thats where you will tack solder the lead to the case.

Strip the insulation from the wire so only bare wire shows from the bottom of the metal case before tack soldering the led in-place.

The led should be centered in the metal case as much as possible. Notice the positive lead of the led is not touching the metal case because of the shrink tubing.

19

Bare wire sticking out of the bottom of the metal case.

Add solder to build up the base.

Cut the excess lead and trim the copper strip around the flange with a scissors.

20

You can make more than one led bulb at a time.

Of course you should test your led bulb at this point to see if the led still works. It could have overheated during its construction. Revision 1. Remember, the pictures above assume you are mounting leds with the heatsink tied to the negative lead or isolated from both negative and positive leads. Do not solder the copper strip to leds with the heatsink tied to the positive lead. Attach the copper strip to the heatsink with the silicon compound/glue. Soldering the negative lead to the V of the flange and the wire to the tip of the metal case is the same for all three categories. Finally assemble your flashlight. You will have to change the straight wire in your spacer with a 2.2 ohm or watt resistor. Place the wooden spacer in the flashlight first. Then the battery with the positive pole up, and then the top of the flashlight. The led bulb is inserted in the cap just like an incandescent bulb. Make sure the flashlight you are buying has a metal holder for the flashlight bulb because we are using that as a heatsink for the led. With the 2.2 ohm resistor limiting the current through the led to about 90 milliamps, the flashlight should be bright for a couple of hours. When the light gets dim, then its time to recharge. Or if you measure the batterys voltage and its below 3 volts. It can go as low as 2.4 volts and still look kind of bright. You could probably use a 2 ohm watt resistor instead of 2.2 ohm. It was a resistor I had around. You could try using the straight wire and not insert the 2.2 ohm resistor. The led will probably draw about 105 milliamps. However, after a while the led will act erratic and flicker. If you open your flashlight youll find the metal housing for the led 21

bulb quite hot. Your heatsink has overheated. I put in the 2.2 ohm resistor to limit the current to around 90 milliamps so the heatsink wouldnt overheat.

I dont know if it will be difficult to find the hourglass led from the electronic companies like mouser or digi-key. I get my hourglass leds from www.dealextreme.com, sku # 13286. Price is around $2.60. The other place is www.goodluckbuy.com, sku # 64689. Price for 5 pack is around $6.50. You are not limited to making rechargeable flashlight batteries. You can make the batteries into many different voltages and capacities.

I like to use the nine volt battery clips as connectors. I hot glue all the exposed metals surfaces to prevent accidental shorts.

22

This is my fathers old portable drill with ni-cad batteries that long since failed. I opened it up and took out the ni-cad batteries, brought out the power connection leads to a 9 volt battery clip. A rubber band around the lithium-ion battery holds it in place and the battery clips make them replaceable and I have a working portable drill again. Any portable tool with failed batteries is fair game. Any bad rechargeable battery, ni-cad or lithium-ion I find I place in the recycle box at Home Depot. I like using 9 volt battery clips to connect and disconnect my batteries. Duracell 9 volt battery clips are the best because the clips are mounted on a type of stiff thick paper. Other brands of 9 volt clips are mounted on plastic. These melt when you try to reuse them and solder wires to the back of the clips. I can reuse only so much Duracell type battery clips because I dont use 9 volt batteries that much. So Ive started to make my own battery clips, Mouser sells the male, female clips and the rivets to hold them. I can make as many as I want now.

Some final notes: test the constant current charging circuit when you make it by shorting through the digital multimeter in the milliamp setting. It should read anywhere between 25 to 35 milliamps, around there. The 5 volt charging circuit is only to charge battery cells to 3.7 volts. If you are planning on putting more battery cells in series, you need to up the source voltage. The source voltage always has to be higher than the final battery cell voltage for the cells to reach full charge. When you take apart the laptop battery and have the cells lined up in series, number them 1, 2, 3, 4. That way if you want to series some cells, series them in the way they originally were hooked up. The metal strips connecting the batteries should all be shiny. If any are discolored, that usually means one or more of the batteries has been leaking. Of course that battery is no good. The battery usually leaks from the positive end, so a discolored metal strip on the negative side of a battery and a shiny metal strip on the positive side of the battery could mean its still good. Test the no overcharging circuit by measuring the voltage at the magnets. It should be around 3.875 volts. The 150 ohm resistor in the circuit is to limit the current from the 5 volt usb adapter to around 36 ma. The precision zener shunts some of that current so about 34 ma is available to charge a battery with zero volts. The charging current will decrease as the battery voltage reaches 3.7 volts.

23

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Flex Pump 47Document2 paginiFlex Pump 47Alex Castañeda100% (1)

- Ch1 - Sustainable Construction ManagementDocument86 paginiCh1 - Sustainable Construction ManagementAmir NazriÎncă nu există evaluări

- Manufacturers in Oil and Gas Industry EgyptDocument107 paginiManufacturers in Oil and Gas Industry Egyptsachin0% (1)

- 90 250 Single Stage Horizon Domestic PDFDocument6 pagini90 250 Single Stage Horizon Domestic PDFherrerafaridÎncă nu există evaluări

- Compact Air and Gas Insulated SSDocument25 paginiCompact Air and Gas Insulated SSPartha Sarathi MannaÎncă nu există evaluări

- Gas Testing e-Learning Certification CourseDocument3 paginiGas Testing e-Learning Certification Coursekanakarao10% (1)

- MXT5000 enDocument2 paginiMXT5000 enntt_121987Încă nu există evaluări

- 2-A-GNLW363CD Standard Decanter CentrifugeDocument6 pagini2-A-GNLW363CD Standard Decanter CentrifugeGeorgeÎncă nu există evaluări

- Innovation in ConstructionDocument165 paginiInnovation in Constructionfoush bashaÎncă nu există evaluări

- NSL Textile BrochureDocument24 paginiNSL Textile BrochureAbhisek AgarwalÎncă nu există evaluări

- Guía de Lubricación de Motos Honda PDFDocument3 paginiGuía de Lubricación de Motos Honda PDFMartin LabatÎncă nu există evaluări

- Transient StabilityDocument16 paginiTransient StabilityRavi Kumar BanalaÎncă nu există evaluări

- MP Solar Power Policy PDFDocument23 paginiMP Solar Power Policy PDFarvindÎncă nu există evaluări

- Starting Duty Limitations for Large MotorsDocument2 paginiStarting Duty Limitations for Large Motorsmalika_00Încă nu există evaluări

- June Delivery SummaryDocument119 paginiJune Delivery SummaryKarlayaanÎncă nu există evaluări

- Non Destructive Testing of Rotors From The BoreDocument2 paginiNon Destructive Testing of Rotors From The BorePankaj KambleÎncă nu există evaluări

- Europa Valve Non Slam Check ValvesDocument16 paginiEuropa Valve Non Slam Check ValvesBryan KellyÎncă nu există evaluări

- APM Title TableOfCOntentsDocument12 paginiAPM Title TableOfCOntentsAlfonso DimlaÎncă nu există evaluări

- Stone Stomper Compactor ManualDocument98 paginiStone Stomper Compactor Manualgroomerz6612Încă nu există evaluări

- Complete Piping Solutions 4300 CPSDocument6 paginiComplete Piping Solutions 4300 CPSalihaydartekinÎncă nu există evaluări

- FM 4924 Pipe InsulationDocument20 paginiFM 4924 Pipe Insulationosama alabsiÎncă nu există evaluări

- BrahmaDocument4 paginiBrahmamegaciclonÎncă nu există evaluări

- Language of Trends - Using PrepositionDocument2 paginiLanguage of Trends - Using PrepositionMai Anh Le0% (1)

- Maintenance Prescription: Analysis Integrated With Accuracy and MeaningDocument1 paginăMaintenance Prescription: Analysis Integrated With Accuracy and MeaningVic AnaboÎncă nu există evaluări

- Bis 15 155 Digital Built Britain Level 3 Strategy PDFDocument47 paginiBis 15 155 Digital Built Britain Level 3 Strategy PDFFiguraDesfiguraÎncă nu există evaluări

- Spare PartsDocument89 paginiSpare PartsWallace ChitambaÎncă nu există evaluări

- Heavy Trucks Buses Catalogue Eng Tcm795-1611335Document72 paginiHeavy Trucks Buses Catalogue Eng Tcm795-1611335chuydb0% (1)

- PG M-Ii L1624Document408 paginiPG M-Ii L1624sridharÎncă nu există evaluări

- Maximizing Energy Production Through Innovative Geothermal TechnologiesDocument7 paginiMaximizing Energy Production Through Innovative Geothermal TechnologiesRidho Adrianto SitepuÎncă nu există evaluări

- 6850/6890 GC Column Installation and Instrument Setup Guide - PPIP/TCDDocument18 pagini6850/6890 GC Column Installation and Instrument Setup Guide - PPIP/TCDWaleed El-azabÎncă nu există evaluări