Documente Academic

Documente Profesional

Documente Cultură

JSA For Disconnect and Removal of Existing Chemical Injection Tank.

Încărcat de

Nasrullah JanDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

JSA For Disconnect and Removal of Existing Chemical Injection Tank.

Încărcat de

Nasrullah JanDrepturi de autor:

Formate disponibile

JOB SAFETY ANALYSIS (JSA) WORK SHEET

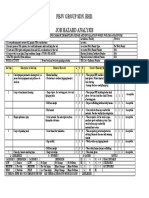

RISK MATRIX

INCREASE PROBABILITY

A Potential Severity People Asset /Production Environment Reputation Never heard of in industry B Has occurred in industry Law C Has occurred in QP D Occurs several times a year in QP Law E Occurs several times a year at this site Law

PROJECT /JOB DETAILS

Project Ref./Job Title/Work Order: Brief Description of Job:

DATE JSA No. REVISION

Job Location:

Sponsoring Department Performing Department Permit Authority JSA Approved by

Hazard Area Classification

0 No injury Slight injury or health effects Minor injury or health effects Major injury or health effects Single fatality or permanent total disability Multiple fatalities No damage Slight damage, No disruption to operation Minor damage (=QR 250,000) Local damage (=QR1 300,000) Minor damage (=QR 25,000,000) Extensive (=QR 25,000,000) No effect No impact No Risk Law

Slight effect

Slight impact Limited impact National effect Regional effect International impact

Law

Law

Law

Law

Law

Permit Requirements: Hot/Cold/Radiography Participant (Parties involve in JSA) SUPERVISOR, SAFETY OFFICER. All the mitigation measures identified in JSA are in place before starting the activities

Minor effect Localized effect

Law

Law

Medium

Medium

Medium

Law

Medium

Medium

Medium

High

Major effect Massive effect

Law

Medium

Medium

High

High

Medium

Medium

High

High

High

Work Site Supervisor

Probability Factor

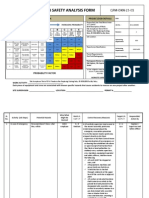

Sl. No. 1 Severity Before Mitigation Medium Required Control/Mitigation Measures & Checks Severity After Mitigation Low

Activity (Job Steps) Morning Tool box Meeting And JHA Discussion

Potential Hazard

Action party Site Supervisor and Safety Officer

People Not Understanding What

The Plan Or Hazards Are; People Afraid To Ask Questions Presence of H2S gas and Toxic gas In Work Areas.

Make Sure Everyone Is Involved With The

JSA/JHA Discussion And Understands; Encourage Everyone To Ask Questions And Participate. Don't Make Anyone Feel For Speaking Up Or Questioning

Page 1 of 6 DOC. NO.: ../HSE/F/JSA REV.0

JOB SAFETY ANALYSIS (JSA) WORK SHEET

Presence of chemical or flammable

items

Try To Identify These Types Of things In Your

Work Areas Before Starting the work; Clear Carefully Work Areas By gas testing and daily site inspection Authorized work permit holders shall ensure obtaining and maintaining valid work permits. The supervisor responsible for this activity has to check the PPE of his staff to ensure that all required items are available and properly used. Inform all people regarding permit conditions before work starts. Supervisors must conduct daily toolbox talk about nature of work and associated potential hazards and their essential precautionary measures. Checkgatepasses. Drivers/operatorsmustknowtheroteandlocationtot hejobsite. UseASpotterToBackUpAndWhenInTightQuarters PlanRoute;CheckHeight&WeightRestrictions;Kno wHeightOf Vehicle;EnsureObjectsOnTheVehicleAreSecured AndNotSticking Out. WatchTurningRadius;TakeWideTurns DriveDefensivelyandCourteously

Work Permit

Unauthorized commencement of

works May result in exposing people and/or potential to harm or danger.

Medium

Low

Site Supervisor and Safety Officer

Transportation of

materials to site

Restricted View While Backing or

in Tight Quarters Striking Bridges or Low Overpasses Along Path of Travel Taking Turns Too Sharp; Hitting Objects or People Other Vehicles on the Road Driving Unsafely, Creating Hazards For You Body pain I injuries or property damage Missed use by other contractor persons Slippery Handmade tools Defective tools Incorrect tools Unsafe method Not wear proper PPE

High

Low

Site Supervisor and Safety Officer

Medium

Usingofhandtools

AlloperativesshallbeTrainedforproperhandlingofto

ols. Appropriatetoolsonly hastobeusedanditsrequirementsshall.be complywithsiteregulations AlloperativesshallweartheirPPEswithoutfail. KeepExtraorUnusedtoolsInStorageContainer. KeepToolsInToolTrailer-DoNotStoreInBuilding. Keep only required amount of tools at site. Alltoolsshallbekeptcleanforeasyuse.

Low

Site Supervisor and Safety Officer

Page 2 of 6 DOC. NO.: ../HSE/F/JSA REV.0

JOB SAFETY ANALYSIS (JSA) WORK SHEET

Notpropercleantools

5 Installation of SS Tubing.

Improperhandlingofmaterial. Hit. Nearby existing facilities Othercontractorsworkingintheare (interfacing) Platformsandrailingscancause obstructionduringtheworkifnot properlyplannedIcoordinatedprior toscaffolderection. Overheadhazardsforpersonnelon theground.

High

Checkareaofactualerectionpriortoactivity Obtain required permit from control room. Ensurethatthelocationofevery tubing

installation at site will not obstruct or will not be object tophysicalcontactwiththepipesduring pipelaying,pulling,anderection.(Requirescoordin ationwithplanning, engineeringorpipingincharge) Providemeansofcontinuoussafeaccessfromplatfo rmtotheground. Barricadedtheareawithwarningtapeandplacedthe caution/warning board

Low

Site Supervisor and Safety Officer

Tie-in with new Pipe to Existing Pipe.

Injuryduetofire Explosionsparks

andflashes,asaresultofpoor building habitat setup. Weld Flash To People In Area Sparks I Burns To People In Area Touching Hot Metal With Hands, CausingBurns MetalinEyesorHand ZincPoisoning Fire Explosion Useofmachine. Weldinglight. Spark. Burn. Toxicgases. Rolloverweldedsegments. HitIstrike.

High

Hotworkproceduremustbeadheredtoandpermitco

nditionsobserved. Obtainrequiredpermitfromcontrolroom. Obtaingastestregularly. EnsureEyeProtectionWillProtectEntireAreaAroun dEyesMayNeedFaceshieldAlso ClearAreaITapeoffIFireWatchUseFlashScreensa nd/orLookoutPersonasNecessary. WearGlovesBeAwareOfAccidentalBodyContactwi thHotParts WearSafetyGlassesandGloves.GrindGalvanizeOf fSteel Before Cutting Or Welding. Fire watch must be present at site during hot work. Firehosechargewithwater. Fireextinguisher. AvoidBreathingFumes- IfZincPoisoningOccurs DrinkaQtOfMilk. WearAppropriateFaceandEyeProtection. UseCorrectMelds&ShotsForEachApplicationUse ProperIgniters MakeSureMelds Are Level & Plum

High

Site Supervisor, Workers and Safety Officer

Page 3 of 6 DOC. NO.: ../HSE/F/JSA REV.0

JOB SAFETY ANALYSIS (JSA) WORK SHEET

Hydrotesting of Pipe & Tube.

Non-compliance of Procedures UnauthorizedPersonnel. DefectiveToolsIEquipment. ExceedingMaximumAllowable. Pressure. Injuryto Workers. DamagetoEquipmentISystem. Un-attendedPressurizedTools. Changing the Duration of Hydrotest. UnsafeDepressurizationofHydrotes t fluid. ScatteredMaterial. Improper Anchoring. High Pressure. Rupture. Environmental Damage. Use of Machinery.

High

When Igniting ShotsWear Full Face Protection Wear LeatherGlovesAvoidContactWithHotMelds. Validchecklist. Properwelder'skit. Propersupporttoholdthe weldedsegments. Skillandcertifiedmanpower. ObtainWorkPermit&otherassociatedpermitsfrom AssetOwner. BarricadetheareawhereHydrotestistobecarriedout. ConductToolBoxTalkand Postwarningnotice. EnsuretheequipmentItooltobeusedforhydro'testing. (Suchashose,pump,coupling,pressuregauge,spa de,gasketetc)are freefromdefectandsuitableforthepressureratingof thesystem. Ensure the pressure relieving device is set at maximum allowablepressureforweakestportionofthesegmen ttobehydro-tested. Keepawayfromthepressurizedsegmentofthesyste mbeing hydrotested. Monitor t h e pressuregauge from a safe distance away from the potentialsourceofhighpressurejetting(SuchasFla ngeJoint,Spade, andCouplingetc.). EnsuretheworkersarewearingrequiredPPE. Never increase the hydro-test pressure more t h a n the maximum allowable pressurefortheweakestportioninthesegmentorpr essure ratingofthehose&coupling. Donotleavethepressurizedhoseorpumpunattende dwhenthehydro- testisgoingon. Donotchange(exceedIdec ease)thedurationofhyd r ro-testwithout

Page 4 of 6 DOC. NO.: ../HSE/F/JSA REV.0

JOB SAFETY ANALYSIS (JSA) WORK SHEET

8 Disconnect and Removal of Existing Chemical Injection Tank.

Physical: injury from heavy

equipment, heavy lifting, pinch point, slip, trips and fall hazards.

High

permissionfromInspectionEngineer. EnsurethesafedepressurizationofHydro-testFluid. Ensureproperwindup&housekeepingatworksite. UseappropriateratingassemblyforHydro-Testing. ApprovedHydroTestingProcedure. NoEntryforUnauthorizedPersons. Makesurepropertightening. TestingPressureasperCode&PipingSpecificatio n. ValidEquipmentCheckListandapprovedhydrotest package. All inlineValveshouldbeinopenposition. HighVentPointAirRemoval. Jointshouldbeexposedforinspection. Theaccessories(hoses& pump)notbeingusedmus tbedisconnected andstoredseparately. Keepsitecleanalways. Obtainnecessarypermit. Surveytheareaandconfirmsafelocationoftemporar yholdingareaof scaffoldingmaterial,priortohauling. Providetemporaryholdingareaatlocationthat willnotconges obstruct siteaccessorrestrictmobilityofotheractivities. Scaffoldrack isamustforholdingscaffoldingmaterial.No pipes, couplerswill bestoredonthegroundor anytimescattered onthe ground. Observeextracautioninmobilizingmaterialatsite. Barricadedtheareawithwarningtapeandplacedthe caution/warning board. Before transporting the loads to the sites, rest assure that the materials are secured and tight by nylon rope for the safe transporting. Ensure that a driver is having knowledge to the hazards while transporting the materials.

High

Site Supervisor, Workers and Safety Officer

Page 5 of 6 DOC. NO.: ../HSE/F/JSA REV.0

JOB SAFETY ANALYSIS (JSA) WORK SHEET

Keep a tidy site.

9 Housekeeping.

Debris causing Slips, trips and

falls. Fire risk due to presence of combustible materials / debris. Infestation of rodents leading to equipment & materials damage (Cables, cords, documents, etc.)

High

Regular housekeeping at site shall be performed. Adequate and correct stacking of materials. Regular inspection and immediate corrective

action. Keep always clear of obstruction.

Low

Site Supervisor, Workers and Safety Officer

Regular clearing of work site shall be

implemented.

Page 6 of 6 DOC. NO.: ../HSE/F/JSA REV.0

S-ar putea să vă placă și

- JHA Cutting of Asphalt Road For Replacement of Protection SlabsDocument5 paginiJHA Cutting of Asphalt Road For Replacement of Protection SlabsNasrullah JanÎncă nu există evaluări

- Safety Inspection ReportDocument1 paginăSafety Inspection ReportNasrullah Jan100% (1)

- Job Safety Analysis for Instrument Sample Point InstallationDocument3 paginiJob Safety Analysis for Instrument Sample Point InstallationNasrullah JanÎncă nu există evaluări

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Document3 pagini(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisÎncă nu există evaluări

- JSA for Night Work at Laydown AreaDocument2 paginiJSA for Night Work at Laydown Areagulryz84100% (9)

- Job Safety Analysis for Instrument Sample Point InstallationDocument3 paginiJob Safety Analysis for Instrument Sample Point InstallationNasrullah JanÎncă nu există evaluări

- JHA Maintenance Tech HVACDocument2 paginiJHA Maintenance Tech HVACMdavaÎncă nu există evaluări

- Job HazardDocument2 paginiJob HazardBre WirabumiÎncă nu există evaluări

- JHA For Tie-In at PCR14-02Document7 paginiJHA For Tie-In at PCR14-02Francis Enriquez TanÎncă nu există evaluări

- RETAIL PERMIT WORK HAZARDDocument7 paginiRETAIL PERMIT WORK HAZARDSanthosh Kumar100% (1)

- Work at Height Safety AnalysisDocument2 paginiWork at Height Safety AnalysiszebmechÎncă nu există evaluări

- Lathe Wood SopDocument1 paginăLathe Wood SopLucas BienertÎncă nu există evaluări

- JSA-002-Safety WatchDocument2 paginiJSA-002-Safety WatchNishad MuhammedÎncă nu există evaluări

- Safety Leadership: What Is It? How Does It Work?Document45 paginiSafety Leadership: What Is It? How Does It Work?Nicu IvanÎncă nu există evaluări

- HSE Training MatrixDocument3 paginiHSE Training MatrixNasrullah Jan100% (1)

- Typical JHA FormDocument5 paginiTypical JHA FormNasrullah Jan100% (4)

- Dry Hands MinecraftDocument1 paginăDry Hands MinecraftBrandon RotzankÎncă nu există evaluări

- Introduction To Windows PDFDocument24 paginiIntroduction To Windows PDFRaymoon Twopass DaysÎncă nu există evaluări

- Power Plant Engineering by G.R.nagpalDocument729 paginiPower Plant Engineering by G.R.nagpalGoutham Peri74% (23)

- Schedule of Rates 2011 Rev1Document144 paginiSchedule of Rates 2011 Rev1Screen BiruÎncă nu există evaluări

- VNX Power UP Down ProcedureDocument8 paginiVNX Power UP Down ProcedureShahulÎncă nu există evaluări

- Services Marketing: Consumer Behavior in Services Unit 2Document78 paginiServices Marketing: Consumer Behavior in Services Unit 2mpsrishaÎncă nu există evaluări

- Job Hazard Analysis for Site Survey WorkDocument5 paginiJob Hazard Analysis for Site Survey WorkFrancis Enriquez Tan100% (1)

- Job Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job DetailsDocument4 paginiJob Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job Detailsnasar_mahsood100% (2)

- Example JSA Job Safety AnalysisDocument13 paginiExample JSA Job Safety AnalysisSiti MaisarahÎncă nu există evaluări

- JSA - For Trays ErectionDocument1 paginăJSA - For Trays ErectionAvinash RaiÎncă nu există evaluări

- 05.JHA-Site Survey For TR-9702A Transformer Marshalling Box Wiring Verification at Substation EDocument5 pagini05.JHA-Site Survey For TR-9702A Transformer Marshalling Box Wiring Verification at Substation EFrancis Enriquez TanÎncă nu există evaluări

- Job Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job DetailsDocument4 paginiJob Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job Detailsnasar_mahsood100% (1)

- 2x150MW Power Plant JSA for Excavation WorkDocument4 pagini2x150MW Power Plant JSA for Excavation WorkRen SalazarÎncă nu există evaluări

- JSA For Hydrotesting PDFDocument6 paginiJSA For Hydrotesting PDFMohammed Minhaj100% (1)

- JHA - (Power Brush & Touch-Up Painting Activities 1)Document1 paginăJHA - (Power Brush & Touch-Up Painting Activities 1)shaiful annuarÎncă nu există evaluări

- RISK ASESSMENT For Grit Blasting and PaintingDocument18 paginiRISK ASESSMENT For Grit Blasting and Paintingadeoye Adeyemi100% (1)

- JHA For Steam PipingDocument17 paginiJHA For Steam PipingM8Rskn6wcÎncă nu există evaluări

- Pipeline Installation JSADocument2 paginiPipeline Installation JSAghazi kallelÎncă nu există evaluări

- JHA TOILET RENOVATIONDocument3 paginiJHA TOILET RENOVATIONBala Subra ManiamÎncă nu există evaluări

- JSA For Welding of HVACDocument4 paginiJSA For Welding of HVACMohammed Minhaj100% (1)

- JSA For New EmployeesDocument20 paginiJSA For New EmployeesNilayÎncă nu există evaluări

- Job Hazard Analysis For Desalination of First Effect RetubingDocument7 paginiJob Hazard Analysis For Desalination of First Effect Retubingmc chesterÎncă nu există evaluări

- JSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility RelayDocument9 paginiJSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility Relayfrancis_e_tan100% (2)

- Piling Works Safety AnalysisDocument6 paginiPiling Works Safety AnalysisamizanÎncă nu există evaluări

- Job Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety PersonnelDocument2 paginiJob Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety Personnelmahammed saleemÎncă nu există evaluări

- SWMSDocument11 paginiSWMSSathika Godawatta100% (1)

- Jha For - TransformerDocument7 paginiJha For - Transformermujahid1137Încă nu există evaluări

- Standard Operating Procedure (SOP) Confined Space: Environmental Health & SafetyDocument5 paginiStandard Operating Procedure (SOP) Confined Space: Environmental Health & SafetyrasulyaÎncă nu există evaluări

- JSA For Installation of Out Door UnitsDocument4 paginiJSA For Installation of Out Door UnitsMohammed MinhajÎncă nu există evaluări

- Safe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro ManilaDocument6 paginiSafe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro Manilanani ferrerÎncă nu există evaluări

- 003 SWMS - ExcavationDocument11 pagini003 SWMS - Excavationsasi kumar50% (2)

- Risk Ass. - AD 417 - Installation of SocketDocument6 paginiRisk Ass. - AD 417 - Installation of SocketnsadnanÎncă nu există evaluări

- Job Safety Analysis: How To Use This FormDocument4 paginiJob Safety Analysis: How To Use This Formjithin shankar100% (1)

- Ra02 - Container OffloadingDocument3 paginiRa02 - Container OffloadingSamÎncă nu există evaluări

- Mig Welding JSADocument2 paginiMig Welding JSANoval Febri100% (1)

- HSE-RA-018 Use of An Angle Grinder - Rev 0Document15 paginiHSE-RA-018 Use of An Angle Grinder - Rev 0عمروÎncă nu există evaluări

- 2014 Energized Electrical Work Permit - ByU-IdahoDocument2 pagini2014 Energized Electrical Work Permit - ByU-Idahocarrot123456Încă nu există evaluări

- JSA Scaffolding Erection and Dismentling New 2021Document5 paginiJSA Scaffolding Erection and Dismentling New 2021Captain ChickenÎncă nu există evaluări

- Job Safety Practices FirefightingDocument16 paginiJob Safety Practices Firefightingmohammed tofiqÎncă nu există evaluări

- Jsa FormDocument3 paginiJsa Formmiaicarba100% (1)

- JSA Excavation PDFDocument6 paginiJSA Excavation PDFmohamedamine.zemouriÎncă nu există evaluări

- PTW JHA Prayer Garment Hanging Rack InstallationDocument2 paginiPTW JHA Prayer Garment Hanging Rack InstallationPHH9834Încă nu există evaluări

- JSA Forklift PDFDocument2 paginiJSA Forklift PDFfauziÎncă nu există evaluări

- Safe Work Method StatementDocument8 paginiSafe Work Method StatementParasÎncă nu există evaluări

- Job Safety Analysis Form HydrotestDocument3 paginiJob Safety Analysis Form Hydrotestyayongjcs100% (4)

- JHA General Maintenance Activity PDFDocument5 paginiJHA General Maintenance Activity PDFdede SinbadÎncă nu există evaluări

- JSA Working in Live AreasDocument1 paginăJSA Working in Live Areasyc safetyÎncă nu există evaluări

- How Chin Engineering: Job Safety AnalysisDocument5 paginiHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdÎncă nu există evaluări

- JSA Safety AnalysisDocument3 paginiJSA Safety AnalysisLusy Gusti EfendiÎncă nu există evaluări

- SW JSA Piping 5 JSA Liquid Penetrate Test LPTDocument5 paginiSW JSA Piping 5 JSA Liquid Penetrate Test LPTAnwar Ali100% (1)

- RA Pump TemoraryDocument12 paginiRA Pump TemoraryCarlos ImmanuelÎncă nu există evaluări

- JOB SAFETY ANALYSIS FOR WATER TREATMENT FACILITIESDocument8 paginiJOB SAFETY ANALYSIS FOR WATER TREATMENT FACILITIESAldrinÎncă nu există evaluări

- Copy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksDocument7 paginiCopy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksMohammed Minhaj80% (5)

- Grounding Rod Installation SafetyDocument5 paginiGrounding Rod Installation SafetyHow Chin Engineering Sdn BhdÎncă nu există evaluări

- Copy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Document5 paginiCopy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Viron BaxhiaÎncă nu există evaluări

- Civil Works Construction Laydown AreaDocument4 paginiCivil Works Construction Laydown AreaMohammed MinhajÎncă nu există evaluări

- HSE Training MatrixDocument3 paginiHSE Training MatrixNasrullah JanÎncă nu există evaluări

- Scaffolding General Guidelines and TablesDocument10 paginiScaffolding General Guidelines and TablesNasrullah JanÎncă nu există evaluări

- Mech-5-20-JSA - Activity For Erection of ScaffoldingDocument10 paginiMech-5-20-JSA - Activity For Erection of ScaffoldingNasrullah JanÎncă nu există evaluări

- Manual Excavation For Replacement of Protection Slabs On Access RoadDocument5 paginiManual Excavation For Replacement of Protection Slabs On Access RoadNasrullah JanÎncă nu există evaluări

- 459-De-SPADING of Fire Water Line For Deluge Skid and Sprinkler System SAT TestDocument4 pagini459-De-SPADING of Fire Water Line For Deluge Skid and Sprinkler System SAT TestNasrullah JanÎncă nu există evaluări

- 362-KMI-N2 Purging Into Station PipingDocument5 pagini362-KMI-N2 Purging Into Station PipingNasrullah JanÎncă nu există evaluări

- 362-KMI-N2 Purging Into Station PipingDocument5 pagini362-KMI-N2 Purging Into Station PipingNasrullah JanÎncă nu există evaluări

- Newsletter Template NewDocument4 paginiNewsletter Template Newapi-458544253Încă nu există evaluări

- Battery Testing and MaintenanceDocument23 paginiBattery Testing and MaintenanceMormor Omerta0% (1)

- Report On Corporate Communication Strategy Analysis ofDocument38 paginiReport On Corporate Communication Strategy Analysis ofNAFISA ISLAMÎncă nu există evaluări

- Piping Class Sdxp10 - 1.4410 - (2507 Superduplex SS)Document3 paginiPiping Class Sdxp10 - 1.4410 - (2507 Superduplex SS)Lucian GrigorasÎncă nu există evaluări

- Updated After 11th BoS Course Curriculum - B.tech CSEDocument120 paginiUpdated After 11th BoS Course Curriculum - B.tech CSEAnonymous 9etQKwWÎncă nu există evaluări

- Dissertation ErsatzteilmanagementDocument7 paginiDissertation ErsatzteilmanagementWriteMyEnglishPaperForMeCanada100% (1)

- Roof Slab of Guard RoomDocument3 paginiRoof Slab of Guard RoomAditya KumarÎncă nu există evaluări

- I) CentrifugesDocument46 paginiI) Centrifugesiahim87Încă nu există evaluări

- Understand Centrifugal CompressorDocument16 paginiUnderstand Centrifugal Compressorramanathan72-1100% (2)

- Fortumo Mobile Payments API GuideDocument8 paginiFortumo Mobile Payments API GuideVladimir UtješinovićÎncă nu există evaluări

- Advances in Remediation-eBookDocument88 paginiAdvances in Remediation-eBookalinerlfÎncă nu există evaluări

- Assessment of Groundwater Quality Using GIS - A Case Study of The Churu District of RajasthanDocument9 paginiAssessment of Groundwater Quality Using GIS - A Case Study of The Churu District of RajasthanSivaShankarÎncă nu există evaluări

- Educational Technology & Education Conferences - January To June 2016 - Clayton R WrightDocument93 paginiEducational Technology & Education Conferences - January To June 2016 - Clayton R WrightEsperanza Román MendozaÎncă nu există evaluări

- Trace MasterDocument29 paginiTrace Masterapi-3858801Încă nu există evaluări

- HTML Project RestaurantDocument8 paginiHTML Project RestaurantSandeep Chowdary0% (1)

- Sitsyll PDFDocument57 paginiSitsyll PDFpreranaÎncă nu există evaluări

- Google Analytics Certification Test QuestionsDocument36 paginiGoogle Analytics Certification Test QuestionsRoberto Delgato100% (1)

- CAT775GDocument32 paginiCAT775GAndy Chan100% (1)

- Plett DawsonDocument270 paginiPlett DawsonRaghu0% (1)

- MPTK Medium Pressure Pump Performance SpecsDocument2 paginiMPTK Medium Pressure Pump Performance SpecssaronandyÎncă nu există evaluări

- Valve Group-Control - AuxiliaryDocument3 paginiValve Group-Control - AuxiliarythierrylindoÎncă nu există evaluări

- Designing The Marketing Channels 13Document13 paginiDesigning The Marketing Channels 13Gajender SinghÎncă nu există evaluări

- Documentation of Xabe - FFmpegDocument11 paginiDocumentation of Xabe - FFmpegTomasz ŻmudaÎncă nu există evaluări

- Circular Tank Radius CalculationDocument25 paginiCircular Tank Radius CalculationQamar AbbasÎncă nu există evaluări