Documente Academic

Documente Profesional

Documente Cultură

Tata Steel Int Offshore Steels

Încărcat de

Steve CowanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Tata Steel Int Offshore Steels

Încărcat de

Steve CowanDrepturi de autor:

Formate disponibile

Tata Steel International

New horizons

Supply solutions in offshore structural steel

Tata Steel International was launched in March 2009. Formed from Corus Internationals global projects, mill sales and trading network and Tata Steels overseas sales ofces, Tata Steel International is the single commercial face for Tata Steel Group across all international markets. Tata Steel International has sales and marketing teams in every part of the world and a valuable customer base. Tata Steel International has a strong position geographically using this network in the four regions of Asia, the Americas, Europe and the Middle East, South Asia & Africa. In terms of structure, the business is made up of three complementary teams:

The Tata Steel Group has a long and successful track record in the supply of structural products into the Offshore Oil and Gas Industry. These steel products were originally developed for the North Sea, but their application and use has now extended into the major offshore hubs such as the Middle East, South East Asia, the Caspian, West Africa, Central/South America and, of course, Europe. We at Tata Steel International have built on this experience by leveraging our own competencies in logistics, supply chain management and global procurement to provide tailored packages to offshore fabricators, contractors and designers. We are able to provide multi-product packages for both conventional and oating structures and have the logistical and supply chain expertise to manage projects in all corners of the globe. As the offshore industry has developed beyond the North Sea, we have kept pace with developments and are capable of providing solutions for warm, temperate and cold seas, as well as having the ability to support deep-water activity in Africa or South America.

Tata Steel Internationals teams have specialist expertise commercially, technically and in the areas of logistics and nance. This skill base, coupled with the product range that we offer from Tata Steel Group enable the business to provide unrivalled service and product packages to global customers. Available products include, but are not limited to, Plates, Sections, Structural Tubulars, Cans, Fabricated Components, Gratings and Handrails. In addition, we also have stockholding facilities in Europe, North America, the Middle East and the Far East and can supplement our supply with the provision of plate and section stock from both internal and external sources. We provide the exibility and dynamism of Tata Steel International, whilst retaining our roots within the Tata Steel Group as a respected and credible partner. This gives a unique dual strength to our operations, which is supported by our ability to source materials in established and emerging markets across the globe.

Global Projects is a strong business sharing expertise and managing projects globally in the Fluid Engineering, Offshore and Renewables and Construction Solutions sectors.

Global Positioning pioneers and develops new opportunities for the Group by positioning Tata Steel in selective international markets. Global Positioning focuses on matching steel customers and suppliers worldwide. Our Field Commercial Teams spread across four major steel-using regions worldwide partner closely with the manufacturing businesses to strengthen and develop Tata Steel Groups international customer base.

2 New Horizons

Exploring opportunities Tata Steel International has the experience and technical expertise to provide solutions in structural steel for the most demanding offshore environments

New horizons

Offshore environments demand total reliability and professionalism from suppliers and technical partners

New Horizons 3

Tata Steel International network

Tata Steel International 897 Silbury Boulevard Milton Keynes Buckinghamshire MK9 3XJ United Kingdom T +44 1908 508 250 F +44 1908 508 258

4 New Horizons

Tata Steel International 24 Rafes Place #29-05 Clifford Centre Singapore 048621 Singapore T +65 6 297 6678 F +65 6 297 6682

Tata Steel International Houston Branch Granite Towers at Sugar Creek 13135 Dairy Ashford, Suite 240, Sugar Land, TX 77478 USA T +1 713 686 8100 F +1 713 686 8182

Tata Steel International Suite 4, 25 Argle Street Fitzroy Melbourne Victoria 3065 Australia T +61 3 9417 0589 F +61 3 9417 0644

Tata Steel International PO Box 18294 Jebel Ali Dubai United Arab Emirates T +971 4 887 3232 F +971 4 887 3966

New Horizons 5

Supply chain management

Experience, knowledge and trust all bring added value to the supply chain

Supplying a wide range of products, primarily from within the Tata Steel Group and a comprehensive range of added value services, we can eliminate your interface risk and reduce your procurement costs. Suppliers are assessed, approved and performance closely monitored to ensure their compliance with contract requirements and specications.

Tata Steel International has its own, in-house technical expertise and is also able to call on the broad product knowledge from within Tata Steel Group producing mills. This is further supported by the extensive experience and resources of the entire Tata Steel Group research departments, who are able to deal with any specialist requirements that may arise.

This enables us to offer a fully comprehensive technical service at all stages of your project from design through to installation. Our logistics teams are expert in dealing with complex supply-chain issues, including consolidation of materials from multiple sources and ensuring that goods arrive on time, in full, in good condition at your chosen destination around the world.

6 New Horizons

Our customers need to be able to rely on a dependable partner, capable of dealing with complex offshore requirements. Tata Steel International has evolved into a specialist project management organisation equipped to deal with major contracts.

Our experience has taught us that stock is an essential part of any project philosophy to cater for quick start-up as well as shortfalls or design changes. Consequently, we have invested in stock material in a number of strategic locations to ensure we can provide you with the security of supplies at short notice. In addition, we have built partnerships with distributors across the world to enhance our service capability.

Our project teams regularly manage production progressing, expediting, and inspection as well as having the capability to deal with your documentation requirements and customs formalities. Expertise in export nance, project nance, performance guarantees, transactions in foreign currencies and other nancial services all generate innovative solutions for our customers.

Our blend of 'know how' and scope of value added services ensures that we provide our customers with a dedicated supply-chain solution.

New Horizons 7

Offshore structural steel specications

European British Plates & tubulars EN10225 BS7191 S355G2+N 355D S355G3+N 355E S355G5+M 355D S355G6+M 355E S355G7+N 355EM S355G7+M 355EM S355G8+N 355EMZ S355G8+M 355EMZ S355G9+N S355G9+M S355G10+N S355G10+M S420G1+Q S420G1+M S420G2+Q S420G2+M S460G1+Q 450EM S460G1+M 450EM S460G2+Q 450EMZ S460G2+M 450EMZ Sections EN10225 BS7191 S355G1 (+N) 355D S355G4 (+M) 355D S355G11 355EM S355G11+N 355EM S355G11+M 355EM S355G12 355EMZ S355G12+N 355EMZ S355G12+M 355EMZ S420G3 S420G3+M S420G4 S420G4+M S460G3 S460G3+M S460G4 S460G4+M Mobile Offshore Units EN EN 10025 S355 (27J@-40C) EN 10113 S420ML EN 10113 S460ML EN 10137 S460QL

8 New Horizons

German Werkstoff 1.8801+N 1.8802+N 1.8804+M 1.8805+M 1.8808+N 1.8808+M 1.8810+N 1.8810+M 1.8811+N 1.8811+M 1.8813+N 1.8813+M 1.8830+Q 1.8830+M 1.8857+Q 1.8857+M 1.8878+Q 1.8878+M 1.8887+Q 1.8887+M Werkstoff 1.8814(+N) 1.8803(+M) 1.8806 1.8806+N 1.8806+M 1.8809 1.8809+N 1.8809+M 1.8851 1.8851+M 1.8859 1.8859+M 1.8883 1.8883+M 1.8889 1.8889+M Werkstoff 1.8819 1.8838 1.8906

Norwegian Norsok M-120 Y21 S355N3 Y21 S355M3 Y25 S355N4 Y25 S355M4 Y20 S355N4z Y20 S355M4z Y35 S420Q3 Y35 S420M3 Y30 S420Q3z Y30 S420M3z Y45 S460Q3 Y45 S460M3 Y40 S460Q3z Y40 S460M3z Norsok M-120 Y03 S355N1 Y26 S355N3 Y26 S355M3 Y21 S355N3 Y21 S355M3 Y36 S420M3 Y31 S420M3z Y46 S460M3 Y41 S460M3z Shipbuilding E36 / EH36 E40 / E420 E460 E460

American API 2H Gr. 50 2W Gr.50/50T 2H Gr. 50 2W Gr. 50/50T 2Y Gr. 60 2W Gr. 60 2Y Gr. 60 2W Gr. 60 2Y Gr. 60 2W Gr. 60 2Y Gr. 60 2W Gr. 60 API 2H Gr. 50 2W Gr. 50/50T 2H Gr. 50 2W Gr. 50/50T 2W Gr. 60 2W Gr. 60 2W Gr. 60 2W Gr. 60 API 2W Gr.60 2W Gr.60 2Y Gr.60

Typical application

Secondary Structure Secondary Structure Secondary Structure Secondary Structure Primary Structure Primary Structure Critical Joints Critical Joints Primary Structure Primary Structure Critical Joints Critical Joints Primary Structure weight saving Primary Structure weight saving Critical Joints weight saving Critical Joints weight saving Primary Structure weight saving Primary Structure weight saving Critical Joints weight saving Critical Joints weight saving

Secondary Structure Secondary Structure Primary Structure Primary Structure Primary Structure Critical Joints Critical Joints Critical Joints Primary Structure Primary Structure Critical Joints Critical Joints Primary Structure Primary Structure Critical Joints Critical Joints

Mobile Structures Mobile Structures Mobile Structures Mobile Structures

Tata Steel International supplies a wide range of products from our own mills or approved suppliers. These can be supplied in a range of grades, dimensions and with extra processing if required.

Plates Tata Steel International can supply Offshore Plate in line with all the plate specications detailed above e.g. BS 7191, EN 10225 and API 2H as well as ASTM A36, ASTM A572 and many other international specications. Plate material can be supplied in a range of standard or tailored sizes or alternatively proled, rolled or painted as described in the extra processing operations below. Structural tubulars Fabricated structural tubulars, for offshore structural applications such as jacket legs and frames, are available broadly in line with the plate specications detailed above e.g. BS 7191, EN 10225 and API 2H as well as ASTM A36, ASTM A572 and many other international specications. Fabrication is normally undertaken using the submerged arc welding process in accordance with either AWS or EN welding procedures to ensure the highest levels of quality. Tata Steel International can also arrange to supply welded or tacked cans for jacket and node manufacture.

Seamless tubulars Seamless tubulars are available in addition to the welded tubular products described above and are also available in accordance with EN 10225 and BS 7191 specically for offshore structural use. Structural sections Tata Steel International can supply structural sections in accordance with offshore grades such as EN 10225 and BS 7191. A full range of sections, sizes and specications is available on request. Bulb ats Bulb ats are increasingly specied as a technically efcient stiffener in offshore fabrication. Tata Steel International can supply a full range of sizes required for offshore fabrication in accordance with the regulations of the major shipbuilding classication societies, as well as BS 7191 and EN 10225 on request.

Extra processing Tata Steel International can offer an extensive range of plate and section extra processing operations including can rolling, shot blasting and priming, bevelling, cutting, forming, proling, cambering and drilling. We would be pleased to discuss your individual requirements in order to build a package to suit your individual project.

All products described here can be specied in alternative grades such as BS 4360 Grades 50D/DD, EN 10025 S355J2/K2 ASTM A572 Grade 50 or ASTM A36 for warmer water applications. Full details of our complete range of specications are available on request.

New Horizons 9

10 New Horizons

Health and safety Tata Steel ensures the health, safety and well-being of its employees, contractors, visitors and neighbouring communities.

High priorities

A positive health and safety culture is encouraged, which only accepts safe behaviour. Tata Steel aims to continuously improve safety performance and ensure safe operating practices. Hazards, risks and control measures Its worth not taking the risk. We will identify the hazards and risks associated with our activities starting with our major risks. We will put in place appropriate control measures and challenge them in the context of change, so that we aim for continuous improvement. Contractors and joint ventures A good relationship is based on trust. Our health and safety standards apply equally to contractors and employees. We believe our joint venture companies should aspire to the Tata Steel health and safety ethos.

New Horizons 11 New Horizons 11

Committed to environmental standards

Sustainability The Tata Steel Group considers care for the environment to be essential both in terms of our duty to society and to ensure the continuity of our business. We are committed to protecting the environment by minimising the impact of our operations and our products through the adoption of sustainable practices and through continuous improvement in environmental performance and control.

12 New Horizons

Tata Steel places great emphasis on the contribution we make to a sustainable society and is committed to incorporating the principles of sustainable development into all aspects of our operations. Steel and aluminium are the worlds most recyclable and recycled materials. Over 40% of the world production of new steel is made from old steel, and 35% of new aluminium is made from old aluminium.

Much of the steel and aluminium in use today will be recovered, melted and used again by future generations in completely different applications. Tata Steel Europe is a member of the International Iron and Steel Institute and supports its policies on Environmental Principles, Life Cycle Assessment and Climate Change. These can be found on the IISI website at www.worldsteel.org

New Horizons 13

Implicit within such a quality system is that Tata Steel International will only procure material from companies with audited quality systems and a demonstrable capability to supply material both in accordance with the required specication and of a quality with which Tata Steel International is prepared to be associated. New suppliers are audited to ensure that quality standards are maintained. In addition, we review and monitor suppliers during production to ensure that the quality of their products matches our required standards.

For offshore projects, we work with third party inspectors, where required, to ensure that all testing and inspection requirements agreed at the pre-production stage are met in full. Tata Steel International may also supplement this process with in-house surveyors, who monitor production at the relevant manufacturing locations, as well as pre-shipment. Loading and discharge surveys are routinely carried out to ensure material is despatched in prime condition and reaches the end client in perfect order. In addition to pre-production and in-process checks, Tata Steel International performs customer satisfaction surveys and supplier performance analysis in the pursuit of continuous improvement.

Quality assurance

14 New Horizons

Tata Steel International specialises in the supply of steel products to a wide variety of market sectors and geographical regions. The nature of the companys activities places signicant emphasis on reliability, dependability and product expertise. We operate a quality system which complies with the requirements of EN ISO 9001:2008

New Horizons 15

www.tatasteelinternational.com

Care has been taken to ensure that this information is accurate, but Tata Steel Group and its subsidiaries do not accept responsibility or liability for errors or information which is found to be misleading. Copyright 2010 Tata Steel International

Tata Steel International 897 Silbury Boulevard Milton Keynes MK9 3XJ United Kingdom T: +44 (0)1908 508 250 F: +44 (0)1908 508 258 E: offshore@tatasteel.com www.tatasteelinternational.com

S-ar putea să vă placă și

- Tata Steel Europe LTDDocument22 paginiTata Steel Europe LTDEntertainment OverloadedÎncă nu există evaluări

- CDR Mechanical Engineer 1 No SummaryDocument24 paginiCDR Mechanical Engineer 1 No SummaryZizo Awad100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesDe la EverandWeld Like a Pro: Beginning to Advanced TechniquesEvaluare: 4.5 din 5 stele4.5/5 (6)

- CISC Advantage 47Document60 paginiCISC Advantage 47greatsteelÎncă nu există evaluări

- ObjectionDocument10 paginiObjectionMy-Acts Of-SeditionÎncă nu există evaluări

- FLI Structure Selection Guide PDFDocument38 paginiFLI Structure Selection Guide PDFsumomonoÎncă nu există evaluări

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!De la EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Evaluare: 5 din 5 stele5/5 (2)

- Startup Fundraising 101Document8 paginiStartup Fundraising 101CrowdfundInsiderÎncă nu există evaluări

- CW4Document19 paginiCW4Steve Cowan100% (1)

- MCQDocument9 paginiMCQthaker richaÎncă nu există evaluări

- Galvanising ManualDocument199 paginiGalvanising Manualdc12dcÎncă nu există evaluări

- Tata Steel Advance To Eurocodes Jun 13Document60 paginiTata Steel Advance To Eurocodes Jun 13s9904055Încă nu există evaluări

- Welding PositionsDocument2 paginiWelding PositionsSteve Cowan100% (1)

- Low Version Final EIRC Directory For WebsiteDocument164 paginiLow Version Final EIRC Directory For WebsiteRaj MittalÎncă nu există evaluări

- Chapter 2 Marketing AspectDocument8 paginiChapter 2 Marketing AspectMike Rajas100% (4)

- Company Profile Stainless Steel Aluminium Copper, Brass & Bronze General DataDocument33 paginiCompany Profile Stainless Steel Aluminium Copper, Brass & Bronze General DataMelissa GrahamÎncă nu există evaluări

- Rig BrochureDocument0 paginiRig BrochureAfrina Wulan Munir-sikumBang100% (1)

- 999 Industrial Guide 2010Document42 pagini999 Industrial Guide 2010kasosei100% (1)

- Catalogo - COMPLETO - Todos Os Itens PDFDocument344 paginiCatalogo - COMPLETO - Todos Os Itens PDFMarcioÎncă nu există evaluări

- Competence in Ironmaking enDocument28 paginiCompetence in Ironmaking enhk168Încă nu există evaluări

- Steel Rebar Industry ProfileDocument34 paginiSteel Rebar Industry ProfileOvidiu TomaÎncă nu există evaluări

- Rail Technical Guide enDocument24 paginiRail Technical Guide enroldskiÎncă nu există evaluări

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesDe la EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesÎncă nu există evaluări

- Media EvolutionDocument61 paginiMedia EvolutionNeelam KadbaneÎncă nu există evaluări

- Rawlplug Commercial CatalogDocument116 paginiRawlplug Commercial CatalogGianfranco TacoÎncă nu există evaluări

- CTHBDocument543 paginiCTHBJose AcostaÎncă nu există evaluări

- Steel Catalog TatapdateDocument134 paginiSteel Catalog TatapdateLaughlikesiao HeheÎncă nu există evaluări

- Midwaymetals Steel Selection GuideDocument100 paginiMidwaymetals Steel Selection GuidegarrybieberÎncă nu există evaluări

- Crane RailsDocument4 paginiCrane Railsmuamer1Încă nu există evaluări

- Tata Steel Strip Product Range Catalogue 2018Document232 paginiTata Steel Strip Product Range Catalogue 2018OmkarÎncă nu există evaluări

- Tata Steel Advance Sections To BS5950 Nov12Document60 paginiTata Steel Advance Sections To BS5950 Nov12bryan.hesp5491Încă nu există evaluări

- Advance® Sections: CE Marked Structural Sections BS 5950 VersionDocument60 paginiAdvance® Sections: CE Marked Structural Sections BS 5950 VersionZsolt NagyÎncă nu există evaluări

- Know Your SteelDocument111 paginiKnow Your SteelJohn TsolomitisÎncă nu există evaluări

- West-Trak Final Catalogue Design Low Res FileDocument180 paginiWest-Trak Final Catalogue Design Low Res Filemarcusdba100% (1)

- Advance To BS5950 June 13-2Document60 paginiAdvance To BS5950 June 13-2Daniel WagnerÎncă nu există evaluări

- Your Partner To Access Local Energy - WorldwideDocument11 paginiYour Partner To Access Local Energy - WorldwideCal LentiÎncă nu există evaluări

- Introduction To Astrak - LennartsforsDocument29 paginiIntroduction To Astrak - LennartsforsHoward BellabyÎncă nu există evaluări

- Altech IntroDocument2 paginiAltech Introatulmittal1972Încă nu există evaluări

- Offshore SteelDocument42 paginiOffshore SteelPuvas NandakwangÎncă nu există evaluări

- Attal Gaskets, KarurDocument15 paginiAttal Gaskets, KarurarvindranganathanÎncă nu există evaluări

- All InformationDocument10 paginiAll InformationAkshay IratkarÎncă nu există evaluări

- Kova BrochureDocument12 paginiKova BrochureRishabgupta12Încă nu există evaluări

- Filestore NSF Brochure PDFDocument19 paginiFilestore NSF Brochure PDFKhaled AmmarÎncă nu există evaluări

- Capral ExtCat Feb2013 WebDocument83 paginiCapral ExtCat Feb2013 WebNanda Hlaing MyintÎncă nu există evaluări

- Plucka 1450909082Document83 paginiPlucka 1450909082AymeeenÎncă nu există evaluări

- Tata Steel Bright Bar Datsheet July 2013Document2 paginiTata Steel Bright Bar Datsheet July 2013Chintan ShahÎncă nu există evaluări

- Tata Steel Projects: For More Information Please ContactDocument4 paginiTata Steel Projects: For More Information Please ContactTata Steel ProjectsÎncă nu există evaluări

- Quality Steel Plate Suppliers To The WorldDocument7 paginiQuality Steel Plate Suppliers To The Worldrisbo12Încă nu există evaluări

- Teyseer BM Company Profile PQ 1Document108 paginiTeyseer BM Company Profile PQ 1Bibin Chacko MammenÎncă nu există evaluări

- PGCC-Steel DVN Profile-Ver 04Document28 paginiPGCC-Steel DVN Profile-Ver 04eiman_zerepÎncă nu există evaluări

- Ewac BrochureDocument9 paginiEwac BrochureRohit MalhotraÎncă nu există evaluări

- Tower Field Service 092015Document8 paginiTower Field Service 092015Shankar CoolÎncă nu există evaluări

- Special Piping Materials BrochureDocument9 paginiSpecial Piping Materials BrochureAndiWSutomoÎncă nu există evaluări

- Kingston Industrial Brochure 12072012Document16 paginiKingston Industrial Brochure 12072012mkpasha55mp100% (1)

- Soudronic Companybrochure PDFDocument16 paginiSoudronic Companybrochure PDFjuanÎncă nu există evaluări

- Product Portfolio - TATA STEELDocument3 paginiProduct Portfolio - TATA STEELAbhi AgarwalÎncă nu există evaluări

- Iron and Steel ReviewDocument2 paginiIron and Steel ReviewSajal SinghÎncă nu există evaluări

- About Us Quality Products Private Label CustomisedDocument4 paginiAbout Us Quality Products Private Label CustomisedVIVEK MAHAJANÎncă nu există evaluări

- WPE Product BrochureDocument2 paginiWPE Product BrochuresrkmÎncă nu există evaluări

- Swastik Profile - NEWDocument11 paginiSwastik Profile - NEWpandy1604Încă nu există evaluări

- FSC ProjectDocument15 paginiFSC ProjectsahilÎncă nu există evaluări

- Steelway Group Brochure 2010Document8 paginiSteelway Group Brochure 2010Laura EddowesÎncă nu există evaluări

- Welcome To Kaivan EngineersDocument13 paginiWelcome To Kaivan EngineersHarsh ModiÎncă nu există evaluări

- Aalco CatalogueDocument92 paginiAalco CatalogueNigin ParambathÎncă nu există evaluări

- Sanki Kigyo Group of CompaniesDocument24 paginiSanki Kigyo Group of CompaniesAfiq FuadÎncă nu există evaluări

- Descriptive Pamphlet of the Richmond Mill Furnishing WorksDe la EverandDescriptive Pamphlet of the Richmond Mill Furnishing WorksÎncă nu există evaluări

- Metal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryDe la EverandMetal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryÎncă nu există evaluări

- CW9 Part 1Document9 paginiCW9 Part 1Steve CowanÎncă nu există evaluări

- CW6 Part 2Document34 paginiCW6 Part 2Steve CowanÎncă nu există evaluări

- CW6 Part 1Document44 paginiCW6 Part 1Steve CowanÎncă nu există evaluări

- CW5Document18 paginiCW5Steve CowanÎncă nu există evaluări

- CW2Document38 paginiCW2Steve CowanÎncă nu există evaluări

- Stainless Steel Bs en EquivalentsDocument3 paginiStainless Steel Bs en EquivalentsSantiago VayasÎncă nu există evaluări

- Lampiran PMK 156 2015Document3 paginiLampiran PMK 156 2015Torang Shakespeare SiagianÎncă nu există evaluări

- Ais Lecture One PDFDocument85 paginiAis Lecture One PDFAndy AsanteÎncă nu există evaluări

- IND AS 103 - Bhavik Chokshi - FR ShieldDocument26 paginiIND AS 103 - Bhavik Chokshi - FR ShieldSoham Upadhyay100% (1)

- Relationship Marketing: Challenges For The Organization: Christian Gro NroosDocument9 paginiRelationship Marketing: Challenges For The Organization: Christian Gro NroosrnaganirmitaÎncă nu există evaluări

- DeKalb County Commissioners Chief of Staff Morris Williams P-Card ActivityDocument37 paginiDeKalb County Commissioners Chief of Staff Morris Williams P-Card ActivityViola DavisÎncă nu există evaluări

- Faulty Workmanship and Ensuing LossDocument4 paginiFaulty Workmanship and Ensuing Lossmichelle_b_griffinÎncă nu există evaluări

- Kaizen Definition & Principles in Brief: A Concept & Tool For Employees InvolvementDocument5 paginiKaizen Definition & Principles in Brief: A Concept & Tool For Employees InvolvementMuna EyobÎncă nu există evaluări

- Thư Tín - NN5-2020 - UpdatedDocument60 paginiThư Tín - NN5-2020 - UpdatedK59 Nguyen Minh ChauÎncă nu există evaluări

- Research Paper - Sample SimpleDocument15 paginiResearch Paper - Sample Simplewarblade_02Încă nu există evaluări

- Myers & Briggs' 16 Personality Types: Infp EnfpDocument4 paginiMyers & Briggs' 16 Personality Types: Infp Enfpmyka ella jimenezÎncă nu există evaluări

- Airline Reservations SystemDocument6 paginiAirline Reservations SystemShanie Rosero BriongosÎncă nu există evaluări

- OSHA 3000 - Employer Rights and ResponsibilitiesDocument28 paginiOSHA 3000 - Employer Rights and ResponsibilitiesWahed Mn ElnasÎncă nu există evaluări

- PAM For Informatica MDM Multidomain Edition 10.1Document2 paginiPAM For Informatica MDM Multidomain Edition 10.1Sourajit MitraÎncă nu există evaluări

- 2013 May Skpi-TesttubeDocument370 pagini2013 May Skpi-TesttubeAngelica Sta. MariaÎncă nu există evaluări

- 28c4fcase Study On Performance ManagementDocument2 pagini28c4fcase Study On Performance ManagementRomil Singh80% (5)

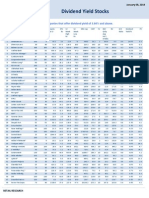

- High Dividend Yield StocksDocument3 paginiHigh Dividend Yield StockskaizenlifeÎncă nu există evaluări

- LoanDocument1 paginăLoansuriya bhaiÎncă nu există evaluări

- Q4 2010 Financial Reports - EnglishDocument364 paginiQ4 2010 Financial Reports - Englishalexa_libraÎncă nu există evaluări

- Local Bankruptcy Rules - COMPLETEDocument196 paginiLocal Bankruptcy Rules - COMPLETEhbs.29645Încă nu există evaluări

- Huimfisllfia: 18 July - August 2006 Aba Bank MarkehngDocument8 paginiHuimfisllfia: 18 July - August 2006 Aba Bank MarkehngGhumonto SafiurÎncă nu există evaluări

- FIS - Meaning and Nature of UnderwritingDocument3 paginiFIS - Meaning and Nature of UnderwritingDr. MURALI KRISHNA VELAVETIÎncă nu există evaluări

- Report On Business LetterDocument28 paginiReport On Business LetterAnum SheikhÎncă nu există evaluări

- Leave Travel Concession (LTC) Rules: Office MemorandumDocument2 paginiLeave Travel Concession (LTC) Rules: Office Memorandumchintu_scribdÎncă nu există evaluări