Documente Academic

Documente Profesional

Documente Cultură

FR 5277 QST30 G4 ATA

Încărcat de

Bernardo GarridoDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

FR 5277 QST30 G4 ATA

Încărcat de

Bernardo GarridoDrepturi de autor:

Formate disponibile

CUMMINS ENGINE COMPANY, INC

Basic Engine Model:

Columbus, Indiana 47201

Engine Critical Parts List:

Date:

QST30-G4

FR-5276 (2P/ 2L)

FR-5277 (Air-to-Air)

Displacement : 30.48 litre (1860 in3 )

Bore : 140 mm (5.51 in)

No. of Cylinders : 12

Aspiration : Turbocharged and Low Temperature Aftercooled

Engine Speed

Standby Power

QST

1

Curve Number:

CPL: 3203 (2 Pump / 2 Loop)

CPL: 3204 (Air-to-AIr)

ENGINE PERFORMANCE CURVE

G-DRIVE

10JAN11

Stroke : 165 mm (6.50 in)

Prime Power

Continuous Power

RPM

kWm

BHP

kWm

BHP

kWm

BHP

1500

970

1300

880

1180

683

915

1800

1112

1490

1007

1350

832

1115

Engine Performance Data @ 1500 RPM

OUTPUT POWER

%

kWm

BHP

Litre/hour

FUEL CONSUMPTION

kg/

kWmh

lb/

BHPh

litre/

hour

U.S. Gal/

hour

0.196

0.323

224

59.1

150.0

100.0

STANDBY POWER

100

970

1300

PRIME POWER

100

880

1180

0.195

0.320

202

53.2

75

660

885

0.194

0.319

151

39.8

50

440

590

0.197

0.324

102

26.9

25

220

295

0.207

0.341

54

14.2

0.194

0.319

156

41.1

CONTINUOUS POWER

100

683

CONVERSIONS:

915

250.0

1500 RPM

200.0

50.0

0.0

0

(litres = U.S. Gal x 3.785)

100

200

300

400

500

600

700

800

900

Gross Engine Output - kWm

(Engine kWm = BHP x 0.746)

(U.S. Gal = litres x 0.2642)

(Engine BHP = Engine kWm x 1.34)

These guidelines have been formulated to ensure proper application of generator drive engines in A.C. generator set installations.

Generator drive engines are not designed for and shall not be used in variable speed D.C. generator set applications.

STANDBY POWER RATING

Applicable for supplying emergency power for the duration of the utility power outage. No overload capability is available for this rating. Under no condition is an engine allowed

to operate in parallel with the public utility at the Standby Power rating. This rating should be applied where reliable utility power is available. A Standby rated engine should be sized

for a maximum of an 80% average load factor and 200 hours of operation per year. This includes less than 25 hours per year at the Standby Power rating. Standby ratings should

never be applied except in true emergency power outages. Negotiated power outages contracted with a utility company are not considered an emergency.

PRIME POWER RATING

Applicable for supplying electric power in lieu of commercially purchased power. Prime Power applications must be in the form of one of the following two categories:

UNLIMITED TIME RUNNING PRIME POWER

Prime Power is available for an unlimited number of hours per year in a variable load application. Variable load should not exceed a 70% average of the Prime Power rating

during any operating period of 250 hours. The total operating time at 100% Prime Power shall not exceed 500 hours per year. A 10% overload capability is available for a

period of 1 hour within a 12-hour period of operation. Total operating time at the 10% overload power shall not exceed 25 hours per year.

LIMITED TIME RUNNING PRIME POWER

Limited Time Prime Power is available for a limited number of hours in a non-variable load application. It is intended for use in situations where power outages are contracted,

such as in utility power curtailment. Engines may be operated in parallel to the public utility up to 750 hours per year at power levels never to exceed the Prime Power rating.

The customer should be aware, however, that the life of any engine will be reduced by this constant high load operation. Any operation exceeding 750 hours per year at the

Prime Power rating should use the Continuous Power rating.

CONTINUOUS POWER RATING

Applicable for supplying utility power at a constant 100% load for an unlimited number of hours per year. No overload capability is available for this rating.

Data shown above represent gross engine performance capabilities obtained and corrected in accordance with ISO-3046 conditions of 100 kPa (29.53 in Hg)

barometric pressure [110 m (361 ft) altitude], 25 C (77 F) air inlet temperature, and relative humidity of 30% with No. 2 diesel or a fuel corresponding to ASTM D2.

See reverse side for application rating guidelines.

The fuel consumption data is based on No. 2 diesel fuel weight at 0.85 kg/litre (7.1 lbs/U.S. gal).

Power output curves are based on the engine operating with fuel system, water pump and lubricating oil pump; not included are battery charging alternator, fan,

optional equipment and driven components.

TECHNICAL DATA DEPT.

CERTIFIED WITHIN 5%

CHIEF ENGINEER

1000

G-DRIVE

QST

2

QST30-G4 Derate Curves @ 1500 RPM

CURVE NO: FR-5276 (2 Pump 2 loop)

FR-5277 (Air-to-AIr)

DATE: 10JAN11

Ambient Temp. (C / F)

Percent Derate of Rated Power (%)

30

50 / 122

40 / 104

25

STANDBY / PRIME

20

15

25 / 77

10

500

1000

1500

Altitude (m)

2000

2500

3000

Ambient Temp. (C / F)

50 / 122

30

40 / 104

Percent Derate of Rated Power (%)

CONTINUOUS

25

20

15

10

5

0

0

500

1000

1500

Altitude (m)

2000

2500

3000

Reference Standards:

BS-5514 and DIN-6271 standards are based on ISO-3046.

Operation At Elevated Altitude and Temperature:

For sustained operation above these conditions, derate an additional 9% per 500 m (1640 ft) and 15% per 10C (18F)

Note: Derates shown are based on 15 in H20 air intake restriction and 2 in Hg exhaust back pressure.

CUMMINS ENGINE COMPANY, INC

Basic Engine Model:

Columbus, Indiana 47201

Engine Critical Parts List:

ENGINE PERFORMANCE CURVE

Date:

10JAN11

QST30-G4

CPL: 3203 (2 Pump / 2 Loop)

CPL: 3204 (Air-to-AIr)

FR-5276 (2P / 2L)

FR-5277 (Air-to-Air)

Bore : 140 mm (5.51 in)

No. of Cylinders : 12

Aspiration : Turbocharged and Low Temperature Aftercooled

Standby Power

QST

3

Curve Number:

Displacement : 30.48 litre (1860 in3 )

Engine Speed

G-DRIVE

Stroke : 165 mm (6.50 in)

Prime Power

Continuous Power

RPM

kWm

BHP

kWm

BHP

kWm

BHP

1500

970

1300

880

1180

683

915

1800

1112

1490

1007

1350

832

1115

Engine Performance Data @ 1800 RPM

OUTPUT POWER

%

kWm

BHP

FUEL CONSUMPTION

kg/

kWmh

lb/

BHPh

litre/

hour

U.S. Gal/

hour

0.204

0.336

267

70.5

STANDBY POWER

100

1112

1490

PRIME POWER

100

1007

1350

0.203

0.333

240

63.3

75

756

1013

0.199

0.327

177

46.7

50

504

675

0.202

0.331

119

31.5

25

252

338

0.223

0.366

66

17.4

0.199

0.327

194

51.4

CONTINUOUS POWER

100

832

1115

CONVERSIONS:

(litres = U.S. Gal x 3.785)

U.S. Gallons/hour

80.0

70.0

1800 RPM

60.0

50.0

40.0

30.0

20.0

10.0

0.0

0

200

400

600

800

1000

1200

Gross Engine Output - BHP

(kWm = BHP x 0.746)

(U.S. Gal = litres x 0.2642)

(BHP = kWm x 1.34)

These guidelines have been formulated to ensure proper application of generator drive engines in A.C. generator set installations.

Generator drive engines are not designed for and shall not be used in variable speed D.C. generator set applications.

STANDBY POWER RATING

Applicable for supplying emergency power for the duration of the utility power outage. No overload capability is available for this rating. Under no condition is an engine allowed

to operate in parallel with the public utility at the Standby Power rating. This rating should be applied where reliable utility power is available. A Standby rated engine should be sized

for a maximum of an 80% average load factor and 200 hours of operation per year. This includes less than 25 hours per year at the Standby Power rating. Standby ratings should

never be applied except in true emergency power outages. Negotiated power outages contracted with a utility company are not considered an emergency.

PRIME POWER RATING

Applicable for supplying electric power in lieu of commercially purchased power. Prime Power applications must be in the form of one of the following two categories:

UNLIMITED TIME RUNNING PRIME POWER

Prime Power is available for an unlimited number of hours per year in a variable load application. Variable load should not exceed a 70% average of the Prime Power rating

during any operating period of 250 hours. The total operating time at 100% Prime Power shall not exceed 500 hours per year. A 10% overload capability is available for a

period of 1 hour within a 12-hour period of operation. Total operating time at the 10% overload power shall not exceed 25 hours per year.

LIMITED TIME RUNNING PRIME POWER

Limited Time Prime Power is available for a limited number of hours in a non-variable load application. It is intended for use in situations where power outages are contracted,

such as in utility power curtailment. Engines may be operated in parallel to the public utility up to 750 hours per year at power levels never to exceed the Prime Power rating.

The customer should be aware, however, that the life of any engine will be reduced by this constant high load operation. Any operation exceeding 750 hours per year at the

Prime Power rating should use the Continuous Power rating.

CONTINUOUS POWER RATING

Applicable for supplying utility power at a constant 100% load for an unlimited number of hours per year. No overload capability is available for this rating.

Data shown above represent gross engine performance capabilities obtained and corrected in accordance with ISO-3046 conditions of 100 kPa (29.53 in Hg)

barometric pressure [110 m (361 ft) altitude], 25 C (77 F) air inlet temperature, and relative humidity of 30% with No. 2 diesel or a fuel corresponding to ASTM D2.

See reverse side for application rating guidelines.

The fuel consumption data is based on No. 2 diesel fuel weight at 0.85 kg/litre (7.1 lbs/U.S. gal).

Power output curves are based on the engine operating with fuel system, water pump and lubricating oil pump; not included are battery charging alternator, fan,

optional equipment and driven components.

TECHNICAL DATA DEPT.

1400

CERTIFIED WITHIN 5%

CHIEF ENGINEER

QST30-G4 Derate Curves @ 1800 RPM

G-DRIVE

QST

4

Ambient Temp. (C / F)

30

Percent Derate of Rated Power (%)

CURVE NO: FR-5276 (2 Pump 2 loop)

FR-5277 (Air-to-AIr)

DATE: 10JAN11

25

STANDBY / PRIME

50 / 122

20

40 / 104

25 / 77

15

10

5

0

0

500

1000

1500

2000

2500

3000

Altitude (m)

Ambient Temp. (C / F)

Percent Derate of Rated Power (%)

30

50 / 122

25

CONTINUOUS

20

40 / 104

15

10

5

0

0

500

1000

1500

Altitude (m)

2000

2500

3000

Reference Standards:

BS-5514 and DIN-6271 standards are based on ISO-3046.

Operation At Elevated Altitude and Temperature:

For sustained operation above these conditions, derate an additional 9% per 1000 ft (300 m) and 15% per 10C

(18F).

Note: Derates shown are based on 15 in H20 air intake restrictions and 2 in Hg exhaust back pressure.

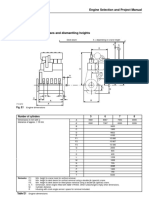

Cummins Engine Company, Inc.

G-DRIVE

Engine Data Sheet

ENGINE MODEL :

QST30-G4

INSTALLATION DIAGRAM

QST

DS-5277

5

10JAN11

FR-5276 (2P / 2L)

FR-5277 (A - A)

DATA SHEET :

CONFIGURATION NUMBER : D573001GX03

DATE :

PERFORMANCE CURVE :

Fan to Flywheel (2 Pump / 2 Loop): 3170314

Fan to Flywheel (Air-to-Air):

3170341

CPL NUMBER

Engine Critical Parts List (2 Pump / 2 Loop) :3203

Engine Critical Parts List (Air-to-Air)

:3204

GENERAL ENGINE DATA

Type................................................................................................................................................................

Aspiration .......................................................................................................................................................

Bore x Stroke .............................................................................................................. mm x mm (in x in)

Displacement.............................................................................................................................. (litre) in3

Compression Ratio........................................................................................................................................

Dry Weight,Fan to Flywheel Engine............................................................................................. kg (lb)

Wet Weight,Fan to Flywheel Engine............................................................................................ kg (lb)

Moment of Inertia of Rotating Components

with FW 5050 Flywheel ........................................................................................... kg m2 (lbm ft2)

Center of Gravity from Rear Face of Flywheel Housing (FH 5031) ........................................ mm (in)

Center of Gravity Above Crankshaft Centerline ....................................................................... mm (in)

Maximum Static Loading at Rear Main Bearing.......................................................................... kg (lb)

4-Cycle; 50 Vee; 12-Cylinder Diesel

Turbocharged and Low Temperature

Aftercooled

140 x165 (5.51 x 6.50)

30.48 (1860)

14.0 : 1

3012

(6640)

3112

(6860)

8.7

845

195

950

(206)

(33.3)

(7.7)

(2100)

3100

(2286)

51

(2)

635

381

(25)

(15)

Engine Only.......................................................................... litre (US gal)

Aftercoolers (2 Pump / 2 Loop) ............................................ litre (US gal)

Minimum Pressure Cap ........................................................................................................... kPa (psi)

79

12

69

(21)

(3.2)

(10)

Jacket Water Circuit Requirements

Maximum Coolant Friction Head External to Engine

1500 / 1800 rpm ..................... kPa (psi)

Maximum Static Head of Coolant Above Engine Crank Centerline............................................ m (ft)

Standard Thermostat (Modulating) Range ................................................................................. C (F)

Maximum Top Tank Temperature for Standby / Prime Power................................................... C (F)

48 / 69

14

82 - 95

104 / 100

(7 / 10)

(46)

(180 - 203)

(220 / 212)

Aftercooler Circuit Requirements (2 Pump / 2 Loop Aftercooling)

Maximum Inlet Water Temperature to Aftercooler @ 77 F....................................................... C (F)

Maximum Inlet Water Temperature to Aftercooler ...................................................................... C (F)

Maximum Coolant Friction Head External to Engine

1500 / 1800 rpm ..................... kPa (psi)

49

65

35 / 48

(120)

(150)

(5 / 7)

Air-to-Air Core Requirements

Maximum Temp. Rise Between Engine Air Inlet and Intake Manifold 1500 / 1800 rpm C (F)

Maximum Air Press. Drop from Turbo AIr Outlet to Intake Manifold 1500 / 1800 rpm mm (in Hg)

33 / 39

102 / 127

(60 / 70)

(4 / 5)

166

310 - 386

121

133 - 114

154

(24)

(45 - 56)

(250)

(35 - 30)

(40.7)

ENGINE MOUNTING

Maximum Bending Moment at Rear Face of Block..................................................... N m (lb ft)

EXHAUST SYSTEM

Maximum Back Pressure............................................................................................... mm Hg (in Hg)

AIR INDUCTION SYSTEM

Maximum Intake Air Restriction

with Dirty Filter Element ......................................................................................... mm H2O (in H2O)

with Clean Filter Element....................................................................................... mm H2O (in H2O)

COOLING SYSTEM (Low Temperature Aftercooling Required)

Coolant Capacity

LUBRICATION SYSTEM

Oil Pressure @ Idle Speed .................................................................................................... kPa (psi)

@ Governed Speed.......................................................................................... kPa (psi)

Maximum Oil Temperature.......................................................................................................... C (F)

Oil Capacity with OP 5133 Oil Pan : High - Low............................................................... litre (US gal)

Total System Capacity (Including Bypass Filter).............................................................. litre (US gal)

FUEL SYSTEM

Type Injection System................................................................................................ Bosch P8500 LLA Direct Injection

Maximum Restriction at Lift Pump with Clean Fuel Pre-Filter...................................................... mm Hg (in Hg)

with Dirty Fuel Pre-Filter ........................................................ mm Hg (in Hg)

Maximum Allowable Head on Injector Return Line (Consisting of Friction and Static Head)........... mm Hg (in Hg)

Maximum Fuel Flow to Injection Pumps (Left and Right Banks Combined) 1500 / 1800 rpm..... litre / hr (US gph)

Maximum Fuel Inlet Temperature ..................................................................................................................... C (F)

Maximum Return Flow..................................................................................... 1500 / 1800 rpm .... litre / hr (US gph)

102

203

508

550 / 570

71

530 / 550

(4.0)

(8.0)

(20)

(145 / 150)

(150)

(140 / 145)

G-DRIVE

QST

6

ELECTRICAL SYSTEM

Cranking Motor (Heavy Duty, Positive Engagement)......................................................................................................... volt

Battery Charging System, Negative Ground................................................................................................................ ampere

Maximum Allowable Resistance of Cranking Circuit ........................................................................................................ ohm

Minimum Recommended Battery Capacity

Cold Soak @ 10 C (50 F) and Above............................................................................................................. 0F CCA

Cold Soak @ 0 C to 10 C (32 F to 50 F)...................................................................................................... 0F CCA

Cold Soak @ -18 C to 0 C (0 F to 32 F)....................................................................................................... 0F CCA

24

35

0.002

1200

1280

1800

COLD START CAPABILITY

Minimum Ambient Temperature for Cold Start with 8000 watt Coolant Heater to Rated Speed................................ C (F)

Minimum Ambient Temperature for Unaided Cold Start to Idle Speed............................................... ....................... C (F)

Minimum Ambient Temperature for NFPA110 Cold Start (90F Minimum Coolant Temperature)............................ C (F)

-7

7

0

(20)

(45)

(32)

PERFORMANCE DATA

All data is based on:

Engine operating with fuel system, water pump, lubricating oil pump, air cleaner and exhaust

silencer; not included are battery charging alternator, fan, and optional driven components.

Engine operating with fuel corresponding to grade No. 2-D per ASTM D975.

ISO 3046, Part 1, Standard Reference Conditions of:

Barometric Pressure : 100 kPa (29.53 in Hg)

Air Temperature

: 25 C (77 F)

Altitude

: 110 m (361 ft)

Relative Humidity : 30%

Air Intake Restriction : 254 mm H2O (10 in H2O)

Exhaust Restriction : 51 mm Hg (2 in Hg)

Steady State Stability Band at any Constant Load .............................................................................................................. %

Estimated Free Field Sound Pressure Level of a Typical Generator Set;

Excludes Exhaust Noise; at Rated Load and 7.5 m (24.6 ft); @1500 / 1800 rpm ................................................. dBA

Exhaust Noise at 1 m Horizontally from Centerline of Exhaust Pipe Outlet Upwards at 45 @1500 / 1800 rpm......... dBA

STANDBY POWER

60 hz

Governed Engine Speed ............................................................. rpm

Engine Idle Speed....................................................................... rpm

Gross Engine Power Output........................................... kWm (BHP)

Brake Mean Effective Pressure........................................... kPa (psi)

Piston Speed ................................................................ m / s (ft / min)

Friction Horsepower ....................................................... kWm (BHP)

Engine Jacket Water Flow at Stated Friction Head External to Engine:

5 psi Friction Head .......................................... litre / s (US gpm)

Maximum Friction Head.................................. litre / s (US gpm)

Engine Data with Dry Type Exhaust Manifold

Intake Air Flow ................................................................ litre / s (cfm)

Exhaust Gas Temperature ..................................................... C (F)

Exhaust Gas Flow .......................................................... litre / s (cfm)

Air to Fuel Ratio ..................................................................... air : fuel

Radiated Heat to Ambient ..................................... kWm (BTU / min)

Heat Rejection to Jacket Water Coolant............... kWm (BTU / min)

Heat Rejection to Exhaust..................................... kWm (BTU / min)

Engine Aftercooler Data

Heat Rejection to Aftercooler................................ kWm (BTU / min)

Aftercooler Water Flow at Stated Friction Head External to Engine:

2 psi Friction Head....................................... litre / s (US gpm)

Maximum Friction Head .............................. litre / s (US gpm)

Charge Air Flow....................................................... kg/ min (lb / min)

Turbocharger Compressor Outlet Pressure ........... mm Hg (in / Hg)

Turbocharger Compressor Outlet Temperature................... C (F)

1500

700 - 900

970 (1300)

2544

(369)

8.3 (1634)

58

(78)

17.0

16.5

(270)

(262)

14.2

13.7

(2840)

(975)

(7775)

25 : 1

130 (7460)

365 (20880)

740 (42130)

1005

575

2980

270 (15420)

170

(9560)

4.5

4.4

70

1534

177

(71)

(68)

(154)

(60)

(350)

1340

525

3670

5.4

5.0

93

1859

202

(85)

(80)

(205)

(73)

(395)

(225)

(217)

(2130)

(1070)

(6310)

22 : 1

115 (6410)

335 (18940)

670 (38050)

91 / 93

128 / 131

PRIME POWER

50 hz

1800

700 - 900

1112 (1490)

2427

(352)

9.9 (1949)

82

(110)

+/- 0.25

60 hz

1800

700 - 900

1007 (1350)

2199

(319)

9.9 (1949)

82

(110)

17.0

16.5

(270)

(262)

1250 (2650)

495

(920)

3285 (6960)

26.5 : 1

115 (6650)

340 (19350)

660 (37640)

215 (12120)

5.4

5.0

87

1666

183

(85)

(80)

(192)

(66)

(360)

50 hz

1500

700 - 900

880 (1180)

2310

(335)

8.3 (1634)

58

(78)

14.2

13.7

(225)

(217)

945 (2005)

565 (1050)

2750 (5820)

22.6 : 1

105 (5860)

320 (18150)

600 (33990)

145

(8240)

4.5

4.4

66

1374

165

(71)

(68)

(145)

(54)

(330)

N.A. - Data is Not Available

N/A - Not Applicable to this Engine

TBD - To Be Determined

ENGINE MODEL : QST30-G4

DATA SHEET : DS-5277

DATE : 10JAN11

S-ar putea să vă placă și

- QSK60G4Document4 paginiQSK60G4Mohamed Hamdallah100% (1)

- Diesel Generator Set N14 Series: Specification SheetDocument4 paginiDiesel Generator Set N14 Series: Specification Sheetsusmitamandali100% (1)

- Data Sheets QSL9 G5Document4 paginiData Sheets QSL9 G5Héctor VilaÎncă nu există evaluări

- Hoja de Datos QSK60G5 - fr6321Document3 paginiHoja de Datos QSK60G5 - fr6321acere18100% (1)

- Diesel Generator Set QSL9 Series Engine: Power GenerationDocument4 paginiDiesel Generator Set QSL9 Series Engine: Power Generationsdasd100% (1)

- Appendix 1b, Engine DatasheetDocument4 paginiAppendix 1b, Engine DatasheetdimasrimantiktoÎncă nu există evaluări

- Manual EA20S CaterpillarDocument3 paginiManual EA20S CaterpillarHernán Peñafiel ReaÎncă nu există evaluări

- 2806a-E18tag2 Electropak Pn1871Document2 pagini2806a-E18tag2 Electropak Pn1871Charles CallahanÎncă nu există evaluări

- N45sm1a 51 To 59KWDocument3 paginiN45sm1a 51 To 59KWsaiyedasadÎncă nu există evaluări

- Fuel Optimized: Specification SheetDocument3 paginiFuel Optimized: Specification SheetArslan AnnaÎncă nu există evaluări

- RENR7941 - CDVR SpecificationDocument4 paginiRENR7941 - CDVR SpecificationХусниддин ГаниевÎncă nu există evaluări

- Caterpillar XQ80 Towable Diesel Generator SetDocument5 paginiCaterpillar XQ80 Towable Diesel Generator SetMacAllister MachineryÎncă nu există evaluări

- 2206a-E13tag3 Electropak Pn1881Document2 pagini2206a-E13tag3 Electropak Pn1881ibrahemÎncă nu există evaluări

- Series: 973 - 1327 KWM (Gross) at 1500 RPMDocument18 paginiSeries: 973 - 1327 KWM (Gross) at 1500 RPMlahcen boudaoudÎncă nu există evaluări

- Specification Sheet (Template) CUMMINS QSL9 G5Document3 paginiSpecification Sheet (Template) CUMMINS QSL9 G5Ricardo La CruzÎncă nu există evaluări

- Cummins C55D5 Specification SheetDocument10 paginiCummins C55D5 Specification SheetilhamÎncă nu există evaluări

- Parts Engine Cummins QSL9-G3Document1 paginăParts Engine Cummins QSL9-G3Defly GustiÎncă nu există evaluări

- P45PBDocument4 paginiP45PBConstantyn_FrederikÎncă nu există evaluări

- C633a GCM PDFDocument6 paginiC633a GCM PDFibrahemÎncă nu există evaluări

- Kohler Model 45rz 45kw Natural Gas Generator SetDocument4 paginiKohler Model 45rz 45kw Natural Gas Generator SetRebecca Winfrey100% (1)

- COMAP IL-MRS11-16 Thong So Ky Thuat PDFDocument2 paginiCOMAP IL-MRS11-16 Thong So Ky Thuat PDFthanhhai31Încă nu există evaluări

- Parts Manual: Generator SetDocument90 paginiParts Manual: Generator SetZez SamuelÎncă nu există evaluări

- Perkins 4012 - 46twg2a Briz MotorsDocument18 paginiPerkins 4012 - 46twg2a Briz MotorsRafiee AdityaÎncă nu există evaluări

- (نسخة) JB-WD-DSE 6120 MKIII - 12.5-200 (1106)Document1 pagină(نسخة) JB-WD-DSE 6120 MKIII - 12.5-200 (1106)Mahmood NabilÎncă nu există evaluări

- Perkins 1103A-33G ElectropaK (PN 1780-02-05)Document2 paginiPerkins 1103A-33G ElectropaK (PN 1780-02-05)MTU650Încă nu există evaluări

- QSB5 G3Document2 paginiQSB5 G3silverlord03Încă nu există evaluări

- 1100 Series PerkinsDocument2 pagini1100 Series PerkinsGilberto Diaz CastilloÎncă nu există evaluări

- S287 Fozmula Capacitance Coolant Level Switch Data JP 24 Nov 15 3.2 Rev 2Document1 paginăS287 Fozmula Capacitance Coolant Level Switch Data JP 24 Nov 15 3.2 Rev 2Parinya0% (1)

- Battery ChargerDocument16 paginiBattery Chargerdimasrimantikto100% (2)

- Parts Catalog - Option Detail: Option Group Graphic Film Card DateDocument3 paginiParts Catalog - Option Detail: Option Group Graphic Film Card DateagvassÎncă nu există evaluări

- Kta19 G8Document4 paginiKta19 G8Yosi DarmawansyahÎncă nu există evaluări

- LT32567 PDFDocument4 paginiLT32567 PDFNikolayÎncă nu există evaluări

- Installation: Industrial/Commercial/Residential Generator SetsDocument56 paginiInstallation: Industrial/Commercial/Residential Generator Setsgearhead1Încă nu există evaluări

- Rotary Actuators For Electronic Speed Governing: B12 SeriesDocument2 paginiRotary Actuators For Electronic Speed Governing: B12 SeriesSamir Khan100% (1)

- ts300 Mosa PDFDocument50 paginits300 Mosa PDFzanioÎncă nu există evaluări

- PSG Governor With Aluminum CaseDocument98 paginiPSG Governor With Aluminum CaseNam Anh TrầnÎncă nu există evaluări

- Dse 509Document2 paginiDse 509SOSÎncă nu există evaluări

- PMB7040 C Catalog Web PDFDocument16 paginiPMB7040 C Catalog Web PDFRached Douahchua0% (1)

- SSAA-001 - Grupo Electrogeno - GENERAC - SD130Document170 paginiSSAA-001 - Grupo Electrogeno - GENERAC - SD130DanielaÎncă nu există evaluări

- C32 Generator Set With EMCP 3 Electrical System: Sxc1-Up Wdr1-UpDocument4 paginiC32 Generator Set With EMCP 3 Electrical System: Sxc1-Up Wdr1-UpJosé100% (1)

- Square D NT and NW Breaker ManualDocument240 paginiSquare D NT and NW Breaker Manualminhtutran1983Încă nu există evaluări

- Aspire Catalogue PDFDocument13 paginiAspire Catalogue PDFJose BaptistaÎncă nu există evaluări

- BF C275DDocument7 paginiBF C275DLebahMaduÎncă nu există evaluări

- PSBU-021-QSK50 - 1750 - 1825kVA-Rev-2 - 19 June 2018Document4 paginiPSBU-021-QSK50 - 1750 - 1825kVA-Rev-2 - 19 June 2018hadÎncă nu există evaluări

- Eq Generacion Electrica Iluminacion Olympian GEP150Document5 paginiEq Generacion Electrica Iluminacion Olympian GEP150Gianni EscalanteÎncă nu există evaluări

- Perkins 400 Series 403D-11Document2 paginiPerkins 400 Series 403D-11Juan henaoÎncă nu există evaluări

- C1100 D5 Technical SpecificationDocument4 paginiC1100 D5 Technical SpecificationmnezamiÎncă nu există evaluări

- QSX15-G8 XpiDocument3 paginiQSX15-G8 XpiMd ShÎncă nu există evaluări

- Perkins 1006TAGDocument2 paginiPerkins 1006TAGNathia Roa100% (1)

- MX-321Document6 paginiMX-321Akun Backup100% (1)

- AVC63-7F Voltage Regulator - Instructions - 9302800994-D - March 2012 - BASLER ELECTRIC PDFDocument4 paginiAVC63-7F Voltage Regulator - Instructions - 9302800994-D - March 2012 - BASLER ELECTRIC PDFpevareÎncă nu există evaluări

- Olympian GEP 450 PrimeDocument4 paginiOlympian GEP 450 PrimeMTU650100% (1)

- 4BT3 9-G2 PDFDocument5 pagini4BT3 9-G2 PDFNv Thái100% (1)

- 6M26 Series: Powerkit EngineDocument2 pagini6M26 Series: Powerkit EngineDuc Thao VuÎncă nu există evaluări

- Technical PG620 (Rev)Document7 paginiTechnical PG620 (Rev)W Winarto100% (1)

- MTU 18V2000 DS1250: Diesel Generator SetDocument4 paginiMTU 18V2000 DS1250: Diesel Generator SetSidali KilardjÎncă nu există evaluări

- Ea16 Manual enDocument6 paginiEa16 Manual enabuzer1981Încă nu există evaluări

- FR 5160Document6 paginiFR 5160Nicholas FryeÎncă nu există evaluări

- QSK 23 G 3 NR 1Document4 paginiQSK 23 G 3 NR 1Anonymous 3RS6JNcÎncă nu există evaluări

- Engine Performance Data at 1500 RPM: QSB 1 Cummins IncDocument4 paginiEngine Performance Data at 1500 RPM: QSB 1 Cummins IncMaged Beshara100% (3)

- Silvolite PistonesDocument114 paginiSilvolite Pistoneswilmen lunarÎncă nu există evaluări

- Major Project: Exhaust Gas Recirculation Test RigDocument18 paginiMajor Project: Exhaust Gas Recirculation Test RigvikrantÎncă nu există evaluări

- Service Guide L110F 2007-07-11Document4 paginiService Guide L110F 2007-07-11Injeletro DieselÎncă nu există evaluări

- M 33Document1 paginăM 33navneetkpatil8409Încă nu există evaluări

- MP7, MP8, and MP10 Engines For MACK VehiclesDocument39 paginiMP7, MP8, and MP10 Engines For MACK VehiclesRichard Ochoa100% (5)

- Engine Control System (6WF1-TC, 6WG1-TC (Common Rail) ) 1A-37Document320 paginiEngine Control System (6WF1-TC, 6WG1-TC (Common Rail) ) 1A-37Aung Hlaing Min Myanmar100% (4)

- Drill Quote PPC-quote Pumps Revised FEBDocument2 paginiDrill Quote PPC-quote Pumps Revised FEBHebert SozinyuÎncă nu există evaluări

- Final ExamDocument2 paginiFinal ExamFlicker LoserÎncă nu există evaluări

- Transient Thermal Analysis of Engine Exhaust ValveDocument20 paginiTransient Thermal Analysis of Engine Exhaust Valvemuki10Încă nu există evaluări

- Prado Problems 3Document23 paginiPrado Problems 3raja antony100% (1)

- Spark Plugs Cross MSDDocument6 paginiSpark Plugs Cross MSDabelcardenÎncă nu există evaluări

- 2006-2008-Cbf1000-A-19 Ignition SystemDocument8 pagini2006-2008-Cbf1000-A-19 Ignition SystemMurariu IonutÎncă nu există evaluări

- The Douvrin PRV V6 Resource CentreDocument4 paginiThe Douvrin PRV V6 Resource CentrejbouzaÎncă nu există evaluări

- Combine PDFDocument55 paginiCombine PDFDessa GuditoÎncă nu există evaluări

- ECM PINOUT Chevrolet-Sail PDFDocument2 paginiECM PINOUT Chevrolet-Sail PDFChemaria0% (1)

- Pollutant Formation in Si EnginesDocument9 paginiPollutant Formation in Si EnginesChirudeep Reddy100% (1)

- KING Parts Catalogue (Jan 2018)Document128 paginiKING Parts Catalogue (Jan 2018)sudhakarirttÎncă nu există evaluări

- Engine Selection and Project Manual E. Installation Data: RT-flex58T-BDocument8 paginiEngine Selection and Project Manual E. Installation Data: RT-flex58T-BRanjeet SinghÎncă nu există evaluări

- Automotive ServicingDocument5 paginiAutomotive ServicingLiezl SabadoÎncă nu există evaluări

- CODURIDocument4 paginiCODURIElectroventica ElectroventicaÎncă nu există evaluări

- Liebherr Hydraulic Components For Heavy Duty On Highway Engines Application Flyer Es WebDocument4 paginiLiebherr Hydraulic Components For Heavy Duty On Highway Engines Application Flyer Es WebDaniel Castillo PeñaÎncă nu există evaluări

- SM N844 N844T-NewHolland enDocument110 paginiSM N844 N844T-NewHolland enjulianmata93% (14)

- Operation Manual For WP10CD Series Marine Diesel Gen-SetDocument52 paginiOperation Manual For WP10CD Series Marine Diesel Gen-SetВячеслав100% (1)

- Cat Remanufactured On-Highway Truck EnginesDocument4 paginiCat Remanufactured On-Highway Truck EnginesSergey SlomchinskiyÎncă nu există evaluări

- 2013 VIXION 1M1PA460EA Rev PDFDocument68 pagini2013 VIXION 1M1PA460EA Rev PDFAgusNurjayaFaiz100% (1)

- 109E a067WB45 HL (T38M)Document16 pagini109E a067WB45 HL (T38M)JoséÎncă nu există evaluări

- 1KD Engine Repair Manual Section 1 (Troubleshooting) Pub. No. CE302Document298 pagini1KD Engine Repair Manual Section 1 (Troubleshooting) Pub. No. CE302ManuelÎncă nu există evaluări

- Job Description Planned Maintenance Caterpillar Diesel Engine Series CD100, Series 3200, Series 3300, Series 3400Document44 paginiJob Description Planned Maintenance Caterpillar Diesel Engine Series CD100, Series 3200, Series 3300, Series 3400apri.kartiwan100% (1)

- MPE 850 NA Installation ManualDocument61 paginiMPE 850 NA Installation Manualraqibapp100% (2)

- ISB, ISBe, ISBe4, QSB4.5, QSB5.9, and QSB6 Exhaust Manifold Installation InstructionDocument6 paginiISB, ISBe, ISBe4, QSB4.5, QSB5.9, and QSB6 Exhaust Manifold Installation Instructionmds9185Încă nu există evaluări