Documente Academic

Documente Profesional

Documente Cultură

Bosch HFM5 Sensors

Încărcat de

restinhoDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Bosch HFM5 Sensors

Încărcat de

restinhoDrepturi de autor:

Formate disponibile

56

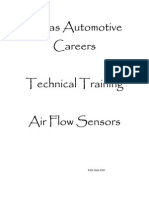

Air-mass meters

Hot-film air-mass meter, Type HFM 5

Measurement of air-mass throughflow up to 1000 kg/h Qm U b Compact design. b Low weight. b Rapid response. b Low power input. b Return-flow detection.

Application In order to comply with the vehicle emission limits demanded by law, it is necessary to maintain a given air/fuel ratio exactly. This requires sensors which precisely register the actual air-mass flow and output a corresponding electrical signal to the open and closed-loop control electronics. Design The micromechanical sensor element is located in the plug-in sensors flow passage. This plug-in sensor is suitable for incorporating in the air filter or, using a measurement venturi, in the air-intake passages. There are different sizes of measurement venturi available depending upon the air throughflow. The micromechanical measuring system uses a hybrid circuit, and by evaluating the measuring data is able to detect when return flow takes place during air-flow pulsation. Operating principle The heated sensor element in the air-mass meter dissipates heat to the incoming air. The higher the air flow, the more heat is dissipated. The resulting temperature differential is a measure for the air mass flowing past the sensor. An electronic hybrid circuit evaluates this measuring data so that the air-flow quantity can be measured precisely, and its direction of flow. Only part of the air-mass flow is registered by the sensor element. The total air mass flowing through the measuring tube is determined by means of calibration, known as the characteristic-curve definition.

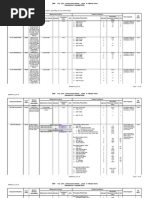

Technical data / range

Nominal supply voltage UN Supply-voltage range UV Output voltage UA Input current IV Permissible vibration acceleration Time constant 63 1) Time constant 2) Temperature range

14 V 8...17 V 0...5 V < 0.1 A 150 ms2 15 ms 30 ms 40...+120 C 3) 0 280 218 019 10...480 kg/h 3% 22 mm 20 mm 96 mm 70 mm 62 mm < 15 hPa Yes 2 0 280 217 531 12...640 kg/h 3% 22 mm 20 mm 130 mm 80 mm 71 mm < 15 hPa Yes 3 0 280 218 008 12...850 kg/h 3% 16 mm 16 mm 100 mm 86/84 mm 6) 78 mm < 15 hPa No 4 0 281 002 421 15...1000 kg/h 3% 22 mm 20 mm 130 mm 92 mm 82 mm < 15 hPa Yes 5

0 280 217 123 Part number Measuring range Qm 8...370 kg/h 3% Accuracy 4) 22 mm Fitting length LE 20 mm Fitting length LA Installation length L 96 mm Connection diam. D 60 mm 50 mm Venturi ID Pressure drop at nominal air mass 5) < 20 hPa Temperature sensor Yes 1 Version

1)

In case of sudden increase of the air-mass flow from 10 kg h1 auf 0,7 Qm nominal, time required to reach 63% of the final value of the air-mass signal. 2) Period of time in case of a throughflow jump of the air mass | m/m | 5%. 3) For a short period up to +130 C. 4) |Q /Q |: The measurement deviation Q from the exact value, referred to the measured value Q . m m m m 5) Measured between input and output 6) Inflow/outflow end

Accessories for connector

Plug housing 1 928 403 836 Contact pins Individual gaskets For conductor cross-section 1 987 280 103 1 987 280 106 0.5...1 mm2 1 987 280 105 1 987 280 107 1.5...2.5 mm2 Note: Each 5-pole plug requires 1 plug housing, 5 contact pins, and 5 individual gaskets. For automotive applications, original AMP crimping tools must be used.

Application In internal-combustion engines, this sensor is used for measuring the air-mass flow so that the injected fuel quantity can be adapted to the presently required power, to the air pressure, and to the air temperature.

Explanation of symbols

Qm Air-mass flow rate Qm Absolute accuracy Qm /Qm Relative accuracy Time until measuring error is 63

5% Time until measured-value change 63%

Air-mass meters

57

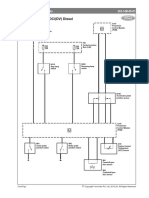

Function diagram with connector-pin assignment. 1 Additional temperature sensor u (not on version 4, Part number 0 280 218 008), 2 Supply voltage UV, 3 Signal ground, 4 Reference voltage 5 V, 5 Measurement signal UA. Temperature-dependence of the resistor, RH Heater resistor, UK Constant voltage

1

HFM 5 plug-in sensor design. 1 Measuring-passage cover, 2 Sensor, 3 Mounting plate, 4 Hybrid-circuit cover, 5 Hybrid, 6 Plug-in sensor, 7 O-ring, 8 Auxiliary temperature sensor.

u

1

2 3 UK 4

3 2 5

RH

8 7 6

Output voltage UA = f(Qm) of the air-mass meter Part number 0 280 217 123 0 280 218 019 0 280 217 531 Characteristic curve 1 2 3 Qm/kg/h UA/V UA/V UA/V 1118 1.4837 1.2390 1110 1.5819 1.3644 1.2695 1115 1.7898 1.5241 1.4060 1130 2.2739 1.8748 1.7100 1160 2.8868 2.3710 2.1563 1120 3.6255 2.9998 2.7522 1250 4.4727 3.7494 3.5070 1370 4.9406 4.1695 3.9393 1480 4.4578 4.2349 1640 4.5669 1850 1000

Air-mass meter output voltage.

0 280 218 008 4 UA/V 1.3395 1.6251 2.0109 2.5564 3.2655 3.6717 3.9490 4.2600 4.5727

0 280 002 421 5 UA/V 1.2315 1.4758 1.8310 2.3074 2.9212 3.2874 3.5461 3.8432 4.1499 4.3312

5 1 Output voltage UA 4 2 3 4 5

Temperature-dependence R = f() of the temperature sensor Temperature C 40 30 20 10 0 10 Resistance R k 39.26 22.96 13.85 8.609 5.499 3.604 Temperature C 50 60 70 80 90 100 Resistance R 835 609 452 340 261 202

Temperature-resistance diagram of the temperature sensor.

20 2.420 110 159

30 1.662 120 127

40 1.166 130 102

0 0 200 400 600 800 1000 kg/ h Air-mass flow Q m

Dimensions overview of the HFM 5. 1 Plug-in sensor, 2 Throughflow direction, 3 Measurement venturi.

1

40 k 30 Resistance R

Nominal resistance R Nom. at 25 C: 2.00 k 5 %

20

2 D 3

10

R Nom.

0 - 40

LE

LA L

-20

20

40 Temperature

60

80

100

S-ar putea să vă placă și

- Bosch MAF SensorsDocument2 paginiBosch MAF Sensorstyby3100% (1)

- Fuse Voltage Drop Chart - Cartridge Fuse PDFDocument2 paginiFuse Voltage Drop Chart - Cartridge Fuse PDFManuel GuillenÎncă nu există evaluări

- Smart Forfour 454-6Document1 paginăSmart Forfour 454-6yamegÎncă nu există evaluări

- Tomihawk Tools CatalogueDocument60 paginiTomihawk Tools CatalogueRosília DomingosÎncă nu există evaluări

- Current Flow Diagram Seats Heating VW Golf 5Document5 paginiCurrent Flow Diagram Seats Heating VW Golf 5Marius NeaguÎncă nu există evaluări

- Honda Civic OBD0 EF ECU PINOUTS - My Pro Street PDFDocument11 paginiHonda Civic OBD0 EF ECU PINOUTS - My Pro Street PDFWill ?100% (2)

- CY320 Product InfoDocument6 paginiCY320 Product InfoRogério MorenoÎncă nu există evaluări

- Map Sensor Technical SpecificationDocument13 paginiMap Sensor Technical SpecificationEdward Fisher100% (2)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentDe la EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentEvaluare: 4.5 din 5 stele4.5/5 (3)

- Westerbeke 4,5BCGTC Instruction Manual PDFDocument53 paginiWesterbeke 4,5BCGTC Instruction Manual PDFcengiz kutukcu100% (2)

- Wind LoadDocument1 paginăWind Loadvikramjain66Încă nu există evaluări

- 3.1 Turbine and GoverningDocument90 pagini3.1 Turbine and GoverningYudo Heru PribadiÎncă nu există evaluări

- Bosch Afs Maf SensorDocument4 paginiBosch Afs Maf SensorAndo Tamkõrv100% (1)

- Bosch HFM 5 Sensors - Airmass PDFDocument3 paginiBosch HFM 5 Sensors - Airmass PDFLaurentiu79Încă nu există evaluări

- SensorDocument25 paginiSensorlyndorÎncă nu există evaluări

- DTC P0420 Catalyst System Efficiency Below Threshold (Bank 1) DTC P0430 Catalyst System Efficiency Below Threshold (Bank 2)Document6 paginiDTC P0420 Catalyst System Efficiency Below Threshold (Bank 1) DTC P0430 Catalyst System Efficiency Below Threshold (Bank 2)dion132Încă nu există evaluări

- Ca18det JDM Ecu PinoutDocument1 paginăCa18det JDM Ecu PinoutMayobanex Moya Martinez100% (1)

- AEM Undocumented Settings v1Document13 paginiAEM Undocumented Settings v1Franklyn RamirezÎncă nu există evaluări

- Electricalcomponentlocations 131222071900 Phpapp02Document91 paginiElectricalcomponentlocations 131222071900 Phpapp02petcucatalinnÎncă nu există evaluări

- 2006fileaveo MTDocument63 pagini2006fileaveo MTeurospeed2100% (1)

- Hyundai Elantra 1.6 Engine Electrical1Document55 paginiHyundai Elantra 1.6 Engine Electrical1MANUALES2000CLÎncă nu există evaluări

- Das PDFDocument527 paginiDas PDFMaiChiVu100% (1)

- TMS 374Document8 paginiTMS 374alefabi2006Încă nu există evaluări

- Characteristic Map ThermostatDocument3 paginiCharacteristic Map ThermostatJhonTorresRamiresÎncă nu există evaluări

- Fgtech Boot Mode Tricore ListDocument3 paginiFgtech Boot Mode Tricore ListCarlos Garcia RodriguezÎncă nu există evaluări

- Wireless Control Module (WCM) : Group 42CDocument102 paginiWireless Control Module (WCM) : Group 42CToponari MedveÎncă nu există evaluări

- Hyundai Specific Trouble CodesDocument8 paginiHyundai Specific Trouble CodesTim GingerichÎncă nu există evaluări

- Sweeper ManualDocument10 paginiSweeper ManualGoran RajkovÎncă nu există evaluări

- Transmision Fluid Presure Nissan Sentra 2008Document2 paginiTransmision Fluid Presure Nissan Sentra 2008Brian Moreno100% (1)

- Catalyst EfficiencyDocument6 paginiCatalyst EfficiencyAlexandra Huțu100% (1)

- 2gr-Fe P0200 PDFDocument7 pagini2gr-Fe P0200 PDFhappy yuliasantiÎncă nu există evaluări

- Cielo TorqueDocument2 paginiCielo Torquemohhizbar100% (1)

- Making Sense of Air Flow SensorsDocument10 paginiMaking Sense of Air Flow SensorsWilliam KibbeÎncă nu există evaluări

- Fiat Bsi Wiring DiagramsDocument8 paginiFiat Bsi Wiring DiagramssergioradÎncă nu există evaluări

- 1.4L Ford FigoDocument21 pagini1.4L Ford FigoAmit Garg100% (1)

- Basic Equipment Wiring AGY EngineDocument20 paginiBasic Equipment Wiring AGY EnginemasterbfishÎncă nu există evaluări

- 89 ZF 1 4hp22-24Document10 pagini89 ZF 1 4hp22-24Aussi SidÎncă nu există evaluări

- Hyundai Accent 98 MFI Control SystemDocument98 paginiHyundai Accent 98 MFI Control Systemwessamalex100% (1)

- 2005 Passat 2.0 TDI - EGR - Boost Pressure IssuesDocument11 pagini2005 Passat 2.0 TDI - EGR - Boost Pressure IssuesSàLàh Cràzy LoveÎncă nu există evaluări

- Peugeot 307 1600cc E3 NfuDocument4 paginiPeugeot 307 1600cc E3 NfuZoli BorbelyÎncă nu există evaluări

- Manual AEM X SERIES WIDEBAND 30-0300Document13 paginiManual AEM X SERIES WIDEBAND 30-0300JoseÎncă nu există evaluări

- CY310 Product InfoDocument2 paginiCY310 Product InfoAnonymous xTGQYFrÎncă nu există evaluări

- Motronic 1.5 Engine Management CodesDocument9 paginiMotronic 1.5 Engine Management CodesMiloš KrnetićÎncă nu există evaluări

- Pressure Pulse Sensor OsciloscopioDocument9 paginiPressure Pulse Sensor OsciloscopioJoao Silva Lopes100% (2)

- 2008 VW JettaDocument14 pagini2008 VW Jettawhynot0567% (3)

- (AUDI) Manual de Taller Esquema Electrico Audi A6Document48 pagini(AUDI) Manual de Taller Esquema Electrico Audi A6Matt0809Încă nu există evaluări

- Gfiquickcat PDFDocument338 paginiGfiquickcat PDFAlejandro SabaÎncă nu există evaluări

- DTC P0008 or P0009: Diagnostic InstructionsDocument2 paginiDTC P0008 or P0009: Diagnostic InstructionsJose Luis Velasquez RomeroÎncă nu există evaluări

- Eprom Auto PDFDocument38 paginiEprom Auto PDFcameraman01Încă nu există evaluări

- Installation Instructions For 30-1910: Fuel Ignition Controller (F/IC)Document24 paginiInstallation Instructions For 30-1910: Fuel Ignition Controller (F/IC)Dmentall IllÎncă nu există evaluări

- Terminal and Connector InspectionDocument3 paginiTerminal and Connector InspectionLojan Coronel José HumbertoÎncă nu există evaluări

- Kia EDDocument22 paginiKia EDscrewyoureg100% (1)

- Manual de Servicio Jac j2 Ilovepdf CompressedDocument243 paginiManual de Servicio Jac j2 Ilovepdf CompressedNatalia Figueroa MamaniÎncă nu există evaluări

- Caja Automatica Optra Ingles-Libre 1Document50 paginiCaja Automatica Optra Ingles-Libre 1Plinio SuarezÎncă nu există evaluări

- ch46Document15 paginich46jose perezÎncă nu există evaluări

- Softelectronic PresentationDocument18 paginiSoftelectronic PresentationKhristina Stefanova100% (1)

- Grand Am Continental Tire Sports Integrating ECU PDFDocument31 paginiGrand Am Continental Tire Sports Integrating ECU PDFsenthilvlÎncă nu există evaluări

- Trz03te Prospekt GBDocument4 paginiTrz03te Prospekt GBMohamed El MaadawyÎncă nu există evaluări

- 14 - 684EN Rev ADocument17 pagini14 - 684EN Rev Avinodk3350% (1)

- Datasheet EE65Document2 paginiDatasheet EE65AdyMichaelÎncă nu există evaluări

- WTM 1000Document2 paginiWTM 1000Edgard HQÎncă nu există evaluări

- Compress Air DS 300-P enDocument4 paginiCompress Air DS 300-P enejaqÎncă nu există evaluări

- Vibration MonitoringDocument8 paginiVibration MonitoringKrzysiek PodsiadłoÎncă nu există evaluări

- 060-061 - ResApps - MerrinDocument2 pagini060-061 - ResApps - MerrinCarlos Luís JúniorÎncă nu există evaluări

- Aws A2.4Document118 paginiAws A2.4restinhoÎncă nu există evaluări

- 02 - Application of DoE To Diesel Calibration - MallamoDocument87 pagini02 - Application of DoE To Diesel Calibration - MallamorestinhoÎncă nu există evaluări

- 2004 01 1264Document14 pagini2004 01 1264restinhoÎncă nu există evaluări

- 03 01 SeabrookDocument24 pagini03 01 SeabrookrestinhoÎncă nu există evaluări

- Practical Engineering Failure Analysis Dekker Mechanical EngineeringDocument607 paginiPractical Engineering Failure Analysis Dekker Mechanical Engineeringsrikanthrajaram18Încă nu există evaluări

- Vedic MathematicsDocument19 paginiVedic MathematicsyogeshÎncă nu există evaluări

- BTICINO Catalog Matix PDFDocument80 paginiBTICINO Catalog Matix PDFsokolobanÎncă nu există evaluări

- 0811 IndiadxerDocument6 pagini0811 IndiadxerAlexander WieseÎncă nu există evaluări

- List of Algorithms Interview QuestionsDocument9 paginiList of Algorithms Interview QuestionsSivaselvi RÎncă nu există evaluări

- Ms For Demin Water Tank Modification Rev 1 Feb. 28 2011lastDocument9 paginiMs For Demin Water Tank Modification Rev 1 Feb. 28 2011lastsharif339100% (1)

- Industrial Visit Report OnDocument41 paginiIndustrial Visit Report OnLalit SharmaÎncă nu există evaluări

- Resume Example 102017Document2 paginiResume Example 102017CharlyÎncă nu există evaluări

- F 1069 - 87 R99 - Rjewnjk - PDFDocument6 paginiF 1069 - 87 R99 - Rjewnjk - PDFRománBarciaVazquezÎncă nu există evaluări

- Der 484Document84 paginiDer 484Rohit SainiÎncă nu există evaluări

- DWF 300Document36 paginiDWF 300Josè Ramòn Silva AvilèsÎncă nu există evaluări

- Cycle CountDocument58 paginiCycle CountPJ190275% (4)

- Doppler NavigationDocument21 paginiDoppler NavigationRe-ownRe-ve100% (3)

- HRTC RoutesDiverted Via KiratpurManali Four LaneDocument9 paginiHRTC RoutesDiverted Via KiratpurManali Four Lanepibope6477Încă nu există evaluări

- Tquins Resources Training Template For MT Work Programme SCS RevisedDocument12 paginiTquins Resources Training Template For MT Work Programme SCS RevisedLileth LagasimÎncă nu există evaluări

- PAYG Price Guide 180518Document21 paginiPAYG Price Guide 180518Jan JanÎncă nu există evaluări

- Getrag DTF BlessingDocument26 paginiGetrag DTF BlessingRafael Nakazato RecioÎncă nu există evaluări

- What Is A Bioclimatic Chart - EHowDocument2 paginiWhat Is A Bioclimatic Chart - EHowonkhgfg kjhh jghÎncă nu există evaluări

- Execution Without ExcusesDocument16 paginiExecution Without ExcusesVishnu Menon100% (1)

- Manual M810Document38 paginiManual M810romiyuddinÎncă nu există evaluări

- ME8595 SyllabusDocument1 paginăME8595 SyllabusDeepak sakthiÎncă nu există evaluări

- SimonKucher Ebook A Practical Guide To PricingDocument23 paginiSimonKucher Ebook A Practical Guide To PricingHari Krishnan100% (1)

- PSS Report206Document90 paginiPSS Report206Abhishek TiwariÎncă nu există evaluări

- 220kV Da Bac - TEL, SER, FR, FL, TN48, INV Panel Drawing - R7Document200 pagini220kV Da Bac - TEL, SER, FR, FL, TN48, INV Panel Drawing - R7Văn Ngọc NguyễnÎncă nu există evaluări

- The Sims 4 Cheats For PC: Platform. If You've DiscoveredDocument2 paginiThe Sims 4 Cheats For PC: Platform. If You've DiscoveredDean Joyce AlborotoÎncă nu există evaluări

- A Review of Error-Related Potential-Based Brain-Computer Interfaces For Motor Impaired PeopleDocument16 paginiA Review of Error-Related Potential-Based Brain-Computer Interfaces For Motor Impaired PeopleAkshay KumarÎncă nu există evaluări

- SAFMC 2023 CAT B Challenge Booklet - V14novDocument20 paginiSAFMC 2023 CAT B Challenge Booklet - V14novJarrett LokeÎncă nu există evaluări

- HCF Spec 190 1.0 PDFDocument31 paginiHCF Spec 190 1.0 PDFvikulovÎncă nu există evaluări