Documente Academic

Documente Profesional

Documente Cultură

Pre-job Safety Briefing Requirements

Încărcat de

liveconnectionz282Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pre-job Safety Briefing Requirements

Încărcat de

liveconnectionz282Drepturi de autor:

Formate disponibile

PRE-JOB BRIEFING AND SAFETY PROCEDURES

A pre-job briefing (sometimes called a tailgate meeting) is a meeting which informs all workers of the job requirements. In particular a pre-job briefing is used to alert workers to potential safety hazards. A pre-job briefing need not be a formal gathering; however, it is mandatory that all workers involved attend, and worker attendance should be documented.

What Should Be Included?

OSHA rules require that a pre-job briefing discuss, at a minimum, the following issues: Special precautions to be taken Hazards associated with the job Energy control procedures Procedures and Policies Personal Protective Equipment Note that the first letters of each of these bulleted items form the acronym SHEPP, which can be used to help remember the important issues that need to be discussed. Pre-job briefings should be proactive meetings in which workers are informally quizzed to make certain that they fully understand the safety issues that they will face.

When Should Pre-Job Briefings Be Held?

At the beginning of each shift At the beginning of any new job Any time that job conditions change When new personnel are introduced to an ongoing job

ENERGIZED OR DE-ENERGIZED?

The Fundamental Rules

All regulatory standards are quite clear in their requirements to de-energize a circuit before employees work on or near it. Stated simply: All circuits and components to which employees may be exposed should be deenergized before work begins. A few basic points will clarify this requirement: Production or loss of production is never an acceptable, sole reason to work on or near an energized circuit. Work that can be rescheduled to be done de-energized should be rescheduled. De-energized troubleshooting is always preferred over energized troubleshooting. The qualified employee doing the work, must always make the final decision as to whether the circuit is to be deenergized. Such a decision must be free of any repercussions from supervision and management.

A Hot-Work Decision Tree

1. Work performed on or near circuits of less than 50 V to ground may usually be considered to be de-energized work. Note that if the circuit has high arcing capability, decision should be answered as a Yes. 2. If de-energizing simply changes the hazard from one type to another, or if it actually increases the degree of hazard. This decision should be answered Yes. The following additional hazards that should be considered in answering this decision: Interruption of life-support systems Deactivation of emergency alarms Shutdown of ventilation to hazardous locations Removal of illumination from the work area 3. The need to keep production up is common to all industries manufacturing, petrochemical, mining, steel,

aluminum, and electrical power systems. However, many employers abuse the concept that production must continue. The following points should clarify when production issues may be allowed to influence the decision to de-energize. a. Shutdown of a continuous process that will add extraordinary collateral costs may be a signal to work on the circuit energized. b. Shutdown of a simple system which does not introduce the types of problems should always be undertaken rather than allowing energized work. 4. In some cases, the very nature of the work or the equipment requires that the circuit remain energized. The most common examples of such work are Testing electrical circuits (to verify de-energization, for example) Troubleshooting complex controls Infrared scan. Note, however that this work should still be de-energized if it is possible to do it that way. For example, troubleshooting a motor starter may be faster with the circuit energized; however, if it can be done de-energized it should be, even at the cost of a little more time. 5. If decisions 2 or 3 lead in the direction of energized work, the next decision should be rescheduling. If energized work can be done de-energized on a different shift or at a later time, it should be postponed. Many companies miss this elegantly simple alternative to exposing their personnel to hazardous electrical energy. 6. The final, and arguably the most important, decision of all is to determine whether the work can be done safely. If, in the opinion of the qualified personnel assessing the job, the work is simply too dangerous to do with the circuits energized, then it must be deenergized..

After the Decision Is Made If the work must be done energized, all employees who work on or near energized conductors must be qualified to do the work, must use appropriate personal protective equipment, and must use appropriate safety-related work practices. If the circuits are to be de-energized, the steps listed are as follows: The most basic safety procedure is to de-energize the parts of the system to which workers may be exposed. This procedure virtually eliminates the hazards of shock, arc, and blast. Deenergizing, also called clearing, involves more than simply turning the switches off. To ensure maximum safety, de-energizing procedures that are precise for each situation should be written. The following sections discuss the proper safety techniques for operation of various types of equipment and provide deenergizing and reenergizing procedures which may be used as the basis for the development of site-specific procedures. Please note that specific procedures may vary depending on the application and type of equipment. Refer to manufacturers and/or local facility procedures for specific information. The methods given in these sections should be considered minimum requirements. These procedures assume that the device is being operated when one or both sides are energized.

Caution: Switching of electric power should only be carried out by qualified personnel who are familiar with the equipment and trained to recognize and avoid the safety hazards associated with that equipment.

Non-load-interrupting devicesthat is, devices which are not intended to interrupt any currentshould never be used to interrupt current flow.

Steps Required Before De-Energized Work May Commence

1. All energy control devices feeding the work area must be opened. 2. Locks and tags shall be placed on the energy control devices. 3. Voltage measurements shall be made at the point(s) of exposure to verify that the circuit is de-energized. 4. Safety grounds (if required) shall be placed to ensure the existence of an equipotential work zone. 5. The work area must be closely inspected by a qualified person to make certain that no energized parts remain. This critical step is often missed.

S-ar putea să vă placă și

- 41 (1) In-Process Revision - 1790 - Visual Inspection of InjectionsDocument10 pagini41 (1) In-Process Revision - 1790 - Visual Inspection of InjectionsBudy WijiyantoÎncă nu există evaluări

- 1 - Fluoroscopy-36063022Document6 pagini1 - Fluoroscopy-36063022Sinta Dewi P.Încă nu există evaluări

- IPQA A Beginner's GuideDocument170 paginiIPQA A Beginner's GuideGoran MickoÎncă nu există evaluări

- Not For Sale: Biosafety Cabinetry: Design, Construction, Performance, and Field CertificationDocument24 paginiNot For Sale: Biosafety Cabinetry: Design, Construction, Performance, and Field CertificationEmiÎncă nu există evaluări

- Recovery Factor Determination in Cleaning ValidationDocument1 paginăRecovery Factor Determination in Cleaning ValidationPrince MoniÎncă nu există evaluări

- 62 The Basics of Bioburden TestingDocument2 pagini62 The Basics of Bioburden Testinghitham shehataÎncă nu există evaluări

- Ausdiagnostics High-Plex Analyser Maintenance Procedure: 1. Standard Dtprime Maintenance GuideDocument12 paginiAusdiagnostics High-Plex Analyser Maintenance Procedure: 1. Standard Dtprime Maintenance GuideJimÎncă nu există evaluări

- 2017 11 22 Guidelines GMP For AtmpsDocument90 pagini2017 11 22 Guidelines GMP For Atmpserdo mandanaÎncă nu există evaluări

- Standard Operating Protocol (HPLC)Document7 paginiStandard Operating Protocol (HPLC)Sandhy TampubolonÎncă nu există evaluări

- A History of The OOS ProblemDocument5 paginiA History of The OOS ProblemmcyqcbsacÎncă nu există evaluări

- USP Seminar - Fundamentals of Bioassay Practices 2014 PDFDocument140 paginiUSP Seminar - Fundamentals of Bioassay Practices 2014 PDFnsk79in@gmail.comÎncă nu există evaluări

- Bilgisayarlı SistemlerDocument14 paginiBilgisayarlı Sistemlerttugce29Încă nu există evaluări

- Global Perspectives in Cleaning ValidationDocument17 paginiGlobal Perspectives in Cleaning ValidationYusuf SalahamanaÎncă nu există evaluări

- AIHce Pharma Forum Quality Risk-MaPP Implications - EditedDocument28 paginiAIHce Pharma Forum Quality Risk-MaPP Implications - EditedipliprensÎncă nu există evaluări

- Guide To AutoclavingDocument12 paginiGuide To AutoclavingAndrew TurnerÎncă nu există evaluări

- Validation of Viral Clearance: S K Patel College of Pharmaceutical Education & Research Ganpat UniversityDocument24 paginiValidation of Viral Clearance: S K Patel College of Pharmaceutical Education & Research Ganpat UniversitynirmalpharmaÎncă nu există evaluări

- Validating Lims in A GMP Environment: HowtoDocument30 paginiValidating Lims in A GMP Environment: HowtoBoza0204Încă nu există evaluări

- Quality Assurance in LaboratoriesDocument36 paginiQuality Assurance in LaboratoriesGeli CruzÎncă nu există evaluări

- GLP Study PlanDocument45 paginiGLP Study PlanashishmathewÎncă nu există evaluări

- Altekar Giacoletti NA17CESEP1 Process Validation Statistical Tool Overvi...Document31 paginiAltekar Giacoletti NA17CESEP1 Process Validation Statistical Tool Overvi...Haroon RasheedÎncă nu există evaluări

- LAL Test - Lonza - 00190169 - enDocument20 paginiLAL Test - Lonza - 00190169 - enPaolo PiccoliniÎncă nu există evaluări

- Bioproc PDFDocument6 paginiBioproc PDFSrijit KhanÎncă nu există evaluări

- WP Gmp-En AnshDocument12 paginiWP Gmp-En AnshFelix ShihÎncă nu există evaluări

- Usp 1116 Microbiological Control and Monitoring of Aseptic Processing EnvironmentsDocument29 paginiUsp 1116 Microbiological Control and Monitoring of Aseptic Processing Environmentsdiogo100% (1)

- CPK Guide 0211 TECH1Document11 paginiCPK Guide 0211 TECH1Mark LacroÎncă nu există evaluări

- Maintenance QualificationDocument5 paginiMaintenance QualificationqlfangÎncă nu există evaluări

- Reprocessing Biotech ProductsDocument14 paginiReprocessing Biotech ProductsawadsonÎncă nu există evaluări

- Lentiviral Vector System For Gene TransferDocument164 paginiLentiviral Vector System For Gene TransferAlfredoÎncă nu există evaluări

- IyerpptDocument35 paginiIyerpptVioleta Grigoras100% (1)

- Metrology and Calibration in GLPDocument30 paginiMetrology and Calibration in GLPNicolas Quero Carvajal100% (1)

- G OwningDocument6 paginiG Owningk.p.100% (1)

- 0108 - Change Managament Enabling Quality - Doyle - P10 - FINALDocument14 pagini0108 - Change Managament Enabling Quality - Doyle - P10 - FINALCesar Rodolfo Angulo DelgadoÎncă nu există evaluări

- Whythe10 ppmCriterionShouldBeAbandonedDocument5 paginiWhythe10 ppmCriterionShouldBeAbandonedMuhammad AsifÎncă nu există evaluări

- Process Validation From An FDA Perspective - Part 2Document4 paginiProcess Validation From An FDA Perspective - Part 2Darren Tan100% (1)

- Introduction To SCDA SystemsDocument21 paginiIntroduction To SCDA SystemsHabiyaremye JosephÎncă nu există evaluări

- Human Factors in Process Safety - Preventing Errors & Improving ResponseDocument33 paginiHuman Factors in Process Safety - Preventing Errors & Improving ResponseborrowmanaÎncă nu există evaluări

- Scale Down Biopharma - EIB 2013 PDFDocument17 paginiScale Down Biopharma - EIB 2013 PDFGeetanjali HubliÎncă nu există evaluări

- Tier 1 CVSDocument23 paginiTier 1 CVSCHETHAN K SÎncă nu există evaluări

- Protocol PQDX 241 v4 Capillary BloodDocument18 paginiProtocol PQDX 241 v4 Capillary Bloodludi100% (1)

- Disinfectant QualificationDocument10 paginiDisinfectant QualificationfarÎncă nu există evaluări

- BPSA 2014 Recommendations For Testing, Evaluation, and Control of Particulates From Single-Use Process EquipmentDocument28 paginiBPSA 2014 Recommendations For Testing, Evaluation, and Control of Particulates From Single-Use Process EquipmentbioÎncă nu există evaluări

- Analytical Quality by Design Concise Review On Approach To Enhanced Analytical Method DevelopmentDocument4 paginiAnalytical Quality by Design Concise Review On Approach To Enhanced Analytical Method DevelopmentEditor IJTSRDÎncă nu există evaluări

- Amendment 1: Replacement of 3Kl Uf Storage Tank & Installation of New 500 Ltr. Brine TankDocument8 paginiAmendment 1: Replacement of 3Kl Uf Storage Tank & Installation of New 500 Ltr. Brine TankprakashÎncă nu există evaluări

- Performance Qualification Report For Syringe Assembling Machine. Machine Identification Name: - Protocol NoDocument3 paginiPerformance Qualification Report For Syringe Assembling Machine. Machine Identification Name: - Protocol NoMusyoka UrbanusÎncă nu există evaluări

- Lecture 11 - QAQCDocument36 paginiLecture 11 - QAQCTMTÎncă nu există evaluări

- Validation of Analytical ProceduresDocument15 paginiValidation of Analytical ProceduresildamonalisaÎncă nu există evaluări

- Shadle PresentationDocument23 paginiShadle Presentationsherri_dobroskay4430100% (1)

- Microbiology Product Catalog EU enDocument94 paginiMicrobiology Product Catalog EU enArifin R HidayatÎncă nu există evaluări

- Good Laboratory PracticesDocument16 paginiGood Laboratory PracticesMerlin DineshÎncă nu există evaluări

- BPOG's ProtocolDocument11 paginiBPOG's ProtocolRadha Krishna B VÎncă nu există evaluări

- En Do Toxin CatalogDocument17 paginiEn Do Toxin CatalogmarronyyyÎncă nu există evaluări

- LabX Bro eDocument12 paginiLabX Bro eWalter BurtonÎncă nu există evaluări

- Project Engineering Under ASTM E2500: Presentation ObjectiveDocument28 paginiProject Engineering Under ASTM E2500: Presentation ObjectiveBiopharma0% (1)

- ObjectionableDocument9 paginiObjectionabledmtalbhogeÎncă nu există evaluări

- Environmental Monitoring Incubation Conditions - JustificationDocument4 paginiEnvironmental Monitoring Incubation Conditions - Justificationveerreddy_157808Încă nu există evaluări

- Sample Size CalculationDocument6 paginiSample Size CalculationYohanes HailuÎncă nu există evaluări

- Data Integrity and Compliance: A Primer for Medical Product ManufacturersDe la EverandData Integrity and Compliance: A Primer for Medical Product ManufacturersÎncă nu există evaluări

- Nonclinical Safety Assessment: A Guide to International Pharmaceutical RegulationsDe la EverandNonclinical Safety Assessment: A Guide to International Pharmaceutical RegulationsWilliam J. BrockÎncă nu există evaluări

- Lessons From AccidentsDocument4 paginiLessons From Accidentsliveconnectionz282Încă nu există evaluări

- Indian Electricty Rules For General SafetyDocument6 paginiIndian Electricty Rules For General Safetyliveconnectionz282Încă nu există evaluări

- Indian Electricty Rules For General SafetyDocument6 paginiIndian Electricty Rules For General Safetyliveconnectionz282Încă nu există evaluări

- Machine Guarding PrinciplesDocument5 paginiMachine Guarding Principlesliveconnectionz282Încă nu există evaluări

- Olfactiory Physiology Issue 1Document16 paginiOlfactiory Physiology Issue 1liveconnectionz282Încă nu există evaluări

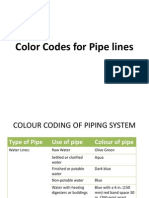

- A Color Codes For Pipe Lines ANSIDocument24 paginiA Color Codes For Pipe Lines ANSIliveconnectionz282Încă nu există evaluări

- A Guide To Personal Protective EquipmentDocument28 paginiA Guide To Personal Protective Equipmentliveconnectionz282Încă nu există evaluări

- Indian Electricty Rules For General SafetyDocument6 paginiIndian Electricty Rules For General Safetyliveconnectionz282Încă nu există evaluări

- Indian Electricty Rules For General SafetyDocument6 paginiIndian Electricty Rules For General Safetyliveconnectionz282Încă nu există evaluări

- KSRCT Mock-Drill Report on Fire EvacuationDocument1 paginăKSRCT Mock-Drill Report on Fire Evacuationliveconnectionz282100% (1)

- Safestoragefertilizers enDocument2 paginiSafestoragefertilizers enliveconnectionz282Încă nu există evaluări

- Worker Engagement Case StudiesDocument3 paginiWorker Engagement Case Studiesliveconnectionz282Încă nu există evaluări

- Hazardous Chemicals RulesDocument58 paginiHazardous Chemicals RulessyamiocÎncă nu există evaluări

- Olfactory - The Science of Smell Issue 2 PDFDocument4 paginiOlfactory - The Science of Smell Issue 2 PDFliveconnectionz282Încă nu există evaluări

- Olfactory. The Science of Smell Issue 3Document4 paginiOlfactory. The Science of Smell Issue 3liveconnectionz282Încă nu există evaluări

- Deadly Explosion at Phillips 66 Chemical Plant in 1989Document13 paginiDeadly Explosion at Phillips 66 Chemical Plant in 1989liveconnectionz282Încă nu există evaluări

- 000 - A Pipeline Isolation Before Line BreakingDocument35 pagini000 - A Pipeline Isolation Before Line Breakingliveconnectionz282Încă nu există evaluări

- L P G Part 1-Safety-LPG Short Course-5-05-Rev1Document18 paginiL P G Part 1-Safety-LPG Short Course-5-05-Rev1liveconnectionz282Încă nu există evaluări

- 000-Providing Information To The CommunityDocument16 pagini000-Providing Information To The Communityliveconnectionz282Încă nu există evaluări

- Olfactory - The Science of Smell Issue 2 PDFDocument4 paginiOlfactory - The Science of Smell Issue 2 PDFliveconnectionz282Încă nu există evaluări

- Safe Flare System Design: John Zink CompanyDocument10 paginiSafe Flare System Design: John Zink CompanyAniket S Jadhav100% (3)

- Hazard and Isolation SchemeDocument23 paginiHazard and Isolation SchemeHoney TiwariÎncă nu există evaluări

- 005-Oxygenates and The Cautionary TaleDocument62 pagini005-Oxygenates and The Cautionary Taleliveconnectionz282Încă nu există evaluări

- Pressure Testing SafetyDocument4 paginiPressure Testing Safetyapi-26143956100% (2)

- The Neurophysiology of PainDocument11 paginiThe Neurophysiology of Painliveconnectionz282Încă nu există evaluări

- Worker Engagement Case StudiesDocument3 paginiWorker Engagement Case Studiesliveconnectionz282Încă nu există evaluări

- Preventing Sulphur Fires and ExplosionsDocument40 paginiPreventing Sulphur Fires and Explosionsliveconnectionz2820% (1)

- Safe Work Procedures in Tea PlantationsDocument5 paginiSafe Work Procedures in Tea Plantationsliveconnectionz282Încă nu există evaluări

- Ws Job Safety Assessment 11Document8 paginiWs Job Safety Assessment 11liveconnectionz282Încă nu există evaluări

- Constitutional Policies & Principles on Labor ScopeDocument4 paginiConstitutional Policies & Principles on Labor ScopeOmar sarmientoÎncă nu există evaluări

- Operation Management, PT Unilever IndonesiaDocument12 paginiOperation Management, PT Unilever IndonesiaFani Putri100% (3)

- Chapter 1Document50 paginiChapter 1CharleneKronstedtÎncă nu există evaluări

- REPORT - MBA Operation - Prathap A RDocument119 paginiREPORT - MBA Operation - Prathap A RBhavani B S PoojaÎncă nu există evaluări

- Recruitment and SelectionDocument44 paginiRecruitment and SelectionRahmatullah PashtoonÎncă nu există evaluări

- Case 3:09 CV 01494 MODocument13 paginiCase 3:09 CV 01494 MOAnonymous HiNeTxLMÎncă nu există evaluări

- Developing A Data-Driven Mindset For HRDocument26 paginiDeveloping A Data-Driven Mindset For HRSpencer FuÎncă nu există evaluări

- Architectural Associate Job - Schiller Engineering Ltd. - Mississauga, ONDocument2 paginiArchitectural Associate Job - Schiller Engineering Ltd. - Mississauga, ONming_zhu10Încă nu există evaluări

- Introduction To Career ManagementDocument15 paginiIntroduction To Career ManagementhafsamaryamÎncă nu există evaluări

- Zamoras vs Su Labor DisputeDocument1 paginăZamoras vs Su Labor DisputeChe Poblete CardenasÎncă nu există evaluări

- Mba Case Analysis - Wong Loh CaseDocument4 paginiMba Case Analysis - Wong Loh CaseMhild GandawaliÎncă nu există evaluări

- Women in Mauritius informal sector survival analysisDocument16 paginiWomen in Mauritius informal sector survival analysisNadia SalsabillaÎncă nu există evaluări

- Mediation Workshop Dispute ResolutionDocument11 paginiMediation Workshop Dispute ResolutionVikramjeet SinghÎncă nu există evaluări

- TeleworkingDocument18 paginiTeleworkingMaria Valero100% (2)

- Case Study FedEx GROUP 22Document6 paginiCase Study FedEx GROUP 22Engel QuimsonÎncă nu există evaluări

- The Differences BetweenDocument30 paginiThe Differences BetweenKissinger DzanieÎncă nu există evaluări

- MillerDocument1.125 paginiMillerJames BowmanÎncă nu există evaluări

- McDonalds Job Application Form 2008-10-17Document2 paginiMcDonalds Job Application Form 2008-10-17Michael GregoryÎncă nu există evaluări

- PolicyRenewal 0000000006381920-01Document37 paginiPolicyRenewal 0000000006381920-01Hemant TiwariÎncă nu există evaluări

- ART. 94. Right To Holiday Pay.-: Than Ten (10) WorkersDocument7 paginiART. 94. Right To Holiday Pay.-: Than Ten (10) WorkersMaribel Nicole LopezÎncă nu există evaluări

- A Summer Internship Report: Submitted byDocument58 paginiA Summer Internship Report: Submitted byKeyur KevadiyaÎncă nu există evaluări

- Compensation Meaning, Significance and ImportanceDocument5 paginiCompensation Meaning, Significance and ImportanceAshok Kumar DhallÎncă nu există evaluări

- Module 2 Project Gap Analysis Strategy For Team #3Document20 paginiModule 2 Project Gap Analysis Strategy For Team #3Mary A. Dillard100% (2)

- FAC215 Elements of Cost - LabourDocument28 paginiFAC215 Elements of Cost - LabourdishaparmarÎncă nu există evaluări

- 52 Safety Manager Interview Questions With Answers PDFDocument77 pagini52 Safety Manager Interview Questions With Answers PDFTonmay MajumderÎncă nu există evaluări

- Workplace Diversity: Emerging Issues in Contemporary ReviewsDocument11 paginiWorkplace Diversity: Emerging Issues in Contemporary ReviewsLA LA LA LA LA MiniÎncă nu există evaluări

- 3 Form BDocument45 pagini3 Form BDevÎncă nu există evaluări

- ICMM Good Practice On HIV-TB-MalariaDocument158 paginiICMM Good Practice On HIV-TB-MalariaShalom NdikuÎncă nu există evaluări

- Management Project 2019Document16 paginiManagement Project 2019Sàąď ŘōmèôöÎncă nu există evaluări

- Human Resources (HR) Standard of Operating Procedures 9-2016Document23 paginiHuman Resources (HR) Standard of Operating Procedures 9-2016rani100% (1)