Documente Academic

Documente Profesional

Documente Cultură

Kalkulasi Steam Trap MFO Rev 00

Încărcat de

Rifka AisyahDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Kalkulasi Steam Trap MFO Rev 00

Încărcat de

Rifka AisyahDrepturi de autor:

Formate disponibile

Asumsi 1.

Kebutuhan steam yang dihitung adalah steam untuk meningkat temperature ke temperatur maintenance dan steam yang dibutuhkan u 2. Penurunan temperatur sehingga mengharuskan pemanasan adalah 5 C 3. Volume oil yang dipanaskan diasumsikan 155 m3 yang merupakan volume maksimal tangki

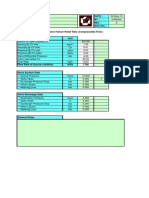

Kalkulasi Kebutuhan Steam per Tangki MFO

Initial T Final T Heating time Maintain T Wind velocity Ambient T Diameter Height h Tank manhole Volume oil Delta T Faktor 60 65 5 65 10.08 6.25 27.4 81.32 6.8 6.04 1.7 20 0.508 155 5 1 C C hr C km/h mph C F m m m in m m3 K

Data

Cp, MFO Densitas MFO Pressure Steam Latent heat 2.09 kJ/kg K 988.8 kg/m3 8 bar 2768.3 kJ/kg 873 Btu/lb

Basic Data Calculation

Tank capacity Weight of fluid in tank Average liquid temperature Tank wall area Tank roof area 219 m3 153266 kg 62.5 144.5 129 1387 41 437 C F m2 ft2 m2 ft2

Heat up Load

Heat up load 320,326 kJ/hr 305,072 Btu/hr

Tank wall heat loss

Tank wall heat loss Wind velocity correction Insulation thickness 120 Btu/hr/ft2 2 1 in

Insulation thickness correction Wall heat loss

0.20 66,181 Btu/hr

Tank roof heat loss

Tank roof heat loss rate Tank roof heat loss 60 Btu/hr/ft2 10,413 Btu/hr

Total heat load

Total heat load 381,666 Btu/hr

Steam Consumption

Maximum steam consumption Maintenance steam consumption 437 lb/hr 197 kg/hr

88 lb/hr 39 kg/hr

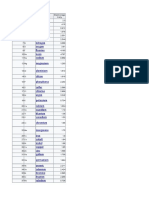

Maximum steam consumption for two tanks Maintenance steam consumption for two tanks

393.47 kg/hr

78.96 kg/hr

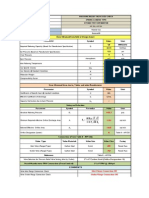

Maximum steam consumption as the function of volume of oil in the tank

Max steam consumption (lb/hr) Oil weight (kg) Heat up load (Btu/hr) Total heat load (Btu/hr) 4,944 9,841 86,435 99.01 9,888 19,682 96,276 110.28 19,776 39,364 115,958 132.83 39,552 78,728 155,323 177.92 59,329 118,092 194,687 223.01 79,105 157,457 234,051 268.10 98,881 196,821 273,415 313.19 118,657 236,185 312,779 358.28 138,434 275,549 352,143 403.37 158,210 314,913 391,507 448.46

Oil volume (m3) 5 10 20 40 60 80 100 120 140 160

Kebutuhan steam satu tangki 450 400 si steam (kg/hr) 350

Kebutuhan steam dua tangki

Asumsi: - Peningkatan temperatur 5 C - Waktu pemanasan 5 jam

Konsumsi steam (kg/hr)

350 300 250 200 150 100 50 0 30 60 90 120 150 180 Volume MFO yang akan dipanaskan (m3)

intenance dan steam yang dibutuhkan untuk meningkatkan temperatur mula-mula 155 m3 fuel oil

Max steam Max steam consumption for consumption (kg/hr) two tanks (kg/hr) 44.55 89.11 49.63 99.25 59.77 119.54 80.06 160.13 100.35 200.71 120.64 241.29 140.94 281.87 161.23 322.45 181.52 363.03 201.81 403.62

1.2 1 0.8 0.6 0.4 0.2 0 0

0.2

0.4

0.6

0.8

1.2

Basic Sizing Step

I. Inlet and Outlet Pressure Condition of the trap

Inlet Pressure Maximum pressure in steam line supply Inlet pressure to control valve Pressure drop in coil Outlet pressure from control valve to coil Pressure drop in coil Inlet pressure to steam trap Outlet Pressure Outlet pressure Differential Pressure Differential pressure 7.990 barg 115.86 psig 0 barg Atmospheric tank system-gravity drainage (see Equipment Type 1, Class A)

10 barg 8.000 barg 0.005 barg 7.995 barg 0.005 barg 7.990 barg

II. Condensate Load Calculation

Asumsi Pemanasan dalam tangki diasumsikan hanya disebabkan oleh heat loss dari tangki karena pengaruh lingkungan Heat loss Tank wall heat loss Tank roof heat loss Total tank heat loss Condensate load Condensate load 87.74 lb/hr 39.48 kg/hr 66,181.43 Btu/hr 10,412.93 Btu/hr 76,594.36 Btu/hr

III. Safety factor

Safety factor 3 see matrix

IV. Desired Trap Capacity

Desired trap capacity each tank

118.44 kg/hr

V. Available Steam Trap Capacity

See graphic below Discharge capacity Discharge capacity 350 kg/hr 3300 kg/hr (Hot condensate near steam temperature) (Cold water 21 C)

7.99 psig

116 psig

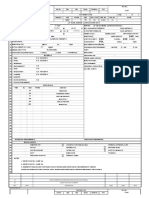

VI. Selection Criteria

Mechanical First level criteria Safety Efficiency Service life Second level criteria Ease of checking P P P Thermostatic P P P Thermodynamic P P P

Sensitivity to backpressure Resistance to freeze damage Dirt sensitivity Some models can be installed successfully in horizontal or vertical line

Tend to decline in efficiency as backpressure exceed 50% of the inlet pressure

Installation versatility

Mechanical traps do not easily lend themselves to flexibility of use

Air venting

Pass air very quicly Must first cool slightly before they can open wider to pass a greater amount of condensate Bimetallic thermostatic generally are very rugged Bellows thermostatic trap will fail either open or closed (depending on the design of bellows)

Some models can be installed successfully in horizontal or vertical line Thermodynamic disc trap and bucket trap release air much more slowlyy

Responsiveness to changing load

Very responsive The closed-float are fragile and damage-prone

Very responsive

Resistance to shock vibration and water hammer

Generally are very rugged

Predominant failure mode

Thermodynamic and bimetal trap fail open when they are worn out Cyclic thermodynamic disc and bucket trap are easier to check for proper maintenance and better at passing dirt particles Most thermodynamic trap follows saturation curve closely

Discharge mode

Condensate discharge temperature relative to saturation curve

Magniture of condensate subcooling Ease of maintenance Supplementing accessories or features Third level criteria Product availability Post-sales service Warranty Price

pheric tank system-gravity drainage quipment Type 1, Class A)

ari tangki karena pengaruh lingkungan

ondensate near steam temperature)

350

Note When properly sized and installed When properly sized and installed When properly sized and installed

The faster the air is vented, the more quickly equipment is brought up to temperature

A trap that fails open is more desirable than one that fails closed in order to preserve the process

Continuous draining float trap is especially responsive to rapidly changing condensate loads and does not contribute to pressure surges in return system

A trap with little subcooling will discharge condensate within 2-3 degrees of steam temperature, while a trap with large subcooling will discharge condensate with 30 or more degree F of steam temperature. It is desirable to discharge condensate as soon as it forms to achieve steady temperature control

S-ar putea să vă placă și

- Pump Powered Cocaine Extraction PDFDocument43 paginiPump Powered Cocaine Extraction PDFDaria SchkaÎncă nu există evaluări

- Fire Relief Dynamic StudyDocument2 paginiFire Relief Dynamic StudyImtinan MohsinÎncă nu există evaluări

- Emulsion Polymerization and Latex ApplicationsDocument158 paginiEmulsion Polymerization and Latex ApplicationsGemunu Wilson75% (4)

- PSV Calculation and PhilosophyDocument33 paginiPSV Calculation and PhilosophysbmmlaÎncă nu există evaluări

- Tank Pressure Vacuum ReliefDocument1 paginăTank Pressure Vacuum ReliefalmadhagiÎncă nu există evaluări

- Tank 2.0Document7 paginiTank 2.0Candra SuryaÎncă nu există evaluări

- Ppgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Document10 paginiPpgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Tifano KhristiyantoÎncă nu există evaluări

- Heat Exchanger Specification Sheet: MM M? M? Performance of One UnitDocument9 paginiHeat Exchanger Specification Sheet: MM M? M? Performance of One UnitGladys ZiSing LeeÎncă nu există evaluări

- API STD 2000-2009, Calculation For Max. Flow Rates For Normal InbreathingDocument2 paginiAPI STD 2000-2009, Calculation For Max. Flow Rates For Normal InbreathingFendy ShirahÎncă nu există evaluări

- Flare Stack Sizing CalculationDocument2 paginiFlare Stack Sizing CalculationSumit BudhiaÎncă nu există evaluări

- Equivalent Length of Pipe FittingsDocument2 paginiEquivalent Length of Pipe FittingsJitheesh Sahadevan100% (1)

- Emergency Vent Flam LiquidsDocument3 paginiEmergency Vent Flam LiquidsSharon LambertÎncă nu există evaluări

- Vertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010Document16 paginiVertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010jnmanivannanÎncă nu există evaluări

- XSteam Excel v2.6 USDocument12 paginiXSteam Excel v2.6 USOnkarabile MatomeÎncă nu există evaluări

- Tank Pressure & Vacuum ReliefDocument12 paginiTank Pressure & Vacuum ReliefsachinumaryeÎncă nu există evaluări

- Control Valve Failure Relief Rate - Gas ServiceDocument3 paginiControl Valve Failure Relief Rate - Gas ServiceSaeid Rahimi Mofrad100% (1)

- Tank Venting Requirements (API 2000) 2Document3 paginiTank Venting Requirements (API 2000) 2RubensBoerngenÎncă nu există evaluări

- Fundamentals of Safety Relief Valves in Ammonia Refrigeration SystemsDocument3 paginiFundamentals of Safety Relief Valves in Ammonia Refrigeration SystemsBehnam AshouriÎncă nu există evaluări

- IA Compressor & SystemDocument51 paginiIA Compressor & SystemKazi Irfan100% (1)

- Demister DatasheetDocument1 paginăDemister Datasheetdeion29Încă nu există evaluări

- Relief Valve Sizing - FireDocument2 paginiRelief Valve Sizing - Firevlcmstne04Încă nu există evaluări

- Fgas Refrigerant CalculatorDocument10 paginiFgas Refrigerant CalculatorKumar sssssÎncă nu există evaluări

- Calculation Sheet For Pump Hydraulic (Fps Unit)Document1 paginăCalculation Sheet For Pump Hydraulic (Fps Unit)chemical todiÎncă nu există evaluări

- Storage Tank Heat Loss Calcs - 28.09.2009Document10 paginiStorage Tank Heat Loss Calcs - 28.09.2009siva kumarÎncă nu există evaluări

- WS-CA-PR-024 - Atmospheric & Low Preesure Tank VentingDocument4 paginiWS-CA-PR-024 - Atmospheric & Low Preesure Tank Ventinghhvg100% (1)

- Fire Heat Flux To Unwetted Vessels For Depressuring CalculationsDocument4 paginiFire Heat Flux To Unwetted Vessels For Depressuring Calculationsuetian729Încă nu există evaluări

- Tank Emergency VentingDocument1 paginăTank Emergency VentingSaeid Rahimi MofradÎncă nu există evaluări

- Coil in Agitated Vessel SizingDocument8 paginiCoil in Agitated Vessel Sizingankur2061Încă nu există evaluări

- Reciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsDocument9 paginiReciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsSlim Toumi0% (1)

- PSV D-103Document24 paginiPSV D-103DIANTOROÎncă nu există evaluări

- Ambient Heat Loss From A VesselDocument3 paginiAmbient Heat Loss From A VesselJaveed KhanÎncă nu există evaluări

- Pressure Relief Valve Sizing and Selection CheckDocument2 paginiPressure Relief Valve Sizing and Selection CheckGiftObionochieÎncă nu există evaluări

- Open TankDocument27 paginiOpen Tankhgagselim2012Încă nu există evaluări

- Condenser & EvaporatorDocument21 paginiCondenser & EvaporatorfitratulqadriÎncă nu există evaluări

- 521 TiDocument4 pagini521 Tisa.somaÎncă nu există evaluări

- Design of Sprinklered Shopping Centre Buildings For Fire SafetyDocument42 paginiDesign of Sprinklered Shopping Centre Buildings For Fire SafetyZyron BatacÎncă nu există evaluări

- Heating Coil Sizing For Fuel Oil TankDocument2 paginiHeating Coil Sizing For Fuel Oil TankPouria Sabbagh100% (1)

- Heat Loss Through TankDocument56 paginiHeat Loss Through Tankinamdar_sameerÎncă nu există evaluări

- NPSHa Calculation SpreadsheetDocument3 paginiNPSHa Calculation Spreadsheetprasad durgaÎncă nu există evaluări

- Tank FixturesDocument21 paginiTank FixturesASSSSSSSSSSSSÎncă nu există evaluări

- Propane Storage TankDocument1 paginăPropane Storage TankMarakanaMaheshÎncă nu există evaluări

- Separators SizingDocument16 paginiSeparators SizingRonald GeorgeÎncă nu există evaluări

- Chemical & Process Technology - Requirements of SDV Bypass Pressurization Line PDFDocument4 paginiChemical & Process Technology - Requirements of SDV Bypass Pressurization Line PDFvenkatrangan2003100% (1)

- Edo-cal-me-gnr-Int-xxx-014-216-244-Rev.a-heating Coil and Suction Heater Calculatin Report For Crude Oil Storage TankDocument13 paginiEdo-cal-me-gnr-Int-xxx-014-216-244-Rev.a-heating Coil and Suction Heater Calculatin Report For Crude Oil Storage TankErol DAĞÎncă nu există evaluări

- Flare SystemDocument60 paginiFlare Systemmmairaja100% (1)

- Main Oxidation Number of Common ElementsDocument2 paginiMain Oxidation Number of Common Elementsvanerie manumbale100% (1)

- N2 Regulator and Gauges DatasheetDocument4 paginiN2 Regulator and Gauges DatasheetpavanÎncă nu există evaluări

- Colum Specification SheetDocument6 paginiColum Specification SheetEddy RainÎncă nu există evaluări

- Spreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2Document26 paginiSpreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2venkatesh801Încă nu există evaluări

- Basco IBC Catalog 2013Document16 paginiBasco IBC Catalog 2013Mario BarbarićÎncă nu există evaluări

- Pressure Vacuum Breather ValvesDocument4 paginiPressure Vacuum Breather ValvesAdhitya DarmadiÎncă nu există evaluări

- 367 Steam Tracing GuidelinesDocument1 pagină367 Steam Tracing Guidelineslink2u_007Încă nu există evaluări

- TEMA SheetDocument2 paginiTEMA SheetFrancisco RenteriaÎncă nu există evaluări

- Valve Sizing SelectionDocument15 paginiValve Sizing SelectionbariÎncă nu există evaluări

- Liquid Overfeed Systems by R. P. ParanjpeyDocument15 paginiLiquid Overfeed Systems by R. P. Paranjpeyurp30234Încă nu există evaluări

- Calculating Expansion TanksDocument4 paginiCalculating Expansion TanksanescuveronicaÎncă nu există evaluări

- Bundwall SampleDocument1 paginăBundwall Samplewawen03Încă nu există evaluări

- Final Energy Balance-Vizag DT 9-6-18Document6 paginiFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYÎncă nu există evaluări

- InputCOIL PDFDocument9 paginiInputCOIL PDFneelÎncă nu există evaluări

- BDVDocument3 paginiBDVJason ThomasÎncă nu există evaluări

- Specification Sheet: Case I Case Ii Operating ConditionsDocument1 paginăSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarÎncă nu există evaluări

- 9.1 Overview: 9 Wiped Film EvaporatorDocument12 pagini9.1 Overview: 9 Wiped Film EvaporatorNoman AslamÎncă nu există evaluări

- Handbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28De la EverandHandbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28Încă nu există evaluări

- Get To Know ChlorellaDocument2 paginiGet To Know ChlorellaRifka AisyahÎncă nu există evaluări

- Alternative Cell Disruption For Chlorella Vulgaris To Get OilDocument1 paginăAlternative Cell Disruption For Chlorella Vulgaris To Get OilRifka AisyahÎncă nu există evaluări

- Flocculation Using PH Increase ProcedureDocument3 paginiFlocculation Using PH Increase ProcedureRifka AisyahÎncă nu există evaluări

- The Potential For Using Bubble Modification Chemicals in DAF For Algae RemovalDocument19 paginiThe Potential For Using Bubble Modification Chemicals in DAF For Algae RemovalRifka AisyahÎncă nu există evaluări

- Comprehensive Strategies For Effective Brain Drug DeliveryDocument13 paginiComprehensive Strategies For Effective Brain Drug DeliveryRifka AisyahÎncă nu există evaluări

- GGG50 PDFDocument2 paginiGGG50 PDFGeorge_Wabag_2014Încă nu există evaluări

- Adiabatic Temperature Rise ConstantDocument3 paginiAdiabatic Temperature Rise ConstantNamik HadziibrahimovicÎncă nu există evaluări

- Lightning and Thunder: Lightining From Cloud To EarthDocument4 paginiLightning and Thunder: Lightining From Cloud To EarthJahnavi PatilÎncă nu există evaluări

- Lab Manual BiochemDocument8 paginiLab Manual BiochemFazreen DzulkafliÎncă nu există evaluări

- Heavy Metal Removal From Water Using Moringa Oleifera Seed Coagulant and Double FiltrationDocument4 paginiHeavy Metal Removal From Water Using Moringa Oleifera Seed Coagulant and Double FiltrationAena RabonzaÎncă nu există evaluări

- TE Connectivity Raychem S01 03 R DatasheetDocument7 paginiTE Connectivity Raychem S01 03 R DatasheetРоман ДяченкоÎncă nu există evaluări

- Gerflor Maintenance Instruction LVT 2018 GBDocument2 paginiGerflor Maintenance Instruction LVT 2018 GBcorzeaÎncă nu există evaluări

- Organic Chemistry - Some Basic Principles and Techniques NEET Study Materials Download PDFDocument10 paginiOrganic Chemistry - Some Basic Principles and Techniques NEET Study Materials Download PDFbrovinsbrovinÎncă nu există evaluări

- LebensmittelDocument582 paginiLebensmittelmaria budiÎncă nu există evaluări

- Organic ChemistryDocument10 paginiOrganic ChemistryAshutosh paniÎncă nu există evaluări

- Curtis Petroleum Reservoir Fluid PropertiesDocument6 paginiCurtis Petroleum Reservoir Fluid Propertiesbenjamin kenyeryÎncă nu există evaluări

- Synergistic Effect of NaCl and SO2 On The Initial Atmospheric Corrosion of Zinc Under Wet-Dry Cyclic ConditionsDocument17 paginiSynergistic Effect of NaCl and SO2 On The Initial Atmospheric Corrosion of Zinc Under Wet-Dry Cyclic ConditionsNaci BolcaÎncă nu există evaluări

- Studying The Performance of Pongamia Biodiesel by Using Nano Partical Fuel AdditivesDocument6 paginiStudying The Performance of Pongamia Biodiesel by Using Nano Partical Fuel Additivessemi1919Încă nu există evaluări

- G200Document4 paginiG200Gul Hassan Akhunzada100% (2)

- Cad WeldDocument24 paginiCad WeldNick JimÎncă nu există evaluări

- Electronegativity (Allen Scale)Document2 paginiElectronegativity (Allen Scale)YourMotherÎncă nu există evaluări

- Jahangirabad Instiute of Technology Barabanki Department of Mechanical EngineeringDocument23 paginiJahangirabad Instiute of Technology Barabanki Department of Mechanical EngineeringMuhammad ImranÎncă nu există evaluări

- The Top 10 Reasons Why You Shall Pick Tupperware Nano Water Filtration SystemDocument12 paginiThe Top 10 Reasons Why You Shall Pick Tupperware Nano Water Filtration Systemsyahmi1337Încă nu există evaluări

- Experiment 3 - Thermal ConductivityDocument9 paginiExperiment 3 - Thermal ConductivitySaniha Aysha AjithÎncă nu există evaluări

- Aspen Exchanger Design and Rating Shell & Tube V9Document1 paginăAspen Exchanger Design and Rating Shell & Tube V9MAYANK AGRAWALÎncă nu există evaluări

- Rak 4.1Document14 paginiRak 4.1Apotik Karya SehatÎncă nu există evaluări

- Dental AmalgamDocument73 paginiDental AmalgamProstho JCSeminarÎncă nu există evaluări

- Masteremaco 2525pdfDocument2 paginiMasteremaco 2525pdfapi-283891975Încă nu există evaluări

- CL 305 Vector Differential Operations, Momentum TransportDocument10 paginiCL 305 Vector Differential Operations, Momentum TransportshubhamÎncă nu există evaluări

- GRG - Spec Data-1 Rev 4-7-11Document1 paginăGRG - Spec Data-1 Rev 4-7-11Chandru MohanÎncă nu există evaluări

- GE ES Module4Document9 paginiGE ES Module4EnzuÎncă nu există evaluări