Documente Academic

Documente Profesional

Documente Cultură

Method Study

Încărcat de

Akshay ShekharDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Method Study

Încărcat de

Akshay ShekharDrepturi de autor:

Formate disponibile

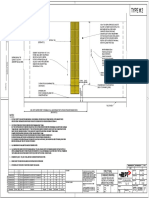

FLOW PROCESS CHART CHART NO.

1 SUBJECT CHARTED:

WORKER/ SHEET NO.1 OF 1

MATERIAL/ SUMMARY

EQUIPMENT TYPE PRESENT PROPOSED SAVINGS

ACTIVITY: SERVICING OF TWO WHEELER METHOD: PRESENT/PROPOSED LOCATION: AUTOMARK SERVICE CENTRE OPERATIVE(S): CHARTED BY: APPROVED BY: DESCRIPTION Collect keys and take the vehicle inside Load the vehicle on the platform and and lift it up Open the oil cork and collect oil in a container Open the air filter cabinet Wash the air filter Clean the cabinet Fit the air filter Close the air filter cabinet Open the battery cabinet Clean the cabinet Open 4 screws Take grease placed at a distance of 4 steps and apply grease Tightening of screws Close the battery cabinet Check the working of brake Check the oil level Check the slagness of chain Open the bottom case of chain Put kerosene on the chain Clean kerosene on the chain with a cloth Put grease on the chain Take bottom case outside for cleaning Wash the bottom case Fit the case properly Check the working of horn Close the oil cork Fill the oil container from the storage tank Fill the oil tank of vehicle from the container Do oiling of various parts of vehicle Supervise the vehicle and check whether everything is in the working condition Wash the vehicle and place it for drying DATE: DATE: QUANTITY(mL)

ACTIVITY OPERATION TRANSPORT DELAY INSPECTION STORAGE DISTANCE (ft) TIME (WORK- MIN) COST LABOUR MATERIAL TOTAL DISTANCE (steps) TIME (SEC) O 70 25 195 45 80 70 10 50 5 20 20 90 20 5 10 5 10 40 25 30 65 60 45 35 75 25 90 15 50 205 900

SYMBOL D

REMARK S 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour

800

800 800

DELAY REASONS: 1. Searching for vehicle after taking the keys 2. Tools not placed in the alloted location hence searching for tools 3. Lubricants like grease, oil etc. kept at a distance hence walk to take them

FLOW PROCESS CHART CHART NO.1 SUBJECT CHARTED:

SHEET NO.1

OF 1

ACTIVITY: SERVICING OF TWO WHEELER METHOD: PRESENT/PROPOSED LOCATION: AUTOMARK SERVICE CENTRE OPERATIVE(S): CHARTED BY: APPROVED BY: DESCRIPTION DATE: DATE: QUANTITY(m DISTANC L) E (steps)

Collect keys and take the vehicle inside Load the vehicle on the platform and and lift it up Open the oil cork and collect oil in a container Open the air filter cabinet Wash the air filter Clean the cabinet Fit the air filter Close the air filter cabinet Open the battery cabinet Clean the cabinet Open 4 screws

800

Take grease placed at a distance of 4 steps and apply grease Tightening of screws Close the battery cabinet Check the working of brake Check the oil level Check the slagness of chain

Open the bottom case of chain Put kerosene on the chain Clean kerosene on the chain with a cloth Put grease on the chain Take bottom case outside for cleaning Wash the bottom case Fit the case properly Check the working of horn Close the oil cork

Fill the oil container from the storage tank Fill the oil tank of vehicle from the container Do oiling of various parts of vehicle Supervise the vehicle and check whether everything is in the working condition Wash the vehicle and place it for drying

800 800

WORKER/ MATERIAL/ EQUIPMENT TYPE SUMMARY ACTIVITY PRESENT OPERATION TRANSPORT DELAY INSPECTION STORAGE DISTANCE (ft) TIME (WORK- MIN) 39.83 COST LABOUR MATERIAL TOTAL TIME (SEC) O SYMBOL D

PROPOSED

SAVINGS

37.83

REMARKS If the keys and parking area are given a number code then searching 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour Container of grease could be placed at each and every station 1 labour 1 labour 1 labour 1 labour 1 labour Tools to be placed at every station instead of searching at every station 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour 1 labour

45 25 200 45 80 70 10 50 5 20 20

75 20 5 10 5 10

10 25 30 65 60 45 30 75 25

40 15 50 205 900

Oil could be refilled by another employee time to time instead of the operator working refilling it 1 labour 1 labour 1 labour 1 labour

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- 2014 PLTB Present Guide PDFDocument125 pagini2014 PLTB Present Guide PDFPato Patiño MuñozÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- TDW PIGG SpecificationsDocument157 paginiTDW PIGG SpecificationsKhwanas LuqmanÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Tutorial SIDRADocument23 paginiTutorial SIDRAAstri Natalia SitumorangÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- MSS 1304 Shaft Sinking - Ventilation Pipe InstallationDocument4 paginiMSS 1304 Shaft Sinking - Ventilation Pipe InstallationPabsepulvÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- STD - S0066-Footpath Up To Kerb Line Greater Than 2400mm wideRevFDocument1 paginăSTD - S0066-Footpath Up To Kerb Line Greater Than 2400mm wideRevFdarren dmuscat1hotmail.comÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Parts News - Unicorn (KSPF)Document16 paginiParts News - Unicorn (KSPF)Jonatan Arango60% (5)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Wingspan HLL Stanchion Instruction Manual - enDocument8 paginiWingspan HLL Stanchion Instruction Manual - enmarkeduardÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- IndexDocument10 paginiIndexvictorbirlanÎncă nu există evaluări

- UttarakhandDocument2 paginiUttarakhandfaisal begÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- USPS OIG Management Advisory - Benchmarking Mail Distribution To CarriersDocument15 paginiUSPS OIG Management Advisory - Benchmarking Mail Distribution To CarriersbsheehanÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Clark SM 555 Service ManualDocument20 paginiClark SM 555 Service ManualTimothy100% (52)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Operation ManualDocument611 paginiOperation ManualchristopherÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- LithiumSafe Battery Bag - BrochureDocument8 paginiLithiumSafe Battery Bag - BrochureAnonymous cKIDzVp8GPÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Airline Leader - Issue 35 PDFDocument76 paginiAirline Leader - Issue 35 PDFRuben HoyosÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- 2012 Traverse Owner's ManualDocument450 pagini2012 Traverse Owner's Manual9495dodgeÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- UTP Module 1Document82 paginiUTP Module 1Bhargavi SÎncă nu există evaluări

- QRF HD785-5Document2 paginiQRF HD785-5Ralf MaurerÎncă nu există evaluări

- Audi TT (8J) 2006: Installation Manual Double DIN Kit 381320-19 / 391320-19Document2 paginiAudi TT (8J) 2006: Installation Manual Double DIN Kit 381320-19 / 391320-19Daniel AdebayoÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Pentagon & Boeing 757 Ground Effect: - Question From EricDocument10 paginiPentagon & Boeing 757 Ground Effect: - Question From Ericbalu119Încă nu există evaluări

- Self Propelled Scissor LiftDocument10 paginiSelf Propelled Scissor LiftDIBNESH PANDITAÎncă nu există evaluări

- Vwunlli 8 PP 2 S 69 Niim 8Document415 paginiVwunlli 8 PP 2 S 69 Niim 8viper_oneÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Layout and Design Techniques of Cross Section For The Large Immersed Tunnel PDFDocument8 paginiLayout and Design Techniques of Cross Section For The Large Immersed Tunnel PDFSEDIMÎncă nu există evaluări

- AstroStart ManualDocument21 paginiAstroStart Manuallcfiner10Încă nu există evaluări

- Transport TTMC 303Document88 paginiTransport TTMC 303Zane 19531Încă nu există evaluări

- Jeepney Phaseout (Affirmative Side) (Necessary)Document1 paginăJeepney Phaseout (Affirmative Side) (Necessary)clarence calamiongÎncă nu există evaluări

- 2018 Index of Military Strength Naval DomainDocument15 pagini2018 Index of Military Strength Naval DomainThe Heritage Foundation100% (2)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- TicketDocument2 paginiTicketSiva KumarÎncă nu există evaluări

- Jettty DesignDocument14 paginiJettty DesignNnamani ajÎncă nu există evaluări

- Drive Axle and Defferentials Institutional AssessmentDocument5 paginiDrive Axle and Defferentials Institutional AssessmentMarion ObongÎncă nu există evaluări

- Land Transportation Safety Recommended Practice: Guidance Note 6Document12 paginiLand Transportation Safety Recommended Practice: Guidance Note 6Pravin GowardunÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)