Documente Academic

Documente Profesional

Documente Cultură

Outline Naomi

Încărcat de

Alieza Del SocorroDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Outline Naomi

Încărcat de

Alieza Del SocorroDrepturi de autor:

Formate disponibile

FORMULATION AND EVALUATION OF NUTRIENT SOLUTION DERIVED FROM FERMENTED Sargassum muticum FOR HYDROPONICS LETTUCE (Lactuca sativa

L.) PRODUCTION1/

1/A thesis outline presented in partial fulfillment of the requirements graduation of the degree of Bachelor of Science in Chemistry, College of Arts Sciences, Visayas State University, Visca, Baybay City, Leyte. Prepared in Department of Pure And Applied Chemistry (DoPAC) under the guidance supervision of Dr. Felix M. Salas.

for and the and

NAOMI LEEH LUZARES POBADORA

CHAPTER I INTRODUCTION

Nature and Importance of the Study Nowadays, farmers are faced with the problem of where to plant their crops. Some farmers do not have their own land. They are only adapting the tenancy system. They till the soil plant the crops and let them grow but are only given a share of the fruit of their labour. So those farmers who wish to commercialize the crops they grow cannot do so. One way of resolving this problem is through hydroponics. Hydroponics simply means growing plant without soil. All the essential nutrients for the plants are called hydroponic nutrients which are dissolved in water and directly absorbed by the plant. Thus, the farmers who do not have their own land can produce crops for commercial purposes. The crops can be grown in their backyard or in places where in-ground agriculture or gardening is not possible. In general, hydroponic gardens

require only about 20% of the overall space required of soil gardens for the same vegetable production (http://www.hydroponicvegetablegardening.com). Moreover,

hydroponics provides less worry on the amount of water because the water stays in the system and can be reused. Due to the controlled system, no nutrition pollution is released into the environment. Another advantage of hydroponics gardening is that it preserves the quality of the soil. It minimizes if not totally eliminate the damage done by soil gardening. Hydroponics gardening involves a natural farming practice because it promotes high productivity and high profitability with lower labour requirements and a minimum negative impact on the environment. This type of gardening contributes to the realization of sustainable agriculture for small farmers. One of the foreseen problems in hydroponics is the expensive nutrient solution available in the market which is not affordable to the farmers. One way of solving this problem is the utilization of the seaweed, Sargassum muticum, as alternative nutrient solution on hydroponic plants. Sargassum muticum is a seaweed species abundant in the coastal areas of the Philippines. It usually grows near the shore lines at a rapid rate. In this study, organic solution will be formulated and compared to the commercial hydroponic solution. Fermented Sargassum muticum will be used as organic solution and lettuce as hydroponic plant. Lettuce is a green leafy vegetable of high nutritional value. Being high in nutritional value, it offers a number of health benefits. It is also a high value crop plant which is relatively easy to grow.

Objectives of the study This study will be conducted with the following objectives: 1. To determine the amount of nitrogen, phosphorus, potassium, sulfur, calcium, and magnesium in the fermented Sargassum muticum; 2. To formulate a nutrient solution derived from fermented Sargassum muticum based on its nutrient analyses and in reference to the commercial hydroponic solution; and 3. To evaluate the applicability of the formulated nutrient solution for lettuce production.

Scope and Limitation of the Study This study will be limited to the analysis of nitrogen, phosphorus, potassium, sulfur, calcium, and magnesium. The formulation of nutrient solution will be based on the chemical analysis of the fermented Sargassum muticum and that of the commercial nutrient solution (hydrosol) for hydroponics system. Appropriate inorganic salts will also be added based on the difference between the nutrient analysis of Sargassum muticumand that of the hydrosol.

Time and Place of Study The chemical analyses will be conducted at the Department of Pure and Applied Chemistry (DoPAC) of the Visayas State University Visca, Baybay City, Leyte. The evaluation of the nutrient solution will be done at the Department of Horticulture of the Visayas State University form June 1, 2012 to December 30, 2013.

CHAPTER II REVIEW OF LITERATURE

Hydroponics Vegetable Production Hydroponics is the art and science of growing crops in soilless medium. Instead of soil, water enables the transport of nutrients necessary for the development of the crops because the nutrients are concentrated in water solutions\, the crops are provided with the best environmental conditions. The plants receive maximum feeding of nutrient elements in a well-balanced range and in turn produce crops of excellent quality in terms of flavour and palatability of fruits. The introduction of hydroponics dates back to the mid-1930. Since then there has been many advances made in soil less cultivation. The technique has been applied to a number of crops including wheat, potato, tomato, cabbage, pechay, lettuce and many others. In Japan, hydroponics was introduced by the US Army after the World War II and upon increase in vegetable injury from microorganisms in the soil

(http://www.mayhillpress.com/ideal.html) Hydroponic lettuce has become popular since consumers are becoming more concerned about where these crops are grown. Field grown lettuce pose problems to the food service industry because of the high labor cost in removing dirt with grit in the plant. By growing lettuce in NFT (Nutrient Film Technique) hydroponic system, these problems are eliminated (http://www.cropking .com/NFT_Lettuce_Herbs.shtml).

Compared to NFT, SNAP hydroponics system is simpler and more budget-friendly. This

type of hydroponics system is commonly used in small scale production for household consumption. This only uses discarded household items. Lettuce production often makes use of grow enhancers for bigger yields and better crops. These enhancers provide plants with essential B vitamins which stimulate plant growth. Grow enhancers are also often packed with seaweed or kelp extract which contain plant hormones that encourages plant growth

(http://hydroponiclettuce.blogspot.com/).

Applicability of Sargassum muticum as Nutrient Solution Sargassum is a species of brown seaweeds growing abundantly in coastal areas (see Figure 1). This species is considered a nuisance because it clogs the intake pipes of boats, produce offensive smells when rotten and cause loss in amenity and recreational use of water areas. Dense growth of Sargassum also affects species diversity of indigenous marine fauna and flora in shallow subtidal regions this

(http://www.issg.org/database/species/ecology.asp?si=727&fr=1&sts).

However,

otherwise considered nuisance offers a number of uses. In Japan, it is added to soups and fermented with other soy sauce ingredients to create specific flavour. It is also home to some sea creatures and serves as their source of food. In some regions, it is collected as fertilizer (http://www.wisegeek.com/what-is-sargassum.htm)

Figure 1. Sargassum muticum (http://www.google.com.ph/imgres?imgurl=http://www.seaweed.ie/_images/) History dates the use of seaweeds, specially the large brown seaweeds, by coastal people to fertilize their lands. In Brittany (France), farmers regularly collect brown seaweeds to fertilize their fields. In Cornwall (United Kingdom), they mix the seaweed with sand, let it rot and then dig it in. In Puerto Madry (Argentina), green seaweeds are composted and used in trials for growing tomato plants. Because brown seaweeds are most readily available in large quantities, they are usually used as basis in seaweed meal drying. Seaweed meals provide approximately equivalent amount of nitrogen, less phosphorus but more potassium, total salts and readily available micronutrients compared to most animal manures (http://www.soeagra.com/abr/vol2/5.pdf). A company in Ireland that produces milled seaweed for the alginate industry is developing applications for seaweed meal in Mediterranean fruits and vegetable cultivation. Species of Ascophyllum, Ecklonia, and Fucus are commonly used as soil additives. Because of their large amounts of insoluble carbohydrates and the trace amounts of elements they contain, they function

as both fertilizer and soil conditioner. An example of a commercially available dried seaweed sold as a fertilizer is Afrikelp. It is based on the brown seaweed Eckloni maxima (http://www.fao.org/docrep/006/y4765e/y4765e0c.htm).

Chemical Analysis of Sargassum Besides water, plants obtain inorganic substances from the soil essential for metabolism. These substances exist as ions and are absorbed by plants. Salts of phosphorus (P), potassium (K), nitrogen (N), sulfur (S), calcium (Ca), iron (Fe), Magnesium (Mg), together with carbon (C), hydrogen (H), and oxygen (O) are the 10 essential nutrients required by plants for maximum growth. Other elements such as boron (B), copper (Cu), manganese (Mn), molybdenum (Mo), zinc (Zn), and sodium (Na) are also needed by plants but only in minute amounts. Hence, they are called trace elements or microelements (Hill, et al., 1967) In the elemental analysis of Sargassum species conducted by Marin, et al. (2001) at La Paz, Baja California Sur, Mexico, sargassum was analysed for nitrogen to calculate protein content. It was found to have 6.3 0.04 % crude protein. Other analyses for essential plant elements with their corresponding values are listed as follows: K-15.9 0.06 mg/g, P-2.7 0.07 mg/g, Mg-7.54 0.07 mg/g, Ca-6.41 0.094 mg/g, Fe-263 9.65 ppm, Zn-1195.41 ppm, Cu-14 0.29 ppm (http://www.ots.ac.cr/

tropiweb.attachments/volumes/vol574/30-Marin-Sargassum.pdf). The details of the nutrients analyzed are shown in Table 1.

Table 1. Analysis of Sargassum spp. (http://www.ots.ac.cr/tropiweb.attachments/volumes/vol574/30-MarinSargassum.pdf)

nutrient moisture crudeprotein ether extract crude fiber Ash GE NDF ADF cellulose Mg K Na Ca P Fe Zn Cu Pb Se Hg tannic acid concentration

7.70.06 % 6.30.04 % 0.450.03 % 6.40.08 % 33.30.11 % 2.130.02 kcal/g 47.10.42 % 44.50.35 % 6.20.37 % 7.540.07 mg/g 15.90.06 mg/g 28.70.16 mg/g 6.410.094 mg/g 2.70.07 mg/g 2639.65 ppm 1195.41 ppm 1195.41 ppm 180.02 ppm 850.13 ppb 1810.26 ppb 220.53 mg/g

CHAPTER III MATERIALS AND METHODS

Collection and Preparation of Sample Sargassum muticum will be collected from the shores of Baranggay Libjo, Merida, Leyte. The collected samples will be washed with tap water. After washing, one kilogram sample will be added with three liters of water and will be boiled for three minutes. Samples will be placed in a clean container after boiling and will be added with one kilogram mascovado to provide a good source of nutrients for the bacteria that will aide in the fermentation process. The container will be covered with cheese cloth to allow air to pass through while preventing the entry of insects. The samples will then be fermented for a month. The fermented sample will be filtered with cheese cloth prior to chemical analysis.

Chemical Analyses

Nitrogen Analysis A modified Kjeldahl method will be used to determine the total nitrogen consisting of organic and ammonium forms. Wet digestion method will be applied. Sulfuric acid will be utilized to digest organic matter of the fermented Sargassum muticum. The sample will be digested for three hours. Details of the digestion process are presented in Appendix 1.Sulfuric acid will convert organic matter to ammonium sulfate in the process. The solution will be made basic prior to distillation of ammonia. The

distilled ammonium sulfate will be received in boric acid and will be titrated with a standard acid (Black, 1965). The details of the procedure and calculation are shown in Appendix 2.

Phosphorus Analysis Appendix 1 lists the details of the digestion of the sample with aqua regia prior to analysis of phosphorus using UV-VIS spectrophotometer. The clear solution from the digest will be determined according to Murphy and Rileys (1962) method. Details of the procedure are presented in Appendix 3.

Sulfur Analysis Sulfur as a sulfate ion will be determined using the turbidimetric method. The sample will first be digested with nitric acid (as in Appendix 1) to convert the organic sulfur to sulfate ion. Sulfate ion will be reacted with barium ion to form a turbid suspension of insoluble barium sulfate. The scattering of light caused by this suspension will indicate the presence of sulfate ion in the sample. Procedure will be based on Chauddry and Cornfield (1966) as shown in Appendix 4.

Calcium, Potassium, and Magnesium Analysis Calcium, potassium and magnesium will be determined using Atomic Absorption Spectrometer (AAS). The sample will be digested with aqua regia as shown in Appendix 1. The clear solution that will be obtained will be subjected to Atomic Absorption Spectrometric analysis according to Murphy and Rileys (1962) method shown in Appendix 5.

Formulation and Application of Nutrient Solution The nutrient solution will be formulated by adding inorganic salts of predetermined amounts to the filtrate that will be obtained from the fermented Sargassum muticum sample solution. The calculated amount of inorganic salts will be added to obtain a nutrient solution chemically of the same nutrient composition as the standard nutrient solution for hydroponics as shown in Table 2. Table 2. Chemical Analysis of Commercial Hydrosol nutrient Solution (Poliquit, 2010) nutrient nitrogen phosphorus potassium calcium sulfur magnesium iron manganese zinc copper boron molybdenum total concentration 215.00 37.00 218.00 152.00 54.00 42.00 4.08 0.96 0.48 0.36 0.036 0.012 723.93

The

inorganic

salts (

to

be )

added

will

be (

computed )

using

the

formula

X in the equation represents the required element. The weight of inorganic salt will be calculated from the difference obtained. This will be done using the formula:

Formulation will be based on the commercial hydrosol solution. The final concentration of the nutrient will be calculated with the formula: ( ) ( )

Set-up of SNAP hydroponics system The technology of Simple Nutrient Addition Program (SNAP) system for hydroponics developed by Santos and Ocampo (2002) and is presently adopted by the Department of Horticulture will be utilized because of its simplicity. The technique makes use of discarded Styrofoam fruit boxes as container of nutrient solution and coco coir dust for anchorage (Robin, 2008; Poliquit, 2010). The SNAP hydroponics system is of great help to farmers who do not have their own land. They could grow the crops in their backyard or in areas where soil for growing crops is inadequate. It would be easier to protect the crops from heavy rain and strong sunlight. The system will need covered containers that can hold about 2 litres of water, SNAP fertilizer, and seeds of chosen heat-tolerant vegetables as shown in Figure 1. Empty styropor fruit boxes will be used to hold approximately 2 litres of corresponding nutrient solution. These will be lined with plastic acetate. Holes (2-3 cm) in diameter will be provided in the cover of the styropor box for ventilation. Additional holes will be made to hold the styropor cups which will contain the lettuce seedlings as in Figure 2.

Figure 2. SNAP hydroponics setup (http://www.google.com.ph/imgres?q=SNAP+hydroponics+setup) The styropor cups (6 ounces) will hold the lettuce seedlings in place. Holes will be provided at the bottom of the cups and a screen net will be used to cover the holes. The styropor cups will be half-filled with coco coir dust (Figure 3).

Figure 3. Seedling plug (http://www.google.com.ph/imgres?q=seedling+plugs) The bottom of the cups will be immersed in the nutrient solution while the roots have not yet developed. Upon development of the roots, the solution will be maintained at 2-4 cm between the bottom of the cups and the top of the solution. Nutrient delivery will be maintained at about 9 litres of the solution as prepared and will be poured onto the

styropor fruit boxes. This may vary, however, depending on the size of the styropor fruit boxes and the number of plants grown. Four litres of nutrient solution will be replenished every two weeks depending on the availability of nutrient solution.

Horticultural Characteristics of Hydroponically Grown Lettuce The following horticultural data will be gathered: 1. Plant height (cm). This will be determined by measuring the height of the plant from the base up to the tip of the longest leaf. 2. Number of leaves. This will be determined by counting the number of leaves per plant every week. 3. Leaf length (cm). This will be determined by getting the average length of the leaves of the lettuce plant from the base up to its apex. 4. Leaf width (cm). This will be determined by taking the average width of the leaves of the lettuce plant. 5. Leaf area index (cm2). The area of the leaf will be determined using the formula; Leaf area index = length x width x 0.75 (correction factor) 6. Yield (g/plant). This will be determined by multiplying the leaves and stem parts of the plant using a digital weighing scale.

Experimental Design and Statistical Analysis A Completely Randomized Design (CRD) will be used for this study. Analysis of variance (ANOVA) will help compare the significance among treatments. Each treatment

will be tested and compared. Lettuce will be used as test plants. Six lettuce plants will be planted for each treatment and will be grown hydroponically. The following are the treatments that will be used to evaluate the applicability of nutrient solution derived from fermented Sargassum muticum for hydroponics lettuce production. T1= Commercial solution (positive control) T2 = tap water (negative control) T3 = ferments from Sargassum muticum T4 = formulated nutrient solution Treatment means will be compared using the analysis of variance for CRD and Least Significant Difference (LSD) test.

LITERATURE CITED

BLACK, C.A. (ed). 1965. Methods of Soil Analysis. Part 2. Chemical and Microbiological Properties. American Society of Agronomy Monograph No. 9. Madison, Winconsin. 1572pp. CHAUDDRY, I.A. and A.H. CORNFIELD.1966. The Determination of Total Sulfur in Soil and Plant Material. Analyst. 91:528-530. HILL, J. B. et al.,1967. Botany A Textbook for Colleges. McGraw-Hill, Inc. pp. 136-137 MURPHY, J. and J.P. RILEY. 1962. A Modified Single Solution for the Determination of Phosphate ion in the Natural Water. Analytical Chemistry. Ad. 27:31-36. POLIQUIT, P.M. 2010. Formulation and Evaluation of Nutrient Solution Derived from Fermented Fish Entrails for Hydroponics Lettuce Production. Unpublished Undergraduate Thesis. pp ROBIN, N.A. 2008. Formulation and Evaluation of Nutrient Solution Derived from Fermented Tomato for Hydroponics Pechay Production. Unpublished Undergraduate Thesis. pp14-15. http://www.cropking .com/NFT_Lettuce_Herbs.shtml http://www.fao.org/docrep/006/y4765e/y4765e0c.htm http://www.hydroponiclettuce.blogspot.com/ http://www.hydroponicvegetablegardening.com http://www.issg.org/database/species/ecology.asp?si=727&fr=1&sts http://www.mayhillpress.com/ideal.html http://www.ots.ac.cr/tropiweb.attachments/volumes/vol574/30-Marin-Sargassum.pdf http://www.soeagra.com/abr/vol2/5.pdf http://www.wisegeek.com/what-is-sargassum.htm

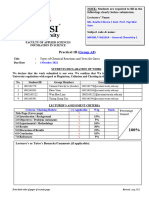

BUDGETARY REQUIREMENTS

Items Conc. HCL Conc.HNO3 Boric Acid Bromcresol green Methyl red Ethanol NaOH K2SO4 Anhydrous CuSO4 Conc. H2SO4 NH4-molybdate Ascorbic acid soln KSb-Tartrate Air pump Styrofoam box Miscellaneous TOTAL

Quantity 500 mL 100 mL 200 g 1g 1g 200 mL 500 g 100 g 10 g 500 mL 20 mL 50 mL 10 mL 1pc. 6 pcs.

Unit Cost (Php) 750/1L 1250/1L 729/250g 925/5g 475/25g 1250/500mL 1872/1kg 860/250g 475/100g 815/1L 3800/1L 1078/450 mL 1408/500 mL 330/pc. 20/pc.

Cost(Php) 375.00 125.00 685.00 6.50 46.72 250.00 650.00 410.00 9.50 200.00 76.00 120.00 28.16 330.00 120.00 2000.00 6196.36

Prepared by:

NAOMI LEEH L. POBADORA

Appendix 1: Wet acid digestion of the fermented Sargassum muticum

Reagents Concentrated hydrochloric acid Concentrated nitric acid

Procedure 1. Measure 1 ml of fermented Sargassum muticum sample and place in a 100 ml beaker. 2. Add 10 ml concentrated hydrochloric acid. 3. Heat gently over hot plate for about 30 minutes. 4. Add 5 ml concentrated nitric acid. 5. Cool the solution when 5 to 10 ml remains in the beaker. 6. Transfer the solution to 100 ml volumetric flask and dilute to the mark with deionized water. 7. Collect filtrate. 8. Store in appropriate container. 9. Label properly.

Appendix 2: Determination of total nitrogen (Black, 1965)

Reagents 1. Boric acid indicator solution. Place 160 g of pure boric acid in a 5-L bottle marked to indicate a volume of 4-L. Add about 3800 ml of water and swirl the flask until the boric acid id dissolved. Add 80 ml of mixed indicator solution which can be prepared by dissolving 0.099 g of bromcresol and 0.066 g of methyl red in 100 ml ethanol. Then add 0.1g sodium hydroxide continuously until the solution assumes a reddish purple tint (pH ca. 5.0) and make the solution 4 L by adding water. Mix the solution thoroughly before use. This is a 4% boric acid solution. 2. Salt mixture. Mix thoroughly 100 g potassium sulfate, 10g anhydrous copper sulfate and 1 g salt mixture. 3. Weigh 400 g of 40% technical sodium hydroxide (4 N) and dissolve to 1 L distilled water in 1 L volumetric flask. 4. Concentrated sulfuric acid. 5. Sulfuric acid or hydrochloric acid, standard, 0.1 N.

Procedure A. Digestion 1. Measure 1 ml of fermented Sargassum muticum solution. 2. Add 1 g of salt mixture. 3. Add 5 ml of 6 M sulfuric acid.

4. Digest the sample. Regulate the heating so that the sulfuric acid condenses about one third of the way up the neck of the flask. The flask is rotated at intervals to facilitate the digestion of the sample. When the sample no longer contains carbonaceous materials as indicated by the disappearance of the blackish color, stop the digestion. 5. Allow the flask to cool. B. Distillation 1. To determine the ammonium-N liberated by digestion, place a 250 ml Erlenmeyer flak containing 25 ml of the 4% boric acid indicator solution under the condenser of the distillation set-up so that the end of the condenser is below the surface of the boric acid solution. 2. old the distillation flas at a 45 angle and pour 125 ml of 10 N sodium hydroxide down the neck so that the alkali reaches the bottom of the flask without mixing the digest. 3. Attach the flask as quickly as possible to the distillation set-up, mix the contents thoroughly by swirling and immediately start the distillation. Regulate the heating to prevent suc -bac of boric acid and to minimi e frothing or bumping during distillation. Chec if the flow of cold water

through the condenser is sufficient to eep the temperature of the distillation about 35 C. 4. When about 50 ml of distillate have been collected, lower the receiver flask so that the end of the condenser is above the surface of the distillate.

5. After rinsing the end of the condenser with distilled water, remove the flask and stop distillation. 6. Determine the ammonium-N on the distillate by titration with 0.1N standardized hydrochloric acid. The color change at the end point is from green to pink.

Calculation: Percentage N is computed as:

( )

Where: a = ml HCl required for titration sample b = ml HCl required for titration blank S = air-dry sample M = molarity HCl 1.4 = 14 x 10-3 x 1000 (14 = atomic weight of nitrogen)

Appendix 3. Determination of Total Phosphorus (Murphy and Rileys, 1962)

Mixed reagent Successively add with a graduated cylinder to a 500 ml pyrex bottle and homogenize after each condition: -50 mL of 2.5 M sufuric acid -15 mL of NH4- molybdate solution -30 mL of ascorbic acid solution -5 mL of KSb-tartrate solution -100 mL water

Procedure 1. Digestion of sample as in appendix 1. 2. Pipette into separate test tubes 3 mL of sample extracts and standard solution. 3. Add 3 mL of mixed reagent and homogenize. 4. Allow the solution to stand for at least one hour for the blue color to develop its maximum. 5. Measure the absorbance on spectrophotometer.

Appendix 5. Determination of Sulfate (Chauddry and Cornfield, 1966)

Reagents Ammonium hydrochloric acid. chloride, calcium hydroxide, barium acetate, acetic acid,

Standards 1. Stock solution: a. 100-ppm sulfate: use certified NIST traceable standard. 2. Instrument calibration standards: a. Pipette the designated amounts of 100-ppm sulfate stock solution into 100 mL volumetric flask. Add 2.674 g ammonium chloride. Dissolve and dilute to the mark with deionized water and mix well. Working solution 1. Precipitating solution: a. Weigh 255g barium acetate and dissolve in 500mL deionized water in 1 L volumetric flask. b. Add 100 mL acetic acid. c. Dilute to the mark with deionized water and mix well. 2. Seed solution: a. Add 210mL of 100mgL-1 sulfate stock solution to a 500mL volumetric flask. b. Add 2mL hydrochloric acid.

c. Add 13.87g ammonium chloride. d. Dilute to the mark with deionized water and mix well. Extracting solution 1. 0.5N ammonium chloride a. Weigh 26.74g ammonium chloride into a 1L volumetric flask containing 700mL of deionized water. b. Add 0.06g calcium hydroxide. c. Dissolve, dilute to the mark with deionized water and mix well.

Procedure 1. Pipette 5mL of fermented Sargassum muticum sample into glass test tubes. 2. Add 1mL seed solution. 3. Add 1mL precipitating solution and mix by slow inversion. This step is critical. Each sample should be mixed in exactly the same manner. 4. Pour the samples into the glass cuvettes and allow to stand for 10 minutes. 5. Analyse the sample on the spectrophotometer at 550 nm. 6. Treat the six calibration standards in the same manner. 7. Prepare one extraction blank for each set of samples. Calculation 1. Construct a graph of sulfate concentration versus absorbance. 2. Determine mgL-1 sulfate in the sample from the graph. 3. Calculate:

mg/L SO4 = (mgL-1 SO4 in sample mgL-1 SO4 in sample blank) x dilution factor 4. Final results will be reported in mg/kg dry weight (mgL-1) calculated as follows:

Appendix 5: Determination of Calcium, Potassium, and Magnesium (Murphy and Riley, 1962) Reagents Strontium chloride Cesium chloride Procedure 1. Digestion of sample as in Appendix 1. 2. An aliquot of digested Sargassum muticum solution, 1mL, will be mixed with 2.5mL 10000 mgL-1 strontium chloride for Ca and Mg and 1mL of 50000 mgL-1 cesium chloride for K and dilute to 25 mL with deionized water. 3. Samples will be read for the total calcium, total magnesium, and total potassium using atomic absorption spectrometry at a wavelength of 239.9, 202.6, and 769.9 nm, respectively.

4. Readings will be converted into elemental concentration. Calculation

where: c = concentration of the metal being analysed (mg/kg sample) R = AAS reading (mgL-1) V = volume of the solution (mL) W = weight of the sample used (g) 5. Instrument readings are recorded in mg/L solution concentration. Final results will be reported in mg/kg dry weight (ppm) calculated as:

S-ar putea să vă placă și

- Final ManuscriptDocument59 paginiFinal ManuscriptNikki Charm Aguilar DeronioÎncă nu există evaluări

- (Lycopersicon Esculentum Mill) As Affected by Padina SPDocument25 pagini(Lycopersicon Esculentum Mill) As Affected by Padina SPjyell cabigasÎncă nu există evaluări

- ResearchhDocument38 paginiResearchhJudy Alonzo TamayoÎncă nu există evaluări

- Juskong Research To Ayoko NaDocument10 paginiJuskong Research To Ayoko NaAnonymous gV9BmXXHÎncă nu există evaluări

- Fermented Fruit Juice (FFJ) : Enhance Growth and Fruiting of Smooth Cayenne Bell Pepper (Capsicum Annuum)Document59 paginiFermented Fruit Juice (FFJ) : Enhance Growth and Fruiting of Smooth Cayenne Bell Pepper (Capsicum Annuum)Jeaniel Joy BabolÎncă nu există evaluări

- INTRODUCTIONDocument6 paginiINTRODUCTIONArnel SisonÎncă nu există evaluări

- Effect of Seaweed Extracts On The Growth of Tomato Plant FINALDocument9 paginiEffect of Seaweed Extracts On The Growth of Tomato Plant FINALMint XÎncă nu există evaluări

- Ragay National Agricultural and Fisheries School Libororagay, Camarines Sur Science and Math Oriented CurriculumDocument18 paginiRagay National Agricultural and Fisheries School Libororagay, Camarines Sur Science and Math Oriented CurriculumCastor Jr JavierÎncă nu există evaluări

- ThesisDocument60 paginiThesisDaisy EgotÎncă nu există evaluări

- Growth and Yield Performance of Container - Grown Radish (Rhapanus Sativus L.) Applied With FFJ and FPJ CombinationsDocument20 paginiGrowth and Yield Performance of Container - Grown Radish (Rhapanus Sativus L.) Applied With FFJ and FPJ CombinationsRoselyn BritanicoÎncă nu există evaluări

- Final Paper Darwin 2.1Document62 paginiFinal Paper Darwin 2.1Raymund Arcos100% (1)

- The Effects of Seaweed "Guso" (Kappaphycus Alvarezii) APPLICATION AT Various Concentrations To Growing PECHAY (Brassica Chinensis L.)Document23 paginiThe Effects of Seaweed "Guso" (Kappaphycus Alvarezii) APPLICATION AT Various Concentrations To Growing PECHAY (Brassica Chinensis L.)Krizzelle Ann DaceraÎncă nu există evaluări

- (Cucumis Sativus L.) APPLIED WITH VERMICOMPOSTDocument23 pagini(Cucumis Sativus L.) APPLIED WITH VERMICOMPOSTTishianie O. JunioÎncă nu există evaluări

- As Growth Enhancer of Kangkong (Ipomoea Aquatica) For Indoor GardenDocument33 paginiAs Growth Enhancer of Kangkong (Ipomoea Aquatica) For Indoor GardenJulie Cadiz OlermoÎncă nu există evaluări

- AmpalayaDocument7 paginiAmpalayaglydel marie nudaloÎncă nu există evaluări

- COFFEE GROUND S-WPS OfficeDocument6 paginiCOFFEE GROUND S-WPS Office3SASHSChristian CreoÎncă nu există evaluări

- RRL Group1Document3 paginiRRL Group1Christian DeanÎncă nu există evaluări

- Chapter 1Document8 paginiChapter 1Dezerie Mae SolascoÎncă nu există evaluări

- Group 1 Chapter 1PDFDocument24 paginiGroup 1 Chapter 1PDFRai-Dale Lorence L. ArrofoÎncă nu există evaluări

- Cuballes Deonel e Chapter-I-VDocument11 paginiCuballes Deonel e Chapter-I-VSheryl CuballesÎncă nu există evaluări

- Growth and Yield Response of Momordica Charantia LDocument7 paginiGrowth and Yield Response of Momordica Charantia Lrouel100% (1)

- Biopesticidal Effects of Madre de Cacao (Gliricidia On Arugula (Eruca Sativa)Document14 paginiBiopesticidal Effects of Madre de Cacao (Gliricidia On Arugula (Eruca Sativa)akosiemÎncă nu există evaluări

- Effect of Carrot (Daucus Carota) Solution On Kalachuchi (Plumeria Rubra) TruncheonsDocument21 paginiEffect of Carrot (Daucus Carota) Solution On Kalachuchi (Plumeria Rubra) TruncheonsLeanne Dela CruzÎncă nu există evaluări

- My NarrativeDocument28 paginiMy NarrativeGauis Laurence CaraoaÎncă nu există evaluări

- Phaseolus Vulgaris) : "String Bean (L. Performance Apply With Different Animal Manure: Effects On Growth and Yield''Document17 paginiPhaseolus Vulgaris) : "String Bean (L. Performance Apply With Different Animal Manure: Effects On Growth and Yield''Jericho Basmayor SajulanÎncă nu există evaluări

- 1 31Document35 pagini1 31Kc0911Încă nu există evaluări

- 3 BodyDocument49 pagini3 BodyjunainaÎncă nu există evaluări

- The Problem and Its Background: Apayao State CollegeDocument44 paginiThe Problem and Its Background: Apayao State CollegeBrille Adrian FernandoÎncă nu există evaluări

- A Proposal On Nutrient Management On RadishDocument10 paginiA Proposal On Nutrient Management On RadishKimmy YowÎncă nu există evaluări

- Einstein Sip AbanillaDocument17 paginiEinstein Sip AbanillaSean AbanillaÎncă nu există evaluări

- UntitledDocument20 paginiUntitledMc joey NavarroÎncă nu există evaluări

- 10 Fermented Golden Apple Snails... Noppawan, 2014Document9 pagini10 Fermented Golden Apple Snails... Noppawan, 2014Gabriel BermudezÎncă nu există evaluări

- Bottle Gourd: Site Selection and Soil TypeDocument2 paginiBottle Gourd: Site Selection and Soil TypeJessielito P. AmadorÎncă nu există evaluări

- Edited Bell PepperDocument9 paginiEdited Bell PepperSubic AutoÎncă nu există evaluări

- Thesis Outline of Martin H. ButacDocument7 paginiThesis Outline of Martin H. ButacRovieda ButacÎncă nu există evaluări

- Eggplant PDFDocument16 paginiEggplant PDFAj Ceniza Amancio0% (1)

- Advances in Legumes for Sustainable IntensificationDe la EverandAdvances in Legumes for Sustainable IntensificationRam Swaroop MeenaÎncă nu există evaluări

- Effect of FAA (Fish Amino Acid) Powder To The Growth Performance of Cucumber (Cucumis Sativus)Document3 paginiEffect of FAA (Fish Amino Acid) Powder To The Growth Performance of Cucumber (Cucumis Sativus)Melody DacanayÎncă nu există evaluări

- Yield Performance of Bunching OnionDocument16 paginiYield Performance of Bunching Onionrusty100% (1)

- Growth Performance of Potted Green Leaf Onion PR 12Document44 paginiGrowth Performance of Potted Green Leaf Onion PR 12Jayzel Suno Ugapang100% (1)

- Full Thesis in PDFDocument139 paginiFull Thesis in PDFOben Oben ObenÎncă nu există evaluări

- Growing Ampalaya (Bitter Gourd) in The Philippines 2Document29 paginiGrowing Ampalaya (Bitter Gourd) in The Philippines 2kishore_hemlani86% (7)

- Ok - Helen Sebastian Final2Document72 paginiOk - Helen Sebastian Final2Lhen Gui Sebastian100% (1)

- Efficacy of The Product of Molasses Grass (Melinis Minutiflora) As A Delaying Agent On Ripening Mangoes (Mangifera Indica)Document26 paginiEfficacy of The Product of Molasses Grass (Melinis Minutiflora) As A Delaying Agent On Ripening Mangoes (Mangifera Indica)Cristine Angela BattungÎncă nu există evaluări

- Rooting Response of KatmonDocument27 paginiRooting Response of KatmonJake SagadÎncă nu există evaluări

- GROWTH AND YIELD OF OKRA 2nd DraftDocument14 paginiGROWTH AND YIELD OF OKRA 2nd DraftSaheden Apo SalilawanÎncă nu există evaluări

- GROUP3 EXODUS Introduction To Scope and Limitation. OKRADocument6 paginiGROUP3 EXODUS Introduction To Scope and Limitation. OKRAMaribel Tan-Losloso Nayad0% (1)

- Status of Organic Agriculture Research and Development Programs in The Bicol Region, PhilippinesDocument8 paginiStatus of Organic Agriculture Research and Development Programs in The Bicol Region, PhilippinesMario Montes100% (1)

- Thesis Crop ScienceDocument28 paginiThesis Crop ScienceGeraldine BlorÎncă nu există evaluări

- Thesis 04Document22 paginiThesis 04Marlexis ConacoÎncă nu există evaluări

- Chapter 1 DoneDocument9 paginiChapter 1 DoneLemuel L. Madridejos0% (2)

- Biodiversity PPT (Science)Document6 paginiBiodiversity PPT (Science)Sujay Raj SrivastavaÎncă nu există evaluări

- Jessac RepublicaDocument21 paginiJessac Republicajessa republicaÎncă nu există evaluări

- Chapter 1Document3 paginiChapter 1Ren Arrivas Bolaños100% (1)

- Research 09 04 19Document19 paginiResearch 09 04 19Aianna Abragan100% (1)

- Simplified Keys To Soil Series Negros OrientalDocument64 paginiSimplified Keys To Soil Series Negros OrientalNoy JuanÎncă nu există evaluări

- Leaf Color Chart Version 1.2Document3 paginiLeaf Color Chart Version 1.2Maribel NimoÎncă nu există evaluări

- RRLDocument3 paginiRRLKeshi LacandazoÎncă nu există evaluări

- Research-is-Fun-Chapter-I-III ExtensionDocument14 paginiResearch-is-Fun-Chapter-I-III ExtensionJessa Marie Nagar CalunodÎncă nu există evaluări

- Tomato: Growing Practices and Nutritional InformationDe la EverandTomato: Growing Practices and Nutritional InformationÎncă nu există evaluări

- Preparation of SaltsDocument8 paginiPreparation of SaltsRose MusariraÎncă nu există evaluări

- Veterinary Pharmaceutical DivisionDocument17 paginiVeterinary Pharmaceutical Divisiongeneral2000Încă nu există evaluări

- Evaporite Salt DepositsDocument71 paginiEvaporite Salt Depositskittipun khamprasoetÎncă nu există evaluări

- 2009 Ifa FertilizerindustrychinaDocument221 pagini2009 Ifa FertilizerindustrychinaMeselao LeeÎncă nu există evaluări

- Assignment - 1-Mole Concept-AbhimanyuDocument7 paginiAssignment - 1-Mole Concept-Abhimanyuaryan aggarwalÎncă nu există evaluări

- SaltwaterDocument28 paginiSaltwaterkuladeepkatragaddaÎncă nu există evaluări

- CT 404jan07 PDFDocument4 paginiCT 404jan07 PDFsaeedhoseiniÎncă nu există evaluări

- PtassiumDocument26 paginiPtassiumsamer iqbalÎncă nu există evaluări

- Micro K (Potassium Chloride)Document2 paginiMicro K (Potassium Chloride)EÎncă nu există evaluări

- Contest Prep Show Day Holding The PeakDocument24 paginiContest Prep Show Day Holding The Peakthekid skyÎncă nu există evaluări

- Analytical Chemistry Volume 28 Issue 10 1956 (Doi 10.1021/ac60118a012) Pflaum, R. T. Howick, L. C. - Spectrophotometric Determination of Potassium With Sodium TetraphenylborateDocument3 paginiAnalytical Chemistry Volume 28 Issue 10 1956 (Doi 10.1021/ac60118a012) Pflaum, R. T. Howick, L. C. - Spectrophotometric Determination of Potassium With Sodium TetraphenylboratekhqqxyzÎncă nu există evaluări

- A Synthesis of Systematic MineralogyDocument9 paginiA Synthesis of Systematic MineralogyElisa Ochoa LindeÎncă nu există evaluări

- Drugstudy PotassiumchlorideDocument3 paginiDrugstudy Potassiumchloridetrina412Încă nu există evaluări

- Objective Type KVPY QuestionsDocument29 paginiObjective Type KVPY QuestionsAnkur Singh75% (4)

- Practice Test On NutritionDocument6 paginiPractice Test On NutritionIvy Yvonne Quinico Malubag100% (1)

- Nutrient Deficiency in PlantsDocument10 paginiNutrient Deficiency in PlantsAnuraag SrivastavÎncă nu există evaluări

- Inorganic ChemDocument158 paginiInorganic ChemChosel LawagonÎncă nu există evaluări

- Ds 2006 Ef Flores CenceDocument8 paginiDs 2006 Ef Flores CencegadÎncă nu există evaluări

- Potassium ChlorideDocument2 paginiPotassium ChlorideRene John Francisco0% (1)

- Practical 1BDocument8 paginiPractical 1BHoe Lam WanÎncă nu există evaluări

- Calcium Carbonate: A Guide For GCSE StudentsDocument35 paginiCalcium Carbonate: A Guide For GCSE StudentsSyed Muhammad AnasÎncă nu există evaluări

- Ash Content DeterminationDocument17 paginiAsh Content DeterminationAnonymous uosYCyX50% (2)

- Electrolytes LecDocument4 paginiElectrolytes LecMichelle San Miguel FeguroÎncă nu există evaluări

- Nomenclature ReviewDocument18 paginiNomenclature ReviewKimberly Robertson WarrenÎncă nu există evaluări

- Cambridge IGCSE: Chemistry 0620/63Document12 paginiCambridge IGCSE: Chemistry 0620/63Rishabh RaoÎncă nu există evaluări

- E 246 - 95 AstmDocument12 paginiE 246 - 95 AstmJOSE ABADÎncă nu există evaluări

- Bamboo Salt Is ScienceDocument36 paginiBamboo Salt Is ScienceOlvyana Linus R Miroh100% (1)

- IIT IIT IIT IIT - JEE JEE JEE JEE: Review QuestionsDocument0 paginiIIT IIT IIT IIT - JEE JEE JEE JEE: Review Questionssabhari_ram100% (1)

- Eden Catalog 10Document84 paginiEden Catalog 10edenfoodsÎncă nu există evaluări

- Model STH Series - Combination Soil Testing Outfit InstructionsDocument24 paginiModel STH Series - Combination Soil Testing Outfit InstructionsedgardokingÎncă nu există evaluări