Documente Academic

Documente Profesional

Documente Cultură

Banner D10 Bargraph Display

Încărcat de

Memik TylnDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Banner D10 Bargraph Display

Încărcat de

Memik TylnDrepturi de autor:

Formate disponibile

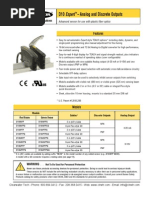

D10 Expert with Discrete Output and Bargraph Display

Advanced sensor for use with plastic fiber optics

Standard Model

Features

Easy-to-read 8-segment light bar indicator for teach and signal strength readout, plus indicators for continuous readout of operating status (user configuration) Easy-to-set automatic Expert-style configuration options include Static and Dynamic TEACH, and Window SET, plus manual adjustment for fine tuning Smart gain-control algorithm to maximize performance in low-contrast applications Fast 500-microsecond sensing response with improved crosstalk avoidance routine (for two sensors) in Normal mode Selectable high-speed (HS) mode option for 200-microsecond response

Stack of Models with Bussable Power Feature

Extreme configuration flexibility via push buttons or a remote input wire Easy selection of Light/Dark Operate (LO/DO), 30 ms pulse stretcher (OFF-delay), and response speed, via push buttons or a remote input wire Visible red (660 nm) or visible green (525 nm) sensing beam, depending on model Sleek, ultra-slim 10 mm housing, mounts to standard 35 mm DIN rail Models with bussable power provide simplified wiring of up to 16 sensors and feature improved temperature compensation for side-by-side mounting

U.S. Patent(s) issued or pending

Models

Model Red Beam

D10BFP D10BFPQ

Green Beam

D10BFPG D10BFPGQ

Description

Cable*

2 m (6.5') Cable 6-pin Pico-style QD

Outputs

Standard sensor

Bipolar NPN/PNP

Models with Bussable Power

D10B5FP D10B2PFP D10B2NFP Main unit Sub-unit 2 m (6.5') Cable 2 m (6.5') Cable 2 m (6.5') Cable Bipolar NPN/PNP Single PNP Single NPN

* 9 m (30') cables are available by adding suffix W/30 to the model number of any cabled sensor (e.g., D10BFP W/30). A model with a QD connector requires a mating cordset (see page 12). NOTE: See page 10 for performance curves.

WARNING . . . Not To Be Used for Personnel Protection

Never use these products as sensing devices for personnel protection. Doing so could lead to serious injury or death. These sensors do NOT include the self-checking redundant circuitry necessary to allow their use in personnel safety applications. A sensor failure or malfunction can cause either an energized or de-energized sensor output condition. Consult your current Banner Safety Products catalog for safety products which meet OSHA, ANSI and IEC standards for personnel protection.

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

D10 Expert Discrete Output with Bargraph Display

Overview

The D10 Expert is an easy-to-use, DIN-rail-mountable fiber optic sensor. It provides highperformance sensing in low-contrast applications. Configuration options include SETUP mode plus Static and Dynamic TEACH, and Window SET options, in addition to manual fine adjustment, remote programming, and security push button lockout. The sensors compact housing has a large, easy-to-see bargraph display plus bright LEDs for easy programming and status monitoring during operation. Standard models have bipolar outputs, one each NPN and PNP. Main units with bussable power have the same bipolar outputs; sub-units feature a single discrete output, either NPN or PNP. Models with bussable power are designed for use in machines and other applications where multiple sensors will be grouped tightly. They feature increased temperature compensation compared with standard models and reduce the amount of wiring necessary for such applications. An accessory clamp is available to secure a bank of connected sensors together on a DIN rail (see page 12).

Configuration Status LEDs (Green) Green Power ON LED For emitter and receiver port locations, see page 10.

Yellow Output LED Switching Threshold

Bargraph Display (Red)

Bussable Power Input Port (cap supplied for unused port)

Configuration Push Buttons Bussable Power Output Port (cap supplied for unused port)

Sensor Configuration

Sensor configuration is accomplished via TEACH, SET, and SETUP modes. After the sensing parameters are defined (using either TEACH or SET mode), SETUP mode may be used to enable the delay, to change the light/dark operate status, or to select the highspeed response option (HS). Manual Adjust may be used to fine-tune the thresholds (see page 8). Two push buttons, Dynamic (+) and Static (), or the remote wire, may be used to access and set the sensing parameters. Sensor sensitivity may be configured using any of three methods. A single switching threshold may be achieved using either Dynamic (on-the-fly) or Static TEACH; or Window SET may be used to define a sensing window, centered on a single sensing condition.

Figure 1. D10 Bargraph Model features

Remote Configuration

The remote configuration function may be used to configure the sensor remotely or to disable the push buttons for security. Connect the gray wire of the sensor to ground (0V dc), with a remote programming switch connected between them. Pulse the remote line according to the diagrams in the configuration procedures. The duration of the individual pulses is equal to the value T: 0.04 seconds T 0.8 seconds

Returning to RUN Mode

Some TEACH, SET, and SETUP modes may be exited either after the 60-second timeout, or by exiting the process: In Static TEACH or Window SET mode, press and hold the Static () button (or hold the remote line) for 2 seconds. The sensor returns to RUN mode without saving any new settings. In SETUP mode, press and hold both the Static () and Dynamic (+) buttons (or hold the remote line) for 2 seconds. The sensor returns to RUN mode and saves the current setting.

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

D10 Expert Discrete Output with Bargraph Display

2nd Taught Condition Sensor positions threshold midway between taught conditions 1st Taught Condition

Two-Point Static TEACH (Threshold)

Establishes a single switching threshold Threshold position is adjustable using + and - buttons (Manual Adjust)

Output OFF Darkest (no signal) Position adjusted by Manual Adjust

Output ON Most Light (saturated signal)

Static TEACH is the traditional setup method, used when two conditions can be presented by the user. The sensor locates a single sensing threshold (the switchpoint) midway between the two taught conditions, with the Output ON condition on one side, and the Output OFF condition on the other (see Figure 2). The first condition taught is the ON condition. The Output ON and OFF conditions can be reversed by changing Light/Dark Operate status in SETUP mode (see page 8).

Figure 2. Static TEACH (Light Operate shown) Darkest Taught Lightest Taught

Condition Condition Sensor positions threshold midway Relative Signal Difference/ between taught conditions

Bargraph LED Following TEACH

6 to 8

Darkest (no signal)5 4 to

Static TEACH and Manual Adjust

Recommendation

Output ON

Using Manual Adjust with Static TEACH moves the switching threshold. The lighted LED on the bargraph will move to exhibit the received signal, relative to the switchpoint.

Output OFF

Excellent: Very stable operation. Good: Minor sensing variables will adjusted by (saturated not Manual sensing reliability. signal) affect Adjust Low: Minor sensing variables may affect sensing reliability. Unreliable: Consider an alternate Sensing window size sensing scheme. adjusted by

Manual Adjust Position Most Light

2 to 3 1

Output OFF seconds Click 0.8 seconds Output ON Output OFF 0.04

Push Button

0.04 seconds T 0.8 seconds

Remote Line

Result

Power LED: OFF Output LED: ON Status LEDs: LO & DO alternately flashing Bargraph: OFF

static DO LO HS

Access TEACH Mode

Darkest (no signal)

Press and hold Static button > No action required; Single Most Light sensing (saturated sensor is ready for 1st 2 seconds. condition signal) TEACH condition.

dynamic

8 7 6 5 4 3 2 1

TEACH Output ON Condition

Present Output ON condition. Click Static button.

T 0.8 seconds

Present Output ON condition. Single-pulse remote line.

T

1x

Power LED: OFF Output LED: Flash, then OFF Status LEDs: LO & DO alternately flashing Bargraph: OFF

static

dynamic

static

DO LO

HS

dynamic

8 7 6 5 4 3 2 1

DO LO

HS

8 7 6 5 4 3 2 1

Present Output OFF condition. Click Static button.

Present Output OFF T T 2x condition. T Single-pulse remote line.

T T T T T T

TEACH Accepted

TEACH Output OFF Condition

T T T T 0.8 seconds T T > 2 seconds

3x 1x 4x 2x 5x 3x 6x 4x 7x

Power LED: ON Bargraph: One LED flashes to show relative contrast (good signal difference shown; see table above) Sensor returns to Run mode.

TEACH Unacceptable

static

DO LO

HS

dynamic

8 7 6 5 4 3 2 1

T T T

T T

or

T T T

T T

T T

T T T T > 2 seconds T T T T T T

T T

T T

T T

T T

T T

Power LED: OFF Bargraph: #1, 3, 5, 7 alternately flash to show failure Sensor returns to TEACH Output ON condition.

static

DO LO

HS

dynamic

8 7 6 5 4 3 2 1

T T

T T

T T

T T

T T

T T

T T

5x Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

T T T T T T T T

T T

T T

T T

T T

T T

threshold midway between taught conditions

D10 Expert Discrete Output with Bargraph Display

Darkest (no signal)

Output OFF Position adjusted by Manual Adjust

Output ON Most Light (saturated signal)

Dynamic TEACH and Adaptive Thresholds

Teach on-the-fly Establishes a single switching threshold Threshold position is adjustable using + and - buttons (Manual Adjust) Dynamic TEACH is best used when a machine or process may not be stopped for teaching. It programs the sensor during actual sensing conditions, taking multiple samples of the light and dark conditions and automatically setting the threshold at the optimum level (see Figure 3). Dynamic TEACH activates the sensors adaptive threshold system, which continuously tracks minimum and maximum signal levels, and automatically maintains centering of the switchpoint between the light and dark conditions. The adaptive threshold system remains in effect during RUN mode. The adaptive routine saves to non-volatile memory at least once per hour. When Dynamic TEACH mode is used, the output ON state (Light or Dark Operate) will remain as it was last programmed. To change the output ON state, use SETUP mode (see page 8).

Darkest Taught Condition

Lightest Taught Condition

Sensor positions threshold midway between taught conditions

Output OFF Darkest (no signal) Position adjusted by Manual Adjust

Output ON Most Light (saturated signal)

Figure 3. Dynamic TEACH (Light Operate shown)

Bargraph LED Following Output OFF TEACH

Darkest 6 to (no signal) 8 Sensing window size adjusted by Manual Adjust

Relative Signal Difference/ Recommendation Output ON Output OFF

Single Most Light signal)

Excellent: Very stable operation. sensing (saturated Good: Minor sensing variables will not affect sensing reliability. Low: Minor sensing variables may affect sensing reliability. Unreliable: Consider an alternate sensing scheme.

condition

Dynamic TEACH and Manual Adjust

4 to 5 2 to 3 1

The switchpoint may be adjusted (fine-tuned) whenever the sensor is in RUN mode by clicking the + and - buttons. However, when a manual adjustment is made, the adaptive threshold system is disabled (cancelled).

T T T T T T

Push Button TEACH Sensing Access Dynamic TEACH Mode Conditions

Press and Hold Dynamic push button > 2 seconds.

Remote Line

Hold remote line low (to ground) > 2 seconds.

T T T T T T

Result

Power LED: OFF Output LED: OFF Bargraph: LO & DO alternately flashing

static

T T T T T T

DO LO

HS

dynamic

8 7 6 5 4 3 2 1

T T T T T T T T T T T T TPower T T Output T T

Continue to hold push button. Present Output ON and OFF conditions.

Continue to hold remote T line low (to ground). T Present Output ON and OFF conditions.

T T

LED: OFF LED: OFF Bargraph: LO & DO alternately flashing

static

T T T T T T T T T T T

DO LO

HS

dynamic

8 7 6 5 4 3 2 1

T T T

Release push button.

Release remote line/ switch.

TEACH Accepted

Return to Run Mode

T T

T T

Power LED: ON Bargraph: One LED flashes to show relative contrast (good signal difference shown; see table above)

static

DO LO

HS

or

Sensor returns to Run mode with new settings.

TEACH Unacceptable

dynamic dynamic

8 7 6 5 4 3 2 1

Power LED: OFF Bargraph: #1, 3, 5, 7 alternately flash to show failure

static

DO LO

HS

8 7 6 5 4 3 2 1

or or

Sensor returns to Run mode without changing settings.

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Sensor positions threshold between taught conditions Output OFF Darkest (no signal) Position adjusted by Manual Adjust Output ON

D10 Expert Discrete Output with Bargraph Display

Most Light (saturated signal)

Sensing window size adjusted by Manual Adjust Sensor positions window thresholds 12.5% from the presented condition Output OFF Darkest (no signal) Output ON Condition Presented Output OFF Most Light (saturated signal)

Single-Point Window SET

Sets a single ON condition that extends 12.5% above and below the taught condition All other conditions (lighter or darker) result in OFF output Sensing window size (sensitivity) is adjustable using + and - buttons (Manual Adjust) Window SET is most useful when a product may not always appear in the same place, or when other signals may appear. Window SET designates a sensing window, with the Output ON condition inside the window, and the Output OFF conditions outside the window (see Figure 4). The sensor accepts a single sensing condition, and adds switching thresholds above and below that condition to create a sensing window. Output ON and OFF conditions can be reversed by changing Light/Dark Operate status in SETUP mode.

Figure 4. Window SET (Light Operate shown) Threshold position

adjusted by Manual Adjust

Sensor positions threshold 12.5% below the presented condition

Window SET and Manual Adjust

Output OFF Darkest (no signal)

Output ON Condition Presented Most Light (saturated signal)

Using Manual Adjust with Window SET expands or contracts the size of the window. The lighted LEDs on the light bar separate to a greater or lesser extent to exhibit the relative sensing window size.

0.04 seconds Click 0.8 seconds

Threshold position Press and hold Static push button adjusted by > 2 seconds. Manual Adjust

Push Button

0.04 seconds T 0.8 seconds

Remote Line

Result

Power LED: OFF Output LED: ON (Push Button) Output LED: OFF (Remote) Static LEDs: LO & DO alternately flashing

static static DO LO HS

Single-pulse remote line.

dynamic

Access SET Mode

8 7 6 5 4 3 2 1

T Sensor positions threshold0.8 seconds 12.5% above the presented condition

1x

or

DO LO HS

dynamic

8 7 6 5 4 3 2 1

Output OFF

T

Output ON Most Light (saturated signal)

SET Sensing Condition

Darkest (no signal)

T

Present sensing condition.

Condition Double-click Presented

Static push

PresentTsensing condition.

2x

Window Accepted

T T T 0.8 seconds T > 2 seconds T T T T T T T T T

button.

T T T Double-pulse remote 3x T T line. T 1x

Power LED: ON Bargraph: 2 indicators flash together to show Window accepted

static

DO LO

HS

Sensor returns to RUN mode with new settings.

T T T T T T T T T T T > 2 seconds T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T

dynamic

8 7 6 5 4 3 2 1

4x

2x

Window Unacceptable

5x

or

3x

Power LED: OFF Bargraph: #1, 3, 5, 7 flash to show failure

static

DO LO

HS

Sensor returns to SET Sensing Condition.

6x 4x

dynamic

8 7 6 5 4 3 2 1

or

7x

5x

T T

T T

T T

T T

T T

6x

T T

T T

T T

T T

T T

T T

7x

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

window thresholds 10% from the presented condition

D10 Expert Discrete Output with Bargraph Display

Darkest (no signal)

Output OFF

Output ON Condition Presented

Output OFF Most Light (saturated signal)

Single-Point Light SET

Sets a threshold 6.25% below the taught condition. Any condition darker than the threshold condition causes the output to change state. Threshold position is adjustable using the + and - buttons (Manual Adjust). Recommended for applications where only one condition is known, for example a stable light background with varying darker targets. A single sensing condition is presented, and the sensor positions a threshold 6.25% below the presented condition. When a condition darker than the threshold is sensed, the output either turns ON or OFF, depending on the Light/Dark Operate setting (see SETUP mode, page 8).

Threshold position adjusted by Manual Adjust

Sensor positions threshold 6.25% below the presented condition

Output OFF Darkest (no signal)

Output ON Condition Presented Most Light (saturated signal)

Figure 5. Single-Point Light SET (Light Operate shown) Threshold position

adjusted by Manual Adjust

Light SET and Light/Dark Operate Selection

In Light Operate mode, Light SET teaches the Output ON condition. In Dark Operate mode, Light SET teaches the Output OFF condition.

Sensor positions threshold 6.25% above the presented condition

Output OFF

Output ON Most Light (saturated signal)

0.04 seconds Click 0.8 seconds

Push Button

0.04 seconds T 0.8 seconds

Remote Line

Darkest (no signal)

ResultCondition

Presented

Access SET Mode

Press and hold Static push button > 2 seconds

T

Single-pulse remote line

T

DO LO

HS

dynamic

T 0.8 seconds

0.8 seconds

1x

1x

T T T

2x

Power LED: OFF Output LED: ON (push button) OFF (remote line) Static LEDs: LO & DO alternately flashing

static static

8 7 6 5 4 3 2 1

or

DO LO HS

dynamic

8 7 6 5 4 3 2 1

Present sensing condition Four-click Static push button

T T T

T Present sensing condition

2x

Threshold Condition Accepted

DO LO HS

Four-pulse remote line

T T

T T T

3x

dynamic

T T T

T

T > 2 seconds

T

T T T T T T

3x

T

SET Sensing Condition

T T

T

T T

T T T

4x

> 2 seconds

T

T T T T T T

4x

T

Power LED: ON Output LED: ON (push button) OFF (remote line) Bargraph: 4 indicators flash together

static

static

8 7 6 5 4 3 2 1

or

DO LO HS

dynamic

8 7 6 5 4 3 2 1

or T

T

T T T

5x

or

T T

T T T

T

T T T

T

T T T

T

T T T T

5x

T

Sensor returns to RUN mode with new settings Threshold Condition Unacceptable

DO LO HS

T T

T

6x

dynamic

T

T T T T T

T

T T T

T

T T T T

6x

T

T T

T T

7x

7x

Power LED: ON Output LED: ON (push button) OFF (remote line) Bargraph: #1, 3, 5, 7 flash to show failure

static

Sensor returns to SET Sensing Condition.

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

static

8 7 6 5 4 3 2 1

or

DO LO HS

dynamic

8 7 6 5 4 3 2 1

threshold 6.25% below the presented condition

Output OFF Darkest (no signal)

Output ON Condition Presented

D10 Expert Discrete Output with Bargraph Display

Most Light (saturated signal)

Threshold position adjusted by Manual Adjust

Sensor positions threshold 6.25% above the presented condition

Single-Point Dark SET

Sets a threshold 6.25% above the taught condition. Any condition lighter than the threshold condition causes the output to change state. Threshold position is adjustable using the + and - buttons (Manual Adjust). Recommended for applications where only one condition is known, for example a stable dark background with varying lighter targets.

Most Light (saturated signal)

Output OFF Darkest (no signal) Condition Presented

Output ON

Figure 6. Single-Point Dark SET (Light Operate shown)

A single sensing condition is presented, and the sensor positions a threshold 6.25% above the taught condition. When a condition lighter than the threshold is sensed, the output either turns ON or OFF, depending on the Light/Dark Operate setting (see SETUP mode, page 8).

Dark SET and Light/Dark Operate Selection

In Light Operate mode, Dark SET teaches the Output OFF condition. In Dark Operate mode, Dark SET teaches the Output ON condition.

0.04 seconds Click 0.8 seconds

T T

Push Button

T

0.04 seconds T 0.8 seconds

Remote Line

Result

1x

DO LO HS

Access SET Mode

Press and0.8 seconds hold Static push button > 2 seconds

T 0.8 seconds

T

Single-pulse remote line

T T

dynamic

1xT

2x

T T T

Present sensing condition Five-click Static push button

> 2 seconds

T Present sensing condition

T T T T T T 2x T T T

3x

Power LED: OFF Output LED: ON (push button) OFF (remote line) Static LEDs: LO & DO alternately flashing Threshold Condition Accepted

static static

8 7 6 5 4 3 2 1

or

DO LO HS

dynamic

8 7 6 5 4 3 2 1

Five-pulse remote line

T

DO LO

HS

dynamic

T T

T T T

T

T

T T T

T

T T T T

3xT

4x

SET Sensing Condition

T T

T > 2 seconds

T

T T

T T T

5x

T

T T T

T

T T T T

4x

T

Power LED: ON Output LED: ON (push button) OFF (remote line) Bargraph: 4 indicators flash together

static

static

8 7 6 5 4 3 2 1

or

DO LO HS

dynamic

8 7 6 5 4 3 2 1

T T

6x

T T

or

T

T T T

T

T T

T

T T T

5x

T

Sensor returns to RUN mode with new settings Threshold Condition Unacceptable

DO LO HS

T T

or

T T

7x

dynamic

28256

6x

T T

T T

T T

T T

T T

T T

7x

Power LED: ON Output LED: ON (push button) OFF (remote line) Bargraph: #1, 3, 5, 7 flash to show failure

static

Sensor returns to SET Sensing Condition.

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

static

8 7 6 5 4 3 2 1

or

DO LO HS 8 7 6 5 4 3 2 1

dynamic

D10 Expert Discrete Output with Bargraph Display

SETUP Mode

SETUP mode is used to change sensor output response for: Light or Dark operate 30-millisecond pulse stretcher (OFF-delay), if required. 200 s high-speed response

If SETUP mode configuration is interrupted and remains inactive for 60 seconds, the sensor returns to RUN mode with the most recent settings (i.e., exits and saves current selection).

SETUP mode operates in the background, while the outputs are active; changes are updated instantly.

static

SETUP Status Indicators

HS DO LO

8 7 6 5 4 3 2 1

dynamic

Press and hold both push buttons > 2 seconds to access SETUP mode

Figure 7. SETUP mode

T T 0.04 seconds Click 0.8 seconds 0.8 seconds

Push Button

0.04 seconds T 0.8 seconds T

Remote Line

Result

Green Power LED turns OFF. Output LED remains active. Icons continue to display current setup. Bargraph turns OFF.

static

Access SETUP Mode

Press and hold both push buttons > 2 seconds.

Double-pulse remote line.

or

T T T

1x

DO LO

HS

dynamic

2x

8 7 6 5 4 3 2 1

T T T

Click either push button until LEDs show desired settings.

T > 2 seconds T T

Select Setting Combination

T T T Pulse the remote line 3x T until LEDsTshow desired settings. T T T TT 0.8 seconds T T T T

Sensor toggles through eight setting combinations, in the following order:

LO DO LO 0.8 seconds DO LO DO LO DO T

T

4x

or

T T

5x NOTE: Double-pulsing the T T T remote line will cause the setting to back up one step.

T T T T Hold remote line low 6x T T > 2 seconds. T T T > T seconds 2 T T T T T

T T

Return to RUN Mode

T Press and hold both push buttons > 2 seconds. T T T T T

T T

Normal TSpeed1x Normal Speed High Speed High Speed T T Normal Speed2x T Normal Speed High Speed High Speed T T 3x

T

No Delay (default) No Delay No Delay No Delay Delay Delay Delay Delay

T

1x

T T

2x

or

T T T

7x

Green TPower LED turns ON. T T T T T Sensor returnsTto RUN mode 4x T T with new settings.T

static

T > 2 seconds T T T T T T T T

T T

3x

DO LO

T T T

HS

dynamic

8 7 6 5 4 3 2 1

T T T T

4x

Manual Adjust

Switching Threshold:

T T B_028256 Sensing Window:

5x

T T

T T T T Manual Adjust is used during RUN mode and is accomplished via the push Tbuttons only. Its behavior depends on whether a switching T T T T T 6x threshold or a sensing window is used. T T T T T T T T T T T 0.8 seconds T T T T T T T T T T T T T T T T T T T T T

5x

Fine-tunes sensing sensitivity Press + to increase; press - to decrease

T

6x

7x

T

T T T

T T

T T

T T

Adjusts sensing window size (tolerance) for the single-point target condition B_028256 Press + to increase; press - to decrease The lighted bargraph LEDs move to reflect the increase or decrease. T

T T T T

1x

7x

2x

Push Button Disable

T T T T T

T T In addition to its configuration function, the remote input may be used to disable the push buttons for security. Disabling the push buttons prevents undesired tampering with the configuration settings. Connect the gray wire of the sensor as described on page 2, and T T T T four-pulse to either enable or disable the push buttons: 4x > 2 seconds T T T

3x

T T T T T Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - 5x Web: www.clrwtr.com - Email: info@clrwtr.com T T T T

D10 Expert Discrete Output with Bargraph Display

Specifications

Standard Sensors

Sensing Beam Supply Voltage Supply Protection Circuitry Delay at Power Up

660 nm visible red or 525 nm visible green, depending on model 10 to 30V dc (10% max. ripple) @ less than 45 mA exclusive of load 200 milliseconds max.; outputs do not conduct during this time Bipolar; 1 current sourcing (PNP) and 1 current sinking (NPN)

Models with Bussable Power

660 nm visible red 12 to 30V dc (10% max. ripple) @ less than 45 mA exclusive of load 850 milliseconds max.; outputs do not conduct during this time Main units: Bipolar; 1 current sourcing (PNP) and 1 current sinking (NPN) Sub-units: 1 current sourcing (PNP) or 1 current sinking (NPN) output, depending on model 100 mA max. load (derate 1 mA per C above 30 C) OFF-state leakage current: < 5 A at 30V dc ON-state saturation voltage: NPN: < 1.5V PNP: < 2V Supply 15V or more: up to 16 units with 100 mA outputs Less than 15V supply (9 m cable): up to 4 units with 100 mA outputs up to 8 units with 50 mA outputs

Protected against reverse polarity, over voltage, and transient voltages

Output Configuration

Output Rating

150 mA max. load @ 25 C (derate 1 mA per C increase) OFF-state leakage current: < 5 A at 30V dc ON-state saturation voltage: NPN: < 200 mV @ 10 mA; 1V @ 150 mA load PNP: < 1V @ 10 mA; 1.5V @ 150 mA load

Output Protection Output Response Time Repeatability

Protected against output short-circuit, continuous overload, transient over-voltages, and false pulse on power up 500 microseconds (normal mode) or 200 microseconds (high-speed mode) 100 microseconds (normal mode) or 66 microseconds (high-speed mode) 2 push buttons and remote wire Expert-style configuration (Static and Dynamic TEACH, and Window SET) Manually adjust (+/) sensitivity (from push buttons only) LO/DO, OFF-delay, and response speed configurable (from push buttons or remote wire) Push button lockout (from remote wire only) Factory Default Settings: Light Operate, Normal Speed, No Delay 8-segment red bargraph: Light-to-dark signal difference relative to taught condition (Window SET) Sensing contrast (Static or Dynamic TEACH) Green Status Indicators: LO, DO, High Speed (HS), and OFF-Delay Green LED: Power ON Yellow LED: Output conducting Black ABS/polycarbonate alloy (UL94 V-0 rated) housing, clear polycarbonate cover IEC IP50, NEMA 1 PVC-jacketed 2 m or 9 m (6.5' or 30') 6-wire integral cable or integral 6-pin Pico-style quickdisconnect Temperature: -10 to +55 C (+14 to 131 F) Storage: -20 to +85 C (-4 to +185 F) Relative Humidity: 90% @ 55 C (non-condensing) Main units: PVC-jacketed 2 m or 9 m (6.5' or 30') 5-wire integral cable Sub-units: PVC-jacketed 2 m or 9 m (6.5' or 30') 2-wire integral cable

Adjustments

Indicators

Construction Environmental Rating Connections

Operating Conditions

Certifications

(CE approval is pending for models with bussable power)

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

D10 Expert Discrete Output with Bargraph Display

Performance Curves Red Beam Models

Opposed Mode

1000 1000 1000 1000

Diffuse Mode

Performance based on 90% reflectance white test card

1000 10000

E X C E S S G A I N

100

E XE CX C E E SS SS

PIT26U PIT16U

D10BFP

Opposed Mode

100 100

PIT66U fibers

E X C E S S G A I N

100

PBT26U

E X C E S S G A I N

PBT66U 100

10

G G A A II N N

1000 mm (40.0")

10 10

PIT66U

PIT46U fibers PIT46U

10

10 PBT46U

PBT16U 1 0.1 mm (.004") 1 mm (.04") 10 mm (0.4") 100 mm (4.0")

1 1 mm (.04")

10 mm (0.4")

100 mm (4.0")

11 1 mmmm 1.0 (.04") 0.04"

1 0.1 mm (.004") 1 mm (.04") 10 mm (0.4") 100 mm (4.0") 1000 mm (40.0")

10 mm 10.0 mm (0.4") 0.4"

100 mm 100 mm (4.0") 4.0"

1000 mm 1000 mm (40.0") 40.0"

DISTANCE

DISTANCE DISTANCE

DISTANCE

DISTANCE

100 mm 30 mm 1.18" PIT26U 300 mm 11.81" 15 mm 0.59" 75 mm 50 mm PBT66U PBT46U

3.93" 2.95" 1.97" 0.98" 0 0.98" 1.97" 2.95" 3.93" 0 32 mm (1.26") 64 mm (2.52") 96 mm (3.78") 128 mm 160 mm (5.04") (6.30")

BEAM WIDTH

BEAM WIDTH

BEAM WIDTH

BEAM WIDTH

20 mm 10 mm 0 10 mm 20 mm 30 mm 0

0.78" 0.39"

200 mm 100 mm 0 100 mm 200 mm 300 mm 0

PIT66U

7.87" 3.93" PIT46U 0 3.93" 7.87" 11.81"

10 mm 5 mm 0 5 mm 10 mm 100 mm 0 4 mm (0.15") 8 mm (0.31") 12 mm (0.47") 16 mm (0.63") PBT26U PBT16U

0.39" 0.19" 0 0.19" 0.39" 0.59" 20 mm (0.78")

25 mm 0 25 mm 50 mm 75 mm 100 mm

PIT16U

0 0.39" 0.78" 1.18"

12 mm (0.47")

24 mm (0.94")

36 mm (1.42")

48 mm (1.90")

60 mm (2.36")

80 mm (3.15")

160 mm (6.30")

240 mm (9.45")

320 mm 400 mm (12.59") (15.74")

DISTANCE

DISTANCE

DISTANCE

DISTANCE

Green Beam Models

Opposed Mode

1000 1000 1000

Diffuse Mode

Performance based on 90% reflectance white test card

1000

E X C E S S G A I N

100

E X C E S S

PIT26U

100

E X C E S S

PIT66U PIT46U

100

E X C E S S

PBT26U

100

PBT66U 10

10

PIT16U 1 1 mm (.04")

G A I N

100 mm (4.0") 1000 mm (40.0")

G A I N

1000 mm (40.0")

10

G A I N

100 mm (4.0")

10 PBT46U 1

10 mm (0.4")

1 1 mm (.04")

1 10 mm (0.4") 100 mm (4.0") 0.1 mm (.004") 1 mm (.04") 10 mm (0.4")

0.1 mm (.004")

1 mm (.04")

10 mm (0.4")

100 mm (4.0")

DISTANCE

8 mm 6 mm 4 mm PIT26U 0.31" 0.23" 0.16" 60 mm 45 mm 30 mm PIT66U

DISTANCE

2.36" 1.77" 1.18" 1.5 mm

DISTANCE

DISTANCE

0.06"

30 mm

1.18" PBT66U PBT46U 0.78" 0.39" 0 0.39" 0.78" 1.18" 0 10 mm (0.39") 20 mm (0.78") 30 mm (1.18") 40 mm (1.57") 50 mm (1.97")

BEAM WIDTH

BEAM WIDTH

2 mm 0 2 mm 4 mm 6 mm 8 mm 0 4 mm (0.16") 8 mm (0.31") 12 mm (0.47") 16 mm (0.63") PIT16U

0.08" 0 0.08" 0.16" 0.23" 0.31" 20 mm (0.78")

BEAM WIDTH

15 mm 0 15 mm 30 mm 45 mm 60 mm 0 24 mm (0.71") 48 mm (1.42") 72 mm (2.12") 96 mm (2.83") PIT46U

0.59" 0 0.59" 1.18" 1.77" 2.36" 120 mm (3.54")

0.5 mm 0 0.5 mm 1.0 mm 1.5 mm 0 1 mm (0.04") 2 mm (0.08") 3 mm (0.12") 4 mm (0.16") 5 mm (0.19") PBT26U

0.02" 0 0.02" 0.04" 0.02" 6 mm (0.23")

BEAM WIDTH

1.0 mm

0.04"

20 mm 10 mm 0 10 mm 20 mm 30 mm

DISTANCE

DISTANCE

DISTANCE

DISTANCE

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

D10 Expert Discrete Output with Bargraph Display

Dimensions

10.5 0.2 mm (typ.) (0.41")

10.5 0.2 mm (typ.) (0.41")

35.9 mm (1.41")

7.6 mm 0.30"

7.6 mm 0.30"

Mounting Bracket (included with some models)

Mounting Bracket (included) 61.3 mm (2.42") 68.1 mm (2.68")

35.9 mm (1.41")

9.8 mm (0.39")

61.3 mm (2.42") 68.1 mm (2.68")

9.8 mm (0.39")

Slides Up to Installing Fibers Fibers Release 14.5 mm (0.57")

Slides Up to Release Fibers

Plastic Fiber Emitter Port Plastic Fiber Plastic Fiber Emitter Port Receiver Port

Plastic Fiber Receiver Port

Bracket Dimensions (Bracket included with Standard Sensor Models)

10.0 mm (0.39") 5.0 mm (0.20") 2x 3.5 mm (0.14") 8.6 mm (0.34") M3 Hardware included: Lock Washer (2) Flat Washer (2) Screws (2) Hex Nuts (2)

5.0 mm (0.20") 2.5 mm (0.10")

35.1 mm (1.38")

15.2 mm (0.60")

16.0 mm (0.63")

25.4 mm (1.00")

2 x 3.3 mm (0.13") max. torque 6 in./lbs. 10.0 mm (0.39") 2x 3.2 mm (0.13") max. torque 6 in./lbs. 2x C'sink 8.0 mm (0.31") 3.2 mm (0.13") deep 4.4 mm (0.18") thru max. torque 10 in./lbs.

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

D10 Expert Discrete Output with Bargraph Display

Hookups

Standard Models and Main Unit

1 3 2 4 5 Load Load Remote Teach + 10-30V dc Standard Models 12-30V dc Bussable Power Models 6-Pin Pico or 5-Pin Euro 1 = Brown 2 = White 3 = Blue 4 = Black 5 = Gray 6 = Pink (not used)

Sub-Units NPN

+ 12-30V dc Connection From Main Unit Bus 4 5 Load Remote Teach 6-Pin Pico or 5-Pin Euro 1 = Brown 2 = White 3 = Blue 4 = Black 5 = Gray 6 = Pink (not used)

150 mA max. load

Key

NOTE: QD hookup is functionally identical (Pink wire not used).

1 = Brown 2 = White 3 = Blue 4 = Black 5 = Gray 6 = Pink

PNP

+ 12-30V dc Connection From Main Unit Bus 4 5 Load Remote Teach 6-Pin Pico or 5-Pin Euro 1 = Brown 2 = White 3 = Blue 4 = Black 5 = Gray 6 = Pink (not used)

Not Used

Quick-Disconnect Cordsets

Style

6-pin Pico-style straight

Model

PKG6Z-2 PKG6Z-9

Length

2 m (6.5') 9 m (30')

Dimensions

10 mm max. (0.4")

Pinout

28 mm max. (1.1")

25 mm max. (1.0")

3 2 6

4 5 1

6-pin Pico-style right-angle

PKW6Z-2 PKW6Z-9

2 m (6.5') 9 m (30')

12 mm max. (0.5")

20 mm (0.8")

6-Pin 6-Wire Pico

Accessories

SA-DIN-CLAMP Pair of metal DIN rail end stops; slide onto DIN rail at either side of D10B sensor stack; holds bussable power models together to maintain electrical connection Combination (#2 Phillips, #8 standard slotted) set screw SA-D10B-CAP Package of 5 each replacement terminal caps and plugs to cover beginning and end of stack of connected sensors

9.1 mm (0.63")

45.0 mm (1.77")

9.1 mm (0.36")

WARRANTY: Banner Engineering Corp. warrants its products to be free from defects for one year. Banner Engineering Corp. will repair or replace, free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the warranty period. This warranty does not cover damage or liability for the improper application of Banner products. This warranty is in lieu of any other warranty either expressed or implied.

P/N 117830 rev. E

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Transmission BibleDocument10 paginiTransmission BibleSoham DeÎncă nu există evaluări

- Masonry Concrete Masonry HandbookDocument31 paginiMasonry Concrete Masonry HandbookNguyễn Hoàng Bảo100% (2)

- Armstrong - Humidification Handbook PDFDocument40 paginiArmstrong - Humidification Handbook PDFJawwadTariqÎncă nu există evaluări

- Design, Construction and Testing of A Zeolite-Water Solar Adsorption RefrigeratorDocument128 paginiDesign, Construction and Testing of A Zeolite-Water Solar Adsorption Refrigeratortechfi50% (2)

- CONTRINEX Safety Screen CatalogDocument23 paginiCONTRINEX Safety Screen CatalogMemik TylnÎncă nu există evaluări

- Contrinex RfidDocument51 paginiContrinex RfidMemik TylnÎncă nu există evaluări

- CONTRINEX Series 600 Proximity Sensors PDFDocument38 paginiCONTRINEX Series 600 Proximity Sensors PDFMemik TylnÎncă nu există evaluări

- CONTRINEX Cable Distribution SystemDocument19 paginiCONTRINEX Cable Distribution SystemMemik TylnÎncă nu există evaluări

- CONTRINEX Fiber Optic SolutionsDocument23 paginiCONTRINEX Fiber Optic SolutionsMemik TylnÎncă nu există evaluări

- Banner Vision SensorsDocument32 paginiBanner Vision SensorsMemik TylnÎncă nu există evaluări

- CONTRINEX Capacitive Proximity SwitchesDocument15 paginiCONTRINEX Capacitive Proximity SwitchesMemik TylnÎncă nu există evaluări

- Banner R GAGE Radar SensorsDocument4 paginiBanner R GAGE Radar SensorsMemik TylnÎncă nu există evaluări

- Banner STB Touch ButtonsDocument26 paginiBanner STB Touch ButtonsMemik TylnÎncă nu există evaluări

- CONTRINEX Background Suppression SensorsDocument17 paginiCONTRINEX Background Suppression SensorsMemik TylnÎncă nu există evaluări

- Banner T18 Compact Photoelectric SensorsDocument37 paginiBanner T18 Compact Photoelectric SensorsMemik TylnÎncă nu există evaluări

- Banner VALU BEAM Series SensorsDocument48 paginiBanner VALU BEAM Series SensorsMemik TylnÎncă nu există evaluări

- Banner Midsize Photo EyesDocument41 paginiBanner Midsize Photo EyesMemik TylnÎncă nu există evaluări

- Banner Q45 Photoelectric SensorsDocument11 paginiBanner Q45 Photoelectric SensorsMemik TylnÎncă nu există evaluări

- Banner QL55 Luminescence SensorsDocument8 paginiBanner QL55 Luminescence SensorsMemik TylnÎncă nu există evaluări

- Banner R58 Color Mark SensorsDocument11 paginiBanner R58 Color Mark SensorsMemik TylnÎncă nu există evaluări

- Banner QL50 Luminescence SensorsDocument8 paginiBanner QL50 Luminescence SensorsMemik TylnÎncă nu există evaluări

- Banner PICO AMP MD14 AmplifiersDocument8 paginiBanner PICO AMP MD14 AmplifiersMemik TylnÎncă nu există evaluări

- Banner QC50 True Color SensorsDocument8 paginiBanner QC50 True Color SensorsMemik TylnÎncă nu există evaluări

- Banner Mounting BracketsDocument9 paginiBanner Mounting BracketsMemik TylnÎncă nu există evaluări

- Banner MINI BEAM Photo EyesDocument37 paginiBanner MINI BEAM Photo EyesMemik TylnÎncă nu există evaluări

- Banner Miniature Photo EyesDocument20 paginiBanner Miniature Photo EyesMemik TylnÎncă nu există evaluări

- Banner Measuring SensorsDocument57 paginiBanner Measuring SensorsMemik TylnÎncă nu există evaluări

- Banner D10 Analog Discrete OutputsDocument15 paginiBanner D10 Analog Discrete OutputsMemik TylnÎncă nu există evaluări

- Banner Fullsize Photo EyesDocument34 paginiBanner Fullsize Photo EyesMemik TylnÎncă nu există evaluări

- Theog Lift TD 080615Document52 paginiTheog Lift TD 080615HemantSharmaÎncă nu există evaluări

- Xaloy Barrel BR Russian Rev1Document4 paginiXaloy Barrel BR Russian Rev1matic91Încă nu există evaluări

- Dictionary of Car TermsDocument9 paginiDictionary of Car TermsrajmehaÎncă nu există evaluări

- TDS WAPDA Control CablesDocument3 paginiTDS WAPDA Control CablesAli ShahzadÎncă nu există evaluări

- Dep Trai Loi Tai AiDocument192 paginiDep Trai Loi Tai AiHoàng Hồng DươngÎncă nu există evaluări

- Deogiri Electronics Cluster Technical PresentationDocument23 paginiDeogiri Electronics Cluster Technical Presentationvikas BÎncă nu există evaluări

- SCHNEIDER Flusarc 36 36kV Gas Insulated - enDocument72 paginiSCHNEIDER Flusarc 36 36kV Gas Insulated - enjopsesÎncă nu există evaluări

- Just in TimeDocument4 paginiJust in TimeRohit KumarÎncă nu există evaluări

- Materials Cost UpdateDocument60 paginiMaterials Cost UpdateMark Roger Huberit IIÎncă nu există evaluări

- Chapter 1: Overview of Apple Inc 1.1. Introduction To General Information of Apple IncDocument8 paginiChapter 1: Overview of Apple Inc 1.1. Introduction To General Information of Apple IncLinh LêÎncă nu există evaluări

- Role and Scope of OpmDocument11 paginiRole and Scope of OpmMohammed ShahrukhÎncă nu există evaluări

- Characteristics, Applications, and Processing of Stress - Strain Behavior (I)Document7 paginiCharacteristics, Applications, and Processing of Stress - Strain Behavior (I)nelson bessoneÎncă nu există evaluări

- THERMOFOX Handheld Printer: Marking Materials Application GuideDocument2 paginiTHERMOFOX Handheld Printer: Marking Materials Application GuideEduin AguilarÎncă nu există evaluări

- SMCDocument175 paginiSMCarun988Încă nu există evaluări

- Coek - Info - Acorga Znx50a New Selective Reagent For The SolvenDocument16 paginiCoek - Info - Acorga Znx50a New Selective Reagent For The SolvenGeorgi SavovÎncă nu există evaluări

- RB - Specifications Piping MaterialsDocument21 paginiRB - Specifications Piping MaterialsFalcon PeregrinusÎncă nu există evaluări

- Natural VentilationDocument6 paginiNatural VentilationSumit Raina100% (1)

- Agilent Crosslab Dionex HPLC SystemsDocument12 paginiAgilent Crosslab Dionex HPLC SystemsJoão PauloÎncă nu există evaluări

- Sulfate Resistance of Filler Cement MortarDocument4 paginiSulfate Resistance of Filler Cement MortarAbd El Nour KahlochÎncă nu există evaluări

- PowerPoint Sample: BioDiesel Production Power Point PresentationDocument16 paginiPowerPoint Sample: BioDiesel Production Power Point PresentationJohn MelendezÎncă nu există evaluări

- Cableado IndustrialDocument16 paginiCableado IndustrialzerohuntercodeÎncă nu există evaluări

- LEVA Parts Catalog V1.4 COLORDocument84 paginiLEVA Parts Catalog V1.4 COLORMionnix KM-Service-premiumÎncă nu există evaluări

- A Virtual Exhibition On Food Processing Technology: List of Exhibitors (As of Now)Document3 paginiA Virtual Exhibition On Food Processing Technology: List of Exhibitors (As of Now)DevasyrucÎncă nu există evaluări

- QCD-F-18 TDC - 165, Rev.00, Dtd. - 14.04.2022Document2 paginiQCD-F-18 TDC - 165, Rev.00, Dtd. - 14.04.2022Ravi TyagiÎncă nu există evaluări

- How Does A Siphon Work?Document8 paginiHow Does A Siphon Work?Govarthanan GopalanÎncă nu există evaluări

- Steel ChemistryDocument22 paginiSteel ChemistryAmit Kumar UkeÎncă nu există evaluări