Documente Academic

Documente Profesional

Documente Cultură

Comparison Between Office and Factory Waste

Încărcat de

Kimmy2010Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Comparison Between Office and Factory Waste

Încărcat de

Kimmy2010Drepturi de autor:

Formate disponibile

A Comparison Between Factory Waste and Office Waste: Live Simulation Case Study in an Office Environment

Paper

Kleber F. Barcia

1023 W. Arkansas Ln Apt. 7 Arlington, TX 76013, USA The University of Texas at Arlington Industrial Manufacturing System Engineering Phone Number: 817-275-2747 Fax Number: 817-272-3406 Email: kleberbarcia@yahoo.com

Bonnie Boardman

PO Box 19017, 420 Woolf Hall Arlington, TX 76019 1107, USA The University of Texas at Arlington Industrial Manufacturing System Engineering Phone Number: 817-272-3220 Fax Number: 817-272-3406 Email: boardman@imse.uta.edu

Mary E. Johnson

PO Box 19017, 420 Woolf Hall Arlington, TX 76019 1107, USA The University of Texas at Arlington Industrial Manufacturing System Engineering Phone Number: 817-272-5919 Fax Number: 817-272-3406 Email: mjohnson@uta.edu

Keywords:

Office waste, lean office, office improvement, office environment, lean techniques

A Comparison Between Factory Waste and Office Waste: Live Simulation Case Study in an Office Environment

Abstract

In the overall production environment, the factory and the office areas have a strong relationship. This paper describes the different types of wastes and non-value added activities in the manufacturing process and their causes. Comparison is made between factory waste and office waste, and the relationship between the two work environments is discussed. A live simulation case study is presented to illustrate the relationship between office waste and factory waste, and to demonstrate the improvement of an office environment through the elimination of waste using lean techniques.

Introduction

In the overall production environment, the factory and the office areas have a strong relationship.

They are both connected and interdependent. The factory demands from the office the right paperwork on the line, at the right time, and in the right amounts [1]. The office demands from the factory the right product or service, at the right time, and in the right amounts. In this relationship, for example, quotations and approved purchase orders are sent to the customers with both product quantity and product delivery time based on the efficiency of the factory process. At the same time, the shop floor depends on the efficiency of document processing to get on-time sales orders and to have an accurate amount of raw material when it is needed. One goal of an enterprise is to reduce the overall lead time that the customer experiences [1]. Increasing product quality, shipping products on time to the customer, and improving the company net income are other goals that can be reached if a lean office works together with a lean factory. The

identification of wastes or non-value added activities in a factory allows eliminating these undesirable wastes through the application of lean techniques. In the same way, the identification of the non-value added activities in an office process allows eliminating them through the application of similar techniques and improves the overall process. Customers expect a higher degree of service each time a purchase is made. The trend of ever increasing customer expectations is expected to continue. A company must implement constant and radical change to develop and maintain a competitive advantage [2]. In recent years, companies have attempted numerous strategies to maximize shop floor efficiency, but companies have often ignored the importance of the office in overall efficiency. Office tasks represent from 50% to 80% of the total lead-time consumed, from receiving the request for the products to delivering the products to the customer [1]. Office tasks consist of as much as 95% non-value added time. Some strategies applied to increase efficiency on the shop floor are total

quality management (TQM), six sigma, reengineering, agility, and lean manufacturing. All of these strategies can also be successfully applied on the office. Suri states in his book, Quick Response Manufacturing, some reasons why office processes are significant, and why office processes are neglected in a manufacturing enterprise [3]. Why office processes are significant: They account for more than half the lead-time in many companies. They can account for more that 25% of the cost of goods sold. They can have a substantial impact on order capture rate.

Why office processes are neglected: A traditional focus on shop floor processes, stemming from the success of scientific management methods. Costing based on the direct labor. Absence of lead-time measurement for office activities. Lack of appreciation for the impact and benefits of lead-time reduction in the office. Cost-based mind-set and misconceptions about Quick Response Manufacturing methods. This paper describes the different types of waste or non-value added activities in a manufacturing process and their causes. Next, a comparison is made between factory waste and office waste. Finally the waste relationship between the two work environments is discussed. The objectives of this paper are twofold. First, establish the similarities and differences in factory waste and office waste. Secondly, provide background on lean principles used to transform an office into a high-performing lean office by identifying and eliminating non-value added activities. A live simulation is described which demonstrates the improvement of an office environment through the elimination of waste using lean techniques.

Factory Wastes

The key measure of a business process is lead-time. Lead-time is the amount of time that elapses

between when a customer requests something, and when the request is met and/or paid for. It consists of value-added time or activities, non-value-added time or activities, and business value-added time or activities [4]. A value-added activity is any activity that increases the market form or function of the product or service. These are things the customer is willing to pay for. A non-value-added activity is any activity that does not add market form, or function to the product or service, or is not necessary. These activities should be eliminated. A business value-added activity is any activity that does not add market form or function to the product or service but is necessary. These activities should be simplified, reduced, or integrated.

In some "good" non-engineered business processes, for every activity that adds value, about 30 activities will fail to add value [5]. Many processes like government entitlement programs, claims processing programs, and insurance approval programs will contain 1,000 or more non-value added activities for every value added activity. In a small company, typically 95 % of the lead-time is non-value added [6]. Waste or non-value-added activity is a term that was born within the Toyota Production System (TPS) [7]. They identify seven kind of waste in a factory area: overproduction, waiting time, transporting, over-processing, inventory (WIP), scrap and rework, and excess motion of operation. Waste is any work that does not add value to a product or service. If the customer does not benefit from it, it is waste [8]. The NIST MEP Lean Training and the Texas Manufacturing Assistance Center training on lean identified two additional wastes for lean factory: people waste, and material and natural resources waste. [4]. The Kaufman Consulting Group developed the Schlipstraeger Wastes that details different office wastes in four groups: people energy waste, process waste, information waste, and people work waste [8]. People energy wastes are divided into seven categories: structure waste, ownership waste, control waste, tampering waste, focus waste, assignment waste, and goal alignment waste. Process wastes are divided into eight categories: strategic waste, sub-optimization waste, unbalance flow waste, standardization waste, reliability waste, work-around waste, checking waste, and boundary waste. Information wastes are divided into five categories: hand-off waste, translation waste, missing information waste, irrelevant information waste, and inaccurate information waste. People work wastes are divided into three categories: processing waste, motion waste, and waiting waste. Mika states three additional types of waste. These are human underutilization, improper use of computers, and working to the wrong metrics. The most important of these is the second one, improper use of computers have added complexity, cost, and waste instead of decreasing them [9]. Wastes in an office can be identified and classified in the same way as wastes in a factory. Identifying and minimizing these wastes can create tremendous saving in office areas. Lean principles, kaizen methods, and reengineering approaches can be applied in an office environment for improving documentation flow and reducing the total lead-time in the process, in general, for achieving excellence in nonmanufacturing areas.

Lean Techniques

Lean is a systematic approach to identifying and eliminating waste or non-value added activities

through continuous improvement by flowing the product at the pull of the customer in pursuit of perfection [4]. Many companies make the mistake of introducing lean thinking only on the manufacturing processes. There is usually a great deal of waste and ineffectiveness within the companys office processes. Lean concepts must be applied throughout a business: order entry, product design, engineering, purchasing and inventory management, schedule and production control, cost accounting, and general accounting. It needs to

be subjected to the same waste analysis and waste elimination efforts as processes within the value streams. Lean principles include understanding customer value, introduction of flow and the pull approach, and the quest of perfection. All can be applied to office processes. Some advantages to making an office lean are: a company can make substantial savings by eliminating waste in the support process, a lean factory needs a lean office, and people, when freed from waste, are available to work on value-added activities [10]. A brief discussion of some lean techniques that can be used to improve an office processes follow.

3.1

Value Stream Mapping (VSM)

Value stream mapping involves step-by-step tracing of the activities that are involved in, ultimately,

the final product or service being delivered to the customer. It is a simple, visual approach that creates a clear picture of current material and information flow associated with a specific product family. Based on this picture, it is possible to identify lean techniques that can improve the flow and eliminate waste in the process. VSM also incorporates new ideas in a new picture of how material and information have to flow for that product group, creating an action plan that makes the new picture a reality. VSM is very important in an office environment. The steps that are taken in an office have a profound effect on what happen on the manufacturing floor. VSM helps workers to understand the flow of paperwork and the timing of that flow. Only then will it be possible to implement lean tools and techniques that can improve the flow and eliminate waste in the process.

3.2

5S

The 5 steps to workplace organization originally came from 5 words used by Japanese manufacturers

to achieve a clean, well-organized, and safe workplace. The National Institute of Standards and Technology Manufacturing Extension Partnership (NIST/MEP) defines the 5 S as follow: Sort. Perform Sort Through and Sort Out by placing a red tag on all unneeded items and moving them to a temporary holding area. Within a predetermined time, the red tag items are disposed, sold, moved or given away. Set in Order. Identify the best location for remaining items, relocate out of place items, set inventory limits, and install temporary location indicators. Shine. Clean everything, inside and out. Continue to inspect items by cleaning them and to prevent dirt, grime, and contamination from occurring. Standardize. Create the rules for maintaining and controlling the first 3 S and use visual controls. Sustain. Ensure adherence to the 5 S standards through communication, training, and self-discipline.

3.3

Point of Use Storage (POUS)

This lean technique states that the location of all parts, raw materials, tools, and fixtures has to be as

close as possible to where they are being used. In office processes, POUS eliminates non-value added kitting of any form or document, eliminates, altogether, the concept of a stockroom, improves inventory accuracy and tracking, and minimizes waste of transportation, processing, people, motion, and waiting.

3.4

Team Work and Cross Training

Process improvement teams are cross-trained and responsible for detecting waste. Departmental

barriers are eliminated and replaced with cross-functional teams that study the process and then immediately implement improvements. The Delaware Valley Industrial Resource Center presents a case study where a distributor of aircraft parts to the commercial and defense industries applied a cross-functional team approach to its order entry process. Customer service, technical support, purchasing, and quality assurance personnel formed the teams. The company reduced its lead-time by 66 %, from 3 months to 1 month [11].

3.5

Cellular Layout

This technique helps to decide the proper placement of equipment in a production or office

environment. The benefits of a good cellular layout are: reduced inventory, work in process, set-up time, and material handling; balanced work; improved use of human resources; improved control and automation; minimized walking time; and improved working area. Cellular layout includes work balancing, which maximizes worker efficiency by matching work content to tatk time.

3.6

Pull System

Another lean technique is flowing the product at the pull of the customer. A technique of controlling

the flow of resources by replacing only what has been consumed. Pull systems eliminate waste of handling, storage, expediting, obsolescence, repair, rework, facilities, equipment, and excess inventory (work-in-process and finished). Pull systems consist of small lots, low inventories, better communication, and management by sight. Converting the manufacturing process and the office process from a push system to a pull system can enable the entire company to run more smoothly. Change from traditional office to lean office often frightens office workers because it represents a dramatically different approach within the company, and demands a very different way of thinking about processing data [10]. Most people need a considerable amount of training and a gradual changeover to their new roles, as the company transforms lean principles from theoretical to an everyday reality throughout the workplace.

Factory Wastes and Office Wastes

Based on the factory waste definitions given by the NIST/MEP and the Texas Manufacturing

Assistance Center (TMAC), it is possible to establish a relationship between factory wastes and office wastes [4, 6]. Table 1 gives the definition of nine factory wastes and the definition for the same nine wastes found in the office area. It is important to establish waste similarities between these two areas. This allows minimizing the presence of waste in the whole process using the same techniques in both areas. Some of these similarities

are: factory and office try to produce more than they need; factory and office try to have more than they need; factory and office lose time waiting for processing a part or a form; and factory and office do not use the correct capacity of people in their areas. For instance, factory area and office area must know that they have to eliminate the common transportation waste. Factory people identify this problem as the necessity of reducing transportation of parts and materials around the plant and office people identify this problem as the necessity of reducing the transportation of forms and information around the office. Waste Overproduction

Inventory Defects Processing Waiting People Motion Transportation Material & Natural Resources

Factory Waste

Making more than is required, earlier than is required, and faster than is required by the next process Any supply in excess of a one-piece flow through your manufacturing process Inspection and repair of material in inventory Effort that adds no value to the product or service from the customers viewpoint Idle time created when waiting for something. The waste of not using peoples abilities (mental, creative, physical, skill). Any movement of people or machines that does not add value to the product or service Transporting parts and materials around the plant Anything that cannot be reused, recycled, or resold

Office Waste

Making more than is required, earlier than is required, and faster than is required by the next process Any supply in excess of a one-piece flow through your office process Inspection and correction of forms and information in inventory Effort that adds no value to the service from the customers viewpoint Idle time created when waiting for something. The waste of not using peoples abilities (mental, creative, physical, skill). Any movement of people or equipment that does not add value to the service. Transporting forms and information around the office Anything that cannot be reduced, reused, or recycled.

Table 1. Factory Waste and Office Waste Comparison

Definition, causes, and examples of each office waste are presented below.

4.1

Overproduction Waste

Overproduction waste can be defined as making more than is required by the next process, or making

earlier than is required by the next process, or making faster than is required by the next process. Causes of overproduction are: just-in-case logic, long process set-ups, unleveled scheduling, unbalanced workload, loss of focus on companys objective, weak organizational structure, ineffective supervision, and lack of communication. Examples of overproduction wastes are: printing documents earlier in batches due to long printer set-up, printing a document twice just in case, preparing monthly reports early, using a shotgun approach for analysis instead of a focused approach (lots of trade shows, instead of focusing on one), multiple bosses and multiple jobs cause wrong order of jobs, and memos to everyone. These examples can be thought of both in terms of too many things produced, and in terms of too much information gathered, stored, and maintained.

4.2

Inventory Waste

Inventory waste is any supply in excess of a one-piece flow through your office process. Causes of

excess inventory are: buying excessive supply material, bad scheduling, unbalanced workload, irrelevant data existence, unstructured reward system, inconsistent work speed, and just-in-case logic. Examples of inventory wastes are: buying supplies just-in-case (too many pens, papers), files pile up between work desks, documents are waiting to be matched or signed, and no storage space because it is filled with other items that are not needed.

4.3

Defect Waste

Defect waste is the inspection and correction of forms and information in inventory. Causes of

defects are: improperly trained/unskilled employees, lack of communication/information, performing monotonous work, doing processes in a rush, poor design of forms and equipment, bad quality of supply material, environmental problems, and confusing procedures. Examples of defect wastes are: improper lighting, not enough space to fill in forms, purchase order does not match with quotation, typographical error, lack of checklist, and leaky pens.

4.4

Processing Waste

Effort that adds no value to the service from the customers viewpoint is processing waste. Causes of

processing wastes are: just-in-case logic, lack of communication /information, redundant approval/inspection, true requirements undefined, improperly trained/unskilled employee, non-standardized business process, and re-entering data. Examples of processing wastes are: printing and mailing, faxing, overnight mailing, and emailing the same memo, lack of proper instruction for filling out forms, repetition of same information in different forms, use of different software in different departments when processing an order, and re-keying a purchase order.

4.5

Waiting Waste

Waiting waste is idle time created when waiting for something. Causes of waiting wastes are:

unbalanced workload, redundant approval, unreliable equipment, material waiting to be handled, improperly coordinated departments, long equipment setups, and inconsistent work speed. Examples of waiting wastes are: waiting for printer to warm-up, printer or computer break-down, mail delivery within the firm, different work schedules of team members meeting, attendees not all on time, and waiting for signatures.

4.6

People waste

People waste involves not using peoples abilities (mental, creative, physical, skill). Causes of people

wastes are: bad hiring practices, politics/corporate culture, improperly trained employees, old guard thinking, politics, and business culture. Examples of people wastes are: bypassing procedures to hire a favorite

candidate, start using MRP software without prior training, unclear qualifications, and not providing opportunity for growth.

4.7

Motion Waste

Any movement of people or equipment that does not add value to the service is motion waste.

Causes of motion wastes are: poor workplace organization, bad scheduling of work, taking many backups, improper/lack of training, nonstandard work methods, redundant approval, and bad hiring practices. Examples of motion wastes are: keeping forms far from reach of employees, looking for items because they do not have a defined place, unfilled papers, not grouping similar orders, saving files everywhere, employee working by experience instead of standard method, and making a draft before preparing formal document.

4.8

Transportation Waste

Transporting forms and information around the office is transportation waste. Causes of

transportation wastes are: poor location of office to other areas, poor location of supply to other desks, large file storage area, poor document flow scheduling, improper batch sizing, lack of signs, and defects. Examples of transportation wastes are: copier is too far from desk, paper and stapler kept away from printer and copier, no signs identifying areas or departments, walking back and forth to correct mistakes, and long travel for small amount of documents.

4.9

Material Waste & Natural Resources Waste

Anything that cannot be reduced, reused, or recycled makes up material waste and natural resources

waste. Causes of material and natural resource wastes are: poor purchasing habits, just-in-case logic, improperly trained or unskilled employees, poor efficiency of support equipment, and bad process and document design. Examples of material and natural resources wastes are: poor storage of temperature sensitive materials; use of poorly maintained copiers causing a waste of paper, ink, time and money; requirement of extra and unnecessary documents; poor utilization of paper space; too many copies in too many places; and non-energy efficient office equipment.

Lean Office Live Simulation

TMAC and the Automation & Robotics Research Institute (ARRI) are exploring the application of

lean principles in administrative processes. They have developed a lean office-training workshop with live simulation [6] to show the relationship between factory wastes and the office wastes. The live simulation also shows the implementation of the lean techniques in two office processes: the generation of quotations based on request for quotations and the generation of sales orders based on purchase orders.

10

The lean office simulation involves a mix of classroom style learning with an interactive live simulation, where participants take on the roles of managers and workers within a company. During the simulation, participants learn and use lean techniques, using the same terms taught in lean for the factory. The participants work in a traditional office environment with forms, calculators, and procedures. By the end of the simulation, they helped redesign a leaner office that gets more done with less effort. In the office live simulation, two departments are setup and staffed to process Request For Quotations (RFQ) and Purchase Orders (PO) that come from the company's customers. The two departments are the Sales Department and the Estimating Department. The Sales Department handles all interactions with the customer. The Sales Department receives RFQ's, requests quotes, checks credit, receives PO's, accepts PO's, issues Sales Orders, and other customer contact. The Estimation Department provides current quotes on manufacturing and material costs, and inventory availability. See Figure 1.

Quotation / Purchase VP

Production Department

Sales Department

Estimating Department Warehouse Sales Sales

RFQ RFQA PO POA POC Q

Customer Order Entry Department Billing/Invoice Department

Figure 1. Workflows in the Sales and Estimating Departments

The office is transformed in three "rounds". Improvements are implemented for each "round". Through the implementation of the lean techniques, the office is transformed from a confused and slow environment to a much more efficient, effective, and predictable one. The relationship between the factory wastes and the office wastes, and the implementation of the lean techniques in two office processes is presented in three steps: Round one-office waste identification. The office wastes are identified based on the factory wastes classification defined by NIST/MEP and TMAC. Round two-lean techniques implementations. After running round one, most of the office wastes are identified. A set of lean techniques is implemented to improve the process as seen in Table 2.

11

Round three-lean techniques implementations. After running round two, additional lean techniques are applied to eliminate wastes. Team work, cross training, cellular layout (see Figure 2), and pull system are implemented. See Table 3.

Waste

Inventory

Description

Buying stuff just-in-case (too many pens, papers) Files pile up between work desks No storage space because it is filled with other stuff we dont need Papers not filed Saving files everywhere No signs identifying areas or departments Keeping forms far from reach of workers

Lean techniques implemented

Changes incorporated in Round 2

Improve documentation (forms & logs) Implement inboxes Remove unnecessary items & forms

5S

Motion

Transportation

Visual Control POUS

Use big signs Use labels on trays

Motion

Remove document keeper Forms available near to the desk

Transportation

Copier is too far from desk

Layout

Move fax closer to sales representative 1 Simplify process Zero copies Improve forms

Overproduction Processing

Material and Natural Resources Defect

Copy documents twice just-in-case Lack of proper instruction for filling out form Repetition of same information in different forms Requirement of extra and unnecessary documents Not enough space to fill in forms

Standardized Work

Reassign work tasks Eliminate steps

Table 2. Round 2. Waste Identified and their Related Lean Techniques

12

Quotation Process

Sales Rep. 2

Inbox Inbox

Sales Manager

To Customer To Order Entry Dept.

Inbox

Fax

Fax

Documentation

Inbox

Inbox

Estimation Assistant

Sales Rep. 1

From Customers

Figure 2. Round 3. Workflows

Waste

Transportation People People Processing Waiting Processing

Description

Long travel for small amount of documents Underutilized workers Workers do not help each other Confusing document flow Documents are waiting to be matched or signed Confusing document flow

Lean technique implemented

Team work Cross training Cellular layout Work Balancing Pull System

Changes incorporated in Round 3

Work as a team Just one department All employees have multiple skills Implement U-shape layout Balance work between team members One piece flow

Table 3. Round 3. Waste Identified and their Related Lean Techniques

The live simulation demonstrates that it is possible to improve the office environment productivity using lean techniques. Some results from previously run simulations are: Movement and transportation of orders decreased 95 %. Total cycle time for generating a quotation decreased 75 %. Office cost and employee cost decreased 50 %. Number of RFQ processed increased 450 %. RFQ in the process (WIP) at the end of the simulation cycle decreased 100 %.

13

Conclusion

Wastes in an office environment can be treated in the same way that wastes are treated in a factory.

Identifying and minimizing these wastes can create tremendous savings in office areas. In an enterprise, the connection between the office and the factory is key to reducing overall lead-time. Lean principles can be applied to office areas for improving documentation flow and reducing the total lead-time. To promote integration and cooperation in the enterprise, lean training for office employees should contain the same terminology as the lean training for the factory. A combination of classroom training and live simulation is recommended. The live simulation has been used to demonstrate lean principles to office employees.

References

[1] B. S. Boardman and M. E. Johnson, "Lean Techniques in an Office Setting," Proceedings of the 2001 8th Annual E&R Foundation Summer Workshop. Chicago, IL, July 2001. [2] D. R. Underdown, "An Entreprise Transformation Methodology," Industrial Engineering. Arlington, TX: University of Texas at Arlington, 1997, pp. 315. [3] R. Suri, Quick Response Manufacturing: A Companywide Approach to Reducing Lead Times: Productivity Press Inc., 1998. [4] NIST/MEP, "Principles of lean manufacturing 101," National Institute of Standards and Technology Manufacturing Extension Partnership 1998. [5] D. Ulis, "Business Process Engineering," CMA Management Accounting Magazine, vol. 67, 1993, pp. 21-25. [6] TMAC and ARRI, "Lean Office Training," Texas Manufacturing Assistance Center and Automation & Robotics Research Institute, Fort Worth, TX 2001. [7] [8] J. P. Womack and D. T. Jones, Lean Thinking. New York: Simon & Schuster, 1996. KCG, "Office Kaizen: Making lean work in service environment," The Kaufman Consulting Group, LLC, Carmel, IN 1999. [9] [10] G. Mika, "Eliminating all muda," Manufacturing Engineering, vol. 126, 2001, pp. 18. B. Maskell, "Accounting for lean manufacturing," Manufacturing Engineering, vol. 125, 2000, pp. 46-47. [11] DVIRC, "Administrative flow," Delaware Valley Industrial Resource Center, Delaware 2000.

14

Bibliographies

Kleber F. Barcia is a Ph. D student of Industrial and Manufacturing Systems Engineering Department at The University of Texas at Arlington (UTA). Kleber is also a Graduate Assistant Researcher at UTA Automation & Robotics Research Institute (ARRI). Kleber has a BS in Mechanical Engineering, MS in Agricultural Economics, and he is currently working on his Ph.D. dissertation. He has experience in lean office techniques application. For the past 2 years at ARRI, he has been focusing on the development of the lean office workshop. His research interests are lean techniques, industrial simulation, and industrial processes design. He is currently working in the development of a methodology to identify and eliminate non-value added in office environment in small companies. USA. Bonnie Boardman is an Assistant Professor of Industrial and Manufacturing Systems Engineering at The University of Texas at Arlington. Her primary research interests are in the logistics and resource planning disciplines. Dr. Boardman holds a B.S. and Ph.D. in Industrial Engineering from The University of Arkansas and an M.S. in Industrial Engineering from Texas A&M University. Dr. Boardman is active in numerous technical and professional organizations. She is the student advisor for the UTA Alpha Pi Mu, the National Industrial Engineering honor society and a co-sponsor of the APICS student chapter, the Educational Society for Resource Management. She also holds the position of Newsletter Editor for the Greater Fort Worth Chapter of APICS. USA. Mary E. Johnson is the Enterprise Engineering Program Coordinator at The University of Texas at Arlington Automation & Robotics Research Institute (ARRI). Mary has a Ph.D in Industrial Engineering. She has hands-on experience as an Industrial Engineer in the aerospace, beverage packaging, and financial services industries. For the past 10 years at ARRI, she has been focusing on the development of the discipline of Enterprise Engineering http://arri.uta.edu/eif/. She has published papers on enterprise performance measures, strategic justification of enterprise technologies, strategic information systems, enterprise modeling, and enterprise process design. Her research interests are enterprise design, supply chain design, performance measures, chaos theory in manufacturing, and complexity. USA.

S-ar putea să vă placă și

- Internet Trends 2019Document334 paginiInternet Trends 2019Kate Clark91% (144)

- SRS DOCUMENT (Hospital Management System)Document24 paginiSRS DOCUMENT (Hospital Management System)Aaqib Sultan80% (5)

- Data Science EssayDocument2 paginiData Science EssayAbdelhak100% (1)

- Lean ManufacturingDocument13 paginiLean ManufacturingMohammad Shaniaz IslamÎncă nu există evaluări

- Operation ManagementDocument17 paginiOperation ManagementAman Gupta0% (1)

- Jamaica Passport Application CompressedDocument6 paginiJamaica Passport Application CompressedScreen MorrisonÎncă nu există evaluări

- 00 Cockpit DoorDocument18 pagini00 Cockpit DoorKıvanc Terzioglu100% (1)

- Arista Openstack Deployment GuideDocument40 paginiArista Openstack Deployment GuideegondragonÎncă nu există evaluări

- A Lean Office Eliminates Waste-June-23-2010Document5 paginiA Lean Office Eliminates Waste-June-23-2010Asel Juárez ViteÎncă nu există evaluări

- 1.1 Lean SystemDocument21 pagini1.1 Lean SystemSujoy DattaÎncă nu există evaluări

- BPM - Lean Unit 4Document22 paginiBPM - Lean Unit 4Srinivas VissapragadaÎncă nu există evaluări

- First Examination in CBM112Document4 paginiFirst Examination in CBM112Jhoyce LumbaÎncă nu există evaluări

- What Is LeanDocument19 paginiWhat Is LeanRudford GectoÎncă nu există evaluări

- Creating QRM EnterprisesDocument6 paginiCreating QRM EnterprisesMohamed YassinÎncă nu există evaluări

- What Is Lean Manufacturing?: Costs and Improved Product QualityDocument8 paginiWhat Is Lean Manufacturing?: Costs and Improved Product QualityMuruga SriÎncă nu există evaluări

- Steps To Improve QualityDocument10 paginiSteps To Improve Qualityabhijit612Încă nu există evaluări

- Question No:01: What Do You Understand by Process Strategy and Process Analysis?Document5 paginiQuestion No:01: What Do You Understand by Process Strategy and Process Analysis?richard gomesÎncă nu există evaluări

- Office Kaizen: Making Lean Work in Service EnvironmentsDocument17 paginiOffice Kaizen: Making Lean Work in Service EnvironmentsMeseret AbebeÎncă nu există evaluări

- Term Report: Seven Deadly Wastes That Could Cost Your CompanyDocument9 paginiTerm Report: Seven Deadly Wastes That Could Cost Your CompanyAnum IqbalÎncă nu există evaluări

- Lean Production For Competitive Advantage A Comprehensive Guide To Lean Methodologies and Management Practices 1st Nicholas Solution ManualDocument38 paginiLean Production For Competitive Advantage A Comprehensive Guide To Lean Methodologies and Management Practices 1st Nicholas Solution Manualwilsonpadillae65p0100% (15)

- VSM Lean Office-A Case StudyDocument13 paginiVSM Lean Office-A Case StudySilviaÎncă nu există evaluări

- Chapter 1 Operation ManagementDocument9 paginiChapter 1 Operation ManagementOnline EducationÎncă nu există evaluări

- WP Eliminate 7 Wastes LTR v3Document10 paginiWP Eliminate 7 Wastes LTR v3southcactusÎncă nu există evaluări

- A Handbook of IPE ToolsDocument13 paginiA Handbook of IPE ToolsS M Ataul KarimÎncă nu există evaluări

- EsterlineDocument7 paginiEsterlineTushar Joshi100% (2)

- LOMDocument6 paginiLOMrajkumar0507Încă nu există evaluări

- Lean in ServicesDocument1 paginăLean in ServicesSandeep SinghÎncă nu există evaluări

- Peration ManenemtDocument8 paginiPeration ManenemtCool BuddyÎncă nu există evaluări

- Om NotesDocument134 paginiOm NotesGovernment PolytechnicÎncă nu există evaluări

- Wilshire BLVD Ste B1008 LA CA 90025 310.473.9064: LW and AssociatesDocument6 paginiWilshire BLVD Ste B1008 LA CA 90025 310.473.9064: LW and AssociatesJainendra GautamÎncă nu există evaluări

- Advantages:: Accounting Records. It Is A Means To Ensure That Cost Accounting Records Are inDocument4 paginiAdvantages:: Accounting Records. It Is A Means To Ensure That Cost Accounting Records Are inPooja AdhikariÎncă nu există evaluări

- Assignment Module 1 OMDocument5 paginiAssignment Module 1 OMAkash Singh Rajput0% (1)

- A Project ON Lean Manufacturing Prepared BY Kunal Bansal Ty-D ROLL NO: 3204Document10 paginiA Project ON Lean Manufacturing Prepared BY Kunal Bansal Ty-D ROLL NO: 3204Kunal BansalÎncă nu există evaluări

- Lean EnterpriseDocument5 paginiLean EnterpriseNAEEMÎncă nu există evaluări

- Ion For LeanDocument8 paginiIon For LeanDarshan AshokkumarÎncă nu există evaluări

- Lean Manufacturing Research PaperDocument6 paginiLean Manufacturing Research Papercan8t8g5100% (1)

- Week 1 - 3Document40 paginiWeek 1 - 3OZIUR Create PrintshopÎncă nu există evaluări

- 8 Waste in FinanceDocument5 pagini8 Waste in FinanceBunret EatÎncă nu există evaluări

- Unit 8 Business Process Re-Engineering: StructureDocument30 paginiUnit 8 Business Process Re-Engineering: StructurePrashant SatamÎncă nu există evaluări

- Research Paper Lean ManufacturingDocument4 paginiResearch Paper Lean Manufacturingajqkrxplg100% (1)

- Operations Management Handbook With Questions & AnswersDocument289 paginiOperations Management Handbook With Questions & AnswersxamzaÎncă nu există evaluări

- Operation ManagementDocument8 paginiOperation ManagementZEESHAN ALIÎncă nu există evaluări

- Lean Manufacturing, or Lean Production DefinitionDocument8 paginiLean Manufacturing, or Lean Production DefinitionAnjan KumarÎncă nu există evaluări

- Reflection Essay On Role of Operations ManagementDocument3 paginiReflection Essay On Role of Operations ManagementshaniÎncă nu există evaluări

- 8 Forms of Waste in A Foundry Shop and Strategies For Elimination 1Document8 pagini8 Forms of Waste in A Foundry Shop and Strategies For Elimination 1Muhammad UsmanÎncă nu există evaluări

- What Is LeanDocument18 paginiWhat Is LeanraunÎncă nu există evaluări

- Assignment Report ON: " " (451) Unit - IiiDocument13 paginiAssignment Report ON: " " (451) Unit - IiiRobin GanjooÎncă nu există evaluări

- Process ManagementDocument11 paginiProcess Managementzoref333Încă nu există evaluări

- Blending The Best of Lean Production and Six SigmaDocument12 paginiBlending The Best of Lean Production and Six SigmaMansoor AliÎncă nu există evaluări

- SCM Assignment DoneDocument12 paginiSCM Assignment DoneAdarsh Kumar RoyÎncă nu există evaluări

- Study Guide For ProdmanDocument5 paginiStudy Guide For ProdmanReimon DoblonÎncă nu există evaluări

- Essay On The Seven Wastes of Enterprises Based On The Theory of Industrial Engineering and Lean ProductionDocument3 paginiEssay On The Seven Wastes of Enterprises Based On The Theory of Industrial Engineering and Lean ProductionMarco Zannie CalkinsÎncă nu există evaluări

- EMBA OM Mid Term 1 Examination Fall 2021Document13 paginiEMBA OM Mid Term 1 Examination Fall 2021Ruel OrvilÎncă nu există evaluări

- Rupesh Patel: Productions and Operations Management ProfDocument51 paginiRupesh Patel: Productions and Operations Management ProfJayendra Patel100% (1)

- ReportsssDocument6 paginiReportsssVia SahipaÎncă nu există evaluări

- 1-Ans. Competitiveness Is at The Core of All Strategies. Even Among Them, Priorities Tend ToDocument5 pagini1-Ans. Competitiveness Is at The Core of All Strategies. Even Among Them, Priorities Tend Toajayabhi21Încă nu există evaluări

- Lean Project Management PDFDocument55 paginiLean Project Management PDFMaryam KhushbakhatÎncă nu există evaluări

- Lean Mro ProductivityDocument6 paginiLean Mro ProductivityDeepak BindalÎncă nu există evaluări

- The 7 Wastes ExplainedDocument12 paginiThe 7 Wastes ExplainedChitrakant DeshmukhÎncă nu există evaluări

- Unit Test OmDocument18 paginiUnit Test OmCool BuddyÎncă nu există evaluări

- Lean Management - ShilDocument3 paginiLean Management - ShilSachith SojuÎncă nu există evaluări

- Bpo2 PPT 2Document17 paginiBpo2 PPT 2Mary Lynn Dela PeñaÎncă nu există evaluări

- Improvement Programs, Starting With Just-In-Time (JIT) and Passing Onto Total QualityDocument16 paginiImprovement Programs, Starting With Just-In-Time (JIT) and Passing Onto Total QualityNawshad HasanÎncă nu există evaluări

- Manufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesDe la EverandManufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesEvaluare: 4.5 din 5 stele4.5/5 (3)

- Identifying Mura-Muri-Muda in the Manufacturing Stream: Toyota Production System ConceptsDe la EverandIdentifying Mura-Muri-Muda in the Manufacturing Stream: Toyota Production System ConceptsEvaluare: 5 din 5 stele5/5 (1)

- How to Enhance Productivity Under Cost Control, Quality Control as Well as Time, in a Private or Public OrganizationDe la EverandHow to Enhance Productivity Under Cost Control, Quality Control as Well as Time, in a Private or Public OrganizationÎncă nu există evaluări

- Economics in The Time of COVID-19Document123 paginiEconomics in The Time of COVID-19Kimmy2010Încă nu există evaluări

- 2010 Culturapolitica Corrected PDFDocument309 pagini2010 Culturapolitica Corrected PDFKimmy2010Încă nu există evaluări

- CMU-special-audit-final-new 2Document12 paginiCMU-special-audit-final-new 2Kimmy2010Încă nu există evaluări

- Careers Music BusinessDocument5 paginiCareers Music BusinessKimmy2010Încă nu există evaluări

- DCFS Annual Report 2016-2017 PDFDocument45 paginiDCFS Annual Report 2016-2017 PDFKimmy2010Încă nu există evaluări

- CMU-special-audit-final-new 2Document12 paginiCMU-special-audit-final-new 2Kimmy2010Încă nu există evaluări

- CMU-special-audit-final-new 2Document12 paginiCMU-special-audit-final-new 2Kimmy2010Încă nu există evaluări

- Jamiacan MaroonDocument19 paginiJamiacan MaroonMaxine RoseÎncă nu există evaluări

- Agricultural Report JamaicaDocument36 paginiAgricultural Report JamaicaKimmy2010Încă nu există evaluări

- Details ST Kitts and Nevis enDocument10 paginiDetails ST Kitts and Nevis enKimmy2010Încă nu există evaluări

- DCFS Annual Report 2016-2017 PDFDocument45 paginiDCFS Annual Report 2016-2017 PDFKimmy2010Încă nu există evaluări

- At Risk Youth in JamaicaDocument17 paginiAt Risk Youth in JamaicaKimmy2010Încă nu există evaluări

- Jamiacan MaroonDocument19 paginiJamiacan MaroonMaxine RoseÎncă nu există evaluări

- JustBet Programme For October 1 October 3 2019Document37 paginiJustBet Programme For October 1 October 3 2019Kimmy2010Încă nu există evaluări

- Visa RequirementsDocument2 paginiVisa RequirementsKimmy2010Încă nu există evaluări

- Impacts On Marine LifeDocument10 paginiImpacts On Marine LifeKimmy2010Încă nu există evaluări

- EndofLife PositionStatement ANADocument10 paginiEndofLife PositionStatement ANADwi Satria SulaimanÎncă nu există evaluări

- Supporting and Strengthening Families Through Expected and Unexpected Life Events PDFDocument59 paginiSupporting and Strengthening Families Through Expected and Unexpected Life Events PDFKimmy2010Încă nu există evaluări

- What Is LifeDocument54 paginiWhat Is LifeSonalÎncă nu există evaluări

- Betting OddsDocument35 paginiBetting OddsKimmy2010Încă nu există evaluări

- Betting OddsDocument35 paginiBetting OddsKimmy2010Încă nu există evaluări

- Case Study Ethical BusinessesDocument1 paginăCase Study Ethical BusinessesKimmy2010Încă nu există evaluări

- Towards A Definition of Tourism, Tourist, and The Tourist IndustryDocument18 paginiTowards A Definition of Tourism, Tourist, and The Tourist IndustryKimmy2010Încă nu există evaluări

- Introduction The Tourist Gaze 4.0 Uncove PDFDocument12 paginiIntroduction The Tourist Gaze 4.0 Uncove PDFKimmy2010Încă nu există evaluări

- Residents Want Candidates Grilled Before Taking Public OfficeDocument6 paginiResidents Want Candidates Grilled Before Taking Public OfficeKimmy2010Încă nu există evaluări

- Kingston JP Listing 2019Document96 paginiKingston JP Listing 2019Kimmy2010Încă nu există evaluări

- Towards A Definition of Tourism, Tourist, and The Tourist IndustryDocument18 paginiTowards A Definition of Tourism, Tourist, and The Tourist IndustryKimmy2010Încă nu există evaluări

- Towards A Definition of Tourism, Tourist, and The Tourist IndustryDocument18 paginiTowards A Definition of Tourism, Tourist, and The Tourist IndustryKimmy2010Încă nu există evaluări

- Epsilon 140z DatasheetDocument2 paginiEpsilon 140z DatasheetRiga RingsÎncă nu există evaluări

- 1KEK Transferring Payables - Receivables To PCADocument6 pagini1KEK Transferring Payables - Receivables To PCABrigitta BallaiÎncă nu există evaluări

- Advanced Motion Controls PS2X3W48Document4 paginiAdvanced Motion Controls PS2X3W48Servo2GoÎncă nu există evaluări

- Xeon Phi CompleteDocument88 paginiXeon Phi CompleteNecmettin yıldızÎncă nu există evaluări

- Knoweldge Repository & Academic Searching TechniquesDocument44 paginiKnoweldge Repository & Academic Searching TechniquesSumesh John100% (2)

- MT7-TL10C900B326 Software Upgrade GuidelineDocument8 paginiMT7-TL10C900B326 Software Upgrade Guidelinehilal288Încă nu există evaluări

- RSP CalibrationDocument23 paginiRSP CalibrationHanyi JangÎncă nu există evaluări

- SI3000 Pono Datasheet PDFDocument2 paginiSI3000 Pono Datasheet PDFJose JoseÎncă nu există evaluări

- 20090610144043A ProductsDocument16 pagini20090610144043A ProductsidontlikeebooksÎncă nu există evaluări

- ATM - Using Fingerprints: University Institute of Technology, Burdwan UniversityDocument25 paginiATM - Using Fingerprints: University Institute of Technology, Burdwan UniversitysaRAth asgaRdianÎncă nu există evaluări

- Understanding Design ThinkingDocument4 paginiUnderstanding Design ThinkingHazell DÎncă nu există evaluări

- Lukas First ResponseDocument4 paginiLukas First ResponseForum PompieriiÎncă nu există evaluări

- Network Protocols PDFDocument39 paginiNetwork Protocols PDFMohan PreethÎncă nu există evaluări

- ICEpower700AS1-X Datasheet 1 6 PDFDocument46 paginiICEpower700AS1-X Datasheet 1 6 PDFGustavo Helldorff UndurragaÎncă nu există evaluări

- Gas Turbine MCQDocument6 paginiGas Turbine MCQnimymech100% (1)

- User Manual: TOTOLINK Wireless-N RouterDocument32 paginiUser Manual: TOTOLINK Wireless-N Routeremil4alexeÎncă nu există evaluări

- Experience: DEVOPS ENGINEER, Wipro Technologies (Pune)Document2 paginiExperience: DEVOPS ENGINEER, Wipro Technologies (Pune)Rishabh PareekÎncă nu există evaluări

- Pengaruh Mobile Shopping Service Quality Terhadap Loyalitas Pelanggan Dimediasi Oleh Kepuasan Pelanggan Mobile Site Tokopedia Di Kota YogyakartaDocument12 paginiPengaruh Mobile Shopping Service Quality Terhadap Loyalitas Pelanggan Dimediasi Oleh Kepuasan Pelanggan Mobile Site Tokopedia Di Kota YogyakartaDanang WibisonoÎncă nu există evaluări

- Medieval/Middle Ages: Science Technology and SocietyDocument10 paginiMedieval/Middle Ages: Science Technology and SocietyMelchorCandelaria100% (1)

- Plano Electrico Cargador 938KDocument34 paginiPlano Electrico Cargador 938KANDRES FUENTES FANDIÑOÎncă nu există evaluări

- Ashok Leyland: General OverviewDocument5 paginiAshok Leyland: General OverviewDevendra PawarÎncă nu există evaluări

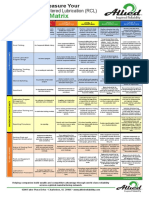

- Allied Maturity Matrix 14 Reliability Centered Lubrication PDFDocument2 paginiAllied Maturity Matrix 14 Reliability Centered Lubrication PDFHossein100% (1)

- Keywords: Google Jamboard, E-Learning, Digital Tools, Level of Acceptance, PISMP StudentsDocument12 paginiKeywords: Google Jamboard, E-Learning, Digital Tools, Level of Acceptance, PISMP StudentsnijalÎncă nu există evaluări

- CA2 - UML Diagrams For ATM V3a PDFDocument4 paginiCA2 - UML Diagrams For ATM V3a PDFMick SousaÎncă nu există evaluări

- AbbriviationDocument8 paginiAbbriviationDushan SenarathneÎncă nu există evaluări

- (4th Year) Roadmap To Dream PlacementDocument1 pagină(4th Year) Roadmap To Dream PlacementashwinÎncă nu există evaluări