Documente Academic

Documente Profesional

Documente Cultură

A Theory For Breakdown of Anodic Oxide Films On Metals

Încărcat de

Thiago Scremin BonelliTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

A Theory For Breakdown of Anodic Oxide Films On Metals

Încărcat de

Thiago Scremin BonelliDrepturi de autor:

Formate disponibile

Ekctrcchimka

Acta, 1971. Vol. 16. pp. 1683 to 1692. Pers~mon Press. Printed in Northern IccJand

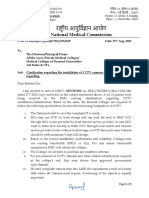

A THEORY FOR BREAKDOWN OF ANODIC OXIDE FILMS ON METALS*

N. SATO Electrochemistry Laboratory, Faculty of Engineering, Hokkaido University, Sapporo, Japan

Ahs&act--The breakdown of anodic oxide films that results in pitting and transpassive dissolution is described thermodynamically as a mechanical deformation or crack formation. The electrostriction pressure due to a high electric field of the order of 10 V/cm produces a compressive stress which could exceed the breakdown stress of oxide films. The surface tension stabilizes anodic oxide fihns, but this surface effect decreases with increasing film thickness. Thus, there is a critical thickness above which mechanical deformation or breakdown of the oxide film could occur. Anion adsorption lowers the surface tension and hence decreases the critical thickness for breakdown. The net stress in anodic oxide films produced by electrostriction and surface tension effects is derived as a function of electric field, dielectric constant, surface tension and lilm thickness, and the breakdown potential at which the film thickness is critical is shown to depend on the anion concentration in solution. The theory is compared with experiments on the effect of halogen ion concentration on the breakdown potential and the effect of inhibitive anions on film breakdown for aluminum and stainless steel. Pore formation and transpassive dissolution of anodic oxide films are also discussed.

R6su&--La

rupture des &h-m anodiques doxyde par suite de piqGres et de dissolution transpassive est interprttke thermodynamiquement comme une deformation mhnique ou une formation de craquelure. La pression dtlectrostriction dite & un champ Clectrique Clevk de lordre de 10 V/cm produit une pression de contrainte qui peut exo5der la pression de rapture des films doxyde. La tension superficielle stabilise les films doxyde anodiques, mais cet effet supeticiel dt?c.rolt quand 16paisseur du film augmente. Ainsi, il y a une Bpaisseurcritique au-dessus de laquelle la d&formation m&anique ou la rupture du film doxyde peut apparaitre. Ladsorption anionique diminue la tension superficielle et db 16paisseur critique de rupture. La tension nette dans les films anodiques doxyde produits par Blectrostriction et les effets de la tension superficielle sont obtenus en fonction du champ Clectrique, de la constante di&ctrique, de la tension supeticielle et de lkpaisseur du film; le potentiel de rupture poru lequel lepaisseur du film est critique est montre d+endre de la concentration en anion dans la solution. La thkorie est cornpar& & lexp&ience par linfluence de la concentration en ion halog&mue sur le potentiel de rupture et Iinfluence des anions inhibiteurs sur la rupture du film pour laluminium et lacier inoxydable. La formation de pore et Ia dissolution transpassive des films doxyde anodiques sont aussi discutbes. Zusammenfassung-Der Durchbruch von anodischen Oxydschichten, der zu Lochfrass und transpassiver Aufliisung ftihrt, wird thermodynamisch als mechanische Deformation oder Rissbildung beschrieben. Der Elektrostriktionsdruck aufgrund der starken Felder von ca. 10s V/cm bewirkt eine Druckspannung, welche grbsser als die Durchbruchsspannung werden ktinnte. Die Oberfltihenspannung stabilisiert anodische Oxydschichten, dieser Effekt wird jedoch mit zunehmender Schichtdicke geringer. Es gibt deshalb eine kritische Schichtdicke, oberhalb welcher mechanische Deformation oder Durchschlag der Oxydschicht eintreten kann. Die Adsorption von Anion vermindert die OberflWhenspannung und setzt somit die kritischeSchichtdicke herab. Diese in anodischen Oxydschichten durch Elektrostriktion und Oberflachenspannungseffekte bewirkte Spannung wird als Funktion des Feldes, der Dielektrizitatskonstanten, der Oberfllchenspannung und der Schichtdicke abgeleitet. Es wird gezeigt, dass das Durchschlagspotential, bei welchem die Schichtdicke kritisch ist, von der Anionenkonzentration in der Lijsung abhlngt. Diese Theorie wird mit Experimenten iiber den Einfluss der Halogenionenkonzentration auf das Durchschlagspotential und iiber den Einfluss inhibierender Anionen auf den Durchschlag der Schichten auf Aluminium und rostfreiem Stahl. Die Porenbildung und die transpassive Auflijsung anodischer Oxydschichten werden ebenfalIs diskutiert. INTRODUCTION

THE

of anodic oxide films that leads to pitting or transpassive dissolution is one of the most important and basic problems in corrosion research, and a number of investigations has therefore been made on the phenomenon for a variety of metals, * Manuscriptreceived3 April 1970.

BREAKDOWN

Presented at the 16th Annual Symposium on Corrosion and Protection, Kanazawa, October 1969. 1683

Japan,

1684

N. SATO

especially for aluminum and stainless steel, in the past decade. Recent reviews of the subject have been given by Kolotyrkin,l Schwenk,* Herbsleb,3 Kaesche, Hoar,6 Sates and Morioka. Among breakdown phenomena, the existence of a critical breakdown potential, confirmed recently for stainless steel by Leckie and Uhlig and for aluminum by Kaesche,a is of importance and can offer a key for clarifying the breakdown mechanism. Based on the concept of a breakdown potential and other experimental facts, theories have been proposed in the literature to describe the breakdown as a chemical or electrochemical reaction occurring between the passive oxide film and aggressive anions absorbed on it. They could not, however, get into the details of the breakdown process with success. Recently, HoaId has suggested a mechanical mechanism for anion penetration into the passive film taking into account the role of the surface tension, which may be so far lowered by anion adsorption that a kind of peptization producing cracks or splits in the film occurs. Since the existence of mechanical stress in anodic oxide Glms on metals has often been recognized, it is worth investigating whether the breakdown of anodic films due to the internal stress is possible. Stress in anodic oxide tis can arise for several reasons: (a) interfacial tension of the film, (b) electrostriction pressure resulting from the presence of a high electric field in the film,lO (c) internal stress caused by the volume ratio of the film and the metal, being compressive if anions are more mobile than cations in the Clm,ll (d) internal stress due to partial hydration or dehydration of the fIlm,12 and (e) local stress caused by impurities. r3 Stress in anodic films, therefore, is dependent on a variety of factors such as metal surface, impurity, film-formation condition and mm-growth mechanism, and is difficult to quantify in a simple form. In the present paper we take account only of the interfacial tension and the electrostriction pressure, for these are general to any kind of anodic oxide film and can be examined in the framework of thermodynamics. The electric field in passive anodic oxide films has been shown to be of the order of lOe-10 V/cm, which is large enough to produce considerable electrostriction pressure. Furthermore, passive anodic oxide films are extremely thin (10-1000 A) so that the interfacial tension effect cannot be neglected in discussing the property of anodic oxide films. The present paper derives thermodynamically the stress in anodic oxide films produced by the interfacial tension and the electrostriction pressure, and explains the breakdown potential and the effect of anion on it.

THERMODYNAMICS OF ANODIC OXIDE FILM

We consider a solid dielectric film in contact with metal on one side and with solution on the other side, which is mechanically free to deform on the side of solution but restrained on the metal surface. The area of the film, A, is so great in comparison with its thickness, L, that the non-uniformity at the edges is negligible. The pressure, p, acting vertically to the film, which will be called here the Clm pressure, is determined by the atmospheric pressure, the interfacial tension and the electrostriction pressure14 that arises from the presence of an electric field, E, in the film. For this film system we have the internal energy given by

dU=TdS-pdV+6W,+,udN+ydA. (1)

Here, Vis the volume of the film, Nthe number of molecules in the film, ,u the chemical potential, y the surface tension of the film, T the absolute temperature, S the entropy,

A theory for breakdownof anodic oxide films on metals

1685

and C? W, the electrostatic work associated with the electric field. SW, is given by15 6 W, = -PV dD with D = E + 47rP, where D is the dielectric displacement and P the polarization of the film representing the dipole moment for the unit volume of the film. Hence, 6 W, = -PV dE - 4vPV dP. Thus, (1) becomes dU= Introducing TdS--dV-4mPVdP-PVdE+pdN+ydA. (2) yA,

the following two functions into (2) U = U + 2?rP2V 2nP2, (3) (4) (5) (6) p = p -

we obtain dU=TdS-pdV--PVdE+pdN-Addy. Furthermore, we have the Gibbs-type function given by G=U-TSfpV.=~N-yyA=LZN,

where fi = p - (yA/N). ,Limay be called the integral chemical potential of molecules in the film, while the ordinary chemical potential, ,u, may be called the differential chemical potential. Taking the differential of (6) and substituting it into (5), we find dp =

where p is the number density of the film, p = N/V. For integration, we need the relation between P and E. In the first approximation P is proportional to E, P .= XE = (e - l)E/47~, (8) where x is the electric susceptibility and E the dielectric constant of the fXm. Integration of (7) can now be made at constant A, T and p with aid of (8) to obtain

0

F

dT+PdE+

dy+pdF+

ctz - CL) dN v 2

P;T,p,E,y,F,N) = P;T,p,j.,E=O.Ci=~,N=m) + *E2X

YAP

The condition of constant p may hold to a sufficient approximation with anodic oxide films of solid dielectrics. Equations (4) and (8) give the relation between p and p as follows, p = p + 27r(~E)~. (10) Since p becomes equal to the atmospheric pressure, po, at the limit of E + 0, N -+ co at this limit is also equal to p,,. Accordingly, from (9) we find for the and ,ii--+p,p fllm pressure that P=Po+-@~x(~ +4q)--,

YAP

(11)

where the last term can also be written by Ayp/N = y/L. An alternative expression of (10) replacing x with E takes the form P-PO= E(E 1)E2 87r y -_ L

(12)

In this final equation we readiIy see that the first term represents the electrostriction effect and the second the interfacial tension effect.

1686

N. SATO

FIG. 1. Thermodynamic system for a surface film on metal in a ueous solution, p, film pressure; pa, atmospheric pressure; E, electric fiel1 strength.

FILM

PRESSURE

The concept of the fZn pressure can be applied to anodic oxide films on metals in solution. In order to estimate the magnitude of the film pressure, we assume E in the range from 2 to 15, E in the range from 1 x 106 to 1 x 10 V/cm and y in the range from 10 to 500 dyne/cm; for metal oxides and hydroxides of our immediate interest, Eand y in the literature fall in the above ranges, although few measurements have been made on E and y of anodic oxide films, Calculation is made of the electrostriction pressure given by the first term in (12), which is the pressure to act on oxide films so large in thickness that the surface tension effect can be negligible. For example, for a mass of oxide dielectric with E larger than 10 the electrostriction pressure at E = 5 x lo6 V/cm is calculated to be larger than 1000 kg/cm2. Metal oxides or hydroxides have been shown to have the critical compressive stress for breakdown of the order of 1OCLlOOO kg/cm2. It appears therefore that metal oxides or hydroxides, when permeated by a field of the order of 108V/cm, could deform or break mechanically because of a high electrostriction pressure. Calculation is then made of the film pressure given by (12), which is an electrostriction pressure modified by the interfacial tension effect. Figure 2 shows the film pressure as a function of film thickness. With increasing film thickness, the interfacial tension effect decreases and hence the film pressure increases approaching a limit of the electrostriction pressure. Accordingly, if the electrostriction pressure exceeds the breakdown stress of the film, there is a critical film thickness at which the film pressure is equal to the breakdown stress and beyond which mechanical breakdown of the film occurs. In Fig. 2 it is seen that the critical thickness of film breakdown decreases with increasing electric field strength in the film. Figure 3 shows the effect of the interfacial tension on the film-pressure thickness curve. It is seen that the larger interfacial tension gives the larger critical thickness for film breakdown. The variation of the film pressure with the interfacial tension is shown in Fig. 4. Decrease in the interfacial tension results in increase of the f%n pressure. Since adsorption of ions decreases the interfacial tension, a mechanical breakdown could be introduced into anodic oxide films by adsorption of anions on the film surface.

A theory for breakdown of anodic oxide films on metals

1687

1,400e-10 r= 100

T dyne /cm

1.200

1.000

FIG.

2. Film pressure calculated as a function of film thickness for a surface film with dielectric constant B = 10, surface tension y = 100 dyne/cm, and electric field strength E=4 x IO*,5 x lOand6 x lo*V/cm.

20

40 L A

60

60

100

FIG. 3. Film pressure calculated as a function of film thickness for a surface film with dielectric constant l = 10, electric field E = 4 x 10 V/cm, and surface tension y = 10, 50, 100 and 200 dyne/cm_

1688

N. Smo

r.

d ynb /cm

FIG. 4. Film pressure calculated as a function of surface tension for a surface film with dielectric constant Q = 10, film thickness L = 40 A, and electric field E = 4 x 10 and 6 x lo6 V/cm. BREAKDOWN POTENTIAL

We now discuss the breakdown potential of anodic oxide films and the effect of anions on it. As mentioned in the preceding section, our theory assumes the breakdown potential to be a critical potential above which the film pressure exceeds the critical compressive stress of film breakdown. Since at steady state of anodic oxide films the rate of film growth is equal to the rate of film dissolution, the Un thickness is maintained constant. The rate of film growth has been shown to be determined by the electric field strength, E, in anodic films. Therefore, if the rate offilm dissolution is independent of the electrode potential, as expected in the ideal case, E is constant irrespective of the potential. Thus, for steady-state films,

&y--f-

= constant,

(13)

where v is the electrode potential and vr the equilibrium potential of film formation. Let anodic oxide film be MO, metal be M, and solution contain salt KA with cation K+ and anion A-; then the Gibbs isotherm gives the interfacial tension aP -dy=qdv+I M+dp, + PA- dpgd + %druno + rrrIo dPHro, where q is the charge density at the interface, I the adsorption densities at the Gibbs surface and ,u the chemical potentials. Because MO is regarded here as an electrically neutral oxide absorbed on the Gibbs surface, the charge required for film formation is excluded from q in the above equation. Since ,uM,p,, and pH80 can be assumed to be constant, we obtain -dr = q dg, + ra- dp,xa. (14)

A theory for breakdown of anodic oxide films on metals

1689

From the simple capacitor model the charge density is given by q = C(v 930) = E(Q, YoYhL (15)

For

where C is the capacitance of anodic film and rpo the pzc at which q = 0. simplicity, we make use of the assumption that IF, - qo[ < 1tp - rp,I M 1tp Then, we find from (13) and (15) that q =

qo)ol. 06)

l E/h.

Since E is constant at steady state, q is also constant irrespective of q and L. The critical condition for film breakdown can be obtained from (12) with p -p. replaced by go, the critical breakdown compressive stress of the film, as (T, =

This

E(C -

l)E2

8?T

--.

y L y/L

(17) is always constant

indicates that at the critical condition whatever may be the film thickness. Hence,

of breakdown l)E2

dy ---_-_-_= dL

Combining

Y L

E(E -

8?r

(18)

(18) with the relation dp, = E dE, given by (13), we obtain --

dy

dq =i?

oc

-

~(4 8~

1)E -

(19)

On the other hand, from

(14) and (16) we also find

dy .- dy

4~

ZE+

r*_

potentia1, q*, we obtain

(20)

Since (19) and (20) should both hold at the breakdown

dp?* -= hu

w*

kT d In oxA =

&EI'A- *

87~7, E(E + 1)E2

(21)

where rA_* is the adsorption density of A- at the breakdown potential. Since &ru, < E(E - 1)E2 in (17), dg?*/dp KA takes always a negative value. If 87rra, < E(E + 1)E2, then (20) can be replaced by

dv*

d In agA = -

87ikTl?A-* E(f + 1)E -

(22)

This gives the relation between the breakdown potentia1 and the concentration of anion in solution. The breakdown of passive anodic oxide films on aluminum has been shown to occur in the presence of Cl-, Br and I- ions and the dependence of the breakdown potential (ie the pitting potential) on the halogen ion concentration has been experimentally given as followsr7): dp7*/d In acl_ = -0-0543 V, dq*/dln a,, = -0~0504 V, and dF*/d In a,_ = -0-0495 V. For passive anodic oxide films of barrier type on aluminum, E w 1 x 10 V/cm and E w 10. Then, from (22) with dg)*/d In a,_ w 0.05 V, we find the adsorption density of halogen ion I?,_* at the breakdown potential

1690

N.

SAT0

to be I,_* = 2 x 1013ions/cm 2. Since the adsorption densityt of H,O is about 1 x 10rs molecuies/cm2, the concentration of adsorbed halogen ions on the passive Clm at the breakdown potential is given by l?a-*/I,r,o w 0*02. In the case when the solution contains two kinds of anions, A- and B-, we also easily find 8nkTl?,_* CW E(E+ 1) E 8?rkTI&* E(E+ 1) E * For the breakdown at constant potential, therefore, we obtain (24) The effect of co-existing anions on the initiation of pitting corrosion of stainless steel at constant potentiaI has been investigated by Leckie and Uhlig,s who gave the relation (a In a&a In aon-) = l-62, (a In ucl-/a In aNo,-) = 1.88, (a In ucr_/a In usor~_) = 085, and (a In ~,,-/a In ac104-)= 083. These results, on referring to (24), indicate that at the initiation of breakdown of passive anodic films on stainless steel the density of aggressive chloride ion adsorption is of the same order as that of inhibitive anion adsorption.

BREAKDOWN MODE AND FORE FORMATION

Wb)

From our theory it appears that the breakdown of anodic oxide films takes a variety of modes depending on the mechanical property of the films. Figure 5 shows

-. X_/ Brittle Crack

Plastic

Slip

Plastic FIG. 5. Three

Flow

modes of me&a&al

breakdown of

surface

films.

-f The plane density of X.0 in aqueous solution is about 1 x 101 molecules/cm* and about the same value has been estimated for the adsorption density of HI0 on a Pt electrode.*

A theory for breakdown of anodic oxide films on metals

1691

three different forms of film breakdown; brittle crack, plastic slip and plastic flow. Brittle crack or fracture would result if the anodic film is rigid anhydrous metal oxide, whereas plastic deformation or flow would proceed if the film is visco-plastic hydrous oxide. In the case of plastic flow, the breakdown proceeds continuously provided the anodic oxidation induces the film pressure large enough for film deformation, and produces pores on top of the anodic oxide film, which eventually align in a closedpacked pattern because of the most stable form for stress relief. As the breakdown in anodic oxidation proceeds, therefore, a porous oxide layer progressively forms and thickens on the compact oxide film which, although undergoing plastic deformation, remains at constant thickness. Such a duplex layer structure of anodic oxide films consisting of an inner barrier-type layer and an outer porous layer with regularly aligned pores has been well known to form on aluminum. Thus the present theory suggests a new mechanical mechanism for the pore formation of anodic oxide films on aluminum. PITTING AND TRANSPASSIVE DISSOLUTION Film breakdown leads to either pitting or transpassive dissolution of underlying metal. For pitting, our theory explains the initiation of pit formation as a mechanical deformation or crack formation in the oxide film. Whether the nucleus of a pit thus produced dies out or becomes a micro- or macro-pit, however, is obviously another subject relating not only to film breakdown but to film formation and the metal dissolution on which the local concentration of solution resulting from pit formation itself, particularly as to pH and anion in the vicinity of pits, has a large influence. If the film breakdown proceeds continuously and evenly on the surface, as may be expected in the case of plastic flow, the transpassive type dissolution would be favoured. This is because the plastically flowing film surface probably behaves very actively in chemical and electrochemical dissolution. Recently, Nagayama and Tamura1s*20have found that the dissolution rate of porous type anodic oxide films on aluminum undergoing anodic oxidation is a hundred or a thousand times larger at the pore base than at the pore wall. According to our theory, the plastic deformation or flow is most violent, ie the flow rate is most rapid, at the base of pores, since for porous anodic oxide films the electric field and hence the film pressure concentrate in the compact barrier layer at the pore base. The increased dissolution at the pore base of porous anodic oxide films on aluminum is therefore concluded to be the transpassive dissolution of the inner compact barrier type oxide layer in which mechanical deformation or flow as well as field-assisted ion migration is taking place, though the dissolution mechanism still remains to be studied. DISCUSSION Our derivation of the film pressure that acts vertically to the film plane has taken account of only effects of electrostriction and interfacial tension referring to a homogeneous film of dielectrics permeated by a uniform electric field. These two effects are general to any passive film whatever the mode of film formation may be. There are, as mentioned above, other stress sources such as defects, impurities, misfits and hydration, which all produce internal mechanical stress and affect more or less the film pressure. In our derivation these structure-and-composition sensitive factors

1692

N.

SAT0

have not all been taken into account, because they cannot be treated with generality and accuracy within the framework of thermodynamics. We should, however, notice that the properties of anodic oxide films that may affect the film pressure, such as the critical breakdown stress, the dielectric constant and the affinity for anion adsorption, are all structure- and composition-sensitive. Therefore, even with the same anodic oxide films, the breakdown potential would change depending, for instance, on hydration and impurities. In facts, the breakdown potential of metal passivity has been shown to be sensitive to conditions of film formation and minor impurities. Our theory suggests that the passive film is more stable with smaller dielectric constant and larger breakdown stress. Furthermore, since the interfacial tension resists the film breakdown and since anion adsorption decreases the interfacial tension, the smaller the affinity of anion adsorption, the more stable is the passive film against breakdown. In conclusion, we suggest that the stability of passive anodic oxide films against breakdown is controlled not only by the electrochemical reactivity to aggressive ions but also by the mechanical and the dielectric properties of the film itself.

REFERENCES 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. YA. M. KOLOTYRKIN, Corrosion 19,261t (1963). W. Scmm, Corrosion 20, 129t (1964). G. HhBSLEB, Werkstoffe Korros. 8, 649 (1966). H. KAIXHZ, Die Korrosion der Metulle, p. 251. Springer-Verlag, Berlin (1966). T. P. HOAR, Corros. Sci. 7, 341 (1967). N. SATO,Bull. Japan Inst. Metals 7, 617 (1969). S. MORIOKA, SAWADA K. and K. SUGIMOTO, Bd. Japan Inst. Metals 7, 731 (1969). H. P. LECKIE and H. H. UHLIG,J. electrochem. Sot. 113,1262 (1966). H. KAESCHE, Z.phys. Chem. 26,138 (1960); 34,87 (1962). H. GINSBERG and K. WEFERS, Metal1 17,202 (1963). D. H. BRADWLIRST J. S. LL. LEACH,J. electrochem. Sot. 113, 1245 (1966). and D. A. VERMILYEA, electrochem. Sot. 110, 345 (1963). J. S. F. BUBAR and D. A. VERMILYEA, electrochem. Sot. 113, 892 (1966). J. F. 0. KOENIG, J.phys. Chem. 41,597 (1937); E. A. GUGGENHEIM, Proc. R. Sac., Land. A155, 49, 70 (1936). T. L. HILL, An Introduction to Statistical Thermodynamics, p. 201. Addison-Wesley, London (1960). P. DELAHAY,Double Layer and Electrode Kinetics, p. 17. Interscience (Wiley), New York (1965). K. SUGIMOTO, SAWADAand S. MORIOKA, Japan Inst. Metals 73, 483 (1968). K. J. 3. W. DIGGLE, C. Dowm and C. W. GOIJLDWG,Chem. Rev. 69,365 (1969). T. M. NAGAYAMAand K. TAMURA, Electrochtm. Acta 12, 1097 (1967). M. NAGAYAMAand K. TAMURA,Electrochim. Actu 13,1773 (1968).

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Anodization Fabrication of Highly Ordered TiO2 NanotubesDocument7 paginiAnodization Fabrication of Highly Ordered TiO2 NanotubesThiago Scremin BonelliÎncă nu există evaluări

- Anodic TiO2 Nanotubes Powder and Its Application in Dye-Sensitized Solar CellsDocument10 paginiAnodic TiO2 Nanotubes Powder and Its Application in Dye-Sensitized Solar CellsThiago Scremin BonelliÎncă nu există evaluări

- Angular Response of Dye Solar Cells To Solar and Spectrally Resolved LightDocument4 paginiAngular Response of Dye Solar Cells To Solar and Spectrally Resolved LightThiago Scremin BonelliÎncă nu există evaluări

- Analysis of The Photovoltaic Properties of SCDocument3 paginiAnalysis of The Photovoltaic Properties of SCThiago Scremin BonelliÎncă nu există evaluări

- All-Solid-State Dye-Sentized Solar Cells With High EfficiencyDocument5 paginiAll-Solid-State Dye-Sentized Solar Cells With High EfficiencyThiago Scremin BonelliÎncă nu există evaluări

- A Simple and Efficient Solar Cell Parameter Extraction Method From A Single CV CurveDocument8 paginiA Simple and Efficient Solar Cell Parameter Extraction Method From A Single CV CurveThiago Scremin BonelliÎncă nu există evaluări

- A New Anode Material of Silver ... On TiO2 in DSSCDocument4 paginiA New Anode Material of Silver ... On TiO2 in DSSCThiago Scremin BonelliÎncă nu există evaluări

- A New Anode Material of Silver ... On TiO2 in DSSCDocument4 paginiA New Anode Material of Silver ... On TiO2 in DSSCThiago Scremin BonelliÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Starbucks Progressive Web App: Case StudyDocument2 paginiStarbucks Progressive Web App: Case StudyYesid SuárezÎncă nu există evaluări

- SetupDocument4 paginiSetupRsam SamrÎncă nu există evaluări

- Tugas Inggris Text - Kelas 9Document27 paginiTugas Inggris Text - Kelas 9salviane.theandra.jÎncă nu există evaluări

- Grammar Practice #2Document6 paginiGrammar Practice #2Constantin OpreaÎncă nu există evaluări

- Intraoperative RecordDocument2 paginiIntraoperative Recordademaala06100% (1)

- Planning Effective Advertising and Promotion Strategies For A Target AudienceDocument16 paginiPlanning Effective Advertising and Promotion Strategies For A Target Audiencebakhoo12Încă nu există evaluări

- T Rex PumpDocument4 paginiT Rex PumpWong DaÎncă nu există evaluări

- Session 1: Strategic Marketing - Introduction & ScopeDocument38 paginiSession 1: Strategic Marketing - Introduction & ScopeImrul Hasan ChowdhuryÎncă nu există evaluări

- Whitepaper ITES Industry PotentialDocument6 paginiWhitepaper ITES Industry PotentialsamuraiharryÎncă nu există evaluări

- Data Structures and Algorithms SyllabusDocument9 paginiData Structures and Algorithms SyllabusBongbong GalloÎncă nu există evaluări

- Chemical Classification of HormonesDocument65 paginiChemical Classification of HormonesetÎncă nu există evaluări

- Case StudyDocument2 paginiCase StudyFadhlin Sakina SaadÎncă nu există evaluări

- Computerized Flat Knitting Machine Computerized Flat Knitting Machine Computerized Flat Knitting Machine Computerized Flat Knitting MachineDocument61 paginiComputerized Flat Knitting Machine Computerized Flat Knitting Machine Computerized Flat Knitting Machine Computerized Flat Knitting MachineAmira's ClothesÎncă nu există evaluări

- Modular ResumeDocument1 paginăModular ResumeedisontÎncă nu există evaluări

- What Is Terrorism NotesDocument3 paginiWhat Is Terrorism NotesSyed Ali HaiderÎncă nu există evaluări

- Intergard 475HS - Part B - EVA046 - GBR - ENG PDFDocument10 paginiIntergard 475HS - Part B - EVA046 - GBR - ENG PDFMohamed NouzerÎncă nu există evaluări

- One Foot in The Grave - Copy For PlayersDocument76 paginiOne Foot in The Grave - Copy For Playerssveni meierÎncă nu există evaluări

- Datalogic tl46 A Manual - 230104 - 140343Document2 paginiDatalogic tl46 A Manual - 230104 - 140343Emmanuel Baldenegro PadillaÎncă nu există evaluări

- Retail Visibility Project of AircelDocument89 paginiRetail Visibility Project of Aircelabhishekkraj100% (1)

- Drawbot 1Document4 paginiDrawbot 1SayanSanyalÎncă nu există evaluări

- IBS and SIBO Differential Diagnosis, SiebeckerDocument1 paginăIBS and SIBO Differential Diagnosis, SiebeckerKrishna DasÎncă nu există evaluări

- Cash Budget Sharpe Corporation S Projected Sales First 8 Month oDocument1 paginăCash Budget Sharpe Corporation S Projected Sales First 8 Month oAmit PandeyÎncă nu există evaluări

- Commercial BanksDocument11 paginiCommercial BanksSeba MohantyÎncă nu există evaluări

- CCTV Guidelines - Commission Letter Dated 27.08.2022Document2 paginiCCTV Guidelines - Commission Letter Dated 27.08.2022Sumeet TripathiÎncă nu există evaluări

- Acc 106 Account ReceivablesDocument40 paginiAcc 106 Account ReceivablesAmirah NordinÎncă nu există evaluări

- UK Tabloids and Broadsheet NewspapersDocument14 paginiUK Tabloids and Broadsheet NewspapersBianca KissÎncă nu există evaluări

- Korea Times - Korean-EnglishDocument313 paginiKorea Times - Korean-EnglishgyeryongÎncă nu există evaluări

- Your Bentley Bentayga V8: PresentingDocument9 paginiYour Bentley Bentayga V8: PresentingThomas SeiferthÎncă nu există evaluări

- Caddy Arc 251i Service ManualDocument52 paginiCaddy Arc 251i Service Manualrikycien100% (8)

- Crown BeverageDocument13 paginiCrown BeverageMoniruzzaman JurorÎncă nu există evaluări