Documente Academic

Documente Profesional

Documente Cultură

Wms

Încărcat de

raushan25Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Wms

Încărcat de

raushan25Drepturi de autor:

Formate disponibile

Warehouse Management System

Raising Warehouse Operation Efficiency & Improving Inventory Management

To many logistics, retail and trading companies, warehouses play a very important role in their daily operations, making the warehouse operation become a key success factor of their business. However, a warehouse involves complicated workflow processes and tedious transaction logging works, which often result in errors and huge manpower consumption. Meanwhile, the growing demand of flexible and fast response supply chain management also brings a great challenge to the warehouse management.

Comprehensive Solution for Warehouse Operations

Warehouse Management System (WMS) is a comprehensive solution to address the problems above. The system is designed to automate the daily inventory handling process in a warehouse. It provides the core functionalities for warehouse management, including receiving & putaway, inventory management, stock allocation, picking & packing, shipment confirmation, reporting, etc. Integrated with barcodes and scanning devices or radio frequency identification (RFID) devices, the system further increases the efficiency and productivity in the management of warehouses and inventories.

Major Benefits of WMS

Speed up warehouse operations Improve correctness and readiness of inventory information Reduce labour cost for tedious transaction documentation and inventory calculation Prevent shipment of wrong goods by item validation at picking and packing processes Utilize inventory usage by rule-based allocation of inventory to orders Enable the integration of barcode or RFID devices to increase the efficiency Facilitate the integration with ERP, Order Taking or Distribution Planning Systems to streamline the whole business workflow

Warehouse Management System

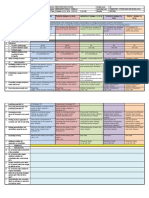

Key Features of WMS

Receiving & Putaway When arrived at warehouse, items are received according to ASN (Advance Shipment Notice). Putaway is then done to move the received items to the appropriate location. The details of the received items and putaway processes are stored in the inventory database to maintain up-to-date inventory records. Inventory Management Users always can access the latest inventory information. On the other hand, the system provides the flexibility to carry out some actions, including inventory adjustment, cycle/physical count, inventory hold and inventory move, to enhance inventory accuracy and maximize space utilization. Stock Allocation This process allocates available inventories in the warehouse to orders due for delivery. Allocation rules can be applied to the system to serve different business or product nature. Pre-defined rules such as FIFO, LIFO, Shelf Life, etc can be fitted into the system.

Picking& Packing After the stock is allocated to particular orders, the warehouse staff has to pick out the allocated inventory. Then the goods are packed into boxes for shipment and the packing details are stored in the system for documentation.

Shipment Confirmation The confirmation of shipment can be done by order or travel route. When the confirmation is made, inventory is decremented accordingly. Reporting Various reports can be generated to keep track of the daily warehouse activities. Examples are Inventory Balance Report to decide stock replenishment schedule and Goods Receiving Report or Shipment Summary Report summarize the inbound and outbound transactions. Support on Barcode/RFID Usage The system can be integrated with barcode scanners or RFID tags and readers to facilitate accurate and fast information capture throughout the warehouse workflow.

AiSoft Logistics Solution Limited

Tel: Fax: Email: URL (852) 3157 1822 (852) 3016 9737 sales@aisoft.com.hk http://www.aisoft.com.hk

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- DLL Ict 10 Week October 15-19, 2018Document3 paginiDLL Ict 10 Week October 15-19, 2018Bernadeth Irma Sawal CaballaÎncă nu există evaluări

- LLVM Crash CourseDocument15 paginiLLVM Crash CourseLauren HuangÎncă nu există evaluări

- PowerChannel KB 15238Document3 paginiPowerChannel KB 15238Rajan KanitkarÎncă nu există evaluări

- Check Lagarconne - Coms SEODocument13 paginiCheck Lagarconne - Coms SEOUmar HanifÎncă nu există evaluări

- Backlog (PH) Disabled (JR - Asst)Document15 paginiBacklog (PH) Disabled (JR - Asst)Ram Charan VeluruÎncă nu există evaluări

- Find optimal sums of three numbers using greedy and backtrackingDocument8 paginiFind optimal sums of three numbers using greedy and backtrackingAida VoicuÎncă nu există evaluări

- SQL and Xquery Tutorial For Ibm Db2, Part 5:: Data ComparisonDocument26 paginiSQL and Xquery Tutorial For Ibm Db2, Part 5:: Data ComparisonprasanthnowÎncă nu există evaluări

- 20BCS7358 CC Exp.5Document4 pagini20BCS7358 CC Exp.5Shudhashekhar DasÎncă nu există evaluări

- JavaScript Print Version - Wikibooks Open Books For An Open World PDFDocument60 paginiJavaScript Print Version - Wikibooks Open Books For An Open World PDFsiriuslotÎncă nu există evaluări

- AxiomV Custom Report DesignerDocument33 paginiAxiomV Custom Report DesignerDiego Velarde LaraÎncă nu există evaluări

- CD Check Reports and Correction Reports For CDHDR and CDPOSDocument7 paginiCD Check Reports and Correction Reports For CDHDR and CDPOSEric HuangÎncă nu există evaluări

- System Documentation For Malaysia GSTDocument10 paginiSystem Documentation For Malaysia GSTviru2allÎncă nu există evaluări

- Online Jewelry Shop - FinalDocument116 paginiOnline Jewelry Shop - FinalTanmaya SahooÎncă nu există evaluări

- Mini Project: Topic 3. Maze SolverDocument11 paginiMini Project: Topic 3. Maze SolverNikhil SoniÎncă nu există evaluări

- Develop Web Services using WSDL and UDDIDocument13 paginiDevelop Web Services using WSDL and UDDIMahamud elmogeÎncă nu există evaluări

- H E L I O D O N: Tropical DesignDocument17 paginiH E L I O D O N: Tropical DesignMichael PosadasÎncă nu există evaluări

- Constructor Chaining in Java With Example Programs - Scientech EasyDocument6 paginiConstructor Chaining in Java With Example Programs - Scientech EasyDEEPAK GUPTAÎncă nu există evaluări

- IP Security: Henric Johnson Blekinge Institute of Technology, Sweden Henric - Johnson@bth - SeDocument31 paginiIP Security: Henric Johnson Blekinge Institute of Technology, Sweden Henric - Johnson@bth - Seahmadamminudin89Încă nu există evaluări

- Previous GATE Questions On Number SystemsDocument4 paginiPrevious GATE Questions On Number SystemshelithiÎncă nu există evaluări

- PowerShell Cheat Sheet - Simple Cheat Sheet - Windows PowerShellDocument11 paginiPowerShell Cheat Sheet - Simple Cheat Sheet - Windows PowerShellPratik RamanÎncă nu există evaluări

- Data Domain, Deduplication and MoreDocument6 paginiData Domain, Deduplication and MorebinhÎncă nu există evaluări

- TS-RAS-GEN-0023__Expiration_of_certificatesDocument28 paginiTS-RAS-GEN-0023__Expiration_of_certificatesAdil MuradÎncă nu există evaluări

- Minios7 UtilityDocument48 paginiMinios7 UtilityfveleaÎncă nu există evaluări

- Motherboard D945GCLF (Mobo in PC3) ProductGuide04Document56 paginiMotherboard D945GCLF (Mobo in PC3) ProductGuide04Marien Collado GermaÎncă nu există evaluări

- E-Commerce Module Structure Benefits LimitationsDocument33 paginiE-Commerce Module Structure Benefits LimitationsNezuko KamadoÎncă nu există evaluări

- Business: Powerpoint Template Designed by Mr. Cai With Microsoft Office 2016Document20 paginiBusiness: Powerpoint Template Designed by Mr. Cai With Microsoft Office 2016daisyÎncă nu există evaluări

- Ch2 (3) Handouts 3e PDFDocument10 paginiCh2 (3) Handouts 3e PDFAnonymous eiYUGFJZ3iÎncă nu există evaluări

- Parábolas Modernas - Modern ParablesDocument9 paginiParábolas Modernas - Modern ParablesfreekidstoriesÎncă nu există evaluări

- Object Oriented Programming: RevisionDocument11 paginiObject Oriented Programming: RevisionMahmoud Abdel-SalamÎncă nu există evaluări

- Product Specifications HP Pavilion Dv5-1012ea Entertainment Notebook PC - HP Technical Support (United Kingdom - English)Document3 paginiProduct Specifications HP Pavilion Dv5-1012ea Entertainment Notebook PC - HP Technical Support (United Kingdom - English)MTIH1992Încă nu există evaluări