Documente Academic

Documente Profesional

Documente Cultură

Plasterers Safety

Încărcat de

hello3232Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Plasterers Safety

Încărcat de

hello3232Drepturi de autor:

Formate disponibile

Health and Safety Executive

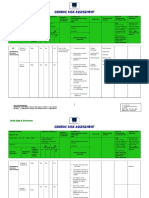

Example risk assessment for a plastering company

Setting the scene

The manager of a plastering company carried out a general risk assessment that covered their typical work. The deputy manager and the employee safety representative also helped. The risk assessment was used to help manage health and safety at the firm, and when tendering for contracts to demonstrate the firms approach to health and safety. This meant that in the tender documents it was made clear exactly what was needed from the principal contractor to do the job safely and properly. The firm won the plastering contract for a development of a three-storey block of flats. Work was due to start on 1 May 2007. The manager checked the construction phase plan and met the principal contractors site manager on the site. One of the issues they considered was the sequencing and logistics of the work, alongside that of other fit-out trades, to ensure safe access and working arrangements for all. Another was the issue of fatigue, and the number of work breaks that were needed. This extra information helped the manager to decide whether the general risk assessment covered all the hazards and risks expected in this job. If it did not, it would need to be amended to make the general risk assessment specific to the work and conditions of this job. However, the manager decided that for this job his general risk assessment did cover all the expected risks and that therefore no additional paperwork was needed. advice and guidance for the construction industry. 2 The manager wrote down who would be harmed by the hazards and how. 3 He considered the risks of each hazard and decided what was needed to control those risks. 4 He discussed the findings with the deputy manager and the safety representative. He then put the risk assessment into practice, writing down who was responsible for doing what, and by when. When each action was completed, it was ticked off and the date recorded. 5 The manager told staff about the risk assessment, explaining that the risks identified were common to most plastering jobs and would be put into practice and the control measures identified would be put into place for all company jobs. 6 However, the manager also said that all sites were different and that extra risk controls might be needed at some jobs. This would be considered during site visits before each job started, and staff are to be made aware of any additional risks and what needs to be done to control those risks. 7 One of the workers did not speak English. The manager had planned for this, having previously arranged with the site manager for another worker, who was bi-lingual in the relevant language, to translate.

1 of 3 pages

Important reminder

This example risk assessment shows the kind of approach a small business might take. Use it as a guide to think through some of the hazards in your business and the steps you need to take to control the risks. Please note that it is not a generic risk assessment that you can just put your company name on and adopt wholesale without any thought. This would not satisfy the law and would not be effective in protecting people. Every business is different you need to think through the hazards and controls required in your business for yourself.

Example risk assessment: Plastering company

How was the risk assessment done?

To produce his general risk assessment, the manager followed the guidance in Five steps to risk assessment (www.hse.gov.uk/pubns/indg163.pdf). 1 To identify the hazards the manager:

used training and experience of similar work; took into account the rules of most construction sites; and looked at HSEs website for free health and safety

Health and Safety Executive

Company name: Smiths Plastering Date of risk assessment: 1 March 2007

(revised to be specific for internal plastering of three-storey flats job, 23 April 2007) What are the hazards? Who might be harmed What are you already doing? and how? Falling from height Serious or even fatal injury could occur if an operator falls from height. Others working below also at risk. All operators, and tradesmen nearby, may suffer sprains, bruising or fractures if they trip over objects, such as work debris, or slip on spillages. Operators risk serious or even fatal injuries from moving vehicles on site particularly when reversing. Operators risk injury, particularly to the back, from lifting and handling heavy or awkward objects, eg, plasterboard, and from repetitive strain problems from plastering.

What further action is necessary? Include work at height in toolbox talk before beginning work on day one.

Action by whom? Site Manager Foreman

Action by when? 1/5/07

Done

Sufficient Step-Ups available, all in good condition. Platform trellis, with guardrail, used for stairwells and operators are trained in how to put it up, use and dismantle it. Stairs and landings have handrails. All operators wear safety boots no boots, no job policy. Good housekeeping, eg debris such as plaster bags put in skip, brush available to use to keep work area clear. All trailing cables in work area hung up or otherwise kept out of harms way. Safe route to job agreed with site manager based on site health and safety plan. Safe route to workplace, and to welfare facilities, agreed with site manager based on site health and safety plan. Staff know that they must never move vehicles on a site unless authorised by site manager. Staff wear high-visibility tabards while on site. Dry plaster mix lifted to the work areas using a hoist supplied by the site manager and operated by a competent person. Dry plaster mix supplied in bags weighing less than 25 kg. Plasterboard for ceilings is of smallest size practicable. Operators know and follow safe system of work for fitting plasterboard to ceiling, including knowledge of maximum weight for an individual manual lift. Job rotation between ceiling and walls.

Slips and trips

Manager to check on-site housekeeping during visits. Include in toolbox talk before beginning work on day one. Include in toolbox talk before beginning work on day one.

Site Manager Site Manager Site Manager Foreman

From 1/5/07 From 1/5/07 1/5/07

Workplace transport

Manual handling

Remind operators of plasterboard safe system of work at toolbox talk.

Site Manager Foreman

1/5/07

Example risk assessment: Plastering company

2 of 3 pages

Health and Safety Executive

What are the hazards? Who might be harmed What are you already doing? and how? Hazardous substances Dry plaster mix Operators and nearby tradesmen at risk from dry plaster powder which may irritate eyes or sensitive skin, or cause short-term irritation of respiratory system. Operators and others risk potentially fatal injuries if they receive a shock from faulty electrical equipment and/or installation. Good welfare facilities reduce risk of dermatitis, help good hygiene etc.

What further action is necessary? At toolbox talk, remind operators of risks of dry plaster powder, and to wear gloves, eye protection and dust masks when emptying sacks and preparing the mix.

Action by whom? Manager

Action by when? 1/5/07

Done

Operators know the risks of dry plaster powder and know to avoid skin contact, excessive dust build-up and contact with eyes. Work area suitable to prevent excessive dust build-up. Water supply nearby to wash dust off skin. Operators wear eye protection when plastering ceilings. Operators keep work area clean. Gloves and barrier creams available. Site manager will arrange for permanent electric supply to be turned off while plastering work ongoing. Site manager to supply 110 v temporary supply. Staff know to check all cables, leads etc of all powered tools/ equipment before use, and to report all faults to their supervisor. Agreement with site manager that staff may use site welfare facilities toilets, washing facilities with hot and cold water and mess room/kitchen.

Electricity

At toolbox talk on day one, manager to reinforce rules on electrical safety.

Manager

1/5/07

Welfare

Tell staff about facilities at toolbox talk on day one.

Manager

1/5/07

Assessment review date: 1/7/08

Example risk assessment: Plastering company Published by the Health and Safety Executive 11/08

3 of 3 pages

S-ar putea să vă placă și

- Concrete Formwork Suspended SlabDocument5 paginiConcrete Formwork Suspended SlabKate HopleyÎncă nu există evaluări

- JSA For Concrete WorkDocument6 paginiJSA For Concrete Worklê ngọc tùng0% (1)

- Safe Work Method Statement Working at Heights SampleDocument8 paginiSafe Work Method Statement Working at Heights Sampledumb2471817100% (1)

- SAFETY IN PETROLEUM FACILITIES TURNAROUND MAINTENANCEDe la EverandSAFETY IN PETROLEUM FACILITIES TURNAROUND MAINTENANCEÎncă nu există evaluări

- DEMOLITION SAFETY Print PDFDocument16 paginiDEMOLITION SAFETY Print PDFTed Alden Magno ZamoraÎncă nu există evaluări

- SWMS 2 Fixing CarpenterDocument3 paginiSWMS 2 Fixing CarpenterJonasÎncă nu există evaluări

- JSA ScaffoldingDocument2 paginiJSA Scaffoldingmyco samÎncă nu există evaluări

- Construction Site Management Training Pack Part 2Document41 paginiConstruction Site Management Training Pack Part 2Jaka Sembung GolokÎncă nu există evaluări

- Job Safety Analysis: JSA Reference #: DateDocument3 paginiJob Safety Analysis: JSA Reference #: DateLi QiÎncă nu există evaluări

- Scaffold RegisterDocument73 paginiScaffold RegistermiaicarbaÎncă nu există evaluări

- Concrete Cutting and Drilling PDFDocument2 paginiConcrete Cutting and Drilling PDFcityofdarwingis100% (1)

- Risk Assessment - Pull Out TestDocument12 paginiRisk Assessment - Pull Out TestMohsin MohdÎncă nu există evaluări

- Kta Alliance Spray /touch Up Painting of Project Materials: Job Safety Analysis (JSA)Document3 paginiKta Alliance Spray /touch Up Painting of Project Materials: Job Safety Analysis (JSA)Ogunwa EmmanuelÎncă nu există evaluări

- Work at Height ProcedureDocument7 paginiWork at Height Procedurecy2sonar50% (2)

- SWMS - PlumberDocument7 paginiSWMS - PlumberSiddiqueShaikhÎncă nu există evaluări

- SWMS DemolitionDocument18 paginiSWMS Demolitionalee0007100% (1)

- JSA-010 Excavation Sampling PDFDocument5 paginiJSA-010 Excavation Sampling PDFArgaYurIstiawanÎncă nu există evaluări

- WoodworkingDocument4 paginiWoodworkinghello3232Încă nu există evaluări

- WoodworkingDocument4 paginiWoodworkinghello3232Încă nu există evaluări

- Toolbox TalksDocument23 paginiToolbox TalksWali ul Islam100% (1)

- Assignment No. 2 General Work Health and Safety Policy (ABC Construction Company) GoalsDocument2 paginiAssignment No. 2 General Work Health and Safety Policy (ABC Construction Company) GoalsfahadÎncă nu există evaluări

- Concrete Bucket Safety2 PDFDocument3 paginiConcrete Bucket Safety2 PDFMuhammad Hamzah Habibburrahman100% (2)

- Trade Area: Construction Industry-PaintingDocument3 paginiTrade Area: Construction Industry-PaintingRam-tech Jackolito FernandezÎncă nu există evaluări

- DW BrochureDocument52 paginiDW BrochureMaxim Efimov100% (1)

- Ironbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy FlooringDocument12 paginiIronbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy Flooringklp_kedarpÎncă nu există evaluări

- 7 Steps To Build A GRC FrameworkDocument29 pagini7 Steps To Build A GRC FrameworkAnkush Markandey50% (2)

- Appointment of Formwork & Support Work SupervisorDocument1 paginăAppointment of Formwork & Support Work SupervisorRickesh Nunkoo100% (1)

- Safe Work Method StatementDocument2 paginiSafe Work Method Statementbuddyhello1Încă nu există evaluări

- Insurance OperationsDocument12 paginiInsurance OperationsIsunni AroraÎncă nu există evaluări

- Method Statements 06 - Drywall Partition WorksDocument7 paginiMethod Statements 06 - Drywall Partition WorksMathewÎncă nu există evaluări

- Checklist Site and Security Fencing SchoolsDocument2 paginiChecklist Site and Security Fencing Schoolsakshay aryaÎncă nu există evaluări

- Safe Work ProcedureDocument2 paginiSafe Work ProcedureSuco IdeunkÎncă nu există evaluări

- SWMS 67 - Safe Use of Nail GunsDocument4 paginiSWMS 67 - Safe Use of Nail GunsJonasÎncă nu există evaluări

- MS - EarthworkDocument29 paginiMS - EarthworkIlyas Khan0% (1)

- HIRARC Rock BlastingDocument4 paginiHIRARC Rock BlastingNajman Hamdi100% (13)

- JHA ConcretePlacingOperationDocument3 paginiJHA ConcretePlacingOperationAnonymous XJ9663C6N4Încă nu există evaluări

- Scaffold Request FormDocument1 paginăScaffold Request FormMark Joseph Balares100% (1)

- Safe Work Method StatementDocument19 paginiSafe Work Method StatementParas100% (2)

- F04 Site Safety HandbookDocument40 paginiF04 Site Safety Handbooksalman ahmed0% (1)

- JSA For Screeding With MeshDocument4 paginiJSA For Screeding With MeshMohammed Minhaj100% (1)

- OGP Report No. 413 Rev 1.1Document54 paginiOGP Report No. 413 Rev 1.1febriekowÎncă nu există evaluări

- Rebar PDFDocument1 paginăRebar PDFjoker batmanÎncă nu există evaluări

- PPE Notice PolicyDocument1 paginăPPE Notice PolicyLenaj EbronÎncă nu există evaluări

- Plasterers SafetyDocument3 paginiPlasterers Safetyhello3232Încă nu există evaluări

- Installation of Cabinetry - JoineryDocument4 paginiInstallation of Cabinetry - JoineryJonas100% (2)

- Safe Work Method Statement: (See Below)Document6 paginiSafe Work Method Statement: (See Below)Siddharth P100% (1)

- Method Statement - Single Layer Partition SystemDocument17 paginiMethod Statement - Single Layer Partition SystemNonie N50% (2)

- Authorized Personnel Only PDFDocument1 paginăAuthorized Personnel Only PDFsubhanmusadiq100% (1)

- Gas Cutting SetDocument1 paginăGas Cutting SetProjects DepartmentÎncă nu există evaluări

- TR Agroentrepreneurship NC IiDocument103 paginiTR Agroentrepreneurship NC IiAljon Balanag100% (1)

- Swing Trade For Profit Report - MarketGaugeDocument19 paginiSwing Trade For Profit Report - MarketGaugelowtarhkÎncă nu există evaluări

- Work Method Statement PurposeDocument2 paginiWork Method Statement PurposeSetyawanÎncă nu există evaluări

- Risk Assessments For ACTIVITY BASEDDocument4 paginiRisk Assessments For ACTIVITY BASEDhello3232Încă nu există evaluări

- 08 Scaffolding Erection DismantlingDocument3 pagini08 Scaffolding Erection DismantlingKhuda Buksh100% (1)

- Portfolio Management and Investment DecisionDocument49 paginiPortfolio Management and Investment Decisionuditasinha85% (13)

- API RP 584 Outline VersionDocument22 paginiAPI RP 584 Outline Versioncoxshuler100% (2)

- Method Statement For Cement Wall PlasteringDocument10 paginiMethod Statement For Cement Wall Plasteringmd_rehan_2Încă nu există evaluări

- The Environmental Monitoring Plan For The Albertine Graben 2012-2017Document100 paginiThe Environmental Monitoring Plan For The Albertine Graben 2012-2017African Centre for Media Excellence100% (1)

- Method Statement For Painting Works: ProjectDocument9 paginiMethod Statement For Painting Works: Projectfaizan khan100% (1)

- RISK ASESSMENT For CorianDocument12 paginiRISK ASESSMENT For Corianadeoye AdeyemiÎncă nu există evaluări

- Tool Box Talk - MK - Emergency Response ProceduresDocument2 paginiTool Box Talk - MK - Emergency Response ProceduresPaul McGahanÎncă nu există evaluări

- Safety-Overhead CraneDocument2 paginiSafety-Overhead CraneaisyahÎncă nu există evaluări

- Risk Assessment Template BathroomDocument2 paginiRisk Assessment Template BathroomRÎncă nu există evaluări

- Sample Fall ProtectionDocument5 paginiSample Fall ProtectionLiz CÎncă nu există evaluări

- General Site Safety - SignDocument1 paginăGeneral Site Safety - SignVũ GiangÎncă nu există evaluări

- Gate PassDocument1 paginăGate PassmukeshÎncă nu există evaluări

- Method Statement of Plastering: Pembinaan Infra E&J SDN BHDDocument5 paginiMethod Statement of Plastering: Pembinaan Infra E&J SDN BHDChezy629Încă nu există evaluări

- Method Statement For "Working at Height" "Structural Erection Work"Document2 paginiMethod Statement For "Working at Height" "Structural Erection Work"Magdy BakryÎncă nu există evaluări

- Ehs PR 03.f01 Patos FormDocument2 paginiEhs PR 03.f01 Patos FormClyde Villanueva100% (4)

- JSA For BuildingDocument4 paginiJSA For BuildingHafis Aikal AmranÎncă nu există evaluări

- Scaffolding SafetyDocument4 paginiScaffolding Safetyrguy3223Încă nu există evaluări

- Unsafe Act Danger of Horseplay at WorkDocument1 paginăUnsafe Act Danger of Horseplay at WorkSn AhsanÎncă nu există evaluări

- Container Fire Behaviour TrainingDocument5 paginiContainer Fire Behaviour Traininghello3232Încă nu există evaluări

- Responding To Emergencies - Arriving and Getting To Work Getting To Work Operational Imperative The Uncontrolled SituationDocument4 paginiResponding To Emergencies - Arriving and Getting To Work Getting To Work Operational Imperative The Uncontrolled Situationhello3232Încă nu există evaluări

- ElectricityDocument4 paginiElectricityhello3232Încă nu există evaluări

- Underground Water TankDocument2 paginiUnderground Water Tankhello3232Încă nu există evaluări

- Drill TowersDocument3 paginiDrill Towershello3232Încă nu există evaluări

- Site Inspections by PersonnelDocument2 paginiSite Inspections by Personnelhello3232Încă nu există evaluări

- ChimneysDocument2 paginiChimneyshello3232Încă nu există evaluări

- Confined Spaces TrainingDocument3 paginiConfined Spaces Traininghello3232Încă nu există evaluări

- Confined SpacesDocument4 paginiConfined Spaceshello3232Încă nu există evaluări

- Collapsed StructuresDocument4 paginiCollapsed Structureshello3232Încă nu există evaluări

- Confined Spaces TrainingDocument3 paginiConfined Spaces Traininghello3232Încă nu există evaluări

- BricklayersDocument5 paginiBricklayerscemilenginÎncă nu există evaluări

- Confined SpacesDocument4 paginiConfined Spaceshello3232Încă nu există evaluări

- Risk Assessments For ACTIVITY BASEDDocument3 paginiRisk Assessments For ACTIVITY BASEDhello3232Încă nu există evaluări

- Car-Parking Lack of Brigade Signage Serious Injury ABCDEF 2 3 6 - Provide Signs Warning of Brigade Training Area. 1 2 2Document3 paginiCar-Parking Lack of Brigade Signage Serious Injury ABCDEF 2 3 6 - Provide Signs Warning of Brigade Training Area. 1 2 2hello3232Încă nu există evaluări

- Responding To Emergencies - Arriving and Getting To Work Getting To Work Operational Imperative The Uncontrolled SituationDocument4 paginiResponding To Emergencies - Arriving and Getting To Work Getting To Work Operational Imperative The Uncontrolled Situationhello3232Încă nu există evaluări

- BiologicalDocument3 paginiBiologicalhello3232Încă nu există evaluări

- Breathing Apparatus TrainingDocument5 paginiBreathing Apparatus Traininghello3232Încă nu există evaluări

- Breathing ApparatusDocument5 paginiBreathing Apparatushello3232100% (1)

- Responding To Emergencies - Arriving and Getting To Work Getting To Work Operational Imperative The Uncontrolled SituationDocument2 paginiResponding To Emergencies - Arriving and Getting To Work Getting To Work Operational Imperative The Uncontrolled Situationhello3232Încă nu există evaluări

- Responding To Emergencies - Arriving and Getting To Work Getting To Work Operational Imperative The Uncontrolled SituationDocument2 paginiResponding To Emergencies - Arriving and Getting To Work Getting To Work Operational Imperative The Uncontrolled Situationhello3232Încă nu există evaluări

- SMP20 Sample FlyerDocument8 paginiSMP20 Sample Flyerhello3232Încă nu există evaluări

- Underground Water TankDocument2 paginiUnderground Water Tankhello3232Încă nu există evaluări

- Safe Ststem of Work PlanDocument2 paginiSafe Ststem of Work Planhello3232Încă nu există evaluări

- Car-Parking Lack of Brigade Signage Serious Injury ABCDEF 2 3 6 - Provide Signs Warning of Brigade Training Area. 1 2 2Document10 paginiCar-Parking Lack of Brigade Signage Serious Injury ABCDEF 2 3 6 - Provide Signs Warning of Brigade Training Area. 1 2 2hello3232Încă nu există evaluări

- SMP20 Sample FlyerDocument8 paginiSMP20 Sample Flyerhello3232Încă nu există evaluări

- Pub 59Document7 paginiPub 59Rahul ShrivastavaÎncă nu există evaluări

- 3b. - Credit Risk in BankingDocument23 pagini3b. - Credit Risk in Bankingonly.oranda.goldfishÎncă nu există evaluări

- Normal - DistributionDocument23 paginiNormal - Distributionlemuel sardualÎncă nu există evaluări

- HSE Procedure For Handling Incident Investigation Nonconformities & Corrective Action Preventive ActionDocument5 paginiHSE Procedure For Handling Incident Investigation Nonconformities & Corrective Action Preventive Actionngomsia parfaitÎncă nu există evaluări

- Project Charter - FinalDocument12 paginiProject Charter - FinalRynardt VogelÎncă nu există evaluări

- GlossaryDocument30 paginiGlossaryHanoodyÎncă nu există evaluări

- FRM StudyGuide Changes FINAL 2Document12 paginiFRM StudyGuide Changes FINAL 2Saurabh PramanickÎncă nu există evaluări

- Method Statement & Risk Assessment PDFDocument5 paginiMethod Statement & Risk Assessment PDFAmit BhattÎncă nu există evaluări

- Erris Resources PLC Annual Report 31st Dec 2017Document55 paginiErris Resources PLC Annual Report 31st Dec 2017Niall Mc DermottÎncă nu există evaluări

- Management Control SystemsDocument6 paginiManagement Control Systemsmohit462Încă nu există evaluări

- Researches On ChallengesDocument188 paginiResearches On ChallengesMike RollideÎncă nu există evaluări

- L. 3 Entrepreneurial Qualities & Self-Assessment: Personal Entrepreneurial Characteristics (Pecs)Document20 paginiL. 3 Entrepreneurial Qualities & Self-Assessment: Personal Entrepreneurial Characteristics (Pecs)ZALDYÎncă nu există evaluări

- MTM Design and Technical Review Procedure: ApprovalDocument27 paginiMTM Design and Technical Review Procedure: ApprovalCK Tang100% (1)

- Suggested Answers - AL - SBM - MA-2023Document20 paginiSuggested Answers - AL - SBM - MA-2023fahadsarkerÎncă nu există evaluări

- Software Metrics: Roadmap: Norman E Fenton Martin NeilDocument10 paginiSoftware Metrics: Roadmap: Norman E Fenton Martin NeilkÎncă nu există evaluări

- Business Analytics For Project Management: Risk in The Project UndertakenDocument3 paginiBusiness Analytics For Project Management: Risk in The Project UndertakenjeganathanÎncă nu există evaluări

- Chapter 4 Decision Making Under Condition of Risk & UncertainintyDocument45 paginiChapter 4 Decision Making Under Condition of Risk & UncertainintyLetaÎncă nu există evaluări

- Simulation of Multiple-Drift Tunnel Construction With Limited ResourcesDocument12 paginiSimulation of Multiple-Drift Tunnel Construction With Limited ResourcestinhxdÎncă nu există evaluări

- Inventory Management Through Lean LogistDocument13 paginiInventory Management Through Lean LogistRoyGeorgeÎncă nu există evaluări

- Gartner Market Share Analysis - Security Consulting, Worldwide, 2012Document9 paginiGartner Market Share Analysis - Security Consulting, Worldwide, 2012Othon CabreraÎncă nu există evaluări

- CourseMarial - Ca11cinvestment Analysis and Portfolio ManagementDocument4 paginiCourseMarial - Ca11cinvestment Analysis and Portfolio Managementfash selectÎncă nu există evaluări