Documente Academic

Documente Profesional

Documente Cultură

MTBF and MTBR

Încărcat de

yogacruiseDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

MTBF and MTBR

Încărcat de

yogacruiseDrepturi de autor:

Formate disponibile

MTBM / MTBF - KPI for rotating equipment within refineries is anyone able to provide or share MTBM and/or MTBF

- KPI's for rotating equipment within refineries in particular those for 'best in class' (BIC)? The only reference I do have so far is the OREDA data of 1999 for upstream business shown in the machinery reliability book of H.Bloch. However I am keen on getting more detailled references or data... Thanks ! 1 month ago Like CommentFollow Flag More Carlos Alberto Moraes likes this 2 comments

Follow Ron Ron Reeves We use MTBR (Mean Time between repair) This help measure any repairs we had to the equipment. Our MTBR for pumps run at arounf 60 months, and pump seals run at 85 months. I do not know of a industry standard that ensures everyone measures it thesame. 1 month ago Like Reply privately Flag as inappropriate

Follow Muhammad Muhammad Aqleem Jamshed I use MTBF for our production critical equipment. that is simply; MTBF = Total running hours of all equipment (over a months time) / Total number of breakdowns (over a months time) the time may very from month to week or may be 03 motnhs. you will get the picture over the period of time. the trend must be decending or atleast stright.

Job Description Knowledge of Piping Codes like ASME B 31.3 is a must.

Knowledge of Piping Layout Design and Piping Material Engineering is required. Knowledge of Caesar II is a must. Knowledge of other Flexibility Analysis software is added advantage. Should be able to do flexibility analysis of: High temperature and high pressure lines with associated supporting. Lines connected with reciprocating and rotating equipments Two phase flow lines

PSV systems Should be familiar with Isometric checking from stress perspective. Should be familiar with generation of Spring Index/ Datasheet, requisitions and purchases. Knowledge of SPR is required. Candidate should have good knowledge of inter discipline interactions and coordination.

Candidate should be a good team player with proven leadership skills and excellent communication skill.

Qualifications Bachelor degree in Mechanical/ Chemical Engineering

10 20 years in Piping Flexibility Analysis with about 5 years in supervisory/ lead position.

Industry Type -Refinery, Petrochemical, Chemical or related industry

is anyone able to provide or share MTBM and/or MTBF - KPI's for rotating equipment within refineries in particular those for 'best in class' (BIC)? The only reference I do have so far is the OREDA data of 1999 for upstream business shown in the machinery reliability book of H.Bloch. However I am keen on getting more detailled references or data... Thanks ! 1 month ago Like CommentFollow Flag More Carlos Alberto Moraes likes this 5 comments

Follow Ron Ron Reeves We use MTBR (Mean Time between repair) This help measure any repairs we had to the equipment. Our MTBR for pumps run at arounf 60 months, and pump seals run at 85 months. I do not know of a industry standard that ensures everyone measures it thesame. 1 month ago Like

Follow Muhammad Muhammad Aqleem Jamshed I use MTBF for our production critical equipment. that is simply; MTBF = Total running hours of all equipment (over a months time) / Total number of breakdowns (over a months time)

the time may very from month to week or may be 03 motnhs. you will get the picture over the period of time. the trend must be decending or atleast stright. 1 day ago Like Reply privately Flag as inappropriate

Follow Tynan Tynan Carroll To reference Ron Reeves, there is not an industry standard that ensures everyone measures it the same, I fully agree. Therefore, how you define the measurement really depends on what you want to achieve from measuring it. You can benchmark your own MTBF or MTBR using a certain rationale. Then regardless of how you measure it, improvement is improvement if you continue to measure it in the same way. Specifically in refining, where there is a built in redundancy in equipment, the focus for pump MTBF/R really means the cost incurred in delivering a level of reliabiity. What I mean is that you wouldn't hope to double your MTBR whilst doubling your maintenance cost to provide it. In which case, when you start to define your measurement, you possibly need to include the cost of maintenance as a key driver. 1 day ago Like1

Follow Adam Adam Marsden For gas turbines there is standard BS ISO 3977-9:1999, where MTBF is defined as the average time between failures which initiate a forced outage, i.e. the ratio of attempted operating hours to the number of forced outages: MTBF=(PH - (RSH - FOH - POH))/FO = SH/FO where PH is the period hours POH is the planned outage hours RSH is the reserve shutdown/service hours SH is the service hours FOH is the forced outage hours FO is the number of forced outages NOTE This index is sometimes referred to as the mean time between unplanned outages (MTBO).

S-ar putea să vă placă și

- CMRPDocument6 paginiCMRPMairuk Al-Huq100% (1)

- CMRP Exam Study ResourcesDocument2 paginiCMRP Exam Study Resourcesabdulrahman elsaiedÎncă nu există evaluări

- MASTERCLASS-Maintenance & Reliability Best PracticesDocument11 paginiMASTERCLASS-Maintenance & Reliability Best PracticesNazaneen Bano100% (1)

- Arp Cat 1Document4 paginiArp Cat 1shahbaz akramÎncă nu există evaluări

- Defect EliminationDocument4 paginiDefect EliminationHossein100% (1)

- Machinery Malfunction Diagnosis and Correction - Constant ContactDocument2 paginiMachinery Malfunction Diagnosis and Correction - Constant ContactLisan YanÎncă nu există evaluări

- Uptime 201804 PDFDocument49 paginiUptime 201804 PDFCarlos IvanÎncă nu există evaluări

- Failure Codes For Power PlantsDocument80 paginiFailure Codes For Power PlantsMohammed Aslam100% (3)

- Reliability Centered Maintenance Rcm Complete Self-Assessment GuideDe la EverandReliability Centered Maintenance Rcm Complete Self-Assessment GuideEvaluare: 3 din 5 stele3/5 (3)

- Exp 9, Ideal Flow Around A Submerged FlowDocument6 paginiExp 9, Ideal Flow Around A Submerged FlowWasi Uddin MahmudÎncă nu există evaluări

- Maintenance ManagementDocument28 paginiMaintenance ManagementAbdul RashidÎncă nu există evaluări

- Apm Book PDFDocument314 paginiApm Book PDFZahid MasoodÎncă nu există evaluări

- R CM BrochureDocument4 paginiR CM Brochureelshamik100% (1)

- Aladon Reliability-Mgmt E-Brochure 062116Document4 paginiAladon Reliability-Mgmt E-Brochure 062116HugoCabanillasÎncă nu există evaluări

- Mobius Institute ARP Brochure Aug 2021Document29 paginiMobius Institute ARP Brochure Aug 2021kalatzoiÎncă nu există evaluări

- Reliability, Maintainability & Availability IntroductionDocument42 paginiReliability, Maintainability & Availability IntroductionVinoth KumarÎncă nu există evaluări

- Useful Key Performance Indicators For Maintenance PDFDocument8 paginiUseful Key Performance Indicators For Maintenance PDFfumerojr5164Încă nu există evaluări

- Handbook: CandidateDocument3 paginiHandbook: Candidatelinbaba123Încă nu există evaluări

- Reliability Centred MaintenanceDocument19 paginiReliability Centred Maintenancefaraherh amberÎncă nu există evaluări

- 12 TPMDocument50 pagini12 TPMGatut SulianaÎncă nu există evaluări

- Ams Machinery Manager v5 71 Installation Guide en 4236422 PDFDocument68 paginiAms Machinery Manager v5 71 Installation Guide en 4236422 PDFgspozoÎncă nu există evaluări

- Six Steps To Condition Based Maintenance - GoodDocument3 paginiSix Steps To Condition Based Maintenance - GoodSelvaraj BalasundramÎncă nu există evaluări

- Predictive MaintenanceDocument9 paginiPredictive MaintenanceGabo García GranizoÎncă nu există evaluări

- 11 - 8 Steps To Success in Maintenance Planning and Scheduling PDFDocument42 pagini11 - 8 Steps To Success in Maintenance Planning and Scheduling PDFmsaad19103564100% (2)

- Effective Lubrication TechniquesDocument5 paginiEffective Lubrication TechniquesSyedNadeemAhmedÎncă nu există evaluări

- Maintenance Planning and Scheduling PPT 2Document9 paginiMaintenance Planning and Scheduling PPT 2Sunday Paul100% (1)

- Reliability Centered Maintenance & Maintenance Planning: Jordan HoltDocument22 paginiReliability Centered Maintenance & Maintenance Planning: Jordan HoltLuis Filipe Pinheiro Santos100% (1)

- Basic Training Program On Vibration AnalysisDocument24 paginiBasic Training Program On Vibration AnalysisMohamed Al-OdatÎncă nu există evaluări

- Key Performance Indicators For Stores and MRO - Reliabilityweb - A Culture of ReliabilityDocument7 paginiKey Performance Indicators For Stores and MRO - Reliabilityweb - A Culture of ReliabilitytohemaÎncă nu există evaluări

- How To Change RCM2 To Get Really Useful Maintenance StrategyDocument14 paginiHow To Change RCM2 To Get Really Useful Maintenance StrategykhalidjohnpkÎncă nu există evaluări

- Optical Gas Imaging: Infrared Cameras For Gas Leak DetectionDocument9 paginiOptical Gas Imaging: Infrared Cameras For Gas Leak DetectionMartabak MbilÎncă nu există evaluări

- Reliability Solutions For Mechanical Equipment DataDocument20 paginiReliability Solutions For Mechanical Equipment DatatohemaÎncă nu există evaluări

- RCM - Reliability Centred Maintenance: Jørn VatnDocument46 paginiRCM - Reliability Centred Maintenance: Jørn VatnTong Bbm100% (1)

- ARP E Reliability Engineer CourseDocument4 paginiARP E Reliability Engineer CourseLyonelÎncă nu există evaluări

- ODR CMMS: Tips and High Level InformationDocument14 paginiODR CMMS: Tips and High Level InformationAhmed100% (1)

- Guide On Benchmarking 2014Document36 paginiGuide On Benchmarking 2014erast_dudeÎncă nu există evaluări

- CMRPDocument31 paginiCMRPSachin100% (1)

- Reliability Engineering For Process PlantsDocument4 paginiReliability Engineering For Process PlantsSyedNadeemAhmedÎncă nu există evaluări

- Condition Based Maintenance PDFDocument3 paginiCondition Based Maintenance PDFjayaram432Încă nu există evaluări

- TPM Reliability FormulasDocument35 paginiTPM Reliability FormulasjapeleÎncă nu există evaluări

- Current Best PracticesDocument8 paginiCurrent Best Practicesmanu_chatÎncă nu există evaluări

- CV - Ajithkumar - Senior Engineer-Condition Monitoring - 5+ Years Experience PDFDocument5 paginiCV - Ajithkumar - Senior Engineer-Condition Monitoring - 5+ Years Experience PDFShyam KumarÎncă nu există evaluări

- Brochure Relability Centered Maintenance RCMDocument8 paginiBrochure Relability Centered Maintenance RCMPrasanta SanyalÎncă nu există evaluări

- What Is A Reliability EngineerDocument7 paginiWhat Is A Reliability EngineerHumayun Rashid Khan100% (1)

- CMRP OverviewDocument2 paginiCMRP OverviewBabatunde Abiodun OluboriÎncă nu există evaluări

- Key Performance Indicators For Maintenance PDFDocument6 paginiKey Performance Indicators For Maintenance PDFnhatnam06dt1Încă nu există evaluări

- UPTIME CurrentIssueDocument68 paginiUPTIME CurrentIssueAnonymous OuY6oAMggxÎncă nu există evaluări

- Course Outline - Vibration Analyst (Category 1)Document5 paginiCourse Outline - Vibration Analyst (Category 1)Abdul Rahman0% (1)

- 1 - Overview Rev-20170225Document11 pagini1 - Overview Rev-20170225AhmadÎncă nu există evaluări

- Optical Gas Imaging For The Chemical Industry: SafetyDocument2 paginiOptical Gas Imaging For The Chemical Industry: SafetyAnonymous Wu6FDjbÎncă nu există evaluări

- FMEADocument23 paginiFMEAtcsÎncă nu există evaluări

- Technical Report Concerning RCM. by Elisony Edward Mweladzi. Dar Es Salaam Tanzania +255 754321825Document14 paginiTechnical Report Concerning RCM. by Elisony Edward Mweladzi. Dar Es Salaam Tanzania +255 754321825Elisony EdwardÎncă nu există evaluări

- Maintenance Planning and SchedullingDocument3 paginiMaintenance Planning and SchedullingAnnisa MarlinÎncă nu există evaluări

- Life Cycle Institute-SMRP BOK-Detailed Outline (2840)Document3 paginiLife Cycle Institute-SMRP BOK-Detailed Outline (2840)jhonatan lorenzoÎncă nu există evaluări

- Centered Maintainance ReliabilityDocument8 paginiCentered Maintainance ReliabilityKifayat Ullah100% (1)

- Failure Reporting, Analysis, Corrective Action System: Presented By: Ricky Smith, CMRPDocument55 paginiFailure Reporting, Analysis, Corrective Action System: Presented By: Ricky Smith, CMRPTeodora DobricăÎncă nu există evaluări

- Reliability Centered Maintenance Rcm A Complete Guide - 2020 EditionDe la EverandReliability Centered Maintenance Rcm A Complete Guide - 2020 EditionÎncă nu există evaluări

- Plant Maintenance A Complete Guide - 2020 EditionDe la EverandPlant Maintenance A Complete Guide - 2020 EditionÎncă nu există evaluări

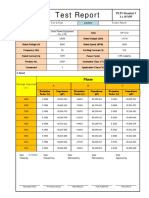

- EDG TestDocument6 paginiEDG Testyogacruise100% (1)

- Protection Relay of Generator TestDocument6 paginiProtection Relay of Generator Testyogacruise100% (2)

- Boiler Feed Pump KSBDocument9 paginiBoiler Feed Pump KSByogacruiseÎncă nu există evaluări

- Refractory Repair and ProcedureDocument3 paginiRefractory Repair and Procedureyogacruise50% (2)

- Ge DGCM Field Rtu CatalogDocument12 paginiGe DGCM Field Rtu CatalogyogacruiseÎncă nu există evaluări

- Calculation Sheet of Bus Protection Unit 3 FinalDocument17 paginiCalculation Sheet of Bus Protection Unit 3 Finalyogacruise100% (1)

- Tan Delta-FDocument1 paginăTan Delta-FyogacruiseÎncă nu există evaluări

- Expansion Bellows Leak RepairDocument1 paginăExpansion Bellows Leak RepairyogacruiseÎncă nu există evaluări

- Manhole On Weld SeamDocument1 paginăManhole On Weld SeamyogacruiseÎncă nu există evaluări

- 3 Heating Load Calculation: 3.1 Heat Transmission LossDocument14 pagini3 Heating Load Calculation: 3.1 Heat Transmission LossyogacruiseÎncă nu există evaluări

- If Steam Drum Under Vacuum Then What Will HappenDocument2 paginiIf Steam Drum Under Vacuum Then What Will HappenyogacruiseÎncă nu există evaluări

- WUXI HUAGUANG BOILER CO., LTD. (无锡华光锅炉股份有限公司) : Wang Fu Jun Zhao Xiao Li Zhang Wei Min Wang Fu Jun Tang Xing LiangDocument4 paginiWUXI HUAGUANG BOILER CO., LTD. (无锡华光锅炉股份有限公司) : Wang Fu Jun Zhao Xiao Li Zhang Wei Min Wang Fu Jun Tang Xing LiangyogacruiseÎncă nu există evaluări

- If The Misalignment Between The Head and Shell in A Pressure Vessel Exceeds The ASME Requirement1Document8 paginiIf The Misalignment Between The Head and Shell in A Pressure Vessel Exceeds The ASME Requirement1yogacruiseÎncă nu există evaluări

- WPS and PQRDocument2 paginiWPS and PQRyogacruiseÎncă nu există evaluări

- Role of Corrosion Engineer at A Petrochemical PlantDocument2 paginiRole of Corrosion Engineer at A Petrochemical PlantyogacruiseÎncă nu există evaluări

- API 571 Required SupportDocument4 paginiAPI 571 Required Supportyogacruise100% (1)

- Rubber Lining Temperature LimitDocument1 paginăRubber Lining Temperature LimityogacruiseÎncă nu există evaluări

- Repair Wps LgiDocument6 paginiRepair Wps LgiyogacruiseÎncă nu există evaluări

- Commissioning of A FurnaceDocument2 paginiCommissioning of A FurnaceyogacruiseÎncă nu există evaluări

- Shut-In and Start-Up Start-Up: Transient FlowDocument2 paginiShut-In and Start-Up Start-Up: Transient FlowyogacruiseÎncă nu există evaluări

- Balancing Specialist: Subject: Basic Balancing (4 Hours)Document3 paginiBalancing Specialist: Subject: Basic Balancing (4 Hours)yogacruiseÎncă nu există evaluări

- NU - Lecture 4 FLUID FLOW MEASUREMENT PDFDocument2 paginiNU - Lecture 4 FLUID FLOW MEASUREMENT PDFHarold Roinan BeñabonÎncă nu există evaluări

- Water HammeringDocument62 paginiWater HammeringMutant_DNAÎncă nu există evaluări

- Mid Sem Question Bank-FFODocument2 paginiMid Sem Question Bank-FFOMihir KhuntÎncă nu există evaluări

- The Brodie International HQ and Manufacturing Plant in Statesboro, GA, USADocument30 paginiThe Brodie International HQ and Manufacturing Plant in Statesboro, GA, USAllllddddÎncă nu există evaluări

- Advantages and Disadvantages of Hydraulic SystemsDocument3 paginiAdvantages and Disadvantages of Hydraulic SystemsTina MilovanovićÎncă nu există evaluări

- TDR 4122Document77 paginiTDR 4122isukuruÎncă nu există evaluări

- Friction Factor ArticleDocument10 paginiFriction Factor ArticleLim BrandonÎncă nu există evaluări

- GPM or GPH Flow Based On PVC Pipe SizeDocument3 paginiGPM or GPH Flow Based On PVC Pipe SizeAziz Khan KakarÎncă nu există evaluări

- Operating and Installation Instructions For HYDAC AccumulatorsDocument4 paginiOperating and Installation Instructions For HYDAC AccumulatorsSholhan AzizÎncă nu există evaluări

- Fire Protection Hydraulic CalculationsDocument25 paginiFire Protection Hydraulic CalculationsVaibhav SawantÎncă nu există evaluări

- Application of Bernoullis EquationDocument11 paginiApplication of Bernoullis EquationChong Zi HaoÎncă nu există evaluări

- Chap 9Document116 paginiChap 9Nayli AthirahÎncă nu există evaluări

- Epc P M - T - C E: Sr. Project Engineer (Project Management) - May2015-April19Document3 paginiEpc P M - T - C E: Sr. Project Engineer (Project Management) - May2015-April19soumya19800000000Încă nu există evaluări

- CL Vs AlphaDocument22 paginiCL Vs Alpharahultri333Încă nu există evaluări

- Calibrated Balance Valve Performance CurvesDocument20 paginiCalibrated Balance Valve Performance CurvesDiana Andreina Linarez ContrerasÎncă nu există evaluări

- Time: 3 Hours Total Marks: 100Document2 paginiTime: 3 Hours Total Marks: 100Sparsh PathakÎncă nu există evaluări

- Versión 1.5 Orifice Gasflow Calcule - ExcelDocument5 paginiVersión 1.5 Orifice Gasflow Calcule - ExceledwinmenaÎncă nu există evaluări

- MHA ZENTGRAF 144-147 BKH Gas SteelDocument3 paginiMHA ZENTGRAF 144-147 BKH Gas SteelPRASHANT KANTEÎncă nu există evaluări

- Pascal Principle LabDocument4 paginiPascal Principle LabAditya Sangita Kisan SonawaneÎncă nu există evaluări

- 04 - Outflow PerformanceDocument37 pagini04 - Outflow Performanceamine aouamÎncă nu există evaluări

- Catalog 12 Section 2 TabDocument40 paginiCatalog 12 Section 2 TabAnonymous oPInocXÎncă nu există evaluări

- Flowing & Static Gradient Survey of AW SGL#1 (05.06.2021-08.06.2021)Document16 paginiFlowing & Static Gradient Survey of AW SGL#1 (05.06.2021-08.06.2021)Vikas kumar singhÎncă nu există evaluări

- Fire Pumps in Accordance EN 12845+A2 GuideDocument30 paginiFire Pumps in Accordance EN 12845+A2 GuideNajaf HussainÎncă nu există evaluări

- Winter - 18 Examination Subject Name: Model Answer Subject CodeDocument15 paginiWinter - 18 Examination Subject Name: Model Answer Subject CodeD06 suraj kumarÎncă nu există evaluări

- Basic Concepts: Drilling Well Control Guide-Section 1Document19 paginiBasic Concepts: Drilling Well Control Guide-Section 1AlvahroziÎncă nu există evaluări

- 5Document6 pagini5Luis Calderon SalasÎncă nu există evaluări

- FFM300 Acceleration Pressure Drop PDFDocument3 paginiFFM300 Acceleration Pressure Drop PDFÁrpád PusztaszeriÎncă nu există evaluări

- A-627 B&G Field Adjustable Venturi Valves For All HVAC Systems BrochureDocument2 paginiA-627 B&G Field Adjustable Venturi Valves For All HVAC Systems Brochurekeith dietrichÎncă nu există evaluări