Documente Academic

Documente Profesional

Documente Cultură

Printing: Offset Printing:: Offset Printing Is The Major Lithographic Technology. in Which The Ink Is

Încărcat de

Gokul PatilDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Printing: Offset Printing:: Offset Printing Is The Major Lithographic Technology. in Which The Ink Is

Încărcat de

Gokul PatilDrepturi de autor:

Formate disponibile

Printing: Printing is the art to take replica (copy) of original image or Text on substrate with help

of ink , dyes , pigments through Photochemical & Mechanical process.

Offset Printing:

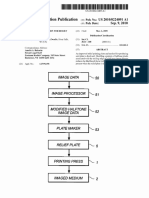

Offset printing is the major lithographic technology. in which the ink is first transferred from the printing plate onto a flexible intermediate carrier the blanket and then Onto the substrate. The principle of offset printing is Shown in figure

There are two offset printing systems used commonly : Conventional offset printing technology: In conventional offset printing the non-image areas on the printing plate that are repellent to ink (water receptive). Where as the image areas on the printing plate that are receptive to ink (Water repellent). In this process Plate need to inked up with Inking rollers & Damped up with dampening rollers to separate the Image & Non Image area. Waterless offset printing technology: The total printing plate surface is basically ink-repellent, which is layer of silicone (approximately 2 m thick). The ink-receptive image area is achieved on plate through developing & applying special treatment solution through Plate processor. Ink is only accepted on areas of the printing plate in which the silicone coating has been removed during developing. Hence here is no need to apply water to separate Image & Non Image area on plate during printing. This procedure is known as waterless offset (quite frequently even as dry offset).

Corresponding printing plates and special inks must be used for both systems. Benefits of Waterless Offset: Specially featured technology for printing on PVC. Excellent printing Quality than conventional offset

Job setting time & change over time is too less. The absence of dampening solution in this process simplifies the printing unit setup, meaning that the desired production run quality is achieved more quickly.

Temperature controlled inking system. No need to concentrate on Ink & water balance. Low wastage during process Faster delivery of print jobs

Waterless offset printing is particularly suitable for fine and very fine screens (low dot gain). No dotgain ( smudgy images) & scum on final print.

Drawbacks: Consumables are very costly ( i. e. Plates, Inks, Press washes, Blankets ) The surfaces of waterless offset printing plates are generally more susceptible to mechanical damage and wear and tear; this calls for more careful handling within the entire process. A further drawback to waterless offset printing is the fact that inks with a different viscosity (greater tack) are used, which places greater demands on the paper surface during printing.

Not economical for short run jobs. ( means below 500 sheets)

Basic 4 colours for offset printing: Cyan, Magenta, Yellow, Black.

Seperation: For offset printing colour image need to split in 4

basic colours.

Color Quality Checking by Densitometer: The main factors that govern the quality of the printed image are the ink supply to the paper and the register, that is, how the individual color separations are printed one on top of the other to give a multicolor image. In addition to the printers eye, color

measurement and control systems are used that can be utilized not only to set up a job quickly and keep it adjusted on the run, but also to monitor production itself.

UV PrintingUV

printing is used to print on plastic, foil, and specialty substrates. UV light is used to dry specially formulated inks that are printed on non-porous materials. In converntional printing, ink dries as it is absorbed into paper. Because plastic is not absorbent, the ink must be dried on the top surface using UV light.

S-ar putea să vă placă și

- CHAPTER 3.0 - GravureDocument10 paginiCHAPTER 3.0 - GravureGiha Tardan100% (1)

- Carton Board Detail With OffsetDocument7 paginiCarton Board Detail With OffsetIzhar ShaikhÎncă nu există evaluări

- Inkformation 4 en 02Document28 paginiInkformation 4 en 02MohammadAlAmeenÎncă nu există evaluări

- Troubleshooting Guide: GravureDocument20 paginiTroubleshooting Guide: Gravureक्षितिजÎncă nu există evaluări

- Flint InksDocument24 paginiFlint InksshoanashokÎncă nu există evaluări

- Pigments Training - Printing - Doman-ShotwellDocument18 paginiPigments Training - Printing - Doman-ShotwellHerbert AguilargonzalezÎncă nu există evaluări

- Agfa Offset Printing Training on Inks and FountainsDocument24 paginiAgfa Offset Printing Training on Inks and FountainssmkazmiÎncă nu există evaluări

- Flexo Vs OffsetDocument18 paginiFlexo Vs OffsetJavier Martinez CañalÎncă nu există evaluări

- Ffta First 5.0 Design GuideDocument87 paginiFfta First 5.0 Design GuideSharlowÎncă nu există evaluări

- Process For Gravure Printing With A Water-Based InkDocument12 paginiProcess For Gravure Printing With A Water-Based InkSyed Mujtaba Ali BukhariÎncă nu există evaluări

- Doctor Systems BrochureDocument8 paginiDoctor Systems BrochureMostafizur RahmanÎncă nu există evaluări

- Offset ProblemiDocument34 paginiOffset ProblemiMica IvanovicÎncă nu există evaluări

- Doctor in PrintingDocument57 paginiDoctor in PrintingKeerthanaÎncă nu există evaluări

- Gravure Coating:: Webinar - April 26, 2012Document43 paginiGravure Coating:: Webinar - April 26, 2012Rob BuitenpuiÎncă nu există evaluări

- In-Mould Labelling Application SheetDocument1 paginăIn-Mould Labelling Application SheetstevierayoÎncă nu există evaluări

- Offset PrintingDocument5 paginiOffset PrintingajiitrÎncă nu există evaluări

- Flexography: The Process of Printing on Raised SurfacesDocument34 paginiFlexography: The Process of Printing on Raised Surfacesfajar ramadhanÎncă nu există evaluări

- Hapa - in House Printing Solutions (Marcel Aeby)Document44 paginiHapa - in House Printing Solutions (Marcel Aeby)Yose RizalÎncă nu există evaluări

- Materi PrintingDocument16 paginiMateri PrintingnuryadyÎncă nu există evaluări

- 1 CDI Advance 5080Document2 pagini1 CDI Advance 5080Diana BonanaÎncă nu există evaluări

- Gravure Printing Cylinder ConstructionDocument70 paginiGravure Printing Cylinder ConstructionKristianto Mathers IIIÎncă nu există evaluări

- Understanding Anilox Roller Engraving Angles and VolumesDocument16 paginiUnderstanding Anilox Roller Engraving Angles and VolumesJose Guerra100% (2)

- The Ink Room of TomorrowDocument4 paginiThe Ink Room of TomorrowQuý Đình Mai MaiÎncă nu există evaluări

- Bobst PDFDocument52 paginiBobst PDFAbdul BasitÎncă nu există evaluări

- NVC Flexographic EguideDocument21 paginiNVC Flexographic EguideBernard Andre Palacios Gomez100% (1)

- Reference Manual Printing and Converting PerformanceDocument74 paginiReference Manual Printing and Converting PerformanceAli HussnainÎncă nu există evaluări

- Issue #9 Printing and Graphics Science Group NewsletterDe la EverandIssue #9 Printing and Graphics Science Group NewsletterÎncă nu există evaluări

- Offset Printing Process PDFDocument87 paginiOffset Printing Process PDFNBAÎncă nu există evaluări

- Offset TrialDocument64 paginiOffset TrialOgi Permana PutraÎncă nu există evaluări

- Printing Ink Technology: A Guide to Raw Materials, Manufacture and ApplicationsDocument13 paginiPrinting Ink Technology: A Guide to Raw Materials, Manufacture and ApplicationsD Rong saÎncă nu există evaluări

- Flexo Uv Ink TroubleshootingDocument22 paginiFlexo Uv Ink TroubleshootingHiba Naser100% (1)

- 2015 BASF Flexible-Packaging-Inks Landscape ELDocument12 pagini2015 BASF Flexible-Packaging-Inks Landscape ELPongthip PesachpinankulÎncă nu există evaluări

- Common Offset Print ProblemDocument11 paginiCommon Offset Print ProblemLisa RodriguezÎncă nu există evaluări

- Problem Cases in The PressroomDocument45 paginiProblem Cases in The PressroomHeidelberg IndiaÎncă nu există evaluări

- Flexographic Ctsa Vol1 PDFDocument390 paginiFlexographic Ctsa Vol1 PDFShrinil DesaiÎncă nu există evaluări

- Flexo Print MistakesDocument9 paginiFlexo Print MistakesGenalyn LeonardoÎncă nu există evaluări

- 2.2 Gravure Printing: 2.2.1 ProcessDocument39 pagini2.2 Gravure Printing: 2.2.1 ProcessDang Thi Ngoc LieuÎncă nu există evaluări

- Important Aspect of Viscosity in Gravure Printing ProcessDocument18 paginiImportant Aspect of Viscosity in Gravure Printing ProcessMakarand Dole100% (1)

- Modern Technology of Printing & Writing Inks GuideDocument46 paginiModern Technology of Printing & Writing Inks GuideaboobakerÎncă nu există evaluări

- GravureDocument17 paginiGravureGopi NathÎncă nu există evaluări

- School Order FormDocument1 paginăSchool Order Formalozie953Încă nu există evaluări

- Relationships Between The Surface Texture of Flexographic Printing Plates and The Printability of Kraft PaperDocument11 paginiRelationships Between The Surface Texture of Flexographic Printing Plates and The Printability of Kraft PaperQuý Đình Mai MaiÎncă nu există evaluări

- Anilox Rolls Selection GuideDocument4 paginiAnilox Rolls Selection GuideMismail EgypacÎncă nu există evaluări

- Harper Anilox RollDocument88 paginiHarper Anilox Rollsuracheted0% (1)

- Water and fountain solution compositionDocument22 paginiWater and fountain solution compositionTomColl66Încă nu există evaluări

- Indian Printing Industry Profile 2010Document36 paginiIndian Printing Industry Profile 2010Anil YadavÎncă nu există evaluări

- ERA Apc06 DreherDocument35 paginiERA Apc06 Dreherrafael_faria_4Încă nu există evaluări

- US 20100224091A1 - Trailing Edge Pattern for Relief Plate FeatureDocument12 paginiUS 20100224091A1 - Trailing Edge Pattern for Relief Plate FeatureCikumunya ArsÎncă nu există evaluări

- Water Based Flexo InksDocument5 paginiWater Based Flexo InksAshish JainÎncă nu există evaluări

- Packaging Gravure Troubleshooting GuideDocument24 paginiPackaging Gravure Troubleshooting GuideAnan Kempanichkul100% (1)

- Proven UV Offset Printing Technology For High Quality LabelsDocument13 paginiProven UV Offset Printing Technology For High Quality LabelsJavier Martinez CañalÎncă nu există evaluări

- Water-Based Trouble Shooting GuideDocument32 paginiWater-Based Trouble Shooting Guidejayw04wrxÎncă nu există evaluări

- Ink Problem Solving Guide OffsetDocument11 paginiInk Problem Solving Guide OffsetTapaskumar ChakrabortyÎncă nu există evaluări

- Anilox RollDocument37 paginiAnilox RollSudhakar Joshi100% (4)

- KBA Rapida 105 Series ENGDocument30 paginiKBA Rapida 105 Series ENGولاءومحمد AHMEDÎncă nu există evaluări

- OpvDocument11 paginiOpvPankaj KumarÎncă nu există evaluări

- OnPress 63Document22 paginiOnPress 63Carlos GrajalesÎncă nu există evaluări

- 30 77 High Speed Gravure ProoferDocument2 pagini30 77 High Speed Gravure ProoferCode 9Încă nu există evaluări

- Commonspoly 3.1 - Game Master's GuideDocument36 paginiCommonspoly 3.1 - Game Master's GuideQuique ZuñigaÎncă nu există evaluări

- Kontak Supplier TrustedDocument15 paginiKontak Supplier TrustedArdiningsih Eka PutriÎncă nu există evaluări

- ALSA ConfigurationDocument40 paginiALSA ConfigurationLuis MezaÎncă nu există evaluări

- ThemeDocument3 paginiThemeapi-338558907Încă nu există evaluări

- TXN Alarms 18022014Document12 paginiTXN Alarms 18022014Sid GrgÎncă nu există evaluări

- LG GuideDocument172 paginiLG GuidethemistzÎncă nu există evaluări

- May The Fourth Be With YouDocument48 paginiMay The Fourth Be With Youapi-26032005Încă nu există evaluări

- ChpsdevsDocument3 paginiChpsdevstomoyo2009Încă nu există evaluări

- All For You: GratefulDocument1 paginăAll For You: GratefulKenneth Dave BorjaÎncă nu există evaluări

- PDR SeriesDocument9 paginiPDR SeriesbansalrÎncă nu există evaluări

- Modul Amalan Pedagogi BiDocument153 paginiModul Amalan Pedagogi Bishamsul100% (1)

- A Suitable Boy Book Review by Devapreeti SharmaDocument2 paginiA Suitable Boy Book Review by Devapreeti SharmaVdg MoonÎncă nu există evaluări

- How To Install Windows XPDocument21 paginiHow To Install Windows XPSajid Aziz SamoÎncă nu există evaluări

- Price List PT Marga Nusantara Jaya (Modern)Document18 paginiPrice List PT Marga Nusantara Jaya (Modern)Lenny hadiÎncă nu există evaluări

- 21 First Date Ideas...Document5 pagini21 First Date Ideas...lo bemÎncă nu există evaluări

- Ontela Picdeck Customer ProfilesDocument11 paginiOntela Picdeck Customer ProfilesTasya Ravida AyuÎncă nu există evaluări

- Petrified Forest National Park: Painted Desert Visitor CenterDocument1 paginăPetrified Forest National Park: Painted Desert Visitor CenterNaaman TakidinÎncă nu există evaluări

- Biss Key DetailsDocument6 paginiBiss Key DetailsAnonymous HZtOQ6if0% (1)

- Om 870Document20 paginiOm 870jussiÎncă nu există evaluări

- Hilal Boxer..by DR Riyaz VeeriDocument2 paginiHilal Boxer..by DR Riyaz VeeriRiyaz VeeriÎncă nu există evaluări

- Shamanic Journey Epic HeroDocument22 paginiShamanic Journey Epic HeroNelly Buquiron100% (2)

- Waist Trimmer Guide by Artemus Dolgin PDFDocument14 paginiWaist Trimmer Guide by Artemus Dolgin PDFalok chawla100% (8)

- Cot CreativeDocument24 paginiCot CreativeIsagani WagisÎncă nu există evaluări

- 12 Teste - Prepare 1 PDFDocument12 pagini12 Teste - Prepare 1 PDFIoana Tanasă100% (1)

- Noongar Six SeasonsDocument2 paginiNoongar Six Seasonsapi-319898397Încă nu există evaluări

- Annex 3 - Template Looking For A Destination - TASK 2. LOOKING FOR A DESTINATIONDocument9 paginiAnnex 3 - Template Looking For A Destination - TASK 2. LOOKING FOR A DESTINATIONValentina RinconÎncă nu există evaluări

- ChicagoReviewPress-Book Reviews at A GlanceDocument132 paginiChicagoReviewPress-Book Reviews at A GlancedustydiamondÎncă nu există evaluări

- 2012 US Olympic Swim Team GuideDocument112 pagini2012 US Olympic Swim Team GuideLukman HakimÎncă nu există evaluări

- Sprinter BrochureDocument56 paginiSprinter BrochureHieuDinhÎncă nu există evaluări

- WLAN Standards and TechnologiesDocument39 paginiWLAN Standards and TechnologiesTitoÎncă nu există evaluări