Documente Academic

Documente Profesional

Documente Cultură

B (1) .Tech Curriculam Final

Încărcat de

Brahadeesh ThiagarajanTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

B (1) .Tech Curriculam Final

Încărcat de

Brahadeesh ThiagarajanDrepturi de autor:

Formate disponibile

Bharathidasan Institute of Technology ANNA UNIVERSITY TIRUCHIRAPPALLI TIRUCHIRAPPALLI-620 024 COURSE COMMITTEE CONTENT

Department of Pharmaceutical Engineering & Technology 25th January 2008

Course: B.Tech

Topic 1: Curriculum I Semester to VIII Semester Topic 2: Syllabi for Third, Fourth, Fifth, Sixth, Seventh and Eighth Semesters Topic 3: Regulations under Choice Based Credit Systems

ANNA UNIVERSITY - TIRUCHIRAPPALLI TIRUCHIRAPPALLI-620 024

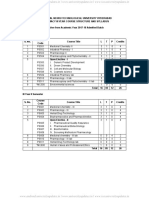

Curriculum for B. Tech in Pharmaceutical Engineering & Technology WORK LOAD, HOURS/ WEEK THEORY 19 19 18 18 18 20 23 12 147 TUTORIAL 5 2 4 4 4 4 1 24 PRACTICAL 6 9 9 9 9 9 6 57 OTHERS 5 5 2 2 2 2 2 22 TOTAL 35 35 33 33 33 35 32 12 248

SEMESTER I II III IV V VI VII VIII TOTAL

CREDITS 24 24 26 25 26 27 27 21 200

DEPARTMENT OF PHARMACEUTICAL ENGINEERING & TECHNOLOGY

Bharathidasan Institute of Technology Anna University, Tiruchirappalli- 620 024

I SEMESTER - B. Tech in Pharmaceutical Engineering & Technology S. No. 1 2 3 4 5 1 2 3 Code EN0011 MA0011 PH0011 CH0011 AT0011 Subject THEORY English Mathematics- I Physics Chemistry Basic engineering- I PRACTICAL AT0021 Engineering Drawing PH0021 Physics Laboratory AT0031 Workshop Laboratory Total 3 19 2 5 3 3 6 4 2 2 24 50 50 50 300 50 50 50 500 100 100 100 800 3 3 3 3 4 1 2 3 4 3 3 3 30 30 30 30 30 70 70 70 70 70 100 100 100 100 100 L T P Cr IA UE TM

Counseling- 2; Library 2; NSS/Hobby Project- 1

DEPARTMENT OF PHARMACEUTICAL ENGINEERING & TECHNOLOGY

Bharathidasan Institute of Technology Anna University, Tiruchirappalli- 620 024

II SEMESTER - B. Tech in Pharmaceutical Engineering & Technology S. No. 1 2 3 4 5 Code MA0022 AT0042 PH0032 CH0022 IT0012 Subject THEORY Mathematics- II Basic engineering- II Material Science Environmental Science Introduction to Information Technology PRACTICAL 1 2 3 CH0032 Chemistry Laboratory IT0022 Information Technology Laboratory AT0052 Auto CAD Laboratory Total 3 19 2 3 3 3 9 2 2 4 24 50 50 50 300 50 50 50 500 100 100 100 800 3 4 3 3 3 2 4 3 3 3 3 30 30 30 30 30 70 70 70 70 70 100 100 100 100 100 L T P Cr IA UE TM

Counseling- 2; Library 2; NSS/Hobby Project- 1

DEPARTMENT OF PHARMACEUTICAL ENGINEERING & TECHNOLOGY

Bharathidasan Institute of Technology Anna University, Tiruchirappalli- 620 024

III SEMESTER - B. Tech in Pharmaceutical Engineering & Technology S. No. 1 2 3 4 5 6 1 2 3 Code Subject L 4 4 4 3 3 T 1 1 2 4 P 3 3 3 9 Cr 4 4 3 4 4 1 2 2 2 26 IA 30 30 30 30 30 50 50 50 50 350 UE 70 70 70 70 70 50 50 50 500 TM 100 100 100 100 100 50 100 100 100 850

THEORY PE0013 Pharmaceutical Organic Chemistry PE0023 Physical Pharmaceutics PE0033 Biochemistry CT0013 Process Calculations CT0023 Fluid flow Operations EN0023 General Proficiency I

PRACTICAL Pharmaceutical Organic Chemistry PEP013 Laboratory PEP023 Physical Pharmaceutics Laboratory CTP013 Fluid Flow Operations Laboratory Total 18

Extra Mural Lecture/ Seminar/ Library 2

DEPARTMENT OF PHARMACEUTICAL ENGINEERING & TECHNOLOGY

Bharathidasan Institute of Technology Anna University, Tiruchirappalli- 620 024

IV SEMESTER B. Tech in Pharmaceutical Engineering & Technology S. No. 1 2 3 4 5 6 1 2 3 Code PE0014 PE0024 CT0034 MA0044 CT0054 EN0064 Subject THEORY Microbiology Unit Processes in organic synthesis Process Heat Transfer Numerical Methods and Statistics Chemical Engineering Operations General Proficiency II PRACTICAL PEP074 Microbiology Laboratory PEP084 Biochemistry Laboratory CTP094 Heat Transfer Laboratory Total 18 4 3 3 3 9 2 2 2 25 50 50 50 350 50 50 50 500 100 100 100 850 4 4 3 4 3 1 1 2 3 4 4 3 4 1 30 30 30 30 30 50 70 70 70 70 70 100 100 100 100 100 50 L T P Cr IA UE TM

Extra Mural Lecture/ Seminar/ Library 2

DEPARTMENT OF PHARMACEUTICAL ENGINEERING & TECHNOLOGY

Bharathidasan Institute of Technology Anna University, Tiruchirappalli- 620 024

V SEMESTER - B. Tech in Pharmaceutical Engineering & Technology S. No. 1 2 3 4 5 6 1 2 3 Code PE0015 PE0025 CT0035 CT0045 PE0055 EN0065 Subject THEORY Pharmaceutical Chemistry 4 Pharmaceutical Technology - I 4 Chemical Reaction Engineering 3 Process Instrumentation 3 Physiology & Pharmacology 4 General Proficiency III PRACTICAL Pharmaceutical Technology I PEP075 Laboratory PEP085 Chemical Analysis Laboratory Mechanical Operations and Reaction CTP095 Engineering Laboratory Total 18 1 1 2 4 3 3 3 9 4 4 4 4 3 1 2 2 2 26 30 30 30 30 30 50 50 50 50 350 70 70 70 70 70 50 50 50 500 100 100 100 100 100 50 100 100 100 850 L T P Cr IA UE TM

Extra Mural Lecture/ Seminar/ Library 2

DEPARTMENT OF PHARMACEUTICAL ENGINEERING & TECHNOLOGY

Bharathidasan Institute of Technology Anna University, Tiruchirappalli- 620 024

VI SEMESTER B. Tech in Pharmaceutical Engineering & Technology S. No. 1 2 3 4 5 6 1 2 3 Code PE0016 Subject THEORY Instrumental methods of 4 Pharmaceutical Analysis PE0026 Advanced Medicinal Chemistry 4 CT0036 Process Equipment design 3 PE0046 Pharmaceutical Technology - II 4 CT0056 Mass Transfer Operations 3 Object Oriented Programming using PE0066 2 C++ PRACTICAL PE0076 Medicinal Chemistry Laboratory Instrumental methods of PE0086 Pharmaceutical Analysis Laboratory CTP096 Mass Transfer Laboratory Total 20 1 1 2 4 3 3 3 9 4 4 4 4 4 1 2 2 2 27 30 30 30 30 30 50 50 50 50 350 70 70 70 70 70 50 50 50 500 100 100 100 100 100 50 100 100 100 850 L T P Cr IA UE TM

Extra Mural Lecture/ Seminar/ Library 2

DEPARTMENT OF PHARMACEUTICAL ENGINEERING & TECHNOLOGY

Bharathidasan Institute of Technology Anna University, Tiruchirappalli- 620 024

VII SEMESTER - B. Tech in Pharmaceutical Engineering & Technology S. No. 1 2 3 4 5 6 1 2 Code CT0017 PE0027 PE0037 PE0047 PE0057 PE0067 CT0077 PE0087 Subject L T 1 1 P 3 3 6 Cr 4 3 4 4 4 4 2 2 27 IA 30 30 30 30 30 30 50 50 280 UE 70 70 70 70 70 70 50 50 520 TM 100 100 100 100 100 100 100 100 800

THEORY Process Dynamics & Control 3 Pharmaceutical Biotechnology 4 Validation of Pharmaceutical 4 Industries Novel Drug Delivery System 4 Separation Technology 4 Technology of Fine Chemicals 4 and Bulk Drugs PRACTICAL Process Dynamics & Control lab Separation Technology lab Total 23

Extra Mural Lecture/ Seminar/ Library 2

DEPARTMENT OF PHARMACEUTICAL ENGINEERING & TECHNOLOGY

Bharathidasan Institute of Technology Anna University, Tiruchirappalli- 620 024

VIII SEMESTER - B. Tech in Pharmaceutical Engineering & Technology S. No. 1 2 3 4 Code Subject THEORY PE0018 Bio Process Technology Safety and Risk Management in PE0028 Industries PE0038 Industrial Management PE0048 Project TOTAL 4 4 4 12 3 3 3 12 21 30 30 30 100 190 70 70 70 200 410 100 100 100 300 600 L T P Cr IA UE TM

Pharmaceutical Organic Chemistry L: 4 Cr: 4 Objective

PE0013 TM: 100

To study about fundamentals of Organic chemistry applied in Pharmacy. Unit I Concept of Aromaticity and Aromatic Character Characteristics of organic compounds - Huckel rule - General mechanism of aromatic electrophilic substitution reactions - Orienting influence of different substituents in benzene and naphthalene rings by charge distribution method and stability of the intermediate method Unit II Friedel Craft and Related Reaction Principle involved in alkylation and acylation - industrial applications - Fries rearrangement Hoesch reaction - Formylation reactions Gattermann - Gattermann Koch Vilsmayer - Reimar Tiemann reactions - Aromatic nucleophilic substitution reactions - mechanisms including benzene mechanism. Unit III Aromatic Amines Methods of introduction of the aromatic amino group into an aromatic nucleus - Diazotization reaction and reactions of aryl diazonium salts such as Sandmeyer Ullmann - azo coupling Deamination etc - and benzidine rearrangement. Aromatic sulphonic acids: Sulphonation reaction chlorosulphonation - reactions of, uses of, SO3H group as the blocking group - kinetic and thermodynamic controls of the reaction. Phenols: Methods of preparation acidity - general reactions. Carbohydrates: Structure of glucose fructose - interconversion of glucose and fructose stereochemistry of common sugars - general considerations of sucrose - starch and cellulose. Unit IV Molecular Rearrangements Wolff rearrangement - Schmidt reaction - Curtius rearrangement - Favorskii reaction-Mechanism and applications Oxidation: Mechanism - stereochemistry and applications of the following oxidations- KMnO4 MnO2 - K2Cr2O7 - CrO3 - H2O2 - SeO2 - Oppenauer oxidation - Baeyer-Villeger oxidation. Reductions: Mechanisms and stereochemistry and applications of the following reductions - catalytic dehydrogenation - Meerwein-Ponndorf-Verley - NaBH4 LAH - hydrazine (Wolff- Kishner) Clemmenson - Rosenmund. Unit V Heterocyclic Aromatic Compounds Nomenclature - aromaticity of pyrrole - thiophene and furan pyridine - dipole moment - reactive sites and stabilities of these heterocycles. Synthesis: General principles of heterocyclic synthesis methods of preparation of pyridines pyrroles - thiophenes and furans - quinolines and isoquinolines - Reactions of pyridine pyrrole thiophene - furan and pyridine-n-oxide. Text books 1. Organic Chemistry, I. L. Finar, 4th Edition, 1964. Longmans Publications. 2. Organic Chemistry. Morrison & Boyd, 6th Edition, 1992. Prentice Hall Publications. 3. Advanced Organic Chemistry, Michael B. Smith & Jerry March, 5th Edition, 2001. References 1. Organic Reaction and Their Mechanisms, P.S.Kalsi, 2nd, Edition, 2004. New Age International Pvt Ltd, Publications. 2. Understanding Organic Reaction Mechanisms, Adam Jacobs, Cambridge University Press, 1997.

Physical Pharmaceutics L: 4 Objective Cr: 4 TM: 100

PE0023

To study the basic concepts involved in the design of dosage forms. Unit I Kinetics Physical degradation of pharmaceutical products, loss of volatile constituents, loss of water, absorption of water, crystal growth, polymorphism, colour change, factors influencing chemical degradations like hydrolysis, oxidation, isomerization, polymerization, decarbosylation, etc., methods of reducing physical and chemical degradations: chemical kinetics and their application to decomposition of pharmaceutical products; Accelerated stability analysis. Unit II Photochemistry Introduction, sources of photochemical radiation, light absorption, basic laws of photochemistry, photochemical reactions and photosensitization. Unit III Suspensions and Emulsions Suspensions, interfacial properties of suspended particles, setting in suspensions, formulation of suspension, emulsion, theories of emulsification, physical stability of emulsions, preservation of emulsions, rheologic properties of emulsions, Phase equilibria and emulsion formulation, special emulsion system, semisolids and gels. Unit IV Colloids Electrical and optical properties of colloids, sedimentation, stokes law, stability of colloidal dispersions, protective colloids, sensitization of colloidal system, applications of colloids in pharmacy. Unit V Micromeritics Particle size and size distribution, methods of determining particle size, particle shape and surface area. Methods of determining surface area, pore size, derived properties of powders. Text Books 1. Physical pharmacy By Alfred Martin, 3rd Edition, 1983. Hagerstown Publications. 2. Experimental Pharmaceutics by Fugena, Prott. References 1. Tutorial Pharmacy Cooper and Gunn, 2. Physical Pharmaceutics, Dr.M.Manavalan. 3. Text book of Pharmaceutics, Bentleys, 8th Edition, 1977, London Publications.

Bio-Chemistry L: 4 Objective Cr: 3 TM: 100

PE0033

To study about biomolecules and the principles involved in their Biochemistry. Unit I Biomolecules Structure and properties of mono, di, oligo and polysaccharides, Structure and properties of fatty acids, glycerolipids. Phospholipids, glycolipids and steroids. Structure and properties of purine, pyrimidines Biological roles of lipids, nucleic acids, proteins and carbohydrates.

Unit II Metabolism Biosynthesis and degradation of fatty acids, cholesterol, proteins and nucleic acids and aminoacids. General mode of vitamins and mineral elements.

Unit III Intermediary Metabolism Glycogenesis, Glycogenolysis, Gluconeogenesis, Glycolysis, Hexose monophosphate shunt, TCA cycle, urea cycle, nitrogen cycle, shikimic acid pathway. Unit IV Bioenergetics Electron transport Chain (Phosporylation) in chloroplast and mitochondria, Exergonic and endergonic reactions chemiosmotic hypothesis Light reactions of Photosynthesis.

Unit V Enzymes Classification and nomenclature, Mechanism of enzyme action, specificity of enzyme, factors affecting enzyme activity.

Text Books 1. Biochemistry, Voet. D, Voet. G, 2nd Edition, 1994.John Wiley and Sons Publications. 2. Biochemistry, Stryer. L, 4th Edition, 1994. References 1. Enzyme kinetics and the Michaelis Menton Euqation, Regulation of enzyme activity Enzyme inhibition. Application of enzymes. 2. Principles of Biochemistry, Lehninger. A.L., Nelson. D.L. and M.M. Cox, CBS Publications, 1993.

PROCESS CALCULATIONS L: 3 Objective To study about stoichiometry, Ideal gases and vapor pressure, Humidity and solubility to make the process flow sheet with mass and energy balance. Unit I T: 1 Cr: 4 TM: 100

CT0013

Stoichiometry Introduction- Units and Dimensions - Stoichiometric principles-composition relations, density and specific gravity.

Unit II Ideal Gases and Vapor Pressure Behavior of Ideal gases - application of ideal gas law- gaseous mixtures - volume changes with change in composition. Vapor pressure- effect of Temperature on vapor pressure-vapor pressure plots - vapor pressure of immiscible liquids-solutions. Unit III Humidity and Solubility Humidity - saturation - vaporization - condensation - wet and dry bulb thermometry -Solubility and Crystallization-Dissolution - solubility of gases. Unit IV Material Balance Material Balance- Processes involving chemical reaction-Combustion of coal, fuel gases and Sulphur - Recycling operations - Bypassing streams - Degree of conversion -excess reactant limiting reactant. Unit V Energy Balance Thermo chemistry - Calculation of Heat of reaction at other temperatures - Hesss law of summation - heat of formation, reaction, mixing, combustion - mean specific heat -Theoretical flame Temperature. Text Books: 1. Stoichiometry, B. I. Bhatt and S. M. Vora, 3rd Edition, Tata McGraw Hill Publishers Ltd. New Delhi. 1976. 2. Process calculation, V.Venkataramani and N.Anantharaman, Prentice Hall of India limited, India. Reference Books: 1. Chemical Process Principles, O.A.Hougen, K.M. Watson and R.A. Ragatz, Vol- I, CBS Publishers and Distributors, New Delhi, 1995 2. Basic Principles and Calculations in Chemical Engineering, D. Himmelblau, 6th Edition, Prentice Hall of India Ltd, India 2000. 3. Process Calculation for Chemical Engineering, 2nd Revised Edition, Chemical Engineering education development centre. I.I.T, Madras, 1981.

FLUID FLOW OPERATIONS L: 3 Objective T: 1 Cr: 4 TM: 100

CT0023

This paper deals with the concepts of fluid flow, measurements and transportation. Unit I Properties of Fluids and Concept of Pressure Introduction - Nature of fluids - physical properties of fluids - types of fluids. Fluid statics: Pressure - density - height relationships-Pressure Measurement. Units & Dimensions. Dimensional analysis. Similarity - forces arising out of physical similarity - dimensionless numbers. Unit II Momentum Balance and its Applications Kinematics of fluid flow; Stream line-stream tube-velocity potential. Newtonian and nonNewtonian fluids - Time dependent fluids - Reynolds number - experiment and significance -Momentum balance - Forces acting on stream tubes - Potential flow - Bernoulli's equation Correction for fluid friction - Correction for pump work. Unit III Flow of Incompressible Fluids through Ducts Flow of incompressible fluids in pipes- laminar and turbulent flow through closed conduits velocity profile & friction factor for smooth and rough pipes-Head loss due to friction in pipes, fitting etc. Introduction to compressible flow-Isentropic flow through convergent and divergent nozzles and sonic velocity. Unit IV Flow of Fluids through Solids Form drag-skin drag - Drag co-efficient -Flow around solids and packed beds- Friction factor for packed beds - Ergun's Equation - Motion of particles through fluids-Motion under gravitational and centrifugal fields - Terminal settling velocity. Fluidization - Mechanism, types- general properties applications. Unit V Transportation and Metering Measurement of fluid flow Orifice meter, venturi meter, Pitot tube, rotameter, weirs and notches Wet gas meter and dry gas meter-Hot wire anemometers-Transportation of fluids-Fluid moving machinery performance-Selection and specification-Air lift and diaphragm pumps-Positive displacement pumps-Rotary & Reciprocating pumps-Centrifugal pumps-performance and characteristics. Text Books: 1. Fluid Mechanics and Hydraulic machines, R.K. Bansal, Laxmi Publications (P) Ltd., New Delhi. 1995 2. Unit operations of Chemical Engineering, W.L. McCabe, J.C. Smith and P.Harriott, 5th Edition, McGraw Hill, International Edition, 1993. Reference Books: 1. Chemical Engineering, J.M. Coulson and J. F.Richardson, Vol-1 3rd Edition, Butterworth Heinemann Publishers. 2. Fluid Mechanics for Chemical Engineers, Noel.D. Nevers, McGraw Hill, International Edition. 1990. 3. Fluid Mechanics for Chemical Engineers, Liggett de Nevers, McGraw Hill, International Edition, 1994.

General Proficiency-I T: 2 Cr: 1 TM: 50

EN0023

Objective The general objective of this course is to give the learners an exposure to the basic rubrics of communication and suggest some strategies by which their communication skills and numerical ability can be developed. Unit 1 Basics of Communication Essential communication skills - elements of communication - basic models of communication frames of reference - purposive communication - channels of communication - developing good communication style. Unit IILanguage Development through Reading TOEFL-based reading comprehension - current affairs - vocabulary building- idioms and phrases basic phonetics. Unit III Speaking Practice Dialogue/Conversation - types of conversations - listening skills - telephone etiquette - public speaking - debate. Unit IV Quantitative Analysis Aptitude Tests Text Books 1. Business Communication Today, Bovee, Courtland Land John V Thill. Pearson Education, 2003. 2. Mastering Public Speaking, Nicholls, Anne, Jaico Publishing House, 2003. 3. Mastering Communication, Nicky Stanton, 4th Edition., Palgrove Series, Macmillan, 2004. Reference Books 1. TOEFL CBT EXAM, Rymniak, Marilyn J and Janet A Shanks, Simon and Schuster, 2002. 2. Word Power Made Easy, Lewis, Norman, Bloomsbury, 2003. 3. Quantitative Aptitude, Aggarwal, R.S., S. Chand & Co., 2004.

Pharmaceutical Organic Chemistry Laboratory PEP013 P: 3 Cr: 2 TM: 100

1. Synthesis of some organic compounds involving single step reactions like nitration, halogenation, acetylation and hydrolysis. 2. Assay of organic compounds involving acidimetry, alkalimetry, Iodometry etc. 3. Determination of rate of reation in zero, first order reations. 4. Determination of physical constants used as criteria of purity like melting point, boiling point, weight per ml, refractive index and viscosity. 5. Determination of pH, Potentiometric & Dead stop endpoint technique. 6. Preparation of buffers, sensitivity, specificity, precision and accuracy. 7. Tests for Purity for official compounds mentioned in IP/BP/USP. 8. Limit test for marketed formulations.

Physical Pharmaceutics Laboratory P: 3 Cr: 2 TM: 100

PEP023

1. Determination of density of Liquid. 2. Determination of surface tension/ interfacial tension of liquid. 3. Determination of critical micellar concentration of surfactant. 4. Effect of concentration on adsorption. 5. Determination of half life, rate constant and order of chemical reaction. 6. Effect of temperature on specific rate constant. 7. Determination of specific surface area of powder by adsorption method. 8. Determination of derived properties of powders like density, porosity, compressibility, angle of repose etc. 9. Effect of electrolytes on the stability of colloids. 10. Preparation of various types of suspensions and determination of their sedimentation parameters. 11. Preparation and stability of emulsion.

Fluid Flow Operations Laboratory P: 3 Cr: 2 TM: 100

CTP013

1. To verify Hagen- Poiseuille Equation. 2. To relate Reynolds Number and Friction factor. 3. To study the effect of coil diameter on Friction factor. 4. Experiment on Orificemeter. 5. Experiment on Venturimeter. 6. Calibration of Rotameter. 7. To evaluate the performance of Weirs and Notches. 8. To evaluate the performance of centrifugal pump. 9. Draining time of open tank. 10. To verify Erguns equation. 11. To characterize the behavior of Fluidized bed. 12. Performance of packed bed (Gas- Liquid).

Microbiology L: 4 Objective Cr: 3 TM: 100

PE0014

To study about micro organisms, its growth, metabolism and its application in medicine and environment. Unit I Introduction to Microbiology General Account of Microorganisms classification and identification of microorganisms Introduction to microscopy Phase, contrast and electron, chemistry and structural organization of bacteria, virus, yeast and fungi . Unit II Growth of Microorganisms Microbial nutrition and environment, factors controlling growth Growth of micro-organisms in different media, growth curve, methods of enumeration of multiplying micro-organisms, culture media, preservation of microbes, sterilization and disinfection. Unit III Microbial Metabolism Microbial Metabolism Metabolic pathways - Aerobic and Anaerobic metabolism, production of secondary metabolites and their complication in industry Beneficial microorganisms and products. Formation of toxic materials by micro-organisms. Unit IV Control of Micro-Organisms Drugs, chemotheraphy, antimicrobial agents and disinfectants, diseases caused by microorganisms and control. Unit V Environmental Applications of Microbiology Recycling of waste biomass, production of biogas. Leaching of ores by micro-organism application of biofertilizers and bio-pesticides. Bioremediation. Text Books 1. Foundations in Microbiology, Talaro. K. and Talaro. A Cassida Pelzar and Reid, W.C. Brown Publishers, 1993. 2. Microbiology, Pelezar. M.J. Chan. E.C.S. and Kreig. N.R., Tata McGraw-Hill Edition, New Delhi. References 1. Microbiology (Fundamental and application), S.S.Purohit, 6th Edition, Agrobios, India, 2001. 2. Modern Food Microbiology, James M:Jay, Chapman & Hall Inc, New York, 2005. 3. Biology of Micro organisms, Michael T.Madigan, John.M.Martinko, Brock, 11th Edition, International, 2006.

Unit Processes In Organic Synthesis L: 4 Cr: 4 TM: 100

PE0024

Objective To train the student in necessary skills involved in unit processing operations for synthesis of organic compounds. Unit I Sulfonation and Sulfation Sulfating and sulfonating agents and their applications chemical and physical factors in sulfonation and sulfation Thermodynamics, mechanism and kinetic considerations Industrial Equipments and techniques Sulfonation of Benzene Aniline. Nitration Nitrating agents aromatic nitration thermodynamics and kinetics of nitration process Nitration of Benzene toluene, phenol, glycerine, Naphthalene Industrial Equipments for Nitration preparation of m-dinitrobenzene, chloro nitro benzenes, continuous nitration process. Unit II Amination by Reduction Methods of reduction Bechamp method Reduction mechanism preparation of aniline, pphenylenediamine catalytic hydrogenation process, catalyst involved in the reduction process reduction mechanism manufacture of aniline, using catalytic reduction manufacture of paminophenol Electrolytic reduction. Animation by ammonolysis: Aminating agents physical and chemical factors affecting ammonolysis catalyst used kinetics and thermodynamics considerations manufacture of aniline from chlorobenzene, N-methyl aniline. Unit III Chemistry of Halogenation Halogenating agents thermodynamic and kinetic considerations chlorination of methane, ethane, propane photo halogenation manufacture of allylchloride, chloroacetic acid, chloral, ethylene chlorohydrin chloromethanes, vinyl chloride. Unit IV Hydrolysis Hydrolyzing agents Mechanism of hydrolysis kinetics and thermodynamics of hydrolysis manufacture of glycerol, furfural, amyl alcohol. Esterification principles: Esterification by organic acids esterification catalysts batch and continuous esterification kinetic and thermodynamics consideration manufacture of ethyl acetate, butyl acetate, acetyl salicylate. Unit V Oxidation Types of oxidation reactions oxidizing agents Liquid phase and vapor phase oxidation with air and oxygen catalysts used kinetics and thermodynamic consideration manufacture of Phthalic anhydride, acetaldehyde, acetic acid, benzaldehyde, salicylic acid. Text Books 1. Unit Processes in Organic synthesis, P.H. Groggins, 5th Edition, International student edition, McGraw Hill Ltd. 2. Organic chemistry, Morison and Boyd, Prentice Hall, New Delhi. References 1. Reaction mechanism in organic chemistry, S.Mukharjee and S.P Singh, 3rd Edition, Mc Millan India Ltd., New Delhi. 2. Advanced organic chemistry Reactions, Mechanism and Structure, Jerry March, 4th Edition, Wiley Interscience Publication, New York

Process Heat Transfer L: 3 T: 1 Cr: 4

CT0034 TM: 100

Objective To improve the fundamental knowledge of various modes of heat transfer and to understand the basic concepts of heat transfer equipment design, which has more application in process industries. Unit I Fundamental Concepts & Conductive Heat Transfer Modes of heat transfer, Fouriers law- Newtons law- thermal conductance and resistancetemperature field and temperature gradient- heat transfer by conduction- concept- general heat conduction equation- thermal diffusivity & equivalent thermal conductivity- One dimensional steady state conduction through thick cylindrical shells- critical thickness of insulation for cylindrical surfaces. Unit II Convective Heat Transfer & Boundary Layer Theory Heat transfer coefficient- forced convection- free convection- dimensional analysis and empirical correlation- physical significance of dimensionless groups- concept of hydrodynamic and thermal boundary layers. Unit III Thermal Radiation Thermal radiation- spectrum of electromagnetic radiation- monochromatic emissive power of black body- plancks distribution law- Kirchoffs Law- Total emissive power- Problems of Stefan Boltzmann Law & Weins displacement law- configuration factor determination- typical examples. Unit IV Design of Heat Exchangers Heat exchangers- types and variation in design- overall heat transfer coefficient- LMTD Correction factors for multiple pass heat exchanger- Illustrative examples- Number of transfer units & effectiveness of heat exchangers. Unit V Heat Transfer in Evaporators Evaporation- Types of Evaporators single & multiple effect operation- capacity & economy of multiple effect evaporators- effect of liquid head and boiling point elevation- Duhrings rule- material & energy balance in evaporators- illustrative examples. Text Books 1. Heat and Mass Transfer, D.S. Kumar, 5th Edition, S.K. Kataria & Sons- - 1997. 2. Unit Operations in Chemical Engineering, W. L. McCabe and J. C. Smith, McGraw Hill Publishing Co, 2001. References 1. Heat Transfer Fundamentals, Binay.K.Dutta, Prentice Hall Publishers. 2. Fundamentals of Heat Transfer, M.Mikheyev, Mir Publishers- Moscow- 1968. 3. Heat Transfer, O.P. Gupta, Khanna Publishers- New Delhi.

6 th Edition,

Numerical Methods and Statistics L: 4 Cr: 3 TM: 100

MA0044

Objective To enrich knowledge in numerical methods and statistics and to solve engineering and physical problems. Unit I Numerical Solution of Algebraic and Transcendental Equation Bisection method, False position, Newton-Raphson method, Iteration method and order of convergence. Unit II Solution of Unsteady State Transfer Equations Classification of PDE of the second order Difference methods for solving boundary value problems involving elliptic, parabolic and hyperbolic equations one dimensional wave equation and two dimensional Laplace and Poisson equations. Unit III Simultaneous Linear Algebraic Equation Gauss elimination method, Jacobis method and Gauss-Seidal iterative method. Numerical differentiation and Numerical integration: Newtons method to compute derivatives, Trapezoidal rule, Simpsons rules. Unit IV Statistics - I Random variables Discrete and continuous random variable Probability density functions Distribution functions Marginal and conditional probability distribution functions. Unit V Statistics - II Mathematical expectations Variants Moment generating functions Correlation coefficients Regression. Text Books 1. Numerical methods, Kandasamy. P, Thilakavathy. K and Gunavathy. K, S. Chand and Co., New Delhi, 1999 (for numerical methods). 2. Fundamentals of statistics, Guptha. S.C., and Kapoor. V.K., Sultan chand and sons (for statistics). References 1. Numerical methods, M. K. Venkataraman, National Publishing Company, Chennai, 1991. 2. Numerical methods, A. Singaravelu, Meenakshi Publication, Chennai.

Chemical Engineering Operations L: 3 T: 1 Cr: 4

CT0054 TM: 100

Objective This subject concerns with the properties- modification and separation of particulate solids in addition it gives knowledge of designing processes and equipment in industrial handling solids. Unit I Particle Separation Properties and characterization of particulate solids- analysis and technical methods for size and surface area distribution of powder; Introduction- preparation and techniques for the measurement of nanoparticles; Introduction to storage and conveying of solids- principles of magnetic separation. Unit II Size Reduction Size reduction equipment: Determination of energy and power requirement in milling operations: Screening equipment- capacity and effectiveness. Unit III Filtration Filtration equipment- filtration media and filter aids- principles of filtration and clarificationEstimation of filtration parameters for compressible and incompressible cakes and calculationscentrifugal filtration equipment and principles of operation. Unit IV Settling and Sedimentation Separation Based On the motion of particles through fluids- gravity settling processesSedimentation- Kynch theory of sedimentation- equipment for sedimentation thickness- rate of sedimentation and sedimentation zones in continuous thickeners- design of thickeners and clarifiers- principles of centrifugal sedimentation. Unit V Agitation and Mixing Introduction to agitation and mixing of liquids- agitation equipment- Axial and radial flow impellers and flow patterns in agitated vessels- prevention of swirling- Power consumption in agitated vessels. Blending and mixing- dispersion operations- mixing of solids and pastes and types of mixers. Text Books 1. Unit Operation of Chemical Engineering, Mc Cabe and J.C.Smith- Harriot, 6 th Edition, McGraw Hill, New York, 2001. 2. Introduction to Chemical Engineering, Badger and Banchero, Tata McGraw Hill, New Delhi. Reference Books 1. Mechanial Operation, Bhattacharaya, Khanna publishers, New Delhi 2. Materials Handling Handbook, Raymond A. Kulweic, 3rd Edition, Wiley- Interscience Publications, 1985. 3. Chemical Engineering, M. Coulson and J.F. Richardson, Vol-II, 4th Edition, Butterworth, Heineman.

General Proficiency-II T: 2 Cr: 1 TM: 50

EN0064

Objective The general objective of this course is to develop both the communication competence of the learners and the personality Unit I Importance of Communication Introduction - verbal and non-verbal codes of communication - barriers to communication - selfassessment - SWOT analysis -identifying strengths and weaknesses. Unit II Personality Development Body language - non-verbal skills - leadership qualities - emotional quotient - effective time management - surviving stress - overcoming failure - professional ethics. Unit III Verbal Communication Social exchanges - planned speech extempore - basics of attending and organizing meetings informal discussions. Unit IV Quantitative Analysis Aptitude Tests. Reference books 1. 2. 3. 4. Developing Communication Skills, Mohan, Krishna and Meera Banerji. Macmillan, 2002. Maximizing Self-confidence, Minchinton, Jerry, Jaico Publishing House, 2003. Mastering Communications, Nicky Stanton, Palgrave Series, Macmillan, 2004 The Perfect Leader, Leigh, Andrew and Michael Maynard, Random House Business Books, 1999. 5. Perfect Communications, Random House Business Books, 1999. 6. Course in Mental Ability and Quantitative Aptitude, Thorpe, Edgar, Tata McGraw-Hill, 2003.

Microbiology Laboratory

PE0074

P: 3

Cr: 2

TM: 100

1. Different methods of Sterilization techniques. 2. Preparation of culture media (a) broth type of media (b) Agar media Synthetic and semisynthetic. 3. Culturing of micro-organisms: (a) Isolation of specific group of microbes symbiotic asymbiotic, (b) Pure culture techniques: Streak plate, pour plate, isolation and preservation of bacterial culture, single spore isolation. 4. Identification of micro-organisms: (a) staining techniques (b) Biochemical testing. 5. Quantification of micro-organisms: (a) Turbidimetry (b) Serial dilution. 6. Preservation of cells, slants stabs, use of mineral oil, liquid parafilm, glycerol, sterile water. 7. Environmental sample analysis Polluted soil, effluent. 8. Food microbiology (a) milk (b) Fermented food. 9. Cream clinical microbiology: Normal mouth flora pus, urine.

Bio-Chemistry Laboratory P: 3 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Cr: 2 TM: 100

PE0084

Units, Volume/Weight, measurements, concentrations units, pH measurements. Preparation of buffers, Sensitivity, Specificity, precision and Accuracy. Qualitative tests for Carbohydrates, Estimation of Reducing sugars by the Benedicts method. Qualitative tests for Amino Acids. Quantitative method for Amino Acids, Ninhydrin method. Protein estimation Biuret, Folins, Spectrophotometry and Bradford Assay. Acid hydrolysis of Proteins and Estimation of Amino Acids by Ninhydrin, OPA, PTH. Enzyme assays: Phosphatase from potato, Amylase from sweet potato, Trypsin digestion of proteins, Assay of proteases, NADH Dehydrogenase, Catalase and peroxidase. Extraction of lipids. Phospholipids: Ashing and estimation of phosphate. Estimation of cholesterol. Estimation of Nucleic Acids, Precipitation by sodium sulphate, Test for ribose and deoxyribose.

Heat Transfer Laboratory P: 3 Heat Transfer Experiments 1. 2. 3. 4. 5. 6. 7. To determine the conduction parameters using composite wall. To determine individual heat transfer film coefficient in forced convection. To determine individual heat transfer film coefficient in free convection. To determine Stefan Boltzmann law constant. To determine condensing heat transfer coefficient in vertical condenser. To determine condensing heat transfer coefficient in horizontal condenser. To determine rate of evaporation in open pan evaporator. Cr: 2 TM: 100

CT0094

8. To determine overall heat transfer coefficient of double pipe heat exchanger by parallel flow. 9. To determine overall heat transfer coefficient of double pipe heat exchanger by counter flow. 10. To determine overall heat transfer coefficient of shell and tube heat exchanger. 11. To determine overall heat transfer coefficient of plate type heat exchanger by parallel flow.

Pharmaceutical Chemistry L: 4 Cr: 4 TM: 100

PE0015

Objective To give through understanding of sources, synthesis of various drugs and their pharmacological actions with respect to structure of the compound. Unit I Basic Principles of Medicinal Chemistry Physico-chemical aspects (Optical, geometric and bioisosterism) of drug molecules and biological action - Drug-receptor interaction including transduction mechanisms. Unit II Synthetic Procedures of Selected Drugs Mode of action uses - structure activity relationship including physico-chemical properties of the following classes of drugs: Drugs acting at Synaptic and neuro-effector junction sites: Cholinergics and Anticholinesterases - adrenergic drugs - Antispasmodic and anti-ulcer drugs - Neuromuscular blocking agents. Unit III CNS Acting Drugs Classification - Chemical structure Synthesis - assay and therapeutic uses of organic synthetic drugs like Antidepressants - General anesthetics - Sedatives and hypnotics - Narcotic analgesics. Unit IV Synthetic Procedures of Organic Drugs Classification - Chemical structure Synthesis - assay and therapeutic uses of organic synthetic drugs like Antifungals Anthelmintics - H2 Blockers. Unit V Natural Products Structural elucidation of natural products - General methods Structure chemistry - methods of estimation - uses of Alkaloids Carbohydrates - Vitamins and Proteins Chemistry - methods of estimation of Steroids - Glycosides and Antibiotics. Textbooks 1. Text Book of Medicinal Chemistry, K. Ilango, P. Valentina, Vol - I, 1st Edition, 2007. Keerthi Publishers, Chennai. 2. Principles of Medicinal Chemistry, S.S.Kadam, K.R.Mahadik, K.G.Bothara, Vol. I & II, 1997. Nirali Prakashan, Pune. Reference 1. Organic Chemistry of Natural Products, Gurdeep Chatwal, Vol. I & II, 3 rd edition, 2002. Himalaya Publishing House, Mumbai.

Pharmaceutical Technology - I L: 4 Cr: 4 TM: 100

PE0025

Objective To impart necessary knowledge in formulation and evaluation of liquid and sterile dosage forms. Unit I Liquid Dosage Forms Definition classification advantages disadvantages - various methods of formulation excipients - official methods of evaluation packing - labeling and storage requirements for galenicals - aromatic waters and spirits solutions syrups - dry syrups elixirs irrigations liquids for external use lotions liniments eardrops - throat paints gargles - glycerines and collodions. Unit II Semisolid Dosage Forms Definition classification - advantages disadvantages - semisolid bases types - mechanism of drug penetration - factors influencing penetration - and their selection - General formulation manufacturing procedure - official methods of evaluation and packaging labeling and storage requirements of ointments paste - gels and suppositories. Unit III Dispersed Dosage Forms Definition classification advantages disadvantages - various methods of formulation classification and selection of suitable excipients - official methods of evaluation packing labeling and storage requirements of suspension - emulsion and magmas. Unit IV Sterile Dosage Forms Parenteral preparations Definition classification advantages disadvantages - various methods of formulation excipients - official methods of evaluation packing - labeling and storage requirements of unit and multi dosage injectables - infusions and irrigations. Ophthalmic preparations Definition classification advantages disadvantages - various methods of formulation excipients - official methods of evaluation packing - labeling and storage requirements of eye ointments - eye drops and lubricants. Unit V Cosmetics Formulation and preparation of other important dentifrices - hair creams Lipsticks - face powders baby and bath powders - shaving cream - skin cream shampoo - hair dyes - manicure preparations. Textbooks 1. Register of General Pharmacy by Carter. 2. Dispensing Pharmacy for pharmaceutical students, Cooper and Gunns, 12th Edition, 1987, New Delhi. 3. Cosmetic Science and Technology, Sagarin & Balasam, M.S.,Vol. 1-3, John Wiley & Sons, New York, USA. 4. Cosmeticology, Harrys. References 1. Introduction to Pharmaceutical Dosage forms, Ansel, H.C., 7th Edition, 2000, Philadelphia. 2. Pharmaceuticals The Science Dosage from Design, Aulton, M.E., 2nd Edition, ELBS London, 2002. 3. Theory and Practice of Industrial Pharmacy, Lachman, L., Liberman, H. A., Lea & Febiger Philadelphia, USA. 1991.

Chemical Reaction Engineering L: 3 T: 1 Cr: 4 TM: 100

CT0035

Objective This subject gives knowledge on the kinetics of chemical reaction- design- choice of reactors for single and multiple reactions. Unit I Reaction Kinetics

Chemical kinetics- Classification of chemical reactions- Concentration & Temperature dependent term of rate equation- Arrhenius- Collision and Transition state theory- searching for a mechanism. Unit II Interpretation of Batch Reactor Data

Integral and differential methods of analysis- Half-life method- Zero-order reaction- Empirical rate equation of nth order- Irreversible first and second order reactions for variable and constant volume systems. Unit III Reactor Design

Ideal Reactors-Batch Reactor- Plug flow reactor- Mixed flow reactor- Space time- Space velocityPerformance equations and their graphical representation. Unit IV Heat Effects

Temperature and pressure effects on single and multiple reactions Adiabatic- non-adiabaticisothermal and non-isothermal operations. Unit V Design of Reactor for Single & Multiple Reactions

Single reactions-Size comparison of single reactors- Recycle reactor- Auto catalytic reactions. Multiple reactions- Irreversible reactions in series and parallel. Text Books 1. Chemical Reaction Engineering, O.Levenspiel- 3rd Edition, John Wiley, SingaporeW.S.E- 1999. 2. Chemical Reaction Engineering, W. Fogler, 3rd Edition, Prentice Hall of India,New Delhi, 1999. Reference Books 1. Chemical Engineering Kinetics, J.M. Smith, 3rd Edition, McGraw Hill, New York, 1981. 2. Principles of Reaction Engineering, S.D.Dawande- , 1st Edition, Central Techno Publications- 2001. 3. Coulson Richardson- Chemical Engineering, J.F. Richardson & D.G.Peacock, Vol-3- 3rd Edition, Asian Books (P) Ltd.

Process Instrumentation L: 3 T: 1 Cr: 4 TM: 100

CT0045

Objective This subject concerns with the various measuring instruments used in industries and research laboratories. Unit I Introduction Introduction-Static and Dynamic performance Characteristics. Elements of Instrument-Transducer Elements- Intermediate Elements- Indicating- Recording Elements. Unit II Temperature Measurements Temperature Measurements-Various Methods of Temperature measuring Instruments based on thermal expansion concept. Resistance Thermometer- Thermocouple- Radiation Type- PyrometerIonization Principle- Recent Methods. Unit III Pressure Measurement Pressure measurement-Manometer- Bourdon Gauge- Diaphragm Gauge- Forced balancing TypeBellows type- vacuum Gauge-Mcleod- Pirani- Ionization gauge- Recent Developments. . Unit IV Flow Measurements Flow Measurements-weight and volumetric flow measurements. Orifice meter- venturimeter- WeirsNotches- rotameter- laminar flow meter- obstruction less flow meters- Positive Displacement typevalve type- metering pump- Recent Developments. Unit V Liquid Level Measurements Liquid level Measurements- Conductivity- pH measurements-Various types. Density MeasurementsViscosity Measurements- Moisture and Humidity measurements. Text Books 1. Instrumental Methods of Chemical Analysis, Ewing G.W., 5th Edition, McGrawHill-1985 2. Instrumentation Measurement and Analysis, Nakra- B C and Chaudhry- K K. New York: Mcgraw Hill International Editions- 1994. 3. Instrumental Methods of Chemical Analysis, Sharma- B K. Meerut: Goel Publishing House1999. Reference Books 1. Instrumental Methods of Analysis, Willard H- Hobart- Lynne L Merritt Jr and John A Dean, 7th Edition, Delhi - 110032. S.K Jain for CPS Publications, 1996. 2. Instrumentation Measurement and Analysis, Nakra- B C and Chaudhry- K K. New York: McGraw Hill International Editions- 1994.

Physiology & Pharmacology

PE0055

L: 4 Cr: 3 TM: 100 Objective To give knowledge about general physiology of human system and pharmacology of drugs. Unit I General Pharmacology Introduction to pharmacology - various routes of administration pharmacokinetics - fate of xenobiotics pharmacodynamics - receptors and its classification - general mechanism of action of drugs agonist - antagonist action of drugs - factors modifying drug action - drug interactions. Unit II Circulatory System Blood - erythropoietic system constituents - physical characters - normal physiological values functions of blood and ABO system of blood grouping - Heart anatomy and function - properties of cardiac muscle - cardiac cycle - cardiac output electrocardiogram - nervous control of heart action - Disorders of circulatory system angina pectoris hypertension - cardiac arrhythmias pharmacology of drugs acting on circulatory system - mechanism of action - dosage and adverse effects. Unit III Nervous System Introduction to nervous system - anatomy and functions of neuronal cellCentral Nervous System anatomy functions - neurotransmitters - receptors of CNS - CNS disorders - pharmacology of drugs acting on CNS. Autonomic Nervous System anatomy functions classification neurotransmitters - receptors of ANS - ANS disorders - pharmacology of drugs acting on CNS. Unit IV Excretory System Renal circulation - functions of kidney - functions of glomerulus - composition of urine and the factors affecting the formation of urine - factors controlling the volume of urine glycosuria micturition. Unit V Clinical Pharmacology Principles and designs of new drug evaluation - toxicity evaluation - regulatory guidelines - various methods of determination and fixation of dosage - preclinical and clinical trials - New drug evaluation techniques and screening methods in pharmacology using animal models Analgesics Anti-inflammatory activity Diuretics - Sedatives and Hypnotics - Anticonvulsants Text Books 1. Principles of Human Anatomy, Tortora,10th Edition, 2004. Wiley Publications. 2. Text book of Pharmacology; Satoskar 3. Text book of Pharmacology, K.D.Tripathi 4. Anatomy and physiology, Ross and Wilson References 1. Physiology of human body, C.Gyton 2. Human Physiology, Chandi Choron, Chatterjee, Medical allied agency, Calcutta. 3. The Pharmacological Basis of Therapeutics, Goodman & Gilmans. 4. Textbook of Clinical Pharmacology, Lawrence.

General Proficiency - III T: 2 Cr: 1 TM: 100

EN0065

Objective The general objective of this course is to apply what the learners save learnt by way of communication skills and numerical ability in the context of presentation, writing and general aptitude tests. Unit I Composition Analysis Technical and nontechnica1 passages (GRE based) - differences in American and British Englishanalyzing contemporary issues-expanding terminology. Unit II Dexterity in Writing Importance of writing- written vs. spoken language- formal and informal styles of writing- resources for improving writing- Grammar and Usage - letter-writing - application essays- project proposals. Unit III Presentation Skills Collecting and organizing materials- audience- content-rehearsing- delivering matter- questionscontrolling anxiety- seminar presentations (subject-oriented / general topics) - language lab practice Unit IV Quantitative Analysis Aptitude tests puzzles - psychometric tests Reference Books 1. The Perfect Presentation, Leigh, Andrew and Michael Maynar, Random House Business Books, 1999. 2. Test of Reasoning, Thorpe, Edgar, Tata McGraw - Hill, 2003. 3. Mastering Communications, Stanton, Nicky, 4th Edition, Palgrave Series, Macmillan, 2004. 4. English for Competitive Examinations, Bhatnagar, R.P and Rajul Bhargava. Macmillan, 1999. 5. Objective English, Thorpe, Edgar and Showick Thorpe, Pearson Education, 2004. 6. GRE Exam 2004, Staff of Kaplan, Simon and Schuster, 2003.

Pharmaceutical Technology - I Laboratory P: 3 Cr: 2 TM: 100

PEP075

1. Preparation and evaluation of solutions syrups elixirs spirits - aromatic waters. 2. Preparation and evaluation of lotions liniments 3. Preparation and evaluation of eardrops- eye drops. 4. Preparation and evaluation of throat paints gargles 5. Preparation and evaluation of collodions 6. Preparation and evaluation of ointments creams pastes jellies suppositories. 7. Preparation and evaluation of - crude extracts. 8. Preparation and evaluation of liquid orals solutions suspensions. 9. Preparation and evaluation of emulsions 10. Preparation of Official Extracts. 11. Formulation of cosmetics for Skin & Hair - Dentifrices and Manicure Preparations

Chemical Analysis Laboratory P: 3

Unit I Spot identification tests Unit II Analysis and identification of functional groups and other properties of pharmaceutical substances Unit III Chromatographic identification of organic compounds Unit IV Analysis of impurities in chemicals/ pharmaceutical substances by conventional chemical methods Unit V Official limit tests for impurities in pharmaceutical raw materials/ formulations in IP/ BP / USP

PEP085

Cr: 2

TM: 100

Unit VI Identification of chemicals substances by determining their physical / chemical / organoleptic properties

Mechanical Operations and Reaction Engineering Laboratory P: 3 Mechanical Operations Laboratory List of Experiments: 1. Screen Effectiveness 2. Jaw Crusher 3. Ball Mill 4. Drop weight Crusher 5. Beaker Decantation 6. Batch Sedimentation 7. Cyclone Separator 8. Terminal settling velocity - Stokes law Verification. Cr: 2 TM: 100

CTP095

Reaction engineering laboratory List of experiments: 1. Determination of reaction rate constant for a saponification reaction in batch reactor I. 2. Determination of reaction rate constant for a saponification reaction in plug flow reactor. 3. Determination of reaction rate constant for a saponification reaction in mixed flow reactor. 4. Determination of mean residence time by RTD studies in plug flow reactor. 5. Determination of mean residence time by RTD studies in mixed flow reactor. 6. Determination of mean residence time by RTD studies in packed bed reactor.

Instrumental Methods of Pharmaceutical Analysis L: 4 Cr: 4 TM: 100

PE0016

Objective To identify the active Pharmaceutical ingredients/excipients/impurities present in the pharmaceutical raw materials/finished dosage forms by various instrumental methods of analysis. Unit I UV-Visible Spectroscopy Brief review of electromagnetic spectrum and absorption of radiations - The chromophore concept absorption law and limitations - Theory of electronic spectroscopy - absorption by organic molecules - choice of solvent and solvent effects - modern instrumentation design and working principle - Applications of UVVisible spectroscopy (qualitative and quantitative analysis). Unit II Chromatographic Techniques Classification of chromatographic methods based on mechanism of separation - paper chromatography - thin layer chromatography - ion exchange chromatography - column chromatography techniques and applications - Gas Chromatography - Theory and principle - column operation instrumentation derivatisation methods and applications in Pharmacy - High Performance Liquid Chromatography Principle instrumentation - solvents used elution techniques. Unit III

Mass spectrometry

Principles, Electron Impact Chemical Ionization - Instrumentation and Ionization methods - Fragmentationrules for predicting prominent peaks in mass spectrum- Nitrogen rule- ring rule- Application of MS-MS, mass spectrometers in the structural elucidation of small and macromolecules.

Unit IV Infrared Spectrophotometry Introduction - basic principles - vibrational frequency and factors influencing vibrational frequency instrumentation and sampling techniques - interpretation of spectra - applications in Pharmacy - FT-IR-theory and applications - Attenuated Total Reflectance (ATR). Unit V Nuclear Magnetic Resonance Spectroscopy Fundamental Principles and Theory Instrumentation solvents - chemical shift - and factors affecting chemical shift - spin-spin coupling - coupling constant - and factors influencing the value of coupling constant - spin-spin decoupling - NMR Spectra and applications. Text Books 1. Principles of Instrumental Analysis, Donglas A. Skoog, James, J. Leary, 4th Edition. 2. Instrumental Methods of Chemical Analysis, B. K. Sharma, 9th Edition. 3. Pharmaceutical Analysis Modern Methods Part A, Part B, James W. Munson, 2001. 4. Chromatographic Analysis of Pharmaceuticals, John A. Adamovics, 2nd Edition. Reference Books 1. Spectrometric identification of Organic Compounds, Robert. M. Silverstein et al, 7th Edition, 1981. 2. Instrumental Methods of Analysis, Hobert H. Willard, 7th Edition. 3. Techniques and Practice of Chromatography, Raymond P. W. Scott, Vol. 70. 4. Liquid Chromatography Mass Spectrometry, W. M. A. Niessen, J. Van Der Greef, Vol. 58. 5. Spectroscopy of Organic Compounds, P. S. Kalsi.

Advanced Medicinal Chemistry L: 4 Cr: 4 TM: 100

PE0026

Objective To introduce the advanced concepts of medicinal chemistry importance and its application to the students. Unit I Quantitative Description of Physicochemical Properties Quantitative description of physicochemical properties of drug molecules with reference to electronic effects in drugs - hydrophobic properties of drugs - methods of calculating partition coefficient - 3D structure of drugs - other physicochemical parameters in relation to biological action. Unit II Quantitative Structure Activity Relationship History and Development of QSAR - Classification of QSAR methodology - Hansch analysis - Free Wilson analysis - applications advantages and pitfalls of QSAR. Unit III Design of Enzyme Inhibitors a. Forces involved information of enzyme substrate and enzyme inhibitor complexes b. Design of Rapid reversible inhibitors Multisubstrate inhibitors, Mechanism based inhibitors Application with recent examples from literature

Unit IV Docking of Flexible Molecules Docking of flexible molecules in protein/enzyme active sites a. Docking by energy minimization superimposition, molecular dynamic, Monte Carlo, distance geometry and build-up methods. b. Applications with recent examples from literature Unit V Computer-Aided Development of Three-Dimensional Pharmacophore Modes Direct and Indirect ligand design - The Pharmacophore concept - steps in 3-D-pharamacophore identification - selection of pharmacophore elements - representation of pharmacophore elements as ligand points or site points - Receptor exclude and receptor essential volumes Text Books 1. Principles of Medicinal Chemistry, Kadam, Vol I and Vol II, 2006. 2. Medicinal Chemistry, Austhoskar, 4th Edition, 2007. New age international Pvt.Ltd 3. Textbook of pharmaceutical organic chemistry, Wilson and Gisvolds, Lippincott William and Wilkins, 2004. 4. Principles of Medicinal Chemistry, William Foye. References 1. Medicinal Chemistry, Alfred burger, John Willey and sons,2003. 2. Comprehensive Medicinal Chemistry, Vol.4, Edited by C.Hansch 3. Molecular Modeling and Drug Design, Cohen 4. Textbook of drug design and discovery, Krogsgaard Larsen et al., 3rd Edirion, Povl, Taylor and Francis 2004.

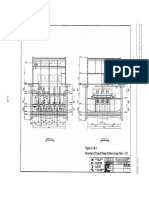

Process Equipment Design L: 4 Cr: 4 TM: 100

CT0036

Objective To understand the Design concepts of various process equipments Note: Data Book prepared by the department staff and Perrys handbook allowed Unit I Heat Exchangers Design of shell and tube Heat Exchangers- double pipe Heat Exchangers Condensers and multiple effect Evaporators. Unit II Liquid Liquid Extraction Design of Liquid Liquid Extraction systems Single stage & Multistage systems Mixer settlers packed and plate column. Unit III Distillation Design of distillation columns sieve and bubble cap towers. Unit IV Absorption Columns Design of Absorption columns plate & packed columns. Unit V Dryers & Crystallizers Design of batch and continuous dryers & crystallizers. Text Books 1. Chemical Engineers handbook, R.H.Perry, 7th Edition, McGraw Hill co 1988. 2. Chemical Engineering, J.M.Coulson and J.F.Richardson, Vol. Pergamon Press- 1977. Reference Books

6-

1. Process equipment design and drawing, M.V.Joshi- Mc Millan Press- New Delhi. 2. Process equipment design, L.E.Brownell and E.H.Young, - 3rd Edition, Macmillan India Limited. 3. Introduction to Chemical Equipment Design Mechanical Aspects, B.C.Bhattacharya, 1st Edition, 1985,CBS Publishers and Distributors- New Delhi. 4. Process Design of Equipment, S.D.Dawande, Central Techno Publication, Nagpur Vol.I & II- 2003.

Pharmaceutical Technology II L: 4 Cr: 4 TM: 100

PE0046

Objective To make understand the Formulation and development of Pharmaceutical dosage forms. To train the students to work in Pharmaceutical industries in formulation, production, packaging departments. Unit I Tablets Types of Tablets Formulation Granulation methods Manufacturing defects in Tablets Evaluation of Tablet. Unit II Capsule Definition Hard gelatin capsule Soft gelatin Capsule Formulation Evaluation of Capsules. Unit III Coating Merits and Demerits Techniques Film coating Sugar Coating Formulation and Evaluation. Unit IV Microencapsulation Merits and Demerits Microencapsulation Techniques Application. Unit V Containers and Closures Containers and Closures for Dosage form Materials of containers Glass Plastics Evaluation. Text books: 1. A Textbook of Pharmaceutical Formulation B.M.Mithal, 6th Edition, 1997. 2. The Theory and Practice of Industrial Pharmacy Leon Lachman. 2nd Edition. 1976. References: 1. Remington. The science and practice of pharmacy. 20th Edition, Volume 1 and 2. 2. Encyclopedia of Pharmaceutical Technology, 2nd Edition, Volume 1, 2 and 3. 2002. 3. Pharmaceutical dosage forms: Tablets, 2nd Edition, Volume 1,2 and 3. 2005.

Mass Transfer Operation

CT0056

L: 3 T: 1 Cr: 4 TM: 100 Objective This subject deals with fundamentals of mass transfer and mass transfer operations like diffusion- absorption- distillation- leaching & drying. Unit I Diffusion Diffusion in fluids: Molecular and eddy diffusion measurement and calculation of diffusivities. Ordinary diffusion in multi component gaseous mixtures. Absorption: Dsign of absorption towers. Tower packing and characteristics. Interphase Mass Transfer: Mass transfer coefficients. Theories of mass transfer. Concept of NTU & HTU. Unit II Absorption Gas Absorption: principles of Absorption and Desorption. Selection of solvents for absorption- tray tower absorber- absorption factor- calculation of number of theoretical stages- Murphree efficiencypoint efficiency- tray efficiency and overall tray efficiency- calculation of actual number of trays. Packed tower absorber-Tower packing and characteristics. Calculation of NTU- HTU- HETP and number of stages in absorption in absorption towers. Unit III Distillation Basic concepts of distillation: vapour-liquid equilibrium; pressure temperature concentration phase diagram-isothermal and isobaric equilibrium-relative volatility- ideal solutions-Raoults lawdeviations from ideality-minimum and maximum boiling azeotropes. Different methods of distillation: flash- steam- vacuum- molecular- azeotropic and extractive distillations. Continuous fractionation: multistage tower- bubble cap- sieve tray and valve tray towers. McCabe Thiele method. Unit IV Leaching Solid-liquid extraction: Description of leaching operations and technologies- applications of leaching preparation of solid methods of operation and classification of equipment solid-liquid equilibrium in leaching multistage cross current and counter current leaching calculation of composition and number of stages. Unit V Drying Drying-principle and definitions- Estimation of drying rates- drying rate curve- critical and equilibrium moisture content- calculation of drying time under constant drying conditions- Different types of dryers. Textbooks 1. Unit Operations of Chemical Engineering, W.L.McCabe- J.C.Smith and P.Harriot, 6th Edition McGraw-Hill Book Co., New York, 2001. 2. Mass Transfer Operations, R.E.Treybal, 3rd Edition, McGraw-Hill Book Co. - New York1980. Reference books 1. Chemical Engineering, J.M.Coulson and J.F.Richardson, Vol.I- II- III- Pergamon PressN.Y. 1977. 2. Momentum- Heat & Mass Transfer, C.O.Bennett- J.E.Myers, 3rd Edition, McGraw Hill Book Company, 1983 3. Transport Processes and unit operations, Christie J.Geankoplis, 3rd Edition, Prentice Hall of India Pvt. Ltd- New Delhi- 2000.

OBJECT ORIENTED PROGRAMMING USING C++ PE0066 L: 2 T: 2 Cr: 1 TM: 100 Objective The objective is to provide computer programming knowledge, to improve the programming skills of the students with respect to industrial applications and to help the students to get selected in campus placement programme. Unit-I Principles of Object Oriented Programming Object oriented programming paradigm, basic concepts of object oriented programming, benefits of OOP. Unit-II Beginning with C++ and Functions in C++ What is C++? Applications of C++. A simple C++ program. More C++ statements. An example with class, structure of C++ program. The main function, function prototyping, call by reference, return by reference, inline functions, default arguments, const argument, function overloading, friend and virtual functions. Unit-III Expressions and Control Structures & Classes and Objects Operators in C++, scope resolution operator, member dereferencing operators, memory management operators, manipulators, type cast operator. Expressions and implicit conversions, operator overloading, operator precedence, control structures. Specifying a class, defining member functions. A C++ program with class, making an outside function inline, nesting of member functions, private member functions, arrays within a class, memory allocation for objects. Static data members, static member functions. Arrays of objects, objects as a function argument, friendly functions, returning objects, const member functions, pointers to members. Unit-IV Constructors and Destructors Constructors, parameterized constructors, multiple constructors in a class, constructors with default arguments, dynamic initialization of objects, copy constructor, dynamic constructors, constructing two-dimensional arrays, destructors. Unit-V Inheritance and Polymorphism Extending Classes: Defining derived classes, single inheritance, making a private member, inheritable, multi level inheritance, multiple inheritance, hierarchical inheritance, and hybrid inheritance. Virtual base classes, abstract classes, constructors in derived classes, member classes, nesting of classes. Polymorphism Pointers, Virtual Functions and Polymorphism: Pointers to objects, pointers to derived classes, virtual functions, pure virtual functions. Test Books 1. Object-oriented programming with C++, E. Balaguruswamy, Tata Megraw Hill, New Delhi, 1998. 2. Object-oriented programming with C++, Ira Pohl, 2nd Edition, 2003. Pearson Education. References 1. C++ Primer, Stanley B.Lippman, Josee Lajoie, 3rd Edition, 2004. Pearson Education. 2. Object-oriented programming with C++, Bhave, Pearson Education, 2004. 3. The C++ Programming Language, Bjarne Stoustrup, Addison Wisley Publication.

Medicinal Chemistry Laboratory P: 3 Practical Cr: 2 TM: 100

PE0076

1. Synthesis of various drugs and drugs intermediates and determination of pKa value of these drugs and drugs intermediates. 2. Determination of partition co-efficient and calculation of values of a series of drugs like barbiturates. 3. Suitable synthesis and the in-vivo / in-vitro evaluation of drugs based on theory topics. 4. Determination of physicochemical properties and electronic properties of drug molecules using simulation softwares. 5. Determination of kinetics of in-vitro enzymatic reaction. 6. Identification of pharmacophores in molecules, receptor mapping by using softwares.

Instrumental Methods of Pharmaceutical Analysis Laboratory

PE0086

P: 3

Cr: 2

TM: 100

1. Identification of active pharmaceutical ingredients and excipients through physical (Organoleptic properties, colour, odour, melting point, boiling point, optical rotation, density, solubility, viscosity etc) and chemical analysis (colour identification tests through simple chemical reactions, thin layer chromatography etc) with special reference to official compounds of Indian Pharmacopoeia. 2. Sample preparation, extraction or separation and purification of active components from pharmaceutical formulations or crude products for various types of pharmaceutical analysis. 3. Quantitative and qualitative determination of active pharmaceutical ingredients in pharmaceutical formulations by, Using different methods of volumetric estimation. b) Chromatographic methods (HPLC, TLC, HPTLC, Column chromatography, size exclusion and ion exchange chromatography). Using various electrochemical methods. Using UV spectrophotometer. 4. Analysis of functional identity of active pharmaceutical ingredients and excipients through IR spectroscopy. 5. Simultaneous estimation of drugs.

Mass Transfer Laboratory P: 3 Mass Transfer Experiments 1. To determine the critical moisture content and drying rate. 2. To determine the critical moisture content and drying rate under vacuum. 3. To verify Rayleigh equation. 4. To determine the efficiency of Steam distillation. 5. To determine diffusion coefficient. 6. To determine HETP. 7. To optimize the number of leaching stages. 8. To determine the break point for Adsorption. 9. To relate mass transfer coefficient with Reynolds Number. Cr: 2 TM: 100

CT0096

Process dynamics and control L: 3 T: 1 Cr: 4 TM: 100 Objective This subject deals with the applications of controls in process industry. Unit I First Order Systems

CT0017

Linear open loop systems - First order and Linear first order systems disturbances. Unit II Higher Order Systems

- Response to various

First order in series - Higher order systems - Response to various disturbances. Unit III Block Diagram

Controls - Block Diagram - closed loop transfer function - Transient response - Simple modes of control and controller characteristics. Unit IV Stability Analysis

Stability - Routh analysis - Frequency response - Control system design - Controller tuning. Unit V Special Controls

Cascade - feed forward and ratio control - dead time compensation - Internal Model Control Control valves - Process identification. Text books Process Systems Analysis and Control, D.P. Coughnowr, 2nd Edition, McGraw Hill- New York, 1991. 2. Principles and Practice of Automatic Process Control, C.A. Smith and A.B. Corripio, 2nd Edition, John Wiley, New York, 1997. 3. Chemical Process control, George Stephanopoulous, Prentice Hall of India Pvt. Ltd, New Delhi, 1999. 1. References 1. 2. Process Control, P. Harriot, Tata McGraw Hill, New Delhi, 1984. Process control Instrumentation technology, Curtis Johnson, 4th Edition, Prentice Hall of India Pvt. Ltd, New Delhi, 1999.

Process Instrumentation- Dynamics & control for Chemical Engineers, Ray Chaudhuri UttamRay Chaudhuri Utpal, Asian Books Pvt Ltd- New Delhi.

Pharmaceutical Biotechnology L: 4 Cr: 3 TM: 100

PE0027

Objective To impart skills of industrial methods for growth, isolation, biochemical analysis, fermentation technology and production of primary, secondary metabolites. Unit I Fermentation Technology A historicial overview of industrial fermentation processes and products. Role of bioprocess engineer in the pharmaceutical biotechnology industry - Outline of various unit processes involved in an integrated bioprocess - process flow sheeting a brief survey of organisms - processes products and market economics relating to modern industrial biotechnology. Unit II Raw Materials for Fermentation Process Isolation - preservation and improvement of industrial microorganisms for overproduction of primary and secondary metabolites. Medium requirements for fermentation process carbon, nitrogen, minerals, vitamins, and other nutrients, examples of simple and complex media. Unit III Production of Primary Metabolites Production of primary metabolites - A brief outline of processes for the production of some commercially important organic acids (e.g.; citric acid, itaconic acid, lactic acid, acetic acid, gluconic acid etc) Unit IV Production of Secondary Metabolites Study of production processes for various classes of low molecular weight secondary metaolites antibiotics- Beta Lactums (Penicillins, cephalosporins etc) aminoglycosides (Streptomycin, Kanamycin etc) - Macrolides (erthromycin) - quinones, aromatics etc Unit V Production and Control of Biotech Derived Products Recombinant DNA products (Insulin - growth hormones erythropoietin - cytokines) vaccines attenuated virus - genetic alterations of live virus as a vector of other pathogens (recombinant virus or recombinant vaccinia virus) - diagnostic proteins (Protein A, protein G, antibodies) Text Books 1. 2. 3. 1. 2. 3. Pharmaceutical Microbiology, Hugo & Russel. Principles of fermentation Technology, Stanbury, Whitaker. Fermentation technology, Casida. C.A

Reference Pharmaceutical Biotechnology, Springer Publications. Materials and Methods in Fermentation, G.L.Solaman, Pergamon press, Oxford. Principles of industrial microbiology, A.Rhodes and D.L.Fletcher, pergamon press, Oxford.

Validation of Pharmaceutical Industries L: 4 Cr: 4 TM: 100

PE0037

Objective To provide necessary exposure to regulatory aspects, GMP for bulk drugs. Unit I GMP for API Personal premises equipment sanitation documentation master formula batch documentation retention of records and reference samples quality control m salt inspection and quality audits storage. Unit II Impurities in Drug Substances and Drug Products USP descriptions of impurities ICH documents on impurities (Q3A & Q3B) validation enantiomers as impurities polymorphs as unwanted components. Unit III Cleaning for API Manufacturing Facilities Multiple use versus dedicated equipment multiple levels approach to cleaning nature of contaminants product groupings and selection of a worst case cleaning techniques analytical methods limits and acceptance criteria cleaning validation documentation. Unit IV Stability Testing Stability testing based on ICH harmonized tripartite guidelines stability testing of new substances and products (Q1A) photo stability testing of new substances and products (Q1B) test on validation of analytical procedures (Q2A). Unit V GMP for Biological Products Premises personal and their health equipment production labeling lot processing records and distribution records- QA and QC disposal of biomedical waste hazardous micro organisms. Text Book 1. How to practice GMPs, P.P.Sharma, 4th edition, 2004. Vandana Publication. 2. Drug stability principles and practices, Jens.T.Carstensen, C.T.Rhodes, 3rd edition, 2005. Marcel Dekker. References 1. Validation of active pharmaceutical ingredients, 2nd edition, Ira.R.Berry and Daniel Harpaz. CRC press. 2. Good manufacturing practice for pharmaceuticals, 5th edition, 2005. Marcel Dekker. 3. Guidelines on cGMP and quality of pharmaceutical products, 1 st edition, 2003. D.K.Publications.

Novel Drug Delivery System L: 4 Cr: 4 TM: 100

PE0047

Objective Upon completion the candidate shall have an understanding of the concept and design of various pharmaceutical dosage forms. Unit I Solid Dosage Forms A detailed account of newer formulation techniques for tablets - discrete compression - coating techniques in tablet technology for product development - enhancing stability and for sustained action purposes. Unit II Sustained Release Drug Delivery Systems Physicochemical and biological properties of drugs - relevant of sustained release formulations micro encapsulation techniques - oral dosage forms - diffusion systems - systems utilizing dissolution - osmotic systems - ion exchange resins. Unit III Targeted Drug Delivery System Using nanoparticles liposomes - resealed erythrocytes - immunologically based system antibodies for drug delivery - magnetic microspheres. Unit IV Marketed Forms of Sustained Action Drugs and Their Evaluation Spansules - slow core release tablets - multi layer tablets - repeat action tablets - liquid products their formulation in vitro and in vivo evaluation. Unit V Controlled Drug Delivery Modules An account of polymers used in CDDM - Advantages and Disadvantages of using the polymers module for gastrointestinal tracts - transdermal module - module for eye (Ocuserts). Text books 1. Controlled Drug Delivery Systems by Joseph R. Robinson & Vincent H.L.Lee. Marcel Dekker, 1992. 2. Bentleys Textbook of Pharmaceutics by E.A.Rawlins,8th edition, ELBS Publications. 3. Controlled drug delivery concepts and advantages, S.P.Vyas and R.K.Khar, 1st edition, 2002. References Novel Drug Delivery Systems by Y.W.Chein Marcel DekkerInc, 2nd edition, 1992. 2. Micro encapsulation and Related drug process by Patrick B.Deasy. 3. Remingtons Pharmaceutical Sciences.

1.

Separation Technology L: 4 Cr: 4 TM: 100

PE0057

Objective To educate the theory and applications of separation science in pharmaceutical industries. Unit I Introduction to Bio-separation Characterization of Biomolecules and fermentation broths - Role of downstream processing in biotechnology - broad strategies for design of bio-separation processes. Unit IICell Disruption, Solid-Liquid and Molecular Size-Based Separations Cell disruption Mechanical and chemical methods - Cake filtration and microfiltration Centrifugation and sedimentation. Membrane processes Dialysis, Ultra-filtration - Reverse osmosis and Electro-dialysis. Unit III Liquid-Liquid Separations and Protein Separations Solvent extraction of small molecules - Aqueous two-phase extraction of proteins - Precipitation of proteins with salts and with organic solvents. Unit IV Adsorption and Chromatographic Separations Adsorption processes Principles of chromatographic separation gel filtration, reversed phase, hydrophobic interaction, ion-exchange, IMAC and bio-affinity chromatography Design and selection of chromatographic matrices Modes of operation; Design of Large-scale chromatographic separation processes Electrophoresis Separation processes. Unit V Final Product Purification and Preparation Crystallization Drying and Lyophilization Formulation Strategies. Textbooks 1. Transport processes and separation process principles, Christie John Geankoplis, unit II and IV, 4 th

edition, 2003. Prentice-Hall, Inc., Jersey, U.S.A.

2. Process Biotechnology Fundamentals, S.N.Mukhopadhyay, Unit I, 2nd edition, 2004. Viva books

private Ltd., New delhi.

References

1. Tutorial Pharmacy, Cooper and Gunns, edited by S.J.Carter, 1986. Pitman, London. 2. Chromatographic Analysis of Pharmaceutical, 2nd edition, 1997. Marcel Dekkea, New yark. 3. Pharmaceutical Engineering, K.Sambhamoorthy, Unit V, 1998. new age International (P) Ltd., New Delhi.

Technology of Fine Chemicals and Bulk Drugs

PE0067

L: 4 Cr: 4 TM: 100 Objective To provide essential infrastructure and information about bulk drugs and fine chemicals industries and its functioning. Unit I Introduction to fine chemicals and bulk drugs Concept of bulk drugs and fine chemicals - Salient features of basic chemicals - knowledge and specialty chemical industries - Present status of chemical and pharmaceutical industries in India Evolution of process, process chemistry, research and development strategies in Pharmaceutical industries. Unit II Production, planning, control and documentation Flow sheets - types of flow sheets - flow symbols, line symbols, and designation-process flow diagram - Production scheduling, concept of all purpose and multipurpose plants, plant design, layout, construction, process economics, materials of construction ,effluent treatment, standard operating procedure and solvent recovery for fine chemicals and bulk drugs production. Unit III Types of drugs / methodology of bulk and fine chemical production Study an overview of methodology of production given below, each with an example. Natural product isolation - semi synthetic synthetic fermentation biogenic - recombinant DNA microbial transgenic - tissue and cell culture. Unit IV Production of raw materials and drug intermediates Manufacture of basic chemicals such as mineral acids, ammonia and caustic soda - Manufacture of petrochemicals (study any three important petrochemicals) - Production of Aniline and vanillin. Unit V Production of bulk Drugs Raw Materials, Production Techniques, Methodology, Reaction Flow Sheet, Equipments, Utility, Effluent Treatment, Validation and Safety Operating Procedure for the Production of Drugs Listed Below: Paracetamol Ibubprofen Sulphamethazole Aspirin Diazepam - Darvon and two fine chemicals (lab chemicals). Text books: 1 Outlines of Chemical Technology, Drydens, 3rd Edition, East West Press, New Delhi. 2. Chemical Process Industries, Shreves, 5th Edition, George. T. Austin, McGraw Hill book Company. 3. The Theory and Practice of Industrial Pharmacy, Libermann and Lachmann. References: 1. Encyclopedia of pharmaceutical technology , Swarbrick 2. A text book of chemical technology, G.N.Pandey, Vol-II, Vikas publishing housing Pvt. Ltd, New Delhi. 3. Hand book of industrial chemistry, by K.M Shah 4. Hand book on chemical industries [alcohol based], H. Panda, Asia pacific business press inc., New Delhi.

Process Dynamics and Control P: 3 Chemical Reaction Engineering Experiments 1. 2. 3. 4. 5 6. 7. Reversible reaction in a batch reactor Irreversible reaction in a batch reactor Plug flow reactor Mixed flow reactor Combined reactor: Mixed flow-plug flow Combined reactor: Plug flow mixed flow RTD studies Cr: 2 TM: 100

CT0077

Process Control Experiments 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Analog Simulator Process trainer Solid level measurement Temperature measurement Flapper Nozzle system Valve characteristics Level control system Purge level control Manometer dynamics Pressure control system Frequency Response

Separation Technology Laboratory P: 3 Cr: 2 TM: 100

PE0087

1. Separation and Identification of amino acids by Chromatography Techniques. 2. Extraction of caffeine from tea dust. 3. Extraction of starch from potatoes. 4. Extraction of piperine from pepper. 5. Isolation of Casein and Lactose from Milk. 6. Estimation of free fatty acids. 7. Stage wise leaching. 8. Purification of Camphor and Pthalic acid by Sublimation Techniques. 9. Separation of sodium chloride from inorganic impurities by Filtration Techniques. 10. Batch Sedimentation Techniques

Bioprocess Technology L: 4 Objective To train the student in the area of Bioprocess technology Unit I Culture Processes Cr: 3 TM: 100

PE0018

Batch - Fed batch and continuous culture processes - two-stage continuous culture and continuous culture with cell recycle - Modeling of non-ideal behavior in bioreactors - tanks in series and dispersion models - application to design of continuous sterilizers and other first order processes. Unit II Transport Phenomena in Biochemical Reactors