Documente Academic

Documente Profesional

Documente Cultură

Sulphate Attack in Concrete

Încărcat de

Raj BharathTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Sulphate Attack in Concrete

Încărcat de

Raj BharathDrepturi de autor:

Formate disponibile

Proceedings of Second International Symposium on Concrete Tecnology for Sustainable February - Development with Emphasis on Infrastructure, Hyderabad, India,

27 February - 3 March (2005) pp. 55-67.

SULPHATE ATTACK AND ALKALI-SILICA EXPANSION

M. Collepardi, ENCO, Engineering Concrete, Ponzano Veneto (TV) Italy

ABSTRACT : A holistic approach was adopted to examine concrete durability problems by taking into account physical aspects (such as capillary porosity, micro-cracking, macrovoids) and chemical reactions. A ternary representation of the complex damage process in reinforced concrete structures was used by examining the coexistence of the main three elements effecting the concrete durability: a) interconnected porosity, b) exposure to aggressive agents, and c) presence of water. This model was adopted to examine two specific examples of the concrete damage dealing with the cement matrix, the embedded aggregates: -sulfate attack of the cement matrix; -alkali-aggregate reaction. Keywords: alkali-silica reaction, durability, sulfate attack

Mario Collepardi is President of ENCO, Engineering Concrete, Ponzano Veneto (Italy). He is author or co-author of numerous papers on concrete technology and cement chemistry. He is also the recipient of several awards for his contributions to the knowledge of superplasticizers and their use in concrete.

Proceedings of Second International Symposium on Concrete Tecnology for Sustainable February - Development with Emphasis on Infrastructure, Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

INTRODUCTION According to the holistic model proposed by Mehta (1, 2), a well-constituted, properly consolidated, and cured concrete continues to be substantially watertight and durable as long as capillary pores and microcracks in the interior do not become interconnected pathways leading to the surface of concrete. Loading effects as well as heating/cooling or wetting/drying cycles in service are responsible for the propagation of microcracks that normally exist in reinforced concrete structures (RCS) at the transition zone between the cement matrix and aggregates or at the interface between the cement mortar and reinforcing bars. This mechanism (Fig. 1) that happens in RCS in service, but not necessarily in laboratory concrete specimens, causes a gradual loss of watertightness (Stage 1). Then initiation and propagation of damage of RCS can occur due to the penetration of environmental aggressive agents (water, air, and ions such as Cl-, SO4=, Na+) through the interconnected porosity. Due to the expansive character of all the interactions between the concrete components (cement matrix, aggregate, reinforcing steel) on the one hand, and the aggressive agents on the other, damaging effects such as cracking, spalling, loss of mass, and strength reduction can occur and then increase more and more the permeability (Stage 2). According to this model, no apparent damage will be observed during Stage 1 corresponding to the gradual loss of watertightness, whereas in Stage 2 the damage occurs slowly at first, then at an increasingly rate (Fig. 2). AN OTHER VIEW OF THE HOLISTIC MODELTERNARY REPRESENTATION According to the above description of the holistic model, preexisting micro-cracks and their interaction with the environmental action play a dominant role in determining the long-term durability behavior of well constituted, properly consolidated and cured concrete.

Proceedings of Second International Symposium on Concrete Tecnology for Sustainable February - Development with Emphasis on Infrastructure, Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

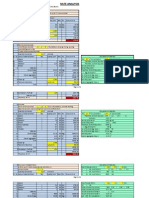

However, this material refers to RCS characterized by a low capillary porosity of the cement matrix (related with a low water-cement ratio and moist curing), and the absence of macrovoids caused by an un-proper consolidation of the fresh mixture related with its inadequate workability. An other view of the holistic model will be presented in this paper in order to put more emphasis in the important role played by the water-cement ratio (w/c) and concrete workability - both affected by the use of superplasticizers - in determining the durability behavior of RCS. This presentation is based on the selection of the most important elements affecting the damage process. For instance Fig. 3 offers an other view of the holistic model through a ternary representation of the damage process determined by the co-existence of the following three principal elements. i) Interconnected porosity. It is related not only to microcracks caused by the environmental action (weathering and loading effects) but even to the capillary porosity of the cement matrix (caused by high w/c and inadequate curing) and un-proper consolidation producing macro-voids particularly when stiff concrete mixtures are placed.

ii) Exposure to aggressive agents. It is related to the main three chemical mechanisms of degradation of RCS: a) sulfate attack b) corrosion of reinforcing bars c) alkali-silica reaction (ASR) iii) Presence of water. It is related to the intermittent or continuous penetration of the environmental water determining the durability behavior of RCS. Water acts as aggressive agent by itself (freezing-thawing) or concurrently with other aggressive agents (CO2, O2, Cl-, SO4=, alkali) in the three mentioned degradation mechanisms. Moreover, it also acts as liquid carrier for reactant ions diffusing through the interconnected pores of the cement matrix. A synthetic representation of the holistic approach for the damage of RCS can be examined through the help of Fig. 3

Proceedings of Second International Symposium on Concrete Tecnology for Sustainable February - Development with Emphasis on Infrastructure, Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

where each element corresponds to a circle. Each area of the circle corresponds to a system in which only one of the three elements of the system is present, and this situation does not present any risk at all for the damage of RCS. The area in the middle, where the three circles overlap, corresponds to situations of serious risk for the damage since all the three needed elements are present: interconnected porosity, environmental water, and exposure to aggressive agents. In the absence of one of these elements the damage of RCS cannot occur. For instance, in porous and/or micro-cracked concrete not exposed to water the damage does dot happen even if there is a potential presence of environmental aggressive agents such as SO4= and Cl-: in the absence of water, these ions cannot migrate through the interconnected pores and neither the sulfate attack of the cement matrix nor the corrosion of the metallic reinforcement can occur. The following examples will illustrate this point. Sulfate attack This attack is related to the expansive character of the ettringite formation by reaction of internal (into the concrete) or external (from the environment) sulfate with the hydrated calcium aluminate of the hardened cement matrix. Not necessarily the ettringite formation produces a damaging effect. When it occurs homogeneously and immediately (within hours or days) in a mixture or in a deformable concrete - early ettringite formation (EEF) - the related expansion does not cause any significant localized disruptive action (Table 1). This happens when ground gypsum reacts with anhydrous calcium aluminates within some hours (set regulation) or when a calcium aluminate sulfate (C4A3S) hydrates within few days producing a relatively small, homogeneous, harmless and rather useful stress (expansive cements for shrinkage compensating concretes). On the other hand, when ettringite forms heterogeneously and later (after months or years) - delayed ettringite formation (DEF) - the localized related expansion in a rigid hardened concrete produces cracking, spalling, and strength loss.

Proceedings of Second International Symposium on Concrete Tecnology for Sustainable February - Development with Emphasis on Infrastructure, Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

Therefore only DEF - and not EEF - is associated with a damaging sulfate attack (Table 1). There are two different types of DEF-related damage depending on the sulfate source (Table 2): external or internal sulfate attack. External sulfate attack (ESA) occurs when environmental sulfate (from water or soil) penetrates concrete structures. Internal sulfate attack (ISA) occurs in a sulfate-free environment for the late sulfate release from either gypsumcontaminated aggregates or thermal decomposition of ettringite (3). Figures 4 and 5 give a view of the holistic model through a ternary representation of the ESA- and ISA-related damage respectively. In particular the ESA induced damage is determined by the co-existence of the following three elements: Permeability Sulfate-rich environment Presence of water On the other hand, the ISA-induced damage is related to the co-existence of the following three elements: Micro-cracking Late sulfate release Presence of water The positive role played by superplasticizers, in reducing the w/c and then the permeability of the cement matrix, is very important in the ESA since this effect significantly retards the penetration of SO4= ions from the environment into the concrete and consequently reduce the corresponding DEF-related damage. On the other hand, the ISA may occur even in superplasticized concretes with very low w/c since sulfate is

According to the terminology currently used "DEF" is related to the internal sulfate attack only in a sulfate-free environment (3). However, more correctly delayed ettringite formation means that ettringite forms later independently of the sulfate source.

Proceedings of Second International Symposium on Concrete Tecnology for Sustainable February - Development with Emphasis on Infrastructure, Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

already available into the concrete (Fig. 5) feed the delayed deposition of ettringite. Alkali-silica reaction Due to interaction between certain aggregates (containing amorphous silica or strained quartz) and the highly alkaline solution of the pore aqueous phase, concrete can deteriorate and this reaction is known as "alkali-silica reaction" (ASR). The alkali content of the pore aqueous phase depends primarily on the alkali content of the clinker phase and even on the exposure to environmental sodium salts (sea water and deicing agents). The three elements needed for the ASR (Fig. 6) are: Alkali content Alkali-reactive silica Presence of water Superplasticizers can mitigate the damaging effect of ASR by reducing the concrete permeability and then the penetration of water as well as of environmental sodium salts. On the other hand, superplasticizers appear to be less effective in preventing ASR-related damage when alkalis come from the clinker phase, then when they are initially into the concrete. In such a case, the best way of preventing ASR-related damage is the use of pozzolanic materials in combination with a water-reducing admixture, if any. CONCLUSIONS A synthetic view of the holistic approach for the deterioration of reinforced concrete structures was proposed through a ternary representation of the damage process determined by the coexistence of the following three principal elements: interconnected porosity exposure to aggressive agents

Proceedings of Second International Symposium on Concrete Tecnology for Sustainable February - Development with Emphasis on Infrastructure, Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

presence of water The following examples of concrete deterioration were examined by using this ternary representation: external sulfate attack; internal sulfate attack; corrosion of reinforcing bars; alkali-silica reaction. External sulfate attack, corrosion of reinforcing bars, and alkali-silica reaction promoted by the alkali penetration from the environment (sea water, deicing salts) can be significantly mitigated by using superplasticizers due to the reduction in concrete permeability and then in the penetration of aggressive agents (SO4=, Cl-, CO2, O2, Na+) from the environment into the concrete. On the other hand, superplasticizers play a less important role in damaging processes, such as internal sulfate attack or alkalisilica reaction promoted by high alkali cement content, where the aggressive agents (SO4= and alkali ions) are already available into the concrete. REFERENCES (1) Mehta, P.K., "Concrete Technology at the Crossroads Problems and Opportunities", Concrete Technology: Past, Present and Future, SP-144, American Concrete Institute, Detroit, 1994, pp 1-31. (2) Mehta, P.K., "Durability-Critical Issues for the Future", Concrete International, V. 19, No. 7, July, 1997, pp 2733. (3) Collepardi, M., "A State-of-the-Art Review on Delayed Ettringite Formation", Cement and Concrete Composites, 25 ,2003, pp 401-407.

Proceedings of Second International Symposium on Concrete Tecnology for Sustainable February - Development with Emphasis on Infrastructure, Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

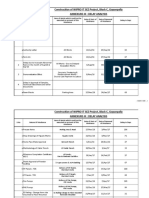

Table 1 - Early and delayed ettringite formation

ETTRINGITE FORMATION

EARLY ETTRINGITE FORMATION (EEF):

It occurs homogeneusly and immediately (within hrs or days). The related expansion does not cause a localized and disruptive action since it occurs in a fresh mixture or in a deformable concrete. It is due to ground gypsum which reacts with calcium alluminates of the portland clinker phase (set regulation) or to sulfate-based expansive agents in shrinkage compensating concretes.

DELAYED ETTRINGITE FORMATION (DEF):

It occurs heterogeneously and later (after months or years) The related expansion produces cracking, spalling, and strength loss since it occurs in a rigid, stiff, hardened concrete. Its damaging effect is related to environmental or internal sulfate source (sulfate attack).

Table 2 - Delayed ettringite formation by external and internal sulfate attack

DELAYED ETTRINGITE FORMATION (DEF)

EXTERNAL SULFATE ATTACK

It occurs when ennvironmental sulfate (from water or soil) penetrates concrete structures in service. It occurs in a permeable concrete.

INTERNAL SULFATE ATTACK

It occurs in a sulfate-free environment for the late sulfate release from gypsum-contaminated aggregates or sulfur-rich clinker phase. It needs preliminary microcracks where deposition of ettringite crystals can occur. It occurs in a moist environment = favoring diffusion of SO4 and other ++ reacting ions (Ca and alluminate) through water-saturated capillary pores.

It occurs in a moist environment favoring diffusion of SO4= through the aqueous phase of the capillary pores.

Proceedings of Second International Symposium on Concrete Tecnology for Sustainable February - Development with Emphasis on Infrastructure, Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

WATERTIGHT RCS WITH DISCONTINUOS MICROCRACKS & CAPILLARY PORES STAGE 1 WEATHERING & LOADING EFFECTS INTERCONNECTED POROSITY & WATERTIGHTNESS LOSS STAGE 2 ENVIRONMENTAL AGGRESSION DUE TO PENETRATION OF: water air (O2 & CO2) ions (Cl-, SO4=, Na+, K+)

EXPANSION CAUSED BY: steel corrosion sulfate sttack on cement matrix alkali attack on aggregates freezing of water

CRACKING, SPALLING, MASS LOSS & STRENGTH REDUCTION

Figure 1. A holistic model of concrete deterioration from environmental effects. Adapted from Mehta (1, 2).

DAMAGE PROPAGATION

DEMAGE OF RCS

DAMAGE INITIATION NO VISIBLE DAMAGE

0 2 4 6 8 10 12

STAGE 1

STAGE 2

TIME

Figure 2. A two-stage damage model for reinforced concrete structures (RCS). Adapted from Mehta (1, 2).

Proceedings of Second International Symposium on Concrete Tecnology for Sustainable February - Development with Emphasis on Infrastructure, Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

DAMAGE OF REINFORCED CONCRETE STRUCTURES (RCS)

capillary pores (high w/c and poor curing) macroroids (unproper compaction of fresh concrete related to its inadequate workability) microcracks (loadings in service and cyclic heating/cooling or wetting/drying)

INTERCONNECTED POROSITY (PERMEABILITY)

PRESENCE OF WATER moist environment

DAMAGE OF RCS

EXPOSURE TO AGRESSIVE AGENTS

air (O2, CO2) SO4=, Cl- and alkali ions

Figure 3. Ternary representation of the damage of RCS.

DEF RELATED TO EXTERNAL SULFATE ATTACK (ESA)

high-capillary porosity microcracking

PERMEABILITY

moist environment

ESA

PRESENCE OF WATER SULFATE-RICH ENVIRONMENT water soil

Figure 4. Ternary representation of the DEF related to ESA in RCS.

Proceedings of Second International Symposium on Concrete Tecnology for Sustainable February - Development with Emphasis on Infrastructure, Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

DEF RELATED TO INTERNAL SULFATE ATTACK (ISA)

MICROCRACKING restrained thermal & drying shrinkage high temperature steam curing alkali-silica reaction loading in service excessive and non-uniform stress distribution in prestressed RCS

moist environment

ISA

PRESENCE OF WATER LATE SULFATE thermal decomposition of RELEASE ettringite gypsum-contaminated aggregates

Figure 5. Ternary representation of the DEF related to ISA in RCS.

ALKALI-SILICA REACTION (ASR)

alkali-rich portland cement environmental alkali salts (sea water and de-icing agents)

ALKALI CONTENT

moist environment

ASR

PRESENCE OF WATER ALKALI REACTIVE SILICA amorphous silica or strained quartzs in aggregate particles

Figure 6. Ternary representation of the ASR concrete damage.

Proceedings of Second International Symposium on Concrete Tecnology for Sustainable February - Development with Emphasis on Infrastructure, Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

S-ar putea să vă placă și

- Rate AnalysisDocument6 paginiRate AnalysisRaj BharathÎncă nu există evaluări

- Hindrance RegisterDocument14 paginiHindrance RegisterRaj Bharath88% (8)

- PH8251 - Material ScienceDocument320 paginiPH8251 - Material ScienceBalaji K100% (1)

- Rate AnalysisDocument6 paginiRate AnalysisKrunal Joshi100% (1)

- A Review Paper On The Effect of Sulphate Attack On Concrete DurabilityDocument7 paginiA Review Paper On The Effect of Sulphate Attack On Concrete DurabilityIJRASETPublicationsÎncă nu există evaluări

- Defects in ConcreteDocument9 paginiDefects in ConcreteJayakumar VenkataramanÎncă nu există evaluări

- How Concrete Creep and Shrinkage Affect Tall BuildingsDocument9 paginiHow Concrete Creep and Shrinkage Affect Tall BuildingsBabarinde OluwatobiÎncă nu există evaluări

- Materials and Design: Viktor Gribniak, Gintaris Kaklauskas, Romualdas Kliukas, Ronaldas JakubovskisDocument11 paginiMaterials and Design: Viktor Gribniak, Gintaris Kaklauskas, Romualdas Kliukas, Ronaldas JakubovskisourebooksÎncă nu există evaluări

- NPS Transaction Statement For Tier I Account: Current Scheme PreferenceDocument2 paginiNPS Transaction Statement For Tier I Account: Current Scheme PreferenceRaj Bharath33% (3)

- Sulphate Attack and Chloride PenetrationDocument8 paginiSulphate Attack and Chloride PenetrationMahmood MuftiÎncă nu există evaluări

- General Biology 1: Quarter 2 - Module 3: When Cells BreatheDocument26 paginiGeneral Biology 1: Quarter 2 - Module 3: When Cells BreathePLS help me get 1k subsÎncă nu există evaluări

- Lecture Notes on Reinforced Concrete DesignDe la EverandLecture Notes on Reinforced Concrete DesignÎncă nu există evaluări

- Dose The Right Amount of ChemicalsDocument3 paginiDose The Right Amount of ChemicalsrajachemÎncă nu există evaluări

- Lab ApparatusDocument10 paginiLab ApparatuslizÎncă nu există evaluări

- Minimate Blaster Operator ManualDocument68 paginiMinimate Blaster Operator Manualernesto gil huiñocanaÎncă nu există evaluări

- Holistic model of reinforced concrete durabilityDocument3 paginiHolistic model of reinforced concrete durabilitySujay SadashivappaÎncă nu există evaluări

- Concrete Durability in A Marine EnvironmentDocument17 paginiConcrete Durability in A Marine EnvironmentAnonymous mcHqIfbnV1Încă nu există evaluări

- HPC Simulations of Alkali-Silica Reaction-Induced Damage: Influence of Alkali-Silica Gel PropertiesDocument13 paginiHPC Simulations of Alkali-Silica Reaction-Induced Damage: Influence of Alkali-Silica Gel PropertiesTao YangÎncă nu există evaluări

- Comparison of Uniform and Non-Uniform Corrosion Induced Damage in Reinforced Concrete Based On A Gaussian Description of The Corrosion LayerDocument12 paginiComparison of Uniform and Non-Uniform Corrosion Induced Damage in Reinforced Concrete Based On A Gaussian Description of The Corrosion LayernagarajuÎncă nu există evaluări

- Durability Study On Engineered Cementitious Composites ECC Under Sulfate and Chloride EnvironmentDocument11 paginiDurability Study On Engineered Cementitious Composites ECC Under Sulfate and Chloride EnvironmentYaswanth SinhaÎncă nu există evaluări

- Chemical Admixtures Today Mario Collepardi, Enco, Engineering Concrete, PonzanoDocument22 paginiChemical Admixtures Today Mario Collepardi, Enco, Engineering Concrete, PonzanoAravindan KrishnamoorthyÎncă nu există evaluări

- Materials 10 00471Document30 paginiMaterials 10 00471Hisham TariqÎncă nu există evaluări

- Clogging Mechanism of Permeable Concrete A ReviewDocument10 paginiClogging Mechanism of Permeable Concrete A ReviewGuilherme GesserÎncă nu există evaluări

- Art:10.1617/s11527 008 9356 ZDocument23 paginiArt:10.1617/s11527 008 9356 ZTarek ChikerÎncă nu există evaluări

- The Effects of Salinity on Buildings Near Marine EnvironmentsDocument10 paginiThe Effects of Salinity on Buildings Near Marine EnvironmentsJuan Pablo Zevallos ZambranoÎncă nu există evaluări

- ProposalDocument22 paginiProposalSuraj MoodÎncă nu există evaluări

- Sustainability 02 02163Document13 paginiSustainability 02 02163Joseph BookerÎncă nu există evaluări

- Abrasion Resistance of ConcDocument13 paginiAbrasion Resistance of ConcjackammoÎncă nu există evaluări

- Importance of Microstructural Understanding For Durable and Sustainable ConcreteDocument8 paginiImportance of Microstructural Understanding For Durable and Sustainable ConcreteAnimesh BiswasÎncă nu există evaluări

- Model For Sulfate Diffusion Depth in Concrete Under Complex Aggressive Environments and Its Experimental VerificationDocument12 paginiModel For Sulfate Diffusion Depth in Concrete Under Complex Aggressive Environments and Its Experimental VerificationHazen MasrafatÎncă nu există evaluări

- SuleymanDocument18 paginiSuleymanBurkan YayçıÎncă nu există evaluări

- Mathematical Model To Predict The Permeability of Water Transport in Concrete StructureDocument7 paginiMathematical Model To Predict The Permeability of Water Transport in Concrete StructureAntonioRodriguezÎncă nu există evaluări

- Seminar Report On Durability of Concrete StructuresDocument17 paginiSeminar Report On Durability of Concrete StructuresTeju AshuÎncă nu există evaluări

- Erosion-Corrosion Interactions and Their Affect On Marine and Offshore ComponentsDocument10 paginiErosion-Corrosion Interactions and Their Affect On Marine and Offshore ComponentsAnonymous uCYIu1Încă nu există evaluări

- Relationship Between Cracking and Electrical Resistance in Reinforced and Unreinforced ConcreteDocument8 paginiRelationship Between Cracking and Electrical Resistance in Reinforced and Unreinforced ConcreteMatthew SmithÎncă nu există evaluări

- Durability of Façades With Ceramic Coverings - Why They FailDocument10 paginiDurability of Façades With Ceramic Coverings - Why They FailRicardo PintoÎncă nu există evaluări

- Structural Modelling of ASR-affected Concrete: The Approach Developed in The PAT-ASR ProjectDocument11 paginiStructural Modelling of ASR-affected Concrete: The Approach Developed in The PAT-ASR ProjectUsman IftikharÎncă nu există evaluări

- Silicate TreatmentsDocument15 paginiSilicate Treatmentsbeto_pimeÎncă nu există evaluări

- Damage of Concrete and Reinforcement of Reinforced-Concrete Foundations Caused by Environmental EffectsDocument8 paginiDamage of Concrete and Reinforcement of Reinforced-Concrete Foundations Caused by Environmental EffectsScribd2015Încă nu există evaluări

- Causes of Distress and Deterioration of ConcreteDocument14 paginiCauses of Distress and Deterioration of ConcretelavanyaÎncă nu există evaluări

- Strength Behavior of Concrete Using Slag With Cement in Sea Water EnvironmentDocument12 paginiStrength Behavior of Concrete Using Slag With Cement in Sea Water Environmentprabhakar polyÎncă nu există evaluări

- 2020_CBM_표면조도계 사용 참고Document14 pagini2020_CBM_표면조도계 사용 참고이호진Încă nu există evaluări

- Causes of Distress and Deterioration of Concrete, EM 1110-2-2002 1995-06-30Document14 paginiCauses of Distress and Deterioration of Concrete, EM 1110-2-2002 1995-06-30RONALD MUELLERÎncă nu există evaluări

- Durability 1Document8 paginiDurability 1santoruno lupinottiÎncă nu există evaluări

- Micromechanical Modeling of Sulphate Corrosion in Concrete Influence of Ettringite Forming Reaction (Collected)Document24 paginiMicromechanical Modeling of Sulphate Corrosion in Concrete Influence of Ettringite Forming Reaction (Collected)Mohammad Lutfor Rahaman KhanÎncă nu există evaluări

- 15 - Chapter 7 PDFDocument24 pagini15 - Chapter 7 PDFpavan_1988Încă nu există evaluări

- Unit 8Document16 paginiUnit 8sandeep nandaÎncă nu există evaluări

- A Critical Review On Different Types of Wear of MaterialsDocument7 paginiA Critical Review On Different Types of Wear of MaterialsIAEME PublicationÎncă nu există evaluări

- Simulation of Chloride Diffusivity For Cracked Concrete Based On RBSM and Truss Network ModelDocument13 paginiSimulation of Chloride Diffusivity For Cracked Concrete Based On RBSM and Truss Network ModelBandula PrasadÎncă nu există evaluări

- Time To Failure For Concrete Exposed To Severe Sulfate AttackDocument7 paginiTime To Failure For Concrete Exposed To Severe Sulfate AttackTomás Venegas PardoÎncă nu există evaluări

- Elastic BehaviourDocument4 paginiElastic BehaviourEhsan WasimÎncă nu există evaluări

- Sulphate Attack On ShotcreteDocument6 paginiSulphate Attack On ShotcreteFaheem SadiqÎncă nu există evaluări

- Marchini-Patzlaff2016 Article BuildingInformationModelingBIMDocument7 paginiMarchini-Patzlaff2016 Article BuildingInformationModelingBIMCarlos Augusto Sánchez RondónÎncă nu există evaluări

- Thermal Concrete CrackingDocument7 paginiThermal Concrete Crackingignacio_vazquez_18Încă nu există evaluări

- Condition Assessment and Retrofitting of Structures (Ce-647)Document15 paginiCondition Assessment and Retrofitting of Structures (Ce-647)Pratyush MishraÎncă nu există evaluări

- Goran Mohammed AbobakerDocument13 paginiGoran Mohammed AbobakerShriÎncă nu există evaluări

- Durability of High Performance Concrete in Relation To 'External' Chemical AttackDocument5 paginiDurability of High Performance Concrete in Relation To 'External' Chemical AttackGeraldÎncă nu există evaluări

- Journal Inter 3 (Selesai 18)Document16 paginiJournal Inter 3 (Selesai 18)Putu DidiÎncă nu există evaluări

- Lecture 8Document8 paginiLecture 8Mask KingÎncă nu există evaluări

- Cement and Concrete Research: Robin.E. BeddoeDocument16 paginiCement and Concrete Research: Robin.E. BeddoeAbdullahÎncă nu există evaluări

- 1 s2.0 S2352710223001031 MainDocument30 pagini1 s2.0 S2352710223001031 MainsoniaÎncă nu există evaluări

- Technical_Evaluation_Method_for_Physical_Property_Document19 paginiTechnical_Evaluation_Method_for_Physical_Property_Nikhil JainÎncă nu există evaluări

- Case Studies in Construction Materials: Stefano Rossi, Mattia Pinamonti, Massimo CaloviDocument16 paginiCase Studies in Construction Materials: Stefano Rossi, Mattia Pinamonti, Massimo CaloviKedar BhaveÎncă nu există evaluări

- Bridge Structures Cracks - What Made That PhenomenDocument10 paginiBridge Structures Cracks - What Made That PhenomenNguyễn Văn MinhÎncă nu există evaluări

- Abrasion ResistanceDocument21 paginiAbrasion ResistanceAdnan SalamÎncă nu există evaluări

- Yuks El 2013Document22 paginiYuks El 2013R T.IÎncă nu există evaluări

- Ordered Porous Solids: Recent Advances and ProspectsDe la EverandOrdered Porous Solids: Recent Advances and ProspectsValentin ValtchevÎncă nu există evaluări

- Stress Management: Ashtanga YogaDocument29 paginiStress Management: Ashtanga YogaRaj BharathÎncă nu există evaluări

- Monthly DDO Reconciliation For Receipts For June, 2021 Ifmis Government of TelanganaDocument1 paginăMonthly DDO Reconciliation For Receipts For June, 2021 Ifmis Government of TelanganaRaj BharathÎncă nu există evaluări

- Revised Ima First FloorDocument1 paginăRevised Ima First FloorRaj BharathÎncă nu există evaluări

- Stress Management: Unit - V Dhyana and StressDocument31 paginiStress Management: Unit - V Dhyana and StressRaj BharathÎncă nu există evaluări

- Pranayama for Stress ReliefDocument16 paginiPranayama for Stress ReliefRaj BharathÎncă nu există evaluări

- AsanSM IIIDocument18 paginiAsanSM IIIRaj BharathÎncă nu există evaluări

- ComparisionDocument14 paginiComparisionRaj BharathÎncă nu există evaluări

- Pune Metro Civil Contract Pay Scale Ad Final 17 10 2017 PDFDocument5 paginiPune Metro Civil Contract Pay Scale Ad Final 17 10 2017 PDFRaj BharathÎncă nu există evaluări

- Road Atlas TracDocument2 paginiRoad Atlas TracRaj BharathÎncă nu există evaluări

- Revised Ima Ground FloorDocument1 paginăRevised Ima Ground FloorRaj BharathÎncă nu există evaluări

- Ac Exam PDF 2019 - Jan To MayDocument99 paginiAc Exam PDF 2019 - Jan To MayRaj Bharath100% (1)

- Road Atlas TracDocument2 paginiRoad Atlas TracRaj BharathÎncă nu există evaluări

- ComparisionDocument14 paginiComparisionRaj BharathÎncă nu există evaluări

- 460 3Document10 pagini460 3Vikas GoelÎncă nu există evaluări

- Is Code CivilDocument10 paginiIs Code CivilgwaliorwalaÎncă nu există evaluări

- Footings-Concrete & Shuttering Block CDocument17 paginiFootings-Concrete & Shuttering Block CRaj BharathÎncă nu există evaluări

- Fuel Safety PDFDocument12 paginiFuel Safety PDFRaj BharathÎncă nu există evaluări

- Flooring QtyDocument17 paginiFlooring QtyRaj BharathÎncă nu există evaluări

- Flooring QtyDocument17 paginiFlooring QtyRaj BharathÎncă nu există evaluări

- Blastware ReadmeDocument1 paginăBlastware ReadmechinomiloÎncă nu există evaluări

- What Is Subprime CrisisDocument3 paginiWhat Is Subprime CrisisRaj BharathÎncă nu există evaluări

- Block C: Concrete Abstract UOMDocument8 paginiBlock C: Concrete Abstract UOMRaj BharathÎncă nu există evaluări

- Hired Vehicles 28sep17-8202Document1 paginăHired Vehicles 28sep17-8202Raj BharathÎncă nu există evaluări

- NRI India, NRI Loans, NRI Banking, Business in India, Account in India, NRI Returning To India, Investment in IndiaDocument184 paginiNRI India, NRI Loans, NRI Banking, Business in India, Account in India, NRI Returning To India, Investment in Indiaprashantdev100% (1)

- 714U3201 Rev 06 - Series III Interface Handbook PDFDocument28 pagini714U3201 Rev 06 - Series III Interface Handbook PDFernesto gil huiñocanaÎncă nu există evaluări

- CIE354 Syllabus 2017Document4 paginiCIE354 Syllabus 2017Sebastian CanoÎncă nu există evaluări

- Engineering Physics Quantum ConceptsDocument9 paginiEngineering Physics Quantum Conceptsnithila bhaskerÎncă nu există evaluări

- Enamel Synthetic, Oil Resistant, Air Drying - Specification: Indian StandardDocument8 paginiEnamel Synthetic, Oil Resistant, Air Drying - Specification: Indian StandardSuman ChatterjeeÎncă nu există evaluări

- 9.0-BUL107 1.10 en Water QualityxDocument2 pagini9.0-BUL107 1.10 en Water QualityxmohamadÎncă nu există evaluări

- Simple Process Produces Boron Citrate PowderDocument5 paginiSimple Process Produces Boron Citrate PowderAliÎncă nu există evaluări

- Molecular ImagingDocument34 paginiMolecular ImagingShaher Bano MirzaÎncă nu există evaluări

- Eoncoat BrochureDocument5 paginiEoncoat BrochureDavid RodriguesÎncă nu există evaluări

- Artificial Intelligence For Natural Product Drug DiscoveryDocument22 paginiArtificial Intelligence For Natural Product Drug DiscoveryKarthik ManguÎncă nu există evaluări

- Alloyed: Case-Hardening Steels RM16 - RM16PBDocument3 paginiAlloyed: Case-Hardening Steels RM16 - RM16PBShubhangi ShindeÎncă nu există evaluări

- Unit IIDocument38 paginiUnit IIMugilÎncă nu există evaluări

- Inorganic ChemistryDocument2 paginiInorganic ChemistryTaqeeb AbbasÎncă nu există evaluări

- B.Tech. (5 Semester Mechanical) TRIBOLOGY (MEPE-17)Document5 paginiB.Tech. (5 Semester Mechanical) TRIBOLOGY (MEPE-17)varunÎncă nu există evaluări

- Module 3 Organic Reaction MechanismsDocument7 paginiModule 3 Organic Reaction Mechanismsycca galianÎncă nu există evaluări

- Nonlinear Analysis in Solid WorksDocument8 paginiNonlinear Analysis in Solid WorksnapoleonmÎncă nu există evaluări

- Chapter 8: Using The Discrete Ordinates Radiation ModelDocument44 paginiChapter 8: Using The Discrete Ordinates Radiation ModelNikhil PimpareÎncă nu există evaluări

- Waukesha Cherry-Burrell centrifugal pump performance curvesDocument4 paginiWaukesha Cherry-Burrell centrifugal pump performance curvesjokishÎncă nu există evaluări

- Non Aqueous - Lecture-1-1Document51 paginiNon Aqueous - Lecture-1-1Sayed AlamÎncă nu există evaluări

- Preventing Generator Damage from Hydrogen MoistureDocument27 paginiPreventing Generator Damage from Hydrogen MoistureIskerÎncă nu există evaluări

- The Rate Equation KnockhardyDocument67 paginiThe Rate Equation KnockhardyStaniaÎncă nu există evaluări

- Design of Boiler Forced Draft FanDocument5 paginiDesign of Boiler Forced Draft Fanhwang2Încă nu există evaluări

- Ammonical Leaching of Metals from OresDocument36 paginiAmmonical Leaching of Metals from OresfirdayuniningÎncă nu există evaluări

- Quantum-enhanced nonlinear microscopy enables imaging beyond photodamage limitDocument3 paginiQuantum-enhanced nonlinear microscopy enables imaging beyond photodamage limitMarkAllenPascualÎncă nu există evaluări

- The Sthir Karakas: Functions of The Char Karkas AtmakarakDocument2 paginiThe Sthir Karakas: Functions of The Char Karkas AtmakarakDipyaman SahaÎncă nu există evaluări

- Sensi Sensi Sensitech: Temptale UltraDocument1 paginăSensi Sensi Sensitech: Temptale Ultrayondi hermawanÎncă nu există evaluări

- Astm D512 - 12 - Cloruros en AguaDocument9 paginiAstm D512 - 12 - Cloruros en AguaEliasÎncă nu există evaluări

- AQA Physics GCSE Combined P9 Practice AnswersDocument1 paginăAQA Physics GCSE Combined P9 Practice AnswersMahebul MazidÎncă nu există evaluări