Documente Academic

Documente Profesional

Documente Cultură

01 1329288772 92267

Încărcat de

raghuramchowdaryDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

01 1329288772 92267

Încărcat de

raghuramchowdaryDrepturi de autor:

Formate disponibile

]OIIRIqAL OF

N~T,T,I~ SG)S

ELSEVIER Journal of Non-CrystallineSolids 184 (1995) 44-50

Chalcogenide glasses: a review of their preparation, properties and applications

A.B. Seddon *

Glass Research Group, Department of Engineering Materials, Sir Robert Hadfield Building, University of Sheffield, Mappin St., PO Box 600, Sheffield, S1 4DU, UK

Abstract

The author provides an update of: glass preparation in bulk, fibre and film form; optical and thermal properties, and potential applications of chalcogenide glasses.

1. Introduction

Chalcogenide glasses are a recognised group of inorganic glassy materials which always contain one or more of the chalcogen elements: S, Se or Te, but not O, in conjunction with more electropositive elements most commonly As and Ge, but also P, Sb, Bi, Si, Sn, Pb, B, AI, Ga, In, T1, Ag, lanthanides and Na. Chalcohalide glasses additionally contain halogen elements and include the TeX (X is halogen) glasses. Chalcogenide glasses are generally less robust, more weakly bonded materials than oxide glasses. Both heteropolar (e.g., G e - S ) and homopolar (e.g., S-S; G e - G e ) bonds can form. Thus glass formulations can contain a non-stoichiometric amount of chalcogen and excess S and Se atoms can form chains. The chemical bonding of the matrix is usually directional and covalent and halogens act as chain or network terminators. The chalcogenide

glasses are bandgap semiconductors and are infrared transmitting. The aim of this short review is to describe the main preparative methods of chalcogenide glasses, to summarise their optical and bulk thermal properties and to highlight potential applications.

2. Preparation of chalcogenide glasses.

2.1. B u l k glasses

* Corresponding author. Tel: + 44-742 768 555. Telefax: + 44742 754 325. E-mail: a.b.seddon@sheffield.ac.uk.

Chemical vapour deposition routes have proved very successful for making high purity, silica-based optical preforms from which telecom fibres are drawn. Analogous vapour deposition techniques have been sought for making bulk optical pieces of nonoxide glasses such as chalcogenides [1], but this effort has been largely unsuccessful and glass melting is commonly used. Chalcogenide glass batches can exhibit high vapour pressures, and the melts tend to have a high viscosity and are susceptible to oxidation and hydrol-

0022-3093/95/$09.50 1995 Elsevier Science B.V. All rights reserved SSDI 0022-3093(94)00686-5

A.B. Seddon / Journal of Non-Crystalline Solids 184 (1995) 44-50

45

420

OH SH

SeF TeH

A,s- ?

I

x X X I oo[ ool I I I J

(o Combination) (X Overtone )

II

I

I I

I I I

As (or ~-0) fie- D Si- O Se- 0

Te- 0

2 t,

e

6 B 10 wovetength / pm

rff

I

i

12 14

16

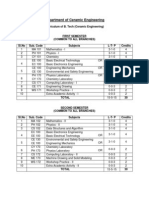

Fig. 1. Absorption bands of common impurities in chalcogenide glasses and CO and CO2 emission lines [19].

ysis. Because of these problems, melting is preferably carried out inside a vitreous silica ampoule sealed under vacuum and the melt is agitated [2]. Purification of the batch and ampoule must be completed prior to sealing and it is important to minimise hydride, hydroxide and oxide impurities which impair the transmission window of the finished glass (Fig. 1). The silicaware should be of low hydroxide content. It may be etched in hydrofluoric acid to remove surface adsorbed species and flaws, then rinsed and dried, and vacuum baked at high temperature (e.g., at < 10 -3 Pa at > 5 0 0 C ) j u s t before batching. A high differential vapour pressure between contaminant and batch component can be exploited by heating the batch component in situ under vacuum (see Table 1). For instance, sulphur can be rid of H 2 0 , H2S, SO 2 and SO 3. The batch may be further purified by distillation directly into the melt ampoule under a reactive atmosphere [3], or mixed with an oxygen getter, of aluminium, and distilled through a silica, fused fine frit connection from the first chamber of a double chambered am-

poule to the second [4,5]. Reitter et al. [6] distilled As, Te and Se in the presence of magnesium strip and hence avoided the use of a silica frit. The batched, sealed ampoule is loaded into a furnace and the temperature is increased gradually to the melting temperature because explosions can occur. Calculations show, for instance, that 10 g of sulphur in an ampoule of internal volume about 2 10 -5 m 3, evacuated at room temperature, will generate a pressure of approximately 6 MPa at 1000C. Should the ampoule fracture at 1000C, then the energy of the explosion would be equivalent to about 60 mg of trinitrotoluene. The ampoule can be rendered to fine dust. Melt quenching can be carried out by cooling and annealing in the melt furnace. Faster cooling rates for unstable glasses can be achieved by air-cooling or, further, by plunging the sealed ampoule into cold water or even liquid nitrogen before annealing. Certain batch components such as Si, AI and also La2S 3 will attack silica at increased temperatures. For LazS3-containing melts, the silica ampoule should be internally coated with a pin-hole free carbon layer or the melt should be contained within an inner vitreous carbon crucible [7].

2.2. Optical fibres

Preform drawing is the most common method of forming chalcogenide glass fibres [8,9], but successful fibre drawing may be limited to a narrow part of the vitreous phase field [10]. The optical cladding may be a UV curable, protective organic coating applied on-line, or a perfluoro-polymeric jacket heat-shrunk onto the preform and then drawn down simultaneously. In addition, thin chalcogenide glass claddings have been successfully vapour deposited onto a preform [11]. Drawing fibre directly from the melt has been

Table 1 Vapour pressures of elements and their oxides Temperature Vapourpressure(mmHg) (C) As AS203 300 0.12 49.2 600 . . .

Se 0.24 .

SeO2 200

Te 10

TeO~ 0.005

46

A.B. Seddon / Journal of Non-Crystalline Solids 184 (1995) 44-50

carried out for fibres of As-S glasses using the double crucible method [12]. A double crucible pressurised with argon was developed by Pitt et al. [5] for pulling selenide and selenide-telluride fibres directly from the melt. Zhang et al. [13] have drawn fibres of T e - S e - B r / I glasses from the melt. These have a glass transformation temperature, Tg, of ~ 80C; hence, an oil-bath was used to heat the crucible.

Youden et al. [15] have announced preliminary results of pulsed laser deposition of La-Ga-S thin films of 1.5 Ixm thick. The target of LaGa2.3S s was ablated using a KrF excimer laser in a chamber at < 10 -2 Pa and the plume of ablated material was condensed onto CaF e substrates.

3. Optical properties

3.1. Optical transmission

Sulphides offer transmission in the long wavelength part of the visible spectrum where selenide and telluride glasses are opaque. Sulphide, selenide and telluride are transmissive in the near IR and mid-IR. For a pathlength of a few mm, the maximum transmission wavelengths in the far-IR are close to: sulphides - 12 Ixm; selenides - 15 txm; and tellurides - 20 txm [16]. Refractive indices range from 2 to > 3 and give rise to a high Fresnel reflection loss of 10 to > 25% for each air/glass interface. The large refractive indices also mean that Rayleigh scattering losses are higher than for silica. For germanium sulphide optical fibres operating in the mid-IR region, the lowest intrinsic optical loss was predicted by Shibata et al. [3] to be 10 -2 dB km -a at 5 Ixm on the basis of the point of intersection of the extrapolated Rayleigh scattering curve and the multiphonon edge. However this did not take into account the extra loss imposed in the mid-IR region by the weak absorption tail emanating from the Urbach edge. This is thought to arise from inter-band-gap states due to extrinsic impurities and intrinsic defects. The minimum loss predicted from the weak absorption tail rather than the Rayleigh scattering curve is > 10 dB km -1 for Ge-S and A s - S fibres [12,17]. In addition, hydride and hydroxide impurities that absorb in the mid-IR are not easily eradicated. The mid-IR region tends in reality therefore to be dominated by the weak absorption tail and extrinsic absorption. In the longer wavelength region of 8-12 Ixm, oxide contamination is a problem [18]. Glasses containing oxide tend to exhibit an increased hydroxide contamination and reduced hydride absorption; conversely oxide absorption is reduced only at the expense of increased hydride absorption in the 4 - 6 Ixm

2.3 Thin films

Elliott [14] has discussed some methods of making thin, amorphous films of chalcogenides. The simplest preparative method is thermal evaporation which is carried out in vacuo to reduce contamination. The starting material, usually a meltderived chalcogenide glass, is heated to evaporation either by resistive heating or by electron bombardment, and is collected on a substrate. A major problem for multicomponent systems is that non-congruent evaporation usually occurs leading to non-homogeneous films. As Elliott points out, the equilibrium vapour may involve a stoichiometry of components different than the solid state; for instance, the vapour above As2S 3 is AsaS 4. This can be alleviated by using flash evaporation which essentially allows total evaporation of smaller mass units. The temperature of the substrate has a significant effect on the structure of the condensate; in addition, the relative orientation of substrate to target is important. Deposition rates are relatively fast at 0.1-1 ixm -1. Deposition from the vapour state influences the structure and hence properties of the as-deposited chalcogenide films, which can be very different from their melted bulk counterparts. Sputtering is more complex than evaporation, but more flexible. Energetic ions from a low pressure plasma, usually Ar gas, bombard and erode the target which is subjected to a radio frequency (rf) field. Deposition on the substrate occurs at a low rate: 1-10 A s -1. Sputtered films are superior to evaporated films as they tend to have the same stoichiometry as the target because sputtering rates of atoms and clusters do not vary with atomic type as much as evaporation rates. Wet chemistry techniques have been used for precipitation of amorphous As2S 3.

A.B. Seddon / Journal of Non-Crystalline Solids 184 (1995) 44-50

47

band. Hence it is difficult simultaneously to optimise transmission at wavelengths both longer and shorter than 6 p~m [19]. Further problems of extrinsic loss can arise. Carbon-based impurities may occur where chalcogenide glass preparation has involved exposure to vacuum oil vapours. The rather high viscosity at glass melting temperatures means that homogeneity is difficult to achieve and striae of slightly different density glass will cause macroscopic distortion and scatter. Forming operations carried out at elevated temperatures may lead to volatilisation, for instance, from the surface of an optical fibre during drawing, causing defects.

3.2. Refractive index

Savage [16] has tabulated refractive indices for sulphide, selenide and telluride glasses containing As, Ge, Si and Sb measured at 20C in the 3 - 5 txm and 8 - 1 2 txm windows. Refractive indices are increased when sulphide (As2S3: n30.rn is 2.395) is replaced by the more polarisable selenide (As2Se3: ns~,m is 2.7840) and telluride. Dispersion curves appear to be flatter than for oxides or fluorides [8]. Addition of Ge lowers refractive index as does Si [16]. The increase in refractive index with addition of Pb, Sn, Sb and Te to G e - A s - S e glasses has been reported [20]. The temperature coefficient of refractive index ranges from -0.0001C ~ at 3 - 5 txm for As2S 3 to +0.00017C ~ at 5 Ixm for a multicomponent S i - G e - A s - T e glass [16]. Glasses in the system G e - A s - S show a similar range [21].

optical constants of the material, in particular in the position of the optical band gap. This is termed photodarkening or photobleaching depending on the whether the bandgap moves to longer or shorter wavelength [22]. The chalcogenide glasses are susceptible to lightinduced changes because there is structural flexibility: the chalcogen elements are only two-fold coordinated and the chalcogen atoms possess a lone pair of electrons which are normally non-bonding but which can undergo light induced reactions to produce structural defects of threefold or singly coordinated chalcogen atoms [23]. The states associated with the non-bonding electrons lie at the top of the valence band and hence are preferentially excited by illumination. Ewen and Owen [24] have summarised the classification of the photosensitive effects in terms of reversibility (i.e., whether they can be annealed out) and whether they are more structural or physicochemical in origin. Reversible effects occur in well annealed glasses. Irreversible effects occur in as-deposited films condensed from the vapour state. Physicochemical effects (e.g., metal photodissolution) can occur no matter the state of annealing. Changes in local atomic structure are readily photoinduced by light of photon energy close to the optical band gap [25]. Photodarkening is sensitive to hydrostatic pressure [26] and does not occur in crystalline analogues. Photoinduced optical anisotropy appears in certain chalcogenide glasses when exposed to plane polarised light and can be erased by unpolarised light [27].

3.3. Photoinduced phenomena 4. Thermal properties

At least seven distinct photoinduced phenomena are observed in amorphous chalcogenides but not usually in crystalline chalcogenides. Thus, when samples of a suitable geometry are exposed to light, then photocrystallisation, photopolymerisation, photodecomposition (e.g., production of A s - A s bonds, and clusters, within As2S 3 glass), photoinduced morphological changes (i.e., photocontraction), photo vapourisation, photodissolution of metals (e.g., Ag into AseS 3) and light-induced changes in local atomic configuration can occur. These changes are accompanied by changes in the For a given chalcogenide glass system, increasing the relative atomic mass of the chalcogen or its proportion in the glass diminishes the average bond strength and hence the Tg decreases. G e - A s - S e - T e glasses demonstrate these principles (Table 2) [16]. Thus Tg falls both as the Se level is increased at the expense of Ge or As, and as Te substitutes for Se. The addition of halogens, which act as network terminators, tends to decrease Tg and increase the thermal expansion coefficient (TEC) [28]. Zhang et al. [29] have added As to TeX glasses and increased

48

A.B. Seddon /Journal of Non-Crystalline Solids 184 (1995) 44-50

Table 2 Thermal properties of some chalcogenide glasses System Ge3oAs2oSeso Ge 30As uJSe60 Ge lOAs40 Ses0 Gel0 As20Se7o Ge3oAs13Sea7Te10 Ge30 As13Se37Te20 Ge3oS7o (Ge3o $70)901 lo (Ge30 S 70)~o 120 GaLaS Tg (C) 361 345 222 159 308 285 368 285 189 550 T E C ( 106 c-l) 11.7 13.7 20.9 24.8 13.2 12.9 14.7 28.2 68.3 [28] Ref. [16]

5. Applications

The first chalcogenide glass to be commercially developed was A2S3, produced for passive, bulk optical components for the mid-IR in the 1950s. During the next two decades, other sulphide and selenide glasses were developed, as well as selenide-telluride glasses for optical components for the far infrared which have since been exploited commercially [39,16]. Applications of infrared optics include energy management, thermal fault detection, electronic circuit detection, temperature monitoring and night vision [40]. As an example of the latter, the blackbody radiation emitted by room temperature objects such as the human body is in the 8-12 p,m region where selenide-telluride-based glasses are applicable for thermal imaging. In the 1970s, chalcogenide glasses were researched to assess their suitability as active electronic device components in photocopying and switching applications. However, a lot of activity in threshold memory and thin film telluride glass electronic switches in fact did not lead to any commercial production [16]. Through the 1980s, attention was focused on the fabrication of ultra-low loss IR fibres for telecom. signal transmission to compete with silica optical fibres [8,9]; however the theoretical minimum losses of mid-IR chalcogenide fibres are probably limited to > 10 dB km-1. Extrinsic losses of far IR chalcogenides are too high [19]. Praseodymium-doped La-Ga-S-based glasses are at present being investigated for 1.3 p~m all-optical fibre amplification. Advantages of using this glass system are: (i) a high solubility of the rare earth dopant and (ii) a low phonon energy host which discourages non-radiative relaxation of t h e 1G4 excited state of Pr. Encouragingly, Becket et al. [41] have observed a single lifetime of about 300 Ixs for the Pr 1G4 level in this system. Laser power transmission has applications for industrial welding operations and also for microsurgery. CO 2 surgical lasers operating at 10.6 ~m have relied on bulky articulated arms to deliver the beam to a micromanipulator and on to the site for surgery. These may be replaced by more compact fibreoptic systems based on chalcogenide fibres. Nishii et al. [42] showed that, at 10.6 Ixm, a chalcogenide core/clad fibre of G e - S e - T e / G e - A s - S e -

[7]

Tg, glass transformation temperature; TEC, thermal expansion coefficient.

Tg from sub-100C to 150C while retaining long wavelength infrared transmission. GaLaS glasses are based on more ionic bonding than most other chalcogenide systems and the characteristic temperatures are unusually high [7]. Many thermal data on chalcogenide glasses have been generated in the cause of testing topological threshold models [30]. Recent examples are: Tg of As-A1-Te [31], G e - I n - S e [32], G e - G a - S e [33] and G e - S b - A s - S e - T e [34] glasses; TEC of G e - S e - T e [35] and thermal diffusivity of A s - S e - T e [36]. Viscosity/temperature curves of the chalcogenide glasses are flatter than for heavy metal fluoride glasses and the upper temperature limit of the working range can be governed by the onset of phase separation. Savage [16] has described the temperature coefficient of viscosity by means of the VogelFulcher type relation often applied to oxide systems. Addition of halogen causes an increase in melt fragility [28]. Moynihan [37] has reported a rapid technique for predicting the viscosity/temperature behaviour above Tg for some halide and oxide glasses. He has demonstrated the validity of a correlation between the width of the glass transition region (measured using differential scanning calorimetry or differential thermal analysis during heating) and the activation enthalpy for the shear viscosity. This approach is being investigated for chalcogenide glasses [38].

A.B. Seddon /Journal of Non-Crystalline Solids 184 (1995) 44-50

49

Te (of dimensions 450 i x m / 5 5 0 Ixm and 100 cm long) was able to receive 21.8 W c.w. and the transmitted power density was 6.0 k W cm 2. Churbanov [43] has reported that G e - A s - S e fibre of 400 Ixm diameter and 1.5 m length transmitted E r / Y A G at 2.9 Ixm using 200 Ixs pulses, giving an output of power density 1.5 m W cm -2. The wide IR window of chalcogenides and the high resolution of Fourier transform infrared spectrometry together p e r m i t remote sensing of g a s e s / l i q u i d s using absorption due to the fundamental vibrational modes, for instance by means of fibre-optic evanescent field spectroscopy [42]. Quantitative analysis of C O / C O 2 within a combustion furnace to 100 ppm at 1550C has proved possible [44]. Acousto-optic devices can rapidly modulate the amplitude and direction of a laser beam. A n rf field is applied to a block of suitable material and and an acoustic grating is thus generated within the block. The grating can be used to produce two optical beams and the measurement of particle flow is then possible at the point of recombination of the beams. Far-IR chalcogenide glasses, when suitably formulated to optimise the acousto-optic figure of merit, are attractive for operation at 10.6 Ixm [45]. G a - L a - S glasses have been investigated for shorter optical wavelength operation [46]. Ewen and Owen [24] have reviewed the applications of light induced effects in chalcogenide glasses and another souce of information is Andriesh et al. [47]. The metal photodissolution effect in chalcogenides has features desirable for image creation and storage. Up to 3 0 - 4 0 at.% A g can be driven into an A s - S amorphous film, forming an embedded structure with up to a 0.5 absolute change in refractive index. On removal of the illumination at ambient temperatures, there is no further movement of the metal ions and hence no degradation of the image. Further, a surface relief structure can be formed by removing undoped material with an alkali etchant. Applications are possible in the production of inorganic resists for VLSI lithography. The embedded or surface relief structures achievable by metal photodoping are attractive for making bulk components for infrared diffractive optics and also for small scale integrated optics [48]. Diffractive optical elements are essentially planar devices which

operate by diffraction rather than by reflection or refraction and are more lightweight than conventional bulk elements such as mirrors, lenses and filters. The photoinduced phase transition amorphous crystalline, and vice versa, in chalcogenide glasses could be the basis for optical mass memory applications. Thus a focused laser writes information by inducing a localised phase transition, and data are read by utilising the difference in reflectance between the amorphous and crystalline phases. Antimony-based chalcogenide glasses appear to be the most suitable [49]. Finally, Nasu et al. [50] have reported a third order non-linear susceptibility of 2.2 X 10 t2 esu for A 2 S 3 glasses, which is 100 times higher than for silica, with the possibility of a fast response time [51]. This opens up possibilities for their use as the active element in all-optical switching devices.

References

[1] D. Blanc and J.I.B. Wilson, J. Non-Cryst. Solids 77&78 (1985) 1129. [2] J.A. Savage, J. Phys. Sci. Instrum. 9 (1976) 622. [3] S. Shibata, Y. Terunuma and T. Manabe, Mater. Res. Bull. 16 (1981) 703. [4] T. Katsuyama, K. Ishida, S. Satoh and H. Matsumura, Appl. Phys. Lett. 45 (1984) 925. [5] N.J. Pitt, G.S. Sapsford, T.V. Clapp, R. Worthington and M.G. Scott. Proc, SPIE Int. Soc. Opt. Eng. Vol. 618 (1986) 124. [6] A.M. Reitter, A.N. Steeram, A.K. Varshneya and D.R. Swiler, J, Non-Cryst. Solids 139 (1992) 121. [7] L. Mattos Jr. and A.G. Clare, Phys. Chem. Glasses 34 (1993) 244. [8] T. Katsuyama and H. Matsumura, Infrared Optical Fibres (Adam Hilger, Bristol, 1989). [9] J.M. Parker and A.B. Seddon, in: High Performance Glasses, ed. M. Cable and J.M. Parker (Blackie, London, 1992) ch. 13. [10] M. Saito and M. Takizawa, J. Appl. Phys. 59 (1986) 1450. [11] M. Saito, M. Takizawa and M. Miyagi, J. Lightwave Technol. 7 (1989) 158. [12] T. Kanamori, Y. Terunuma, S. Takahashi and T. Myashita, J. Lightwave Technol. LT-2 (1984) 607. [13] X.H. Zhang, G. Fonteneau, H.L. Ma and J. Lucas, Proc. SPIE Int. Soc. Opt. Eng. Vol. 1128 (1989) 301. [14] S.R. Elliott, Physics of Amorphous Materials, 2nd Ed. (Longman, Harlow, UK, 1990).

50

A.B. Seddon /Journal of Non-Crystalline Solids 184 (1995) 44-50

[34] A.K. Varshneya, A.N. Steeram and D.R. Swiler, Phys. Chem. Glasses 34 (1993) 179. [35] A. Giridhar, S. Mahadevan and A.K. Singh, J. Non-Cryst. Solids 103 (1988) 73. [36] K. Nandakumar and J. Philip, J. Non-Cryst. Solids 144 (1992) 247. [37] C.T. Moynihan, J. Am. Ceram. Soc. 76 (1993) 1081. [38] C.T. Moynihan, private communication (1993). [39] A.R. Hilton, C.E. Jones and M. Brau, Phys. Chem. Glasses 7 (1966) 105. [40] R.B. Johnson, in: Proc. Soc. Photo-Optical Instrumentation Engineers, SPIE 915 (1988) 106. [41] P.C. Becker, M.M. Broer, V.G. Lambrecht, A.J. Bruce and G. Nykolak, in: Technical Digest of Topical Meeting on Optical Amplifiers and their Applications 1992 (Optical Society of America, Washington, DC, 1992) post-deadline papers PDP5. [42] J. Nishii, S. Morimoto, I. Inagawa, R. lizuka, T. Yamashita and T. Yamagishi, J. Non-Cryst. Solids, 140 (1992) 199. [43] M.F. Churbanov, J. Non-Cryst. Solids 140 (1992) 324. [44] M. Maeda, in: Chemical Sensor Technology 3, ed. N. Yamazoe (Kodansha, Tokyo, 1991) p. 185. [45] M.J. Laifie and A.B. Seddon, these Proceedings, p. 30. [46] I. Abdulhalim, C.N. Pannell, R.S. Deol, D.W. Hewak, G. Wylangowski and D.N. Payne, J. Non-Cryst. Solids 164-166 (1993) 1251. [47] A.M. Andriesh, V.V. Ponomar, V.L. Smiruov and A.V. Mironos, Soy. 1. Quantum Electron. 16 (1986) 721. [48] P.J.S. Ewen, A. Zekak, C.W. Slinger, G. Dale, D.A. Pain and A.E. Owen, J. Non-Cryst. Solids 164-166 (1993) 1247. [49] S.R. Ovshinsky, J. Non-Cryst. Solids 141 (1992) 200. [50] H. Nasu, Y. Ibara and K Kubodera, J. Non-Cryst. Solids 110 (1989) 229. [51] H. Nasu and J.D. Mackenzie, Opt. Eng. 26 (1987) 102.

[15] K.E. Youden, T. Grevatt, R.W. Eason, H.N. Rutt, R.S. Deol and G. Wylangowski, Appl. Phys. Lett. 63 (1993) 1601. [16] J.A, Savage, Infrared Optical Materials and their Antireflection Coatings (Adam Hilger, Bristol, 1985). [17] T. Kanamori, Y. Terunuma, S. Takahashi and T. Miyashita, J. Non-Cryst. Solids 69 (1985) 231. [18] C.T. Moynihan, P.B. Macedo, M.S. Maklad, R.K. Mohr and R.E. Howard, J. Non-Cryst. Solids 17 (1975) 369. [19] N.L Pitt, Proc. SPIE Int. Soc. Opt. Eng. Vol. 799 (1987) 25. [20] L.G. Aio, A.M. Efimov and V.F. Kokorina, J. Non-Cryst. Solids 27 (1978) 299. [21] 1.I. Rosola and I.I. Shpak, Soy. J. Glass Phys. Chem. 17 (1991) 593. [22] G. Pfeiffer, M.A. Paesler and S.C. Agarwal, J. Non-Cryst. Solids 130 (1991) 111. [23] S.R. Elliott, J. Non-Cryst. Solids 81 (1986) 71. [24] P.J.S. Ewen and A.E. Owen, in: High Performance Glasses, ed. M. Cable and J.M. Parker (Blackie, London, 1992) ch. 14. [25] C.A. Spence and S.R. Elliott, Phys. Rev. B39 (1989) 5452. [26] K. Tanaka, J. Non-Cryst. Solids 90 (1987) 363. [27] A.V. Kolobov, V.M. Lyubin and V.K. Tikhomirov, Sov. J. Glass Phys. Chem. 18 (1992) 457. [28] A.B. Seddon and M.A. Hemingway, J. Therm. Anal. 37 (1991) 2189. [29] X.H. Zhang, H.L. Ma, C. Blancheti~re and J. Lucas, J. Non-Cryst. Solids 146 (1992) 154. [30] J.C. Phillips, J. Non-Cryst. Solids 34 (1979) 153. [31] S. Mahadevan and A. Giridhar, J. Mater. Sci. 28 (1993) 1205. [32] A. Giridhar and S. Mahadevan, J. Non-Cryst. Solids 151 (1992) 245. [33] S. Mahadevan and A. Giridhar, J. Non-Cryst. Solids 152 (1993) 42.

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Katalog SealentDocument15 paginiKatalog SealentWulan EgidiaÎncă nu există evaluări

- Syllabus 4Document33 paginiSyllabus 4microsoftkarthiÎncă nu există evaluări

- 4 Ceramic BiomaterialsDocument47 pagini4 Ceramic BiomaterialsIshan BhatÎncă nu există evaluări

- Astm C1036-16Document10 paginiAstm C1036-16josemanuel0525100% (3)

- Insulation Inspection 2 Days - 2021-11-22Document353 paginiInsulation Inspection 2 Days - 2021-11-22bikashmaity030100% (1)

- Kata LogDocument36 paginiKata LogBunPământÎncă nu există evaluări

- Glass Check - EuDocument85 paginiGlass Check - EumaneranÎncă nu există evaluări

- 2535-S Industriaseko GlassDocument17 pagini2535-S Industriaseko GlassFreddy De la BarraÎncă nu există evaluări

- 9.automatic TranformationDocument12 pagini9.automatic Tranformation차지훈Încă nu există evaluări

- Minerals and Their UsesDocument15 paginiMinerals and Their UsesAnonymous i6E1p4RtPÎncă nu există evaluări

- PackingDocument8 paginiPackingCẩm Tú Phan ThịÎncă nu există evaluări

- Bullet Proof Glass: BY Divya Mathew Kavyashri S Savitha BalajiDocument6 paginiBullet Proof Glass: BY Divya Mathew Kavyashri S Savitha Balajiraj kÎncă nu există evaluări

- GIB-Proper Procedures, Cleaning 01-0300Document4 paginiGIB-Proper Procedures, Cleaning 01-0300vgskumarchennaiÎncă nu există evaluări

- Glass SppuDocument12 paginiGlass SppuPrashantÎncă nu există evaluări

- Env 8Document44 paginiEnv 8Kamal Kant GuptaÎncă nu există evaluări

- T SC 203 ks1 Translucent Transparent or Opaque Sorting Powerpoint - Ver - 2Document39 paginiT SC 203 ks1 Translucent Transparent or Opaque Sorting Powerpoint - Ver - 2Cheryell AnnÎncă nu există evaluări

- Bulk Metallic GlassesDocument43 paginiBulk Metallic GlassesCa NdyÎncă nu există evaluări

- Engineered Plastic Characteristics II: Bakelite, Epoxy Glass and CeramicsDocument1 paginăEngineered Plastic Characteristics II: Bakelite, Epoxy Glass and CeramicsKmgsa BandaraÎncă nu există evaluări

- ALIA Manual AUT8500A Thickness GaugeDocument12 paginiALIA Manual AUT8500A Thickness GaugeRexCrazyMindÎncă nu există evaluări

- United States Patent (10) Patent No.: US 6,327,954 B1: Medlin (45) Date of Patent: Dec. 11, 2001Document29 paginiUnited States Patent (10) Patent No.: US 6,327,954 B1: Medlin (45) Date of Patent: Dec. 11, 2001Mary HullÎncă nu există evaluări

- Comparision of CTE Values of Different MaterialsDocument107 paginiComparision of CTE Values of Different MaterialsPurvesh NanavatiÎncă nu există evaluări

- Stem Correction 2Document29 paginiStem Correction 2Choudhary AhmadÎncă nu există evaluări

- Washing Machine Catalogue 2020Document10 paginiWashing Machine Catalogue 2020api-404330673Încă nu există evaluări

- Kpo 00 Pip SPC 00019 eDocument24 paginiKpo 00 Pip SPC 00019 erameshqcÎncă nu există evaluări

- Untitled PresentationDocument10 paginiUntitled Presentationanurag singhÎncă nu există evaluări

- 262 - PDFsam - DLP TEXTBOOK Chemistry FORM 4 PDFDocument25 pagini262 - PDFsam - DLP TEXTBOOK Chemistry FORM 4 PDFnaseem wanÎncă nu există evaluări

- Glass Production: From Wikipedia, The Free EncyclopediaDocument10 paginiGlass Production: From Wikipedia, The Free EncyclopediaMahfuzur Rahman SiddikyÎncă nu există evaluări

- Curtain Wall (Revise1)Document8 paginiCurtain Wall (Revise1)Mohammad BurhanÎncă nu există evaluări

- SR 11 AE Us Basic Characteristics of AEROSIL 2006-04Document72 paginiSR 11 AE Us Basic Characteristics of AEROSIL 2006-04Michele Negri100% (1)

- ವಿಜ್ಞಾನ ಪ್ರಯೋಗಾಲಯ ಉಪಕರಣಗಳುDocument4 paginiವಿಜ್ಞಾನ ಪ್ರಯೋಗಾಲಯ ಉಪಕರಣಗಳುghshmkadiwalinamÎncă nu există evaluări