Documente Academic

Documente Profesional

Documente Cultură

Group 4 Single Operation

Încărcat de

thierrylindoDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Group 4 Single Operation

Încărcat de

thierrylindoDrepturi de autor:

Formate disponibile

GROUP 4 SINGLE OPERATION

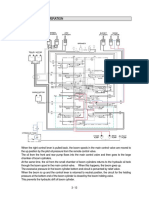

1. BOOM UP OPERATION

ARM CYLINDER BUCKET CYLINDER BOOM CYLINDER

TRAVEL MOTOR

CK1 Rs Pn2 Pn1

B5 A5 C5 D5 Pc5 Pd5

Pb5 Pa5

OPTION

BUCKET

CK2

C4

T/JOINT

D4 DR3 Pc41 Pd40 Pc40 B4 Pb4 Pa4

ARM1

ARM REGENERATION

Pc42

SWING MOTOR

Pc3 DR2 Pa21 Pb3 Pd41

BOOM2

V3 C2 D2 Pc2 Pd2

ARM2 BOOM HOLDING VALVE

B2 A2 Pb21 DR1 Pb20 Pa20

SWING

BOOM1

B1

C1 D1 Pc1 Pd1

A1 Pb1 Pa1

TRAVEL(LH)

DR0 P01 Ptr

TRAVEL(RH)

P1

P2

Pu

T1

HYD TANK FRONT PUMP REAR PUMP PILOT PUMP

2907A3HC10

When the RH control lever is pulled back, the boom spools in the main control valve are moved to the up position by the pilot oil pressure from the remote control valve. The oil from the front and rear pump flows into the main control valve and then goes to the large chamber of boom cylinders. At the same time, the oil from the small chamber of boom cylinders returns to the hydraulic oil tank through the boom spool in the main control valve. When this happens, the boom goes up. The excessive pressure in the boom cylinder bottom end circuit is prevented by relief valve. When the boom is up and the control lever is returned to neutral position, the circuit for the holding pressure at the bottom end of the boom cylinder is closed by the boom holding valve. This prevents the hydraulic drift of boom cylinder.

3-13

2. BOOM DOWN OPERATION

ARM CYLINDER BUCKET CYLINDER BOOM CYLINDER

TRAVEL MOTOR

CK1 Rs Pn2 Pn1

B5 A5 C5 D5 Pc5 Pd5

Pb5 Pa5

OPTION

BUCKET

CK2

C4

T/JOINT

D4 DR3 Pc41 Pd40 Pc40 B4 Pb4 Pa4

ARM1

ARM REGENERATION

Pc42

SWING MOTOR

Pc3 DR2 Pa21 Pb3 Pd41

BOOM2

V3 C2 D2 Pc2 Pd2

ARM2 BOOM HOLDING VALVE

B2 A2 Pb21 DR1 Pb20 Pa20

SWING

BOOM1

B1

C1 D1 Pc1 Pd1

A1 Pb1 Pa1

TRAVEL(LH)

DR0 P01 Ptr

TRAVEL(RH)

P1

P2

Pu

T1

HYD TANK FRONT PUMP REAR PUMP PILOT PUMP

2907A3HC11

When the RH control lever is pushed forward, the boom spools in the main control valve are moved to the down position by the pilot oil pressure from the remote control valve. The oil from the rear pump flows into the main control valve and then goes to the small chamber of boom cylinders. At the same time, the oil from the large chamber of boom cylinders returns to the hydraulic tank through the boom spool in the main control valve. When the down speed of boom is faster, the oil returned from the large chamber of boom cylinder combines with the oil from the rear pump, and flows into the small chamber of the boom cylinder. This prevents cylinder cavitation by the negative pressure when the rear pump flow can not match the boom down speed. And the excessive pressure in the boom cylinder rod end circuit is prevented by the relief valve.

3-14

3. ARM ROLL IN OPERATION

BOOM CYLINDER

ARM CYLINDER

BUCKET CYLINDER

TRAVEL MOTOR

CK1 Rs Pn2 Pn1

B5 A5 C5 D5 Pc5 Pd5

Pb5 Pa5

OPTION ARM HOLDING VALVE

C4

BUCKET

CK2

T/JOINT

D4 DR3 Pc41 Pc40 Pd40 B4 Pb4 Pa4

ARM1

ARM REGENERATION

Pc42

SWING MOTOR

Pc3 DR2 Pa21 Pb3 Pd41

ARM2 BOOM2

V3 B2 A2 Pb21 DR1 Pb20 Pa20

C2 D2 Pc2 Pd2

SWING

BOOM1

B1

C1 D1 Pc1 Pd1

A1 Pb1 Pa1

TRAVEL(LH)

DR0 P01 Ptr

TRAVEL(RH)

P1

P2

Pu

T1

HYD TANK FRONT PUMP REAR PUMP PILOT PUMP

2907A3HC12

When the LH control lever is pulled back, the arm spools in the main control valve are moved to the roll in position by the pilot oil pressure from the remote control valve. The oil from the front and rear pump flows into the main control valve and then goes to the large chamber of arm cylinder. At the same time, the oil from the small chamber of arm cylinder returns to the hydraulic oil tank through the arm spool in the main control valve. When this happens, the arm roll in. When the roll in speed of arm is faster, the oil returned from the small chamber of arm cylinder combines with the oil from both pump, and flows into the large chamber of the arm cylinder by a make up valve. The excessive pressure in the arm cylinder bottom end circuit is prevented by relief valve.

3-15

4. ARM ROLL OUT OPERATION

ARM CYLINDER BUCKET CYLINDER BOOM CYLINDER

TRAVEL MOTOR

CK1 Rs Pn2 Pn1

B5 A5 C5 D5 Pc5 Pd5

Pb5 Pa5

OPTION

BUCKET

CK2

C4

T/JOINT

D4 DR3 Pc41 Pc40 Pd40 B4 Pb4 Pa4

ARM1

ARM REGENERATION

Pc42

SWING MOTOR

Pc3 DR2 Pa21 Pb3 Pd41

ARM2 BOOM2

V3 B2 A2 Pb21 DR1 Pb20 Pa20

C2 D2 Pc2 Pd2

SWING

BOOM1

B1

C1 D1 Pc1 Pd1

A1 Pb1 Pa1

TRAVEL(LH)

DR0 P01 Ptr

TRAVEL(RH)

P1

P2

Pu

T1

HYD TANK FRONT PUMP REAR PUMP PILOT PUMP

2907A3HC13

When the LH control lever is pushed forward, the arm spools in the main control valve are moved to the roll out position by the pilot oil pressure from the remote control valve. The oil from the front and rear pump flows into the main control valve and then goes to the small chamber of arm cylinder. At the same time, the oil from the large chamber of arm cylinder returns to the hydraulic oil tank through the arm spool in the main control valve. When this happens, the arm roll out. When the roll out speed of arm is faster, the oil returned from the large chamber of arm cylinder combines with the oil from both pump, and flows into the small chamber of the arm cylinder by a make up valve. The excessive pressure in the arm cylinder rod end circuit is prevented by relief valve. When the arm is rolled out and the control lever is returned to neutral position, the circuit for the holding pressure at the rod end of the arm cylinder is closed by the arm holding valve. This prevents the hydraulic drift of arm cylinder.

3-16

5. BUCKET ROLL IN OPERATION

ARM CYLINDER

BUCKET CYLINDER

BOOM CYLINDER

TRAVEL MOTOR

CK1 Rs Pn2 Pn1

Pcb Center bypass valve

B5 A5 C5 D5 Pc5 Pd5 Pcb Pa5 CK2

Pb5

OPTION

BUCKET

C4

T/JOINT

D4 DR3 Pc41 Pd40 Pc40 B4 Pb4 Pa4

ARM1

ARM REGENERATION

Pc42

SWING MOTOR

Pc3 DR2 Pa21 Pb3 Pd41

ARM2 BOOM2

V3 B2 A2 Pb21 DR1 Pb20 Pa20

C2 D2 Pc2 Pd2

SWING

BOOM1

B1

C1 D1 Pc1 Pd1

A1 Pb1 Pa1

TRAVEL(LH)

DR0 P01 Ptr

TRAVEL(RH)

P1

P2

Pu

T1

HYD TANK FRONT PUMP REAR PUMP PILOT PUMP

2907A3HC14

When the RH control lever is manually placed in the bucket roll in position. Then the oil flows from pilot pump through the pilot valve to bucket section of the main control valve. Here the spool position is moved to bucket roll in position. The center bypass valve is change over by the pilot pressure(Pcb) and then the oil from front pump is joint to the flow of rear pump via check 1 and external piping. The oil flows from both pump through rod end of the cylinder through the bucket section returned to the hydraulic tank. The cavitation which will happen to the bottom of the bucket cylinder is prevented by a make up valve, on other hand. The excessive pressure is also prevented by an overload relief valve in the main control valve.

3-17

6. BUCKET ROLL OUT OPERATION

ARM CYLINDER

BUCKET CYLINDER

BOOM CYLINDER

TRAVEL MOTOR

CK1 Rs Pn2 Pn1

B5 A5 C5 D5 Pc5 Pd5

Pb5 Pa5

OPTION

BUCKET

CK2

C4

T/JOINT

D4 DR3 Pc41 Pd40 Pc40 B4 Pb4 Pa4

ARM1

ARM REGENERATION

Pc42

SWING MOTOR

Pc3 DR2 Pa21 Pb3 Pd41

ARM2 BOOM2

V3 B2 A2 Pb21 DR1 Pb20 Pa20

C2 D2 Pc2 Pd2

SWING

BOOM1

B1

C1 D1 Pc1 Pd1

A1 Pb1 Pa1

TRAVEL(LH)

DR0 P01 Ptr

TRAVEL(RH)

P1

P2

Pu

T1

HYD TANK FRONT PUMP REAR PUMP PILOT PUMP

2907A3HC15

When the RH control lever is manually placed in the bucket roll out position. Then the oil flows from pilot pump through the pilot valve to bucket section of the main control valve. Here the spool position is moved to bucket roll out position. The oil flows from rear pump through bucket section of main control valve to the rod end of the bucket cylinder, and to roll out bucket. The return oil flows from the bottom end of the cylinder through the bucket section returned to the hydraulic tank. The cavitation which will happen to the rod of the bucket cylinder is prevented by a make up valve, on other hand. The excessive pressure is also prevented by an overload relief valve in the main control valve.

3-18

7. SWING OPERATION

ARM CYLINDER

BUCKET CYLINDER

BOOM CYLINDER

TRAVEL MOTOR

CK1 Rs Pn2 Pn1

B5 A5 C5 D5 Pc5 Pd5

Pb5 Pa5

OPTION

BUCKET

CK2

C4

T/JOINT

D4 DR3 Pc41 Pd40 Pc40 B4 Pb4 Pa4

ARM1

ARM REGENERATION

Pc42

SWING MOTOR

Pc3 DR2 Pa21 Pb3 Pd41

ARM2 BOOM2

V3 B2 A2 Pb21 DR1 Pb20 Pa20

C2 D2 Pc2 Pd2

SWING

BOOM1

B1

C1 D1 Pc1 Pd1

A1 Pb1 Pa1

TRAVEL(LH)

DR0 P01 Ptr

TRAVEL(RH)

P1

P2

Pu

T1

HYD TANK FRONT PUMP REAR PUMP PILOT PUMP

2907A3HC16

When the LH control lever is manually placed in the left(Right) swing position. Then the oil flows from front pump through the swing section of the main control valve to swing motor to left(Right) swing the superstructure. The return oil flows from swing motor through the swing section of the main control valve returned to the tank. When the control lever placed in the neutral position, the pressure of the pilot oil passage down. Then the brake release valve returned to the neutral position and the oil is returned from the brake piston to the tank. And the brake is set to "ON". The swing parking brake, make up valve and the overload relief valve are provide in the swing motors. The cavitation which will happen to the swing motor is prevented by the make up valve in the swing motor itself.

3-19

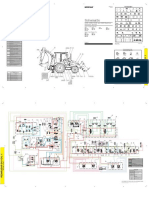

SWING CIRCUIT OPERATION

SWING MOTOR DEVICE PARKING BRAKE BRAKE RELEASE VALVE SH BRAKE OFF

PG DB (dr4) BRAKE ON MAKE UP VALVE MOTOR BRAKE VALVE PA PB MAKE UP PORT C

A(CW)

B(CCW)

2907A3HC17

TO/FROM MAIN CONTROL VALVE

1) MOTOR BRAKE VALVE Motor brake valve for the swing motor limits to cushion the starting and stopping pressure of swing operation. 2) MAKE UP VALVE The make up valves prevent cavitation by supplying return oil to the vacuum side of the motor. 3) PARKING BRAKE In case that the parking, of the machine at slope is required during operation, there is the danger of involuntary swing caused by the self weight of the machine. The brake is connected to prevent this involuntary swing. PARKING BRAKE "OFF" OPERATION The parking brake is released by the pilot pressure oil from the pilot pump. When the left control lever placed in the swing position, the pilot pressure at the shuttle valve is transferred to the brake release valve and the brake release valve is change over. Then the pilot pressure lift the brake piston and release the parking brake. PARKING BRAKE "ON" OPERATION When the control lever placed in the neutral position, the pressure of the pilot oil passage down. Then the brake release valve returned to the neutral position and the oil is returned from the brake piston to the tank. And the brake is set to 'ON". 4) BYPASS VALVE This bypass valve absorbs shocks produced as swing motion stops and reduced oscillation cause by swing motion.

3-20

8. TRAVEL FORWARD AND REVERSE OPERATION

ARM CYLINDER

BUCKET CYLINDER

BOOM CYLINDER

TRAVEL MOTOR

CK1 Rs Pn2 Pn1

B5 A5 C5 D5 Pc5 Pd5

Pb5 Pa5

OPTION

BUCKET

CK2

C4

T/JOINT

D4 DR3 Pc41 Pd40 Pc40 B4 Pb4 Pa4

ARM1

ARM REGENERATION

Pc42

SWING MOTOR

Pc3 DR2 Pa21 Pb3 Pd41

ARM2 BOOM2

V3 B2 A2 Pb21 DR1 Pb20 Pa20

C2 D2 Pc2 Pd2

SWING

BOOM1

B1

C1 D1 Pc1 Pd1

A1 Pb1 Pa1

TRAVEL(LH)

DR0 P01 Ptr

TRAVEL(RH)

P1

P2

Pu

T1

HYD TANK FRONT PUMP REAR PUMP PILOT PUMP

2907A3HC18

When the right and left travel levers are manually placed to the forward or reverse position, the oil flows from pilot pump through the pilot valve to travel sections of the main control valve. Here, spool position is moved to forward and reverse position. The oil flows from rear pump through the travel(RH) section of the main control valve and turning joint to the right travel motor and oil flows from front pump through the travel(LH) section of the main control valve and turning joint to the left travel motor and move the machine forward or reverse. The return oil flows from both travel motor through the turning joint and travel(RH, LH) sections returned to the tank.

3-21

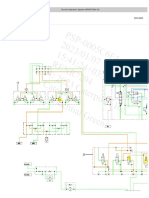

TRAVEL CIRCUIT OPERATION

PARKING BRAKE Dr

Dr

Dr

Dr

Pi

Pi

Pi

Pi

Am

Bm

Bm

Am

A P

A OVERLOAD RELIEF VALVE

COUNTER BALANCE VALVE

Dr

Pk dr3

TO/FROM MAIN CONTROL VALVE

2907A3HC19

Valves are provided on travel motors to offer the following functions. 1) COUNTER BALANCE VALVE When stopping the motor of slope descending, this valve to prevent the motor over run. 2) OVERLOAD RELIEF VALVE Relief valve limit the circuit pressure below 365kgf/cm2 to prevent high pressure generated at a time of stopping the machine. Stopping the motor, this valve sucks the oil from lower pressure passage for preventing the negative pressure and the cavitation of the motor.

3-22

S-ar putea să vă placă și

- Mechanical Engineering Internship ReportDocument66 paginiMechanical Engineering Internship ReportJob Lazarus Okello Sr.74% (39)

- JOHN DEERE 06 - 644K - English PDFDocument300 paginiJOHN DEERE 06 - 644K - English PDFthierrylindo100% (3)

- 10795750-DKP8P8EM-Download Komatsu Pc138us-8 Pc138uslc-8 Excavator ManualDocument946 pagini10795750-DKP8P8EM-Download Komatsu Pc138us-8 Pc138uslc-8 Excavator ManualEdison Correa92% (39)

- 10795750-DKP8P8EM-Download Komatsu Pc138us-8 Pc138uslc-8 Excavator ManualDocument946 pagini10795750-DKP8P8EM-Download Komatsu Pc138us-8 Pc138uslc-8 Excavator ManualEdison Correa92% (39)

- CLARK Forklift - GEX 30Document417 paginiCLARK Forklift - GEX 30Vagif71% (7)

- 06 d155 Hyd Fan CircuitDocument12 pagini06 d155 Hyd Fan Circuitghitacrainic100% (6)

- Hyundai R450LC-7 Pilot CircuitDocument20 paginiHyundai R450LC-7 Pilot CircuitHai VanÎncă nu există evaluări

- Diagrama Hidraulico D9TDocument2 paginiDiagrama Hidraulico D9TCristian Valencia100% (1)

- Volvo Penta Md11-17Document48 paginiVolvo Penta Md11-17api-370610071% (7)

- Basic Hydraulic ValvesDocument72 paginiBasic Hydraulic ValvesFajar Rahardika100% (1)

- Goldcup Denison p24 - 01Document72 paginiGoldcup Denison p24 - 01thierrylindo100% (1)

- Goldcup Denison p24 - 01Document72 paginiGoldcup Denison p24 - 01thierrylindo100% (1)

- Transit.2006.5. (04 2006-)Document306 paginiTransit.2006.5. (04 2006-)asteriskcopÎncă nu există evaluări

- Piaggio X10 Brochure enDocument11 paginiPiaggio X10 Brochure enavatarpetrovicÎncă nu există evaluări

- TFG320 Ge115 - enDocument355 paginiTFG320 Ge115 - enПетр50% (2)

- Safety & Maintenance Checklist-Articulated TrucksDocument1 paginăSafety & Maintenance Checklist-Articulated TruckskkmechÎncă nu există evaluări

- MAST30S Hub Motor User Manual - v3 - enDocument31 paginiMAST30S Hub Motor User Manual - v3 - enSerkan AyazÎncă nu există evaluări

- Group 5 Combined Operation: 1. OutlineDocument9 paginiGroup 5 Combined Operation: 1. OutlinethierrylindoÎncă nu există evaluări

- 3-4 Single OperationDocument10 pagini3-4 Single OperationWilliam FernandoÎncă nu există evaluări

- Section 6 Work EquipmentDocument37 paginiSection 6 Work EquipmentPriscila RodriguesÎncă nu există evaluări

- Group 4 Single OperationDocument12 paginiGroup 4 Single OperationRafał DworakÎncă nu există evaluări

- Boiler Feed PumpDocument11 paginiBoiler Feed PumpSolai100% (2)

- Group 2 Hydraulic Pump: 1. GeneralDocument8 paginiGroup 2 Hydraulic Pump: 1. GeneralJet AcostaÎncă nu există evaluări

- Group 3 Pilot Circuit: RCV Pedal Remote Control Valve (LH Lever) Remote Control Valve (RH Lever)Document8 paginiGroup 3 Pilot Circuit: RCV Pedal Remote Control Valve (LH Lever) Remote Control Valve (RH Lever)thierrylindoÎncă nu există evaluări

- HyundaiDocument8 paginiHyundainajafaliÎncă nu există evaluări

- 6steering System ENGLISH-G9180Document47 pagini6steering System ENGLISH-G9180George Jhonson50% (2)

- Bucket Hydraulic SystemDocument3 paginiBucket Hydraulic Systemjuan david loyola100% (1)

- 980b Wheel Loader HydraDocument13 pagini980b Wheel Loader HydraChrissz Noxd0% (1)

- D85EX-15 Hydraulic FanDocument9 paginiD85EX-15 Hydraulic FanQuy Le Thanh67% (3)

- Plano de Transmision D6TDocument2 paginiPlano de Transmision D6TronaldÎncă nu există evaluări

- Plano Hidráulico 430-D PDFDocument4 paginiPlano Hidráulico 430-D PDFJose Alberto IzquielÎncă nu există evaluări

- Vetus Filling BleedingDocument2 paginiVetus Filling BleedingFranko ZaneticÎncă nu există evaluări

- 5.B230 Hydraulic KnowledgeDocument35 pagini5.B230 Hydraulic KnowledgeSilfia Wahyuni100% (1)

- Valvula Selectora Trans.Document4 paginiValvula Selectora Trans.enriqueÎncă nu există evaluări

- Boom Hydraulic System CAT 330Document17 paginiBoom Hydraulic System CAT 330hectorÎncă nu există evaluări

- Boom Hydraulic System CAT 330Document17 paginiBoom Hydraulic System CAT 330hector100% (1)

- Bucket Hydraulic SystemDocument4 paginiBucket Hydraulic SystemNay SoeÎncă nu există evaluări

- 320dl Bucket Hydraulic SystemDocument3 pagini320dl Bucket Hydraulic SystemDaniel Rhasty-ghee AhmanorÎncă nu există evaluări

- Group 5 Combined Operation: 1. OutlineDocument9 paginiGroup 5 Combined Operation: 1. OutlinePower MobileÎncă nu există evaluări

- 2-3 Swing DeviceDocument21 pagini2-3 Swing Devicejesus silva100% (2)

- Negative Flow Control System: Systems OperationDocument9 paginiNegative Flow Control System: Systems OperationYudi setiawanÎncă nu există evaluări

- Hydraulic Systems - Hydraulic Schema - Pilot Circuit: Suction, Delivery and Return CircuitDocument28 paginiHydraulic Systems - Hydraulic Schema - Pilot Circuit: Suction, Delivery and Return Circuitroparts clujÎncă nu există evaluări

- Group 3 Swing Device: 1. StructureDocument11 paginiGroup 3 Swing Device: 1. StructurethierrylindoÎncă nu există evaluări

- 5brake System Englisg-G9165Document28 pagini5brake System Englisg-G9165George Jhonson90% (10)

- Stick Hydraulic SystemDocument11 paginiStick Hydraulic SystemAllan LariosaÎncă nu există evaluări

- Quick-Drop Valve: Previous ScreenDocument9 paginiQuick-Drop Valve: Previous ScreenBroCactusÎncă nu există evaluări

- Group 4 Travel Device: 1. ConstructionDocument9 paginiGroup 4 Travel Device: 1. ConstructionthierrylindoÎncă nu există evaluări

- 3 CASE ADT 30 Ton Hydraulic Section PDFDocument40 pagini3 CASE ADT 30 Ton Hydraulic Section PDFBaciu NicolaeÎncă nu există evaluări

- Speed TronicDocument3 paginiSpeed Tronicscribdkhatn0% (1)

- Engine Running: Pressure RegulationDocument24 paginiEngine Running: Pressure RegulationFernando RodriguezÎncă nu există evaluări

- 4L60e Hydraulic Schematic Key Гидравлическая СхемаDocument24 pagini4L60e Hydraulic Schematic Key Гидравлическая Схемаivan vanÎncă nu există evaluări

- Fuel PumpDocument4 paginiFuel PumpRajesh Kumar100% (2)

- Boom Drift Reduction ValveDocument4 paginiBoom Drift Reduction ValveJuan Daniel Martinez MontoyaÎncă nu există evaluări

- Section 5 Steering SystemDocument13 paginiSection 5 Steering SystemPriscila RodriguesÎncă nu există evaluări

- Excavator Hydraulic System-Bucket SystemDocument3 paginiExcavator Hydraulic System-Bucket Systemjohn ayengahÎncă nu există evaluări

- Group 5 RCV Lever: 1. StructureDocument7 paginiGroup 5 RCV Lever: 1. StructurethierrylindoÎncă nu există evaluări

- 04 05 Hydraulic System LG956LDocument82 pagini04 05 Hydraulic System LG956LGeorge Jhonson100% (2)

- Section 6 Hydraulic SystemDocument20 paginiSection 6 Hydraulic SystemJorge Ugalde CuevasÎncă nu există evaluări

- t03 - 1 HitachiDocument116 paginit03 - 1 Hitachijacklyn ade putraÎncă nu există evaluări

- Section 3 Hydraulic SystemDocument34 paginiSection 3 Hydraulic SystemRafał DworakÎncă nu există evaluări

- C.P Training Module Levl.2 HydraulicDocument56 paginiC.P Training Module Levl.2 HydraulicEslam Mansour100% (1)

- Hydraulic Power SteeringDocument6 paginiHydraulic Power SteeringMohamad Nadzri YahayaÎncă nu există evaluări

- Bucket Hydraulic System: Operación de SistemasDocument4 paginiBucket Hydraulic System: Operación de SistemasvidalÎncă nu există evaluări

- Hydraulic System: Systems OperationDocument28 paginiHydraulic System: Systems OperationRoberto BaierÎncă nu există evaluări

- Structure and Function Steering SystemDocument15 paginiStructure and Function Steering SystemKristian FonÎncă nu există evaluări

- Tecnico Swing DeviceDocument21 paginiTecnico Swing DeviceSilvio RomanÎncă nu există evaluări

- Diagrama Hidraulico de Power Train d8t InteractivoDocument14 paginiDiagrama Hidraulico de Power Train d8t InteractivoVeimar Gutierrez100% (1)

- Embruague Luc 994Document4 paginiEmbruague Luc 994sergio toroÎncă nu există evaluări

- Manual Del Estudiante D8T - 12Document14 paginiManual Del Estudiante D8T - 12David CeronÎncă nu există evaluări

- Group 6 RCV Pedal: 1. StructureDocument6 paginiGroup 6 RCV Pedal: 1. StructurethierrylindoÎncă nu există evaluări

- Cr-24/30 Propulsion: Brake Pressure SwitchDocument29 paginiCr-24/30 Propulsion: Brake Pressure SwitchMACHINERY101GEARÎncă nu există evaluări

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SDe la EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SÎncă nu există evaluări

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDe la EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementÎncă nu există evaluări

- High Pressure Pump - Pump, Pilot Control (Optional)Document4 paginiHigh Pressure Pump - Pump, Pilot Control (Optional)thierrylindoÎncă nu există evaluări

- Control Block EDC Modular Directional Valve Flow Sharing SystemDocument8 paginiControl Block EDC Modular Directional Valve Flow Sharing Systemthierrylindo100% (1)

- HGAService Rotory Steering ValveDocument30 paginiHGAService Rotory Steering ValveChristopher FinkÎncă nu există evaluări

- CA 250 Maintenance M250enDocument35 paginiCA 250 Maintenance M250enthierrylindoÎncă nu există evaluări

- 151-09 - E KomatsuDocument6 pagini151-09 - E Komatsuthierrylindo100% (8)

- 2011 PDF Catalog AllisonDocument56 pagini2011 PDF Catalog Allisonthierrylindo86% (7)

- Hy17 8537Document12 paginiHy17 8537thierrylindoÎncă nu există evaluări

- Re30042 11.02Document6 paginiRe30042 11.02thierrylindoÎncă nu există evaluări

- Re64025 B - 2010 06Document44 paginiRe64025 B - 2010 06thierrylindo100% (1)

- Re64354 2003-06Document20 paginiRe64354 2003-06thierrylindoÎncă nu există evaluări

- Proportional Joystick Control: Precision Control With All Excavator AttachmentsDocument1 paginăProportional Joystick Control: Precision Control With All Excavator AttachmentsthierrylindoÎncă nu există evaluări

- Linde Synchron Control BrochureDocument24 paginiLinde Synchron Control BrochurethierrylindoÎncă nu există evaluări

- High Pressure Pump - Pump, Pilot Control (Optional)Document4 paginiHigh Pressure Pump - Pump, Pilot Control (Optional)thierrylindoÎncă nu există evaluări

- Hydraulic Mining Excavator - RH 200: General Data: FeaturesDocument8 paginiHydraulic Mining Excavator - RH 200: General Data: FeaturesEduardo Andres Contreras LetelierÎncă nu există evaluări

- GILERA Fuoco - 500 PDFDocument396 paginiGILERA Fuoco - 500 PDFMindaugas VizbarasÎncă nu există evaluări

- STORAGE MANUAL VMT 865 GR Rev00Document7 paginiSTORAGE MANUAL VMT 865 GR Rev00nigelÎncă nu există evaluări

- Unit V AutomobileDocument4 paginiUnit V AutomobileKaushik SÎncă nu există evaluări

- Final Report - PPR223Document47 paginiFinal Report - PPR223iamjithinjoseÎncă nu există evaluări

- Road Traffic (Motor Vehicles, Construction and UseDocument120 paginiRoad Traffic (Motor Vehicles, Construction and Usejeremytoh89Încă nu există evaluări

- SEM660D Wheel LoaderDocument2 paginiSEM660D Wheel LoaderAhmad SmadiÎncă nu există evaluări

- Technical DescriptionDocument18 paginiTechnical DescriptionHugo LeiteÎncă nu există evaluări

- Siemens - VFD Catalog 2019Document110 paginiSiemens - VFD Catalog 2019SuryaRaoTirumallasetti100% (1)

- (ABB) Braking A Drive SystemDocument2 pagini(ABB) Braking A Drive Systemvnnvpsh1Încă nu există evaluări

- Bendix Atr1dc Antilock Traction RelayDocument12 paginiBendix Atr1dc Antilock Traction RelayHenry NicaraguaÎncă nu există evaluări

- 2006 f750Document272 pagini2006 f750Afton RobertÎncă nu există evaluări

- Light and Heavy Vehicle TechnologyDocument20 paginiLight and Heavy Vehicle TechnologyDolovan DsÎncă nu există evaluări

- Underground Mining Vehicles: Innovative Drivetrain SolutionsDocument8 paginiUnderground Mining Vehicles: Innovative Drivetrain SolutionsSales Aydinkaya100% (1)

- Especificaciones Tecnicas Cat R1300g-EDocument20 paginiEspecificaciones Tecnicas Cat R1300g-EGianfranco GardellaÎncă nu există evaluări

- '21 Honda CMX1100 Rebel Motorcycle Owner's Manual PDFDocument173 pagini'21 Honda CMX1100 Rebel Motorcycle Owner's Manual PDFruiboeningerÎncă nu există evaluări

- Wheel Loader: Engine Gross Power Net Power Operating Weight Standard Bucket SizeDocument2 paginiWheel Loader: Engine Gross Power Net Power Operating Weight Standard Bucket SizeLinio Calixto De JesusÎncă nu există evaluări

- 9fa2b PDFDocument73 pagini9fa2b PDFWilson CendalesÎncă nu există evaluări

- Power PDFDocument3 paginiPower PDFZachez MahabirÎncă nu există evaluări

- Effect of Turbocharging On Exhaust Brake Performance in An AutomobileDocument6 paginiEffect of Turbocharging On Exhaust Brake Performance in An Automobileabhisaxena93Încă nu există evaluări

- Cha 2Document52 paginiCha 2yaredÎncă nu există evaluări

- Cks 600 SpecDocument24 paginiCks 600 SpecRajan MullappillyÎncă nu există evaluări

- MECHANICAL (AUTOMOBILE) ENGINEERING - 2019-Scheme-S3-Syllabus - Ktustudents - inDocument44 paginiMECHANICAL (AUTOMOBILE) ENGINEERING - 2019-Scheme-S3-Syllabus - Ktustudents - injishnu unniÎncă nu există evaluări