Documente Academic

Documente Profesional

Documente Cultură

ThaiREC Checklist-Barge Inspection Questionnaire Gas

Încărcat de

เปีย วันชัย สวนทองDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ThaiREC Checklist-Barge Inspection Questionnaire Gas

Încărcat de

เปีย วันชัย สวนทองDrepturi de autor:

Formate disponibile

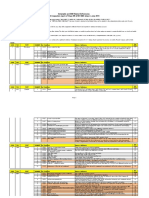

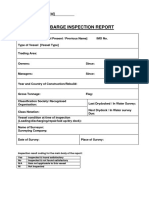

Thai-REC Inspection Report from

Vessel Inspection Report

(BARGE INSPECTION QUESTIONNAIR - GAS)

NAME OF VESSEL:

PORT OF INSPECT:

DATE OF INSPECT:

NAME OF INSPECTOR:

JOB ORDER No. :

Page 1 of 18

Confidential use for Thai-REC Member and Correspondence Owner Only

Thai-REC Inspection Report from

INTRODUCTION THE OCIMF SIRE VESSEL INSPECTION QUESTIONNAIRE GUIDELINES AND REPORT FOR THE INSPECTION OF BULK OIL CARRIER (1ST EDITION 1997) FORMS THE BASIS OF THIS DOCUMENT.

THE INSPECTION GUIDELINES FOR BULK OIL TANKERS HAS BEEN DEVELOPED IN ORDER TO PROVIDE COMPREHENSIVE GUIDANCE ON THE CONDUCT OF INSPECTIONS WITH THE PURPOSE OF PROMOTING TANKER SAFETY AND POLLUTION PREVENTION ON OIL AND GAS TANKERS

THE GUIDELINES HAVE BEEN DEVELOPED PRIMARILY TO ASSIST INSPECTORS TO ASSESS WHETHER A SHIP COMPLIES WITH RELEVANT LEGISLATION AND ACCEPTED INDUSTRY RECOMMENDATION AND PRACTICES IN RESPECT TO OPERATIONAL PROCEDURES.

THE INTENT OF THESE GUIDELINES IS TO HIGHLIGHT IMPORTANT AREAS OF OPERATIONAL SAFETY AND CAPABILITY WHICH ARE OF CONCERN TO OWNERS/ OPERATORS OF TANKERS.

THESE GUIDELINES ARE TO PROMOTE THE DEVELOPMENT OF CONSISTENT AND EFFECTIVE OPERATIONAL PRACTICES OF OIL CARRIERS AND ARE NOT INTENDED TO DEFINE OR DICTATE CRITERIA FOR SHIP SELECTION

IN ACCORDANCE WITH OCIMF RECOMMENDATION, INSPECTIONS MUST BE CARRIED OUT IN FULL KNOWLEDGE OF THE MASTER OR HIS DEPUTY AND WITH HIS COOPERATION . A LIST OF OBSERVATIONS SHOULD BE LEFT WITH THE MASTER UPON COMPLETION OF THE INSPECTION; OPPORTUNITY SHOULD BE GIVEN TO DISCUSS THE OBSERVATIONS RECORDED.

ACCEPTANCE OF A VESSEL FOR CHARTERER USE SHOULD NOT BE INDICATED TO THE MASTER; THE OWNER SHOULD BE GIVEN THE RELEVANT MARINE AND TECHNICAL ADVISORS CONTACT DETAILS FOR ANY MATTERS PERTAINING TO A VESSELS ACCEPTANCE

Page 2 of 18

Confidential use for Thai-REC Member and Correspondence Owner Only

Thai-REC Inspection Report from

CONTENTS

1 2 3 4 5 6 7 8 9

General information Certification and documentation Crew management Navigation Safety management Pollution prevention Structural condition Cargo and ballast systems - Petroleum Mooring

10 Towing and Pushing Vessels 11 Machinery 12 General appearance and condition

Page 3 of 18

Confidential use for Thai-REC Member and Correspondence Owner Only

Thai-REC Inspection Report from

Chapter 1.

1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 1.10 1.11 1.12 1.13 1.14 1.15 1.16 1.17 1.18 1.19 1.20 1.21 1.22 1.23 1.24 1.25 1.26 1.27

General information

Vessel Variant. Is the inspected vessel subject to USA Regulations? Name of Vessel. IMO number. International or Local Registered Number. Official Number or Vessel Identification Number. Date of the inspection. Port of the inspection. Geographic region where the vessel normally trades. Flag. Deadweight. Gross tonnage. Date the vessel was delivered. Name of the Company commissioning the inspection. Name of the inspector. Time the inspector boarded the vessel. Time the inspector departed the vessel. Hull type. Vessel's operation at the time of the inspection. Products being handled. Name of the vessel's Operator. Address of the vessel's Operator. Telephone number. Fax number. Email address. Date the Operator assumed control of the vessel. Does the data entered in the Barge and Tug Particulars Questionnaire appear to be accurate and up to date? Additional Comments:

1.28

Page 4 of 18

Confidential use for Thai-REC Member and Correspondence Owner Only

Thai-REC Inspection Report from

Chapter 2.

Key

Certification and documentation

Vessel Inspection Questionnaire Yes No NS NA

2.1 2.2

2.4

Has the vessel been provided with national or international trading certificates? Has the vessel been provided with Certificate of Registry Has the vessel been provided with DoC Has the vessel been provided with SMC Has the vessel been provided with Safety Equipment Has the vessel been provided with Safety Radio Has the vessel been provided with Safety Construction Has the vessel been provided with Loadline Has the vessel been provided with Ship Security Has the vessel been provided with Minimum Safe Manning Cert Has the vessel been provided with Engine Air Pollution Prevention Has the vessel been provided with Certificate of Fitness for the carriage of chemical? Has the vessel been provided with Certificate of Fitness for the carriage of Gas? Has the vessel been provided with Noxious Liquid Substances Has the vessel been provided with Civil Liability Convention (1992) What is the Name of vessel's P and I Club? Does the vessel possess a US Certificate of Financial Responsibility? What is the USCG Certificate of Compliance date of expiry? Is the vessel Qualship certified? What was the date of the last USCG Certificate of Inspection? Does the vessel carry a USCG Certificate of Documentation? Does the vessel carry a USCG Certificate for Marine Vapour Recovery System? Is the vessel registered with a Classification Society? Which Classification society is the vessel registered with? What is the date of expiry of Class Certificate? What was the date of the last Intermediate Survey? What was the date of the last Annual Survey? What was the date of the last Survey Report or Quarterly Summary? What was the date of the last Special Survey?

2.5 2.6 2.7 2.8 2.12 2.13 2.16 2.18 2.19 2.20 2.21 2.22 2.23 2.24 2.25 2.26 2.27 2.28 2.29 2.30 2.31 2.32 2.33 2.34 2.35 2.36

Page 5 of 18

Confidential use for Thai-REC Member and Correspondence Owner Only

Thai-REC Inspection Report from

2.37 2.38 2.39 2.40 2.42 2.43 2.44 2.45 2.46 2.47 2.48 2.49 2.50

What is the date of the next Special Survey? Is the vessel free of outstanding USCG 835 non-conformities? Is the vessel operating within its certificate renewal dates applicable to dry docking and structure? Is the Loading Record Book complete and up to date? Is the General Arrangement Plan available and legible? Is a Damage Stability Plan on board? What is the interval between scheduled dry-dockings? What was the date of departure from the last scheduled dry-dock? What was the date of last port State control inspection? Was the last port State control inspection report free of non-conformities? If propane gas is used for cooking and/or heating, is the equipment operated outside of a gas-hazardous area; is a certificate provided and is it valid? Has the Operator provided operating policies and procedures, and are these being followed? Additional Comments :

Chapter 3.

Key

Crew management

Vessel Inspection Questionnaire Yes No NS NA

3.2 3.4 3.5 3.6 3.7 3.8 3.9 3.10 3.11

If the vessel has been provided with a Minimum Manning Document (MMD) does the actual manning meet or exceed the MMD requirements? If the vessel is manned, complete the attached crew matrix for all officers and ratings If the vessel is manned, are personnel directly employed by vessel's Operator? Are policies relating to work and rest periods in place and are they being complied with? Does the Operator or the contractor supplying personnel, have a Drug and Alcohol policy that meets or exceeds OCIMF guidelines? What was the date of the last unannounced alcohol test? What is the frequency of unannounced drug testing? What was the date of the last unannounced test for drugs? Additional Comments :

Page 6 of 18

Confidential use for Thai-REC Member and Correspondence Owner Only

Thai-REC Inspection Report from

Chapter 4.

Key

Navigation

Vessel Inspection Questionnaire Yes No NS NA

4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 4.9 4.10 4.11 4.12 4.13 4.14 4.15 4.16 4.17 4.18 4.19 4.20 4.21 4.22 4.23 4.24 4.25 4.26 4.27 4.28 4.29 4.30

Is an up to date Operator's Navigational and Bridge Organization Manual on board that lists the duties of the watchkeeping responsible persons? Are the duties of watch keeping responsible persons and persons in charge clearly defined? If applicable to the type of vessel, is the navigational equipment appropriate and operating satisfactorily? Is an operational magnetic compass with light provided? Is an operational gyro compass with repeaters provided? Is an operational GMDSS provided? Is an operational Global Navigation System receiver (GNS) provided? Is an operational Terrestrial Navigation System receiver (TNS) provided? Is an operational main engine RPM indicator provided? Is an operational 3cm radar provided? Is an operational 10cm radar provided? Is an operational VHF Radio provided? Are operational hand-held radios (walkie talkies) provided? Is an operational search light provided? Are operational sound signals provided? Is an operational depth sounder provided? Is an operational speed and distance indicator provided? Is a rudder angle indicator provided? Is a rate of turn indicator provided? Are operational navigation lights and signals provided? Is an operational single side band (SSB) radio provided? Is an operational Digital Selective Calling (DSC) Communications system fitted? Is an operational ARPA system provided? Is an operational Automatic Identification System (AIS) provided? Is an operational NAVTEX system provided? Is an operational automatic pilot provided? Are appropriate optical signals/daylight shapes provided? Is an operational internal communication system provided? Is an operational general alarm provided? Are operational binoculars provided?

Page 7 of 18

Confidential use for Thai-REC Member and Correspondence Owner Only

Thai-REC Inspection Report from

4.31 4.32 4.33 4.34 4.35 4.36 4.37 4.38 4.39 4.40 4.41

Are local regulations relating to navigation and collision avoidance provided, and are these adequate for the vessel's trading area? Are the navigation charts, light lists, tide tables and pilot books provided, adequate for the vessel's trading area? If an ECDIS system is fitted, is it fully operational and are fully operational backup components provided? Are emergency steering gear changeover instructions posted and are they clearly understood? If a bow or stern thruster is fitted, are operating instructions provided and are the directions of thrust clearly indicated on the operating console? Are the air draughts clearly displayed in the wheelhouse? Are local navigation warnings received on board on a regular basis, and readily available to the navigators? Was a comprehensive passage plan available for the previous voyage and did it cover the full voyage from berth to berth? Are compass errors ascertained each watch when the vessel is operating in open waters? Are the intervals between position fixes appropriate to the vessel's location? Additional Comments :

Chapter 5.

General Safety

Key

Safety management

Vessel Inspection Questionnaire Is the deck area free of visible safety deficiencies? Does the Operator provide adequate personal protection equipment, (PPE) appropriate to the cargo(es) being carried; are instructions for its use provided, and is it being used correctly? Is a Quality Manual (Safety Management Manual) available on board and are personnel familiar with its contents? Are all responsible persons aware of the emergency procedures for dealing with leakage, spillage or fire involving the cargo? Are places where smoking is permitted adequately identified, are smoking regulations being observed, and are doors and other means of access kept closed? Is the IMO Coastal Contact list or local equivalent provided? Is the vessel provided with a safe means of access? Is loose gear on deck or in internal spaces properly secured? Is an operational emergency lighting system provided? Is an operational accommodation gas detection system provided?

Yes

No

NS

NA

5.1 5.2

5.3 5.4 5.5

5.6 5.7 5.8 5.9 5.10

Page 8 of 18

Confidential use for Thai-REC Member and Correspondence Owner Only

Thai-REC Inspection Report from

Fire Fighting Equipment

Key

Vessel Inspection Questionnaire Is an Emergency Plan posted? Is sufficient fire fighting equipment on board, including hoses, nozzles, firemen's outfits, breathing apparatus and portable extinguishers and is it in satisfactory condition, and ready for immediate use? If fitted, are fixed fire, smoke and gas detection systems and emergency systems fully operational, tested, and are the inspection records up to date? If a fixed fire fighting system is installed, is it in satisfactory condition? If fitted, is the type of foam compound suitable for the cargoes which the vessel is certified to carry? Do records and personnel demonstrate effective fire fighting and safety training and competence? Is the vessel provided with a deck water spray system? Is an operational General Alarm system provided? Is the emergency stop for the accommodation ventilation system clearly marked?

Yes

No

NS

NA

5.11 5.12

5.13 5.14 5.15 5.16 5.17 5.18 5.19

Lifesaving Equipment

Key

Vessel Inspection Questionnaire Is all required lifesaving equipment on board; is it in satisfactory condition and ready for immediate use and are personnel familiar with its operation? Are survival suits provided for all personnel? Are safety ropes and equipment available to effectively undertake rescue from enclosed spaces? Are emergency escape sets provided for every person on board where required?

Yes

No

NS

NA

5.20 5.21 5.22 5.23

Operational Safety

Key

Vessel Inspection Questionnaire Are Material Data Safety Sheets (MSDS) provided specifically for the cargoes being carried and are they posted? Are all personnel aware of the emergency procedures for dealing with leakage, spillage or fire involving the cargo? If appropriate to the cargoes carried, are gas-tight proximity suits or chemical resistance suits available and in satisfactory condition? Are dangerous cargo signals (red flag or red light) displayed? Are procedures in place to respond to a breakout from the berth during cargo operations? Are procedures in place to keep the accommodation space free of gas? Are procedures in place to respond to the development of dangerous concentrations of gas? Are procedures in place to respond to a burst cargo hose or cargo pipeline fracture? Are procedures in place to respond to a cargo tank overflow?

Page 9 of 18

Yes

No

NS

NA

5.24 5.25 2.27 5.29 5.30 5.31 5.32 5.33 5.34

Confidential use for Thai-REC Member and Correspondence Owner Only

Thai-REC Inspection Report from

5.35 5.36 5.37 5.38 5.39 5.40 5.41 5.42 5.43 5.44 5.45 5.46 5.47 5.48 5.49 5.50 5.51 5.52

Are procedures in place to respond to cargo leakage into an adjoining space? Are procedures in place to respond to a failure of the steering gear? Are procedures in place to respond to collision or grounding that results in pollution? Are procedures in place to respond to situations that involve the jettisoning of cargo? Are procedures in place to respond to incident involving nitrogen? Are procedures in place to ensure that oxygen levels are safety controlled during nitrogen purging? Are procedures in place to ensure that self reacting products are handle safely? If a pump room is installed, does it meet controlling international, national and local regulations? Are the cargo pumps fitted with emergency stops and are these tested regularly? Are the maximum cargo pumps operating temperatures displayed at the cargo control position? Are means provided for the testing of void spaces for explosive and/or toxic gases? Do personnel demonstrate familiarity with the operation and calibration of portable gas detection instruments? Are emergency eye bath, sprays and decontamination showers available and in satisfactory condition? At what frequency do personnel undergo medical examinations? Are emergency first aid kits available? When unfamiliar cargo is to be carried, is there a procedure to review the safety aspects and handling procedures? Are satisfactory safety procedures provided for cargo transfer, entering pump rooms, cargo tanks, enclosed and other dangerous spaces, and for hot work? If the vessel is certified to carry benzene, are warning signs posted and is the restricted zone marked? Vessel Inspection Questionnaire Do the responsible persons understand the dangers associated with cleaning tanks that have previously contained toxic products? Are the dangers associated with tank cleaning clearly understood? Are cargo tank atmospheres controlled during tank cleaning? Are deck atmospheres regularly monitored for gas accumulations during cargo transfer and tank cleaning operations? If COW is being conducted, is it in accordance with the procedures described in an approved Crude Oil Washing Equipment and Operations Manual? Are any hydrant-type connections to the Crude oil washing lines securely closed and capped? If fitted, are outside air conditioning units type-approved for use in gashazardous areas? Vessel Inspection Questionnaire Yes No NS NA Yes No NS NA

Tank Cleaning Safety

Key

5.53 5.54 5.55 5.56 5.57 5.58 5.59

Vessel Security

Key

Page 10 of 18

Confidential use for Thai-REC Member and Correspondence Owner Only

Thai-REC Inspection Report from

5.60 5.61 5.62

Has the vessel been issued with an approved Ship Security Plan? Are measures in place to prevent unauthorized boarding? Additional Comments :

Chapter 6.

Key

Pollution prevention

Vessel Inspection Questionnaire Yes No NS NA

6.1 6.2 6.3 6.4 6.5 6.6 6.7 6.8 6.9 6.10 6.11 6.12 6.13 6.14 6.16 6.17 6.18 6.19 6.20 6.21

Is the vessel provided with Oil Record Books? Is an approved MARPOL Shipboard Oil Pollution Emergency Plan (SOPEP) or Shipboard Marine Pollution Emergency Plan (SMPEP) provided? Is the vessel provided with a USCG approved Vessel Response Plan (VRP)? Is suitable equipment provided to deal with small oil spills? Are anti-pollution notices posted? Are bulkheads, pipelines and the hull, free of visible leaks? If fitted, are hydraulic lines on deck free of visible leaks? Is a perimeter spill rail fitted; are scuppers in place and are they liquid tight? Are all the cargo manifolds provided with spill trays? Are all hose connections and manifold blank flanges fully bolted? Are spill savealls installed around bunker and diesel tank vents? Are decks free of oily material? If so required, is the vessel provided with a containment boom? If fitted, are tank side overboard discharge valves lashed or sealed in the fully closed position? Are bilge water and cargo slops handled in accordance with MARPOL or in accordance with the requirements of the local authorities? Is the engine space free of unauthorised overboard discharges and any evidence that unlawful oil discharge has taken place? Are receipts maintained for each disposal of garbage? Are sampling connections, valves, caps or plugs properly secured to pipeline drains and vents? Are sampling connections, valves, caps or plugs in satisfactory condition? Additional Comments :

Page 11 of 18

Confidential use for Thai-REC Member and Correspondence Owner Only

Thai-REC Inspection Report from

Chapter 7.

Key

Structural condition

Vessel Inspection Questionnaire Yes No NS NA

7.1 7.2 7.3 7.4

If the vessel is enrolled in a structural survey programme, are records available? If structural survey records are available, do they record that the hull thickness measurements are within acceptable limits? Are records available to indicate regular inspection and testing of tank coatings and/or stainless steel tanks? Additional Comments :

Chapter 8.

Cargo and ballast systems - Petroleum

General Cargo Handling

Key

Vessel Inspection Questionnaire Is the vessel provided with company policy statements, instructions and procedures with regard to safe cargo operations? Has a Ship/Shore Safety Check List (SSSCL) been properly completed and have those items that require reinspection, been inspected at the appropriate intervals? Have written loading, discharge or ballast transfer plans, as appropriate, been prepared for the current operations? Are legible and up to date pipeline and/or mimic diagrams of the cargo system, inert gas system and venting system available in the cargo control position? Is information readily available to the responsible persons relating to maximum loading rates and venting capacities? Are cargoes being carried listed on the Certificate of fitness? Is there a Procedures and Arrangements manual available? Are the responsible persons familiar with the carriage requirements for the cargoes on board and chemicals in general? If cargoes being carried are not listed ion the Certificate of Fitness, are these cargoes loaded with the approved of a competent authority? Are safe and effective procedures in place for the effective stripping (final draining) of tanks at the end of cargo discharge? Are safe and effective procedures in place for changing cargo grades? Are safe and effective procedures in place for ballasting and de-ballasting? Are safe and effective procedures in place for Ship to Ship (STS) cargo transfer operations? If fitted, is the general condition of the cargo tank heating system satisfactory? Are safe and effective procedures in place for gas freeing? As applicable, are cargo pumps, booster pumps, ballast pumps and stripping pumps, eductors and their associated instrumentation and controls in satisfactory operational condition, free of leaks and is there evidence of regular testing?

Page 12 of 18

Yes

No

NS

NA

8.1 8.2

8.3 8.5 8.6 8.8 8.9 8.10 8.11 8.13 8.14 8.15 8.16 8.17 8.18 8.19

Confidential use for Thai-REC Member and Correspondence Owner Only

Thai-REC Inspection Report from

8.20 8.22 8.23 8.24 8.25 8.26

Have satisfactory column/cofferdam purging routines been established where deep well pumps are fitted? If fitted, is the Emergency Shut-Down (ESD) System fully operational? Are powered valves set to closed within 20-30 seconds? Is an emergency discharge method available? If so required, are static electricity precautions being observed? If the vessel is equipped with derricks or hose handling booms, are they in satisfactory condition, marked with Safe Working Load (SWL) and are they regularly tested? Are cargo pipelines in satisfactory condition? If multiple cargoes are being handled, are signs placed at each cargo manifold, identifying the grade of cargo? Are cargo pipelines free of soft patches or other temporary repairs? Are cargo pipelines tested annually to 1.5 times their normal working pressure and are the results recorded? If the vessel uses its own cargo hoses, are they in good order, pressure tested annually to their design working pressure, and is a record of all hose tests and inspections maintained on board? Is cargo system, including fitting on the tank domes, free of leaks? If refrigerated cargoes are carried, is a means of hydrate control provided, and is a supply of freezing depressant maintained onboard? Where fitted, is cargo tank insulation reported to be in good condition? Are submerged electrical cargo pumps, if fitted, isolated from their electrical supply during gas-freeing operations? Are sample lines for both liquid and vapour provided and are they fitted valves and caps? Is low temperature pipework adequately from the hull structure? If cargo or vapour lines are insulated, is the insulation in a satisfactory condition? Where cargo or vapour lines are isolated from the structure, are joints electrically bonded? Are cargo and vapour line expansion arrangements in a satisfactory condition? Are liquid and vapour lines free to move inside their clamps? Are pipeline drains fitted with valves and caps, and in a satisfactory condition? Are relief valves fitted to the cargo pipeline system in a satisfactory condition? Are manifolds properly supported? If cargo segregations using blank flanges are fitted, are the flanges fully bolted? Are the correct product-related packings and gaskets used for every cargo transfer? Are the valves serving the cargo and ballast system in satisfactory operational condition? Is the vessel free from unauthorised connections between the bunker, ballast and cargo systems?

8.27 8.28 8.29 8.30 8.31

8.32 8.33 8.34 8.35 8.36 8.37 8.38 8.39 8.40 8.41 8.42 8.43 8.44 8.45 8.46 8.47 8.48

Page 13 of 18

Confidential use for Thai-REC Member and Correspondence Owner Only

Thai-REC Inspection Report from

8.49 8.50 8.51 8.52 8.53 8.54 8.55 8.56

Are the cargo pumps fitted with temperature sensors? Are operational pressure gauges fitted at the cargo manifolds outboard of the manifold valves on both onshore and offshore sides? Are remote and local, temperature and pressure sensors and gauges in satisfactory operational condition? Are satisfactory records maintained of the calibration of key cargo instrumentation, including temperature and pressure gauges? Is the cargo conditioning (reliquefaction) plant and associated machinery and instrumentation in good order? Is the compressure room well lit; and the light fittings suitable for use in gashazardous area and are they in a satisfactory condition? Is a motor room access system maintaining a positive pressure and is it operating satisfactorily? If motor room access is located in a gas-hazardous area, is it provided with airlock suitably alarmed to warn if both doors are opened at the same time?

Cargo Compressure and Motor Rooms

Key

Vessel Inspection Questionnaire Is the gas detection equipment in a satisfactory condition? Are fixed gas detection sample points fitted at the appropriated levels for cargo being carried?

Are cargo compressors isolated from cargo when carrying Propylene Oxide?

Yes

No

NS

NA

8.57 8.58 8.59 8.60 8.61

Key

Are void space seals, where fitted, in a satisfactory condition? Is the environmental control of void spaces satisfactory? Vessel Inspection Questionnaire Is the oxygen and hydrocarbon content of the interbarrier spaces regularly monitored and are the results recorded? Is the interbarrier space nitrogen purging system in good order? Is the pressure in the interbarrier space being maintained at sufficient level to prevent ingress from external atmosphere? Are relief valves for the hold space and primary and secondary barrier in satisfactory condition? If a cargo heating system is fitted and is in use at the time of the inspection, is it properly insulated, in a satisfactory operational condition and free of leaks? If diesel engines are installed on the open deck, are these certificated and approved by a recognised authority and situated outside the gas-hazardous area? Are tank access openings, flame screens and standpipes in satisfactory condition? Vessel Inspection Questionnaire Are tank calibration tables available and approved by a recognised authority? Are cargo tank and/or other gauging points clearly identified? Yes No NS NA Yes No NS NA

Void and Interbarrier space and seals-other cargo tank types 8.63 8.64 8.65 8.66 8.67 8.68

8.69

Cargo Measurement

Key

8.70 8.71

Page 14 of 18

Confidential use for Thai-REC Member and Correspondence Owner Only

Thai-REC Inspection Report from

8.72 8.73 8.74 8.75 8.76 8.77 8.78 8.79 8.80 8.81 8.82 8.83 8.84 8.85

If fixed cargo level measuring equipment is fitted, is it operational, certified and regularly calibrated? Last Calibration Are cargo tanks provided with an overfill protection system (High Level Alarms) and is the system fully operational? Is the cargo high level alarm system operated during both loading and discharging? Is the cargo tank overfill alarm system independent of both the gauging devices and the high-level alarm system? Are bunker tanks provided with an overfill protection system (High Level Alarms) and is the system fully operational? Are personnel aware of the relationship between tank filling limits and cargo temperature? Are portable measuring tapes and/or sticks available? If fixed tank gauges are not fitted, are sufficient portable tapes provided to simultaneously gauge each tank being worked? Are vapour locks, if fitted, calibrated and certified by a competent authority? If slip tubes are fitted, are they used only in emergencies? Is a reference thermometer carried and is its certificate valid? If a flow meter is fitted, is it operational and calibrated in accordance with the requirements of the approving autrhority? Are records kept of the calibration of key cargo instrumentation, including temperature and pressure gauges? Is the responsible person in charge familiar with the term reference temperature and it been determined for this cargo?

Venting and Inert Gas Systems

Key

Vessel Inspection Questionnaire If the vessel is fitted with a cargo venting system, is it in a satisfactory operational condition? Is the vessel capable of operating in a closed condition if volatile or toxic products are handled, including ullaging and sampling? If the vessel is handling volatile or toxic cargoes, is it operating in a closed condition at the time of the inspection? Are the P/V valves in good order, fitted with flame screens, inspected and cleaned as part of a regular maintenance routine, and are there records to support this? If cargo tank inlet valves are fitted which permit the isolation of individual tanks from the venting system, are these provided with positive locking arrangements and are the keys under the control of a responsible person? Is the venting system provided with full-flow secondary means of cargo tank protection against over, or under-pressurisation in the event of accidental closure of the inlet valve? If an inert gas system is fitted are its components in a satisfactory condition? If the inert gas system is in use, is it operating satisfactorily?

Yes

No

NS

NA

8.86 8.87 8.88 8.89

8.90

8.91

8.92 8.93

Page 15 of 18

Confidential use for Thai-REC Member and Correspondence Owner Only

Thai-REC Inspection Report from

8.94 8.95 8.96 8.97

If fitted, are nitrogen cylinders and associated pipework in a satisfactory condition? If the vessel is equipped with a vapour-return system, is it operational and are personnel trained in its use? Do tank hatches, tank cleaning apertures and sighting ports appear to be liquid and gas tight? Additional Comments

Chapter 9.

Key

Mooring

Vessel Inspection Questionnaire Yes No NS NA

9.1 9.2 9.3 9.4 9.5 9.7 9.8 9.9

Is the vessel effectively moored? Are pedestal fairleads, roller fairleads, and other mooring system rollers well greased and free to turn, and are bitts and chocks free of grooving? Are auxiliary mooring equipment, rollers, chocks and fairleads in a satisfactory condition? Are the winches that are employed for mooring in a satisfactory condition? Do personnel demonstrate evidence of being properly trained to moor the vessel correctly? Are the mooring lines in satisfactory condition? If synthetic tails are used in conjunction with wires, are they in satisfactory condition and is a suitable joining shackle used between the wire and the tail? If fitted, are windlasses, anchors, locking bars and cables in satisfactory condition and operating effectively?

Chapter 10.

Towing and Pushing Vessels

Chapter 11.

Key

Machinery

Vessel Inspection Questionnaire Yes No NS NA

11.1 11.2 11.3 11.4 11.5 11.6 11.7

Is the general cleanliness and housekeeping in the engine space satisfactory? Is a planned maintenance system being followed, and is it up to date? Is the machinery space free from visible safety deficiencies? Are all electrical wiring and plugs intrinsically safe and megger tested regularly? Is the engine space adequately lit? If the vessel is provided with an emergency diesel generator, is it in satisfactory operational condition? Is the main engine machinery space equipment in a satisfactory operational condition?

Page 16 of 18

Confidential use for Thai-REC Member and Correspondence Owner Only

Thai-REC Inspection Report from

11.8 11.9 11.10 11.11 11.12 11.13 11.14

Are the emergency main fuel stops prominently marked and operational? Are the boiler fuel emergency stops operational? If fitted, are the batteries in satisfactory condition? Is the fire pump in satisfactory condition and operational? Last Test : Are safety devices and alarms operational? Last Test : Are bilge alarms operational? Last Test : If fitted, are the pump room gas detection systems operational? Last Test :

11.15 11.16 11.17 11.18 11.19 11.20 11.21 11.22 11.23 11.24 11.25 11.26 11.27 11.28 11.29 11.30 11.31 11.32 11.33 11.34

Are the pumproom ventilation fans shut-down arrangements operational? Is the emergency steering gear operational? Last Test : Is the engine room alarm operational? Last Test : Is the engine room instrumentation in satisfactory operation condition? If a fixed engine room fire extinguishing system is fitted, is it in satisfactory operational condition? Is all moving machinery provided with effective guards where this presents a hazard? Are hazard/warning notices posted? Are the emergency escape exits clearly marked, unobstructed and adequately lit? Are fuel oil tanks, slop tanks and drums clearly labeled? Are flammable/combustible materials properly stored? Are bilges clean and free of excessive oil waste? Is the oily water separator arrangement and overboard discharge operated correctly? Is electrical wiring and equipment approved for intended service and free from exposed electrical shock hazards? Is the condition of the steering compartment satisfactory? Is the operation of the steering equipment satisfactory? Do the engine room and steering room control systems appear to be satisfactory? Is the engine room emergency equipment in fully operational condition and are operating instructions clearly displayed? Is the electrical power supply adequate? If fitted, do emergency generators have two independent means of starting? Are the fire main, fire pump, and sea chest valves clearly marked and labelled?

Page 17 of 18

Confidential use for Thai-REC Member and Correspondence Owner Only

Thai-REC Inspection Report from

Chapter 12.

Key

General appearance and condition

Vessel Inspection Questionnaire Yes No NS NA

12.1 12.2 12.3 12.4 12.5 12.6 12.7 12.8

Is the general condition and cleanliness of the hull satisfactory? If permanent fendering is fitted is it is a satisfactory condition? Does the structural appearance and cleanliness of the weather deck appear to be satisfactory? Is the general condition of service pipework satisfactory, is it free from significant corrosion, pitting, soft patches or other temporary repairs? Does the overall appearance of the superstructure appear to be satisfactory? Does the internal appearance of the superstructure appear to be satisfactory? Does the internal appearance of the machinery compartment appear to be satisfactory? Additional Comments :

Page 18 of 18

Confidential use for Thai-REC Member and Correspondence Owner Only

S-ar putea să vă placă și

- Survey Checklist ANCODocument23 paginiSurvey Checklist ANCOkonstadine100% (1)

- Bulk Carrier - General Cargo - Container Vessel Survey Report R1.3 FullDocument27 paginiBulk Carrier - General Cargo - Container Vessel Survey Report R1.3 FullKurupath SidharthanÎncă nu există evaluări

- SIRE Inspection Preparation Document BLANKDocument5 paginiSIRE Inspection Preparation Document BLANKhmmbacon100% (1)

- Docking Survey Checklist: Name of The Ship: IR. Number: Port of Registry: Report No.Document3 paginiDocking Survey Checklist: Name of The Ship: IR. Number: Port of Registry: Report No.capone55Încă nu există evaluări

- East of England Management Ltd. vessel condition survey reportDocument55 paginiEast of England Management Ltd. vessel condition survey reportThan Htet100% (1)

- OPS 01 - Fleet Superintendent's Onboard Meeting ChecklistDocument3 paginiOPS 01 - Fleet Superintendent's Onboard Meeting ChecklistEmre AlgülÎncă nu există evaluări

- Vessel InspectionDocument19 paginiVessel Inspectionmega10612014100% (1)

- Report Part A Container Sample 1 - CompressedDocument22 paginiReport Part A Container Sample 1 - CompressedMohamed OmarÎncă nu există evaluări

- Ship Initial Inspection Checklist: Port State ControlDocument34 paginiShip Initial Inspection Checklist: Port State ControlBHASKAR HALDAR100% (1)

- Sample Vessel Condition ReportDocument15 paginiSample Vessel Condition ReportredchaozÎncă nu există evaluări

- Samplesurvey SailDocument14 paginiSamplesurvey SailSoldatos AthanasiosÎncă nu există evaluări

- Good Maintenance On Board ShipsDocument54 paginiGood Maintenance On Board ShipssivanandrayÎncă nu există evaluări

- Report On The Surveys Concerning International Oil Pollution Prevention CertificateDocument3 paginiReport On The Surveys Concerning International Oil Pollution Prevention CertificateSUNILÎncă nu există evaluări

- Dana de Mer Pre Purchase Survey ReportDocument20 paginiDana de Mer Pre Purchase Survey ReportSteve HartÎncă nu există evaluări

- Ship Inspection ReportDocument30 paginiShip Inspection ReportKervin YnquillaÎncă nu există evaluări

- Tanker Inspection Report SummaryDocument15 paginiTanker Inspection Report SummaryMalik Badi Uz Zaman100% (1)

- DKT0/2020/J5110: Ships in Service Survey ReportDocument26 paginiDKT0/2020/J5110: Ships in Service Survey ReportLeonidas Galanis100% (1)

- Guide To Vetting Proceed 2017 - Part71 PDFDocument2 paginiGuide To Vetting Proceed 2017 - Part71 PDFQuang Hòa LưuÎncă nu există evaluări

- Pre-Purchase Report - CiucioloDocument26 paginiPre-Purchase Report - CiucioloCESAR VIECNTEÎncă nu există evaluări

- Sire InspectionDocument8 paginiSire InspectionAnil yucebasÎncă nu există evaluări

- Bulk Carrier Condition Survey ReportDocument33 paginiBulk Carrier Condition Survey Reportalxgam100% (1)

- FG-18 Report of Sea Trial 200-215) PDFDocument16 paginiFG-18 Report of Sea Trial 200-215) PDFvran77Încă nu există evaluări

- Survey ChecklistDocument17 paginiSurvey ChecklistSamuel Blandes Rwegasira100% (1)

- Detainable and ISM Related Deficiencies PSC Inspection Report of Class NK & NK-SMC Ships in June 2015Document9 paginiDetainable and ISM Related Deficiencies PSC Inspection Report of Class NK & NK-SMC Ships in June 2015Btwins123100% (1)

- Marine SurveyorsDocument1 paginăMarine SurveyorsNick SmithÎncă nu există evaluări

- Ship Inspection FormDocument67 paginiShip Inspection Formitavsa100% (3)

- CDI 9th Edition SIR Consolidated Gas - Amendments June 2020Document5 paginiCDI 9th Edition SIR Consolidated Gas - Amendments June 2020AlexandrosÎncă nu există evaluări

- Hull Inspection Book: United States Coast GuardDocument26 paginiHull Inspection Book: United States Coast Guardnapoleonpt2Încă nu există evaluări

- Preparation For Dry Docking: (As A Chief Engineer) : 27 February 2012 at 11:40Document6 paginiPreparation For Dry Docking: (As A Chief Engineer) : 27 February 2012 at 11:40Swopon ShahjahanÎncă nu există evaluări

- Sample Offshore Vessel: Inspected at Cardiff, United Kingdom & Northern Ireland 1 JANUARY 2018Document56 paginiSample Offshore Vessel: Inspected at Cardiff, United Kingdom & Northern Ireland 1 JANUARY 2018seluarbolaÎncă nu există evaluări

- General Survey Report PDFDocument20 paginiGeneral Survey Report PDFEmmÎncă nu există evaluări

- Australian Government Ship Inspection ChecklistDocument34 paginiAustralian Government Ship Inspection ChecklistConrad ManacapÎncă nu există evaluări

- Valuing Marine Vessels and EquipmentDocument41 paginiValuing Marine Vessels and EquipmentReza Babakhani100% (1)

- DNV Machinery CM Guidance 2008Document13 paginiDNV Machinery CM Guidance 2008Andre100% (1)

- AMSA Ship Initial Inspection ChecklistDocument13 paginiAMSA Ship Initial Inspection ChecklistKEITH DESOUZA100% (1)

- Ship InspectionDocument3 paginiShip Inspectionseamaniac100% (1)

- Ship Inspection Form F P - R: 1. G I / S DDocument6 paginiShip Inspection Form F P - R: 1. G I / S DRonachai FuangfoongÎncă nu există evaluări

- Maintenance Checklists for Vietnamese ShipsDocument75 paginiMaintenance Checklists for Vietnamese ShipsphongantoanÎncă nu există evaluări

- Condition Survey SERSOU at Bejaia Road On 21 03 2012Document30 paginiCondition Survey SERSOU at Bejaia Road On 21 03 2012Adrian West100% (1)

- Ism - Internal Inspection ChecklistDocument16 paginiIsm - Internal Inspection Checklistsenayudha123100% (2)

- Ship Risk Review 2021 Ver 6Document37 paginiShip Risk Review 2021 Ver 6KEISHIN ISO100% (1)

- OPS 02 - Pre-Visit Checklist For SuperintendentsDocument6 paginiOPS 02 - Pre-Visit Checklist For SuperintendentsEmre AlgülÎncă nu există evaluări

- Hull & Machinery Survey Report - MV FRI SKY - Damage To Auxiliary Engine Ref. 471-S-2020Document15 paginiHull & Machinery Survey Report - MV FRI SKY - Damage To Auxiliary Engine Ref. 471-S-2020JackÎncă nu există evaluări

- Short Condition Survey Report-2012-1Document7 paginiShort Condition Survey Report-2012-1alive2flirtÎncă nu există evaluări

- Ship Registration Requirements and Flag State ResponsibilitiesDocument15 paginiShip Registration Requirements and Flag State Responsibilitiesrider_382150% (2)

- Tanker Condition Survey ReportDocument35 paginiTanker Condition Survey ReportHashem Gam60% (5)

- Crew Boat Table Provides Vessel DetailsDocument4 paginiCrew Boat Table Provides Vessel DetailsVICTORÎncă nu există evaluări

- DNV - CAP - Tanker GuidelinesDocument27 paginiDNV - CAP - Tanker GuidelinesAnonymous 7z6OzoÎncă nu există evaluări

- Annual, Docking, Intermediate SurveyDocument29 paginiAnnual, Docking, Intermediate SurveyAjay SinghÎncă nu există evaluări

- Ship inspection report summaryDocument28 paginiShip inspection report summaryJavier Rayleigh100% (2)

- SurveysDocument3 paginiSurveysAndy James Roberts100% (1)

- Tug and Barge Survey ReportDocument14 paginiTug and Barge Survey Reportchepurthi100% (1)

- Dynamic positioning The Ultimate Step-By-Step GuideDe la EverandDynamic positioning The Ultimate Step-By-Step GuideÎncă nu există evaluări

- Commercial Ship Surveying: On/Off Hire Condition Surveys and Bunker SurveysDe la EverandCommercial Ship Surveying: On/Off Hire Condition Surveys and Bunker SurveysEvaluare: 4.5 din 5 stele4.5/5 (6)

- ExxonMobil VPQ Review Form1Document27 paginiExxonMobil VPQ Review Form1qualiman1Încă nu există evaluări

- Chapter 1. General InformationDocument33 paginiChapter 1. General InformationaliÎncă nu există evaluări

- Annexure-4 Checklist For The General Inspection of Indian Flag VesselsDocument13 paginiAnnexure-4 Checklist For The General Inspection of Indian Flag VesselsveronicaÎncă nu există evaluări

- FSI Checklist (May 2011)Document13 paginiFSI Checklist (May 2011)Arun Mishra67% (3)

- Offshore Helideck Review ChecklistDocument24 paginiOffshore Helideck Review ChecklistKelvin100% (1)

- United States Army Field Manuals FM 55-17 Army CargoDocument440 paginiUnited States Army Field Manuals FM 55-17 Army CargoChristophe CaronÎncă nu există evaluări

- Good Practice: Galley Fire HazardsDocument1 paginăGood Practice: Galley Fire Hazardsเปีย วันชัย สวนทองÎncă nu există evaluări

- Aid To NavigationDocument256 paginiAid To Navigationsuanthong100% (2)

- Calculation & Assignment of FreeboardDocument26 paginiCalculation & Assignment of Freeboardapi-26251207100% (7)

- Good Practice: Engine Room Emergency ExitsDocument1 paginăGood Practice: Engine Room Emergency Exitsเปีย วันชัย สวนทองÎncă nu există evaluări

- Good Practice: Hold Access LidsDocument1 paginăGood Practice: Hold Access Lidsเปีย วันชัย สวนทองÎncă nu există evaluări

- Life Saving Equipment & Fire Control Marks ListDocument1 paginăLife Saving Equipment & Fire Control Marks Listเปีย วันชัย สวนทองÎncă nu există evaluări

- Q88 Version 5-Oil PDFDocument8 paginiQ88 Version 5-Oil PDFเปีย วันชัย สวนทอง100% (1)

- Deutz China TD226B 4DDocument3 paginiDeutz China TD226B 4Dเปีย วันชัย สวนทอง100% (2)

- Good Practice: Admiralty CorrectionsDocument1 paginăGood Practice: Admiralty Correctionsเปีย วันชัย สวนทองÎncă nu există evaluări

- Poster 84Document1 paginăPoster 84เปีย วันชัย สวนทองÎncă nu există evaluări

- SOLAS Training ManualDocument147 paginiSOLAS Training Manualเปีย วันชัย สวนทอง100% (1)

- Annex V Discharge Requirements 01-2013Document1 paginăAnnex V Discharge Requirements 01-2013JJK112Încă nu există evaluări

- Toka Gas Instruction Ts 303Document1 paginăToka Gas Instruction Ts 303เปีย วันชัย สวนทองÎncă nu există evaluări

- Record MaintenanceDocument1 paginăRecord Maintenanceเปีย วันชัย สวนทองÎncă nu există evaluări

- Class NK Good Maintenance Onboard ShipsDocument74 paginiClass NK Good Maintenance Onboard Shipsiacovosf836100% (2)

- Section 19 Summary of Minimum Requirements: GuidanceDocument5 paginiSection 19 Summary of Minimum Requirements: Guidanceเปีย วันชัย สวนทองÎncă nu există evaluări

- Aid To NavigationDocument256 paginiAid To Navigationsuanthong100% (2)

- Service Manual For Vertu Inverter SeriesDocument58 paginiService Manual For Vertu Inverter Seriescmorley5057Încă nu există evaluări

- Proof Pressure Test Leak Detection Test PDFDocument2 paginiProof Pressure Test Leak Detection Test PDFDan Nicole DadivasÎncă nu există evaluări

- PNAE G-7-019-89Document57 paginiPNAE G-7-019-89ASME TURKEYÎncă nu există evaluări

- Requalification of LPG Tanks in Europe Verifying The Structural Integrity by Monitoring The Pressure Test With Acoustic EmissionDocument8 paginiRequalification of LPG Tanks in Europe Verifying The Structural Integrity by Monitoring The Pressure Test With Acoustic EmissionDavid RodriguesÎncă nu există evaluări

- Vapor Cycle Air Conditioning System TR-134 SMDocument33 paginiVapor Cycle Air Conditioning System TR-134 SMDavid BondÎncă nu există evaluări

- EV Battery Innovation SAEDocument30 paginiEV Battery Innovation SAEολγαÎncă nu există evaluări

- Pulsa Series 680 IomDocument26 paginiPulsa Series 680 IomAgung Pramu AjiÎncă nu există evaluări

- Pneumatic Actuator Assembly and Maintenance ProceduresDocument22 paginiPneumatic Actuator Assembly and Maintenance ProceduresAgustina De WinneÎncă nu există evaluări

- 820 825 850DigitalMeter ManualDocument12 pagini820 825 850DigitalMeter Manualtiualbert8729Încă nu există evaluări

- Eaton Fro 15210c TransDocument194 paginiEaton Fro 15210c Transsonicbluel83% (6)

- Reactive Report 04-02-22Document39 paginiReactive Report 04-02-22abisankar333Încă nu există evaluări

- Compressed Gas Cylinders and Related SystemsDocument26 paginiCompressed Gas Cylinders and Related SystemsPassmore DubeÎncă nu există evaluări

- Procedure - Hot TappingDocument6 paginiProcedure - Hot Tappingmanimaran_ratnam100% (4)

- Mechanical Seal PresentationDocument48 paginiMechanical Seal Presentationsathesh100% (6)

- Reac Inspection ChecklistDocument7 paginiReac Inspection Checklistmsr510Încă nu există evaluări

- RCFA-2023-CPF1-COR-001 ( " Outlet Line From Reverse Demulsifier) (SK-11680) (25-2-23)Document3 paginiRCFA-2023-CPF1-COR-001 ( " Outlet Line From Reverse Demulsifier) (SK-11680) (25-2-23)Vignesh PanchabakesanÎncă nu există evaluări

- Install, operate and maintain Hopkinsons swing check valveDocument7 paginiInstall, operate and maintain Hopkinsons swing check valveGiorgiana RosuÎncă nu există evaluări

- Skid Steer Loader Inspection Report (OUT)Document4 paginiSkid Steer Loader Inspection Report (OUT)Bishoo ShenoudaÎncă nu există evaluări

- O-Ring Kit: Hitachi Select PartsDocument2 paginiO-Ring Kit: Hitachi Select PartsAnonymous q5GsFpazI100% (1)

- Aseptic ProcessingDocument63 paginiAseptic ProcessingAmir Ilyas100% (1)

- Basic Pre Commissioning and Commissioning Safety 220826 082857Document32 paginiBasic Pre Commissioning and Commissioning Safety 220826 082857İlyas FeyziyevÎncă nu există evaluări

- 11.1 Maintenance and InspectionDocument6 pagini11.1 Maintenance and InspectionNguyễn PhúÎncă nu există evaluări

- 3dd028-N12-Api 6fa Fire Safe Test Procedure For High and Low Pressure Ball ValvesDocument7 pagini3dd028-N12-Api 6fa Fire Safe Test Procedure For High and Low Pressure Ball ValvesPrathik Yeresh ReddyÎncă nu există evaluări

- FAT ProcedureDocument7 paginiFAT ProcedureOlek TybińskiÎncă nu există evaluări

- Performing Leak TestingDocument12 paginiPerforming Leak TestingKhaleesi LunÎncă nu există evaluări

- Modelos Compressor LG PDFDocument29 paginiModelos Compressor LG PDFjoelÎncă nu există evaluări

- 8' MPV User's Manual For Side Port PDFDocument20 pagini8' MPV User's Manual For Side Port PDFdavibrenoÎncă nu există evaluări

- GROUP 2 CHECKS AND TROUBLESHOOTINGDocument8 paginiGROUP 2 CHECKS AND TROUBLESHOOTINGthierrylindoÎncă nu există evaluări

- PS Power Steering PS Power Steering: G Steering G SteeringDocument32 paginiPS Power Steering PS Power Steering: G Steering G Steeringscott glackenÎncă nu există evaluări

- ManifoldCatalogJune02pt1 PGIDocument37 paginiManifoldCatalogJune02pt1 PGIManuel GerardoÎncă nu există evaluări