Documente Academic

Documente Profesional

Documente Cultură

Synthesis and Structural Properties of MG (OH) 2 On RF Sputtered MG Thin Films by Simple Hot Water Process Method

Încărcat de

IJASCSETitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Synthesis and Structural Properties of MG (OH) 2 On RF Sputtered MG Thin Films by Simple Hot Water Process Method

Încărcat de

IJASCSEDrepturi de autor:

Formate disponibile

DEC.

31

IJASCSE, VOL 1, ISSUE 4, 2012

Synthesis and structural properties of Mg (OH)2 on RF sputtered Mg thin films by simple hot water process method

S.Shanmugan, P.Anithambigai, D.Mutharasu

Nano Optoelectronics Research Laboratory, School of Physics, University Sains Malaysia, 11800 Minden, Penang, Malaysia

I. Abdul Razak

X-ray Crystallography Group,

School of Physics, University Sains Malaysia, 11800 Minden, Penang, Malaysia

Abstract - Mg thin films were prepared on commercial

glass substrate by RF sputtering and processed in highly pure hot water at 95 C. Various process time were used to study the growth behavior of Mg (OH)2 phases. Thin films processed at above 4 hrs duration showed the growth of preferred (001) oriented Mg (OH)2 phase. The observed XRD spectra also showed the changes on structural properties of processed Mg thin films. The nano (< 12 nm) size crystals were observed in the processed samples. The properties of Mg phase influenced by tensile stress due to Mg (OH)2 growth. FTIR spectra also evidenced the formation of Mg (OH)2 over the Mg thin film by hot water process. AFM images revealed the dense nature of hot water processed Mg thin film. Increased particle size was achieved with process time at 1 and 6 hrs process time.

Keywords: Mg thin film; Mg(OH)2; Hot water process;

Xray diffraction; AFM analysis

I.

INTRODUCTION

The devises such as mobile phones, laptop computers, cameras, composite materials and other electronic components are prepared by the using material such as Mg since it is lightest among the metallic one. Now a days, Mg has been considered as an alternative for Al because of its attractive properties such as 35% weightless than Al, good mechanical, electrical properties and good vibration resistivity. But it has poor corrosion resistivity in all environments. For new application in various fields, a new surface coating would be used to improve its corrosion resistivity. Moreover, the structural and other properties of thin film material are different from that of the bulk material [1]. In addition to their applications as elemental form, it combines with other

material and showed good performance e.g. Mg2Si, has attracted much interest as a narrowgap semiconductor and environmentally friendly material [2], and thermoelectric power devices [3]. Because of its excellent mechanical properties and high corrosion-resistance, Mg2Si was used and applied to structural components [4]. In addition to the above, Mg based switchable mirror are also attractive materials for regulation of light and heat transfer in buildings, vehicles, satellites and many more applications in sensor technologies. It is necessary to understand the influence of environmental condition on the properties of Mg based thin film for the specific applications. A window using this technology can be programmed to respond to local sunlight and weather conditions, optimizing the amount of daylight entering a building, while controlling the gain or loss of infrared radiation or heat [5]. Recently, Richardson et al. [6] reported the influence of 3d transition metals such as Ni, Mn, Fe, and Co on the properties of Mg thin films. Magnesium can be deposited as thin film by means of various techniques under vacuum conditions. Many research papers have been published based on the preparation of Mg thin film by physical vapor deposition [7-9]. Recently, Y. K. Gautam et al. have prepared Mg thin film by DC sputtering and reported their properties [10]. Still there are no reports published based on the reaction at the surface of the Mg thin film and their products. Magnesium hydroxide (Mg(OH)2) is one among the derivatives of Mg thin film and has some attractive properties such as fire retarding, halogen-free flame retardant filler in composites materials, catalysis, and additive in refractory, paint, and ceramics brings [11]. When it undergoes endothermic decomposition at 332 C, it produces MgO and water as byproduct. Mg(OH)2 MgO + H2O (1)

The heat absorbed by the reaction acts as a retardant by delaying ignition of the associated substance. The

www.ijascse.in

Page 63

DEC. 31

IJASCSE, VOL 1, ISSUE 4, 2012

resultant product, water released during the reaction dilutes any combustible gases and inhibits oxygen from aiding the combustion [12]. A simple, mild, and practical method for the low-cost and large-area fabrication of high-quality Mg(OH)2 is still a challenge for material scientists and chemists. In this paper, the rf sputtered Mg thin films were processed in high pure hot water at various time durations and their structural and surface properties have been reported here. It is also an attempt to synthesize of Mg(OH)2 over Mg thin film for fire retardant applications. II. EXPERIMENTAL METHODS

A.

Structural Properties

Mg thin films were deposited on glass substrates using Mg (99.99% purity) target (3 inch in diameter and 5 mm in thickness) by RF sputtering (Edwards make, Model-Auto 500). The base pressure of the chamber was ~2 x 106 torr. High pure (99.999%) Ar was used in sputtering. The sputtering pressure was 3.0 x10-3 mbar during the synthesis of Mg thin films. The substrates were cleaned by rinsing in ultrasonic bath of acetone and isopropyl alcohol. To get 1.5 m film thicknesses, the deposition time and sputtering power were kept fixed at 45 min and 300 W, respectively. All Mg thin films were coated at room temperature. The target was pre-sputtered for 5 min before starting deposition. To get the uniform thickness, rotary drive system was used and 25 rpm was fixed for all Mg film coatings. Substrate to target distance of 15 cm was kept as constant for all depositions. Ultra high pure hot water (resistivity more than 18.2M cm) treatment was performed in 500 ml beaker at 95 C, using a temperature controlled magnetic stirrer for the specimen coated with metallic Mg thin film. All Mg thin film samples are dipped in ultra high pure hot water for five different times (1 hr, 2 hrs, 4 hrs, 5 hrs and 6 hrs). To verify the hot water treatment, all prepared films are treated with ultra high pure water at room temperature for the said time durations. The crystalline nature of the as-grown and processed Mg thin films was investigated by using a high resolution X-ray diffraction (HRXRD, Xpert-PRO, Philips, Netherlands). A CuK (k = 1.54056 ) source was used, with a scanning range between 2 = 20 and 80. The surface properties of the as grown and processed films were analyzed by using AFM system (Dimension Edge Bruker AXS make). The FTIR spectra were recorded in the range 4004000 cm1, with a spectral resolution of 4 cm1 using Perkin Elmer spectrum GX. III. RESULTS AND DISCUSSION

The XRD spectrum of as grown and hot water processed Mg thin films was recorded as shown in Fig.1. No reaction can be observed for all films treated in ultra high pure at room temperature. Since the results of the film processed at 3 hrs duration shows almost similar and no difference could be observed from the sample processed at 2 hrs duration, the results of the samples treated at 3 hrs duration are not discussed here. It depicts that the as grown and processed samples are polycrystalline nature with an intensive peak at 2 ~ 34.25 corresponding to a hexagonal closed packed (hcp) structure reflected from (002) orientation. The reason for this highly intense (002) orientation of Mg is the low energy configuration corresponding to this plane [13]. The observed peaks were indexed as the hexagonal structure and compared with the standard data of both Mg (JCPDS Card No: 897195) and Mg (OH)2 (JCPDS Card No:441482). The observed peak positions and structural parameters are given in Table 1 and 2. No oxide or hydroxide peaks are observed with as grown films. In addition, two more peaks related to cubic (200) and hexagonal (004) phase are also observed with very low intensity in the as grown film. But the peak related to (002) plane was observed at lower 2 when compared to standard 2 position (JCPDS No. 897195). This may be due to stress developed during deposition process. Substrate (SiO2) related peaks were also observed at ~2 = 30.80 in all samples. The preferred (002) plane could be possible only with high Ar pressure during the sputtering process which exhibits granular and fine structure [14].

Figure 1 XRD spectra of as grown and hot water processed Mg thin film for various time

www.ijascse.in

Page 64

DEC. 31

IJASCSE, VOL 1, ISSUE 4, 2012

TABLE I THE STRUCTURAL PROPERTIES OF AS GROWN AND HOT WATER PROCESSED Mg THIN FILM

TABLE II THE STRUCTURAL PROPERTIES OF Mg(OH)2 PHASE OBSERVED FROM THE HOT WATER PROCESSED Mg THIN FILM

In addition to (002) Mg peak, it is also noticed that the XRD spectra of films processed at above 4 hrs duration show the presence of some Mg(OH) 2 peaks with different orientations. The spectra also show the presence of hexagonal related (001), (011) and (110) peaks of Mg(OH)2 when the process time increases at and above 4 hrs. In order to study the structural properties in detail, the structural parameters are calculated as given in Table 1 and 2. Since the peak position and intensity seem to be important factors which decide the crystalline quality, the intensity analysis has also been considered in this study. Fig. 2 shows the change in intensity of (002) peak of Mg for various process time. It depicts that the Mg film processed at 2 hrs shows a higher value in intensity than the film processed at various time duration that has the improved crystalline quality of such films. It is also noticed that the peak width increases as the process time increases. It also reveals that the films processed at above 4 hrs duration shows low intensity peaks compared to 1 hr and 2 hrs durations. It is attributed to the growth of Mg(OH)2 from Mg for long process time. Fig. 2 also shows the change in peak position towards left when the

process time increases from 1 hr to 5 hrs. Thereafter, the peak position does not change as observed with as grown Mg thin film. Fig. 3 shows the peak of (004) plane with respect to process time. It is visible that the (004) peak diminishes when the film processed at and above 4hrs duration in hot water. It is also noticed that the position of the peak slightly moves towards left as observed for (002) peak. Fig. 4 (a-c) shows the change in intensity of Mg(OH)2 related peaks with process time. Fig. 4(a) clearly indicates that the intensity of (001) oriented peak increases with process time upto 5 hrs and reduces at 6 hrs. The film processed at 6 hrs duration shows very broad peak which seems to be the nature of low crystallite size. Fig. 4(b) represents the variation of intensity of (011) peak and shows that the film processed at 5 hrs duration exhibit the higher intensity as well as broad. It also reveals that all peaks are broadened and seems to be the peak merging. Fig. 4c shows the change in intensity of (110) peak and also shows the higher intensity for the film processed at 5 hrs duration. It also shows the growth behavior of (011) and (110) phases at this process time.

www.ijascse.in

Page 65

DEC. 31

IJASCSE, VOL 1, ISSUE 4, 2012

Figure 2 Variation in peak intensity and position of the (002) plane of Mg phase

Figure 3 Variation in peak intensity and position of (004) plane of Mg phase

A considerable reduction in intensity could also be observed for the process time longer than 5 hrs. Moreover a small shift in peak position for all (001), (011), and (110) peaks towards right angle could also be observed with peak broadening. In order to understand the influence of hot water process in structural properties of Mg thin film, a detailed structural analysis is required and hence the structural parameters of the processed film were calculated from the observed XRD spectra. The calculated structural parameters are given in Table 1. Table 2 shows the structural parameters of Mg (OH)2 phase formed on the surface of the processed samples. In order to investigate the possibility of preferred orientation, the Harris analysis [15] was performed using the following relationship for the texture coefficient. Pi (TC) = N (Ii/I0)/ Ni=1(Ii/I0) (1)

Figure 4 Change in intensity of Mg(OH)2 related peaks reflected from (a) (0 0 1), (b) (0 1 1), and (c) (1 1 0) planes

www.ijascse.in

Page 66

DEC. 31

IJASCSE, VOL 1, ISSUE 4, 2012

Where Pi is the Texture Coefficient of the plane I, Ii is the measured intensity, I0 is the intensity of the JCPDS powder diffraction pattern of the corresponding peak and N is the number of reflections considered for the analysis. Pi is unity for each reflection in the case of a randomly oriented sample and values of Pi greater than unity indicate preferred orientation of the crystallites in that particular direction. Fig. 5 shows the variation of texture coefficient of Mg (OH)2 related phases. It exhibits that the (001) peak shows high value for the film processed at 5 hrs duration and afterwards it decreases considerably for longer process time (>5 hrs). A reverse behavior could also be observed for (110) phase. It shows that 5 hr process time enhance the growth of (001) plane of Mg (OH)2 phase and hence the preferred (001) oriented growth is achieved. Overall, the Mg films processed at 4 hrs and 6 hrs in hot water helps to grow the preferred oriented Mg (OH)2 phase with (001) and (110) planes. It is also noticed that the (011) oriented Mg (OH)2 phase grows randomly over on Mg thin film when processed in hot water at more than 4 hrs duration. The crystallite size (D) was calculated using the Debye Scherer formula [16] from the Full-Width at HalfMaximum (w) measurements: D = 0.94 / w cos (2)

where do and da are the d spacing of bulk Mg and thin film forms respectively. E and Y are the Youngs modulus and Poissons ratio of Mg respectively. The Youngs modulus and Poissons ratio of Mg is E = 45 Gpa and Y = 0.29 respectively [17]. From Table 1, it is observed that the calculated stress from the XRD results shows negative sign. It seems to be the behavior of applied stress for (002) orientation during the process time as tensile stress.

Figure 5 Calculated texture coefficient of Mg(OH)2 planes for various process time.

Where, is the wavelength of incident X-ray. The calculated crystallite sizes of all films are given in Table 1 and 2. The change in crystallite size of (002) Mg plane is graphically represented in Fig. 6. It reveals that the crystallite size decreases gradually as the process time increases. It seems that the crystallite size of as grown and films processed at 4 and 5 hrs durations shows high value and low value respectively. Afterwards, an increasing manner in crystallite size could also be noticed with the films processed at longer than 5 hrs durations. Based on the peaks observed from Mg (OH)2 phases, the crystallite size could be evaluated for (001) and (011) peaks only (see Table 2). It depicts that the crystals size of (001) plane show high value (34.92 nm) when the film processed for 5 hrs duration. For (011) plane, a small increase in crystallite size from 3.27 nm to 5.43 nm is observed as the process time increases from 5 hr to 6 hrs duration. The internal stress () in the processed samples is calculated using the relation = - E (da do) / (2doY) (3)

It also depicts that the change in internal stress is observed as increasing for the film processed upto 5 hrs duration. It is also noticed that the high value in micro strain of (002) plane could be observed with the thin film processed at 4 hrs duration. Overall the hot water process plays an important role to increase the micro strain value of (002) plane. To strengthen this point, the dislocation density (), defined as the length of dislocation lines per unit volume of the crystal, was evaluated from the formula [18]; = 1/ D2 (4)

It is a term to define the crystal quality with defects. Overall, the calculated dislocation density is found to increase for hot water process. It shows that the high values of 2.59 x1020 lin/m2 and 2.57 x1020 lin/m2 are observed for the films processed at 4 hrs and 5 hrs duration respectively. Afterwards, the dislocation density decreases as process time increases. From the formula, it is clear that the crystallite size plays a vital role in dislocation density. In addition, the (001) plane of Mg (OH)2 phase has also influence on the crystal quality of Mg (002) plane when Mg thin film processed at 4 hrs duration. The results show that it can also be applicable for the observation made for the strain analysis too.

www.ijascse.in

Page 67

DEC. 31

IJASCSE, VOL 1, ISSUE 4, 2012

Figure 6 Change in crystallite size of the hot water processed Mg thin films for various process time

In order to analyze the structural properties of Mg (OH) 2 phase, the structural parameters are calculated from the XRD spectra for the samples processed at above 4 hrs duration as given in Table 2. In this Mg (OH)2 phase, the applied stress during the growth is tensile nature. It is observed that the applied stress for both (001) plane and (011) plane decreases gradually as the process time increases from 4 hrs to 6 hrs. But a change from tensile to compressive could be observed with the (110) plane when the process time increases from 4 hrs to 5 hrs. Afterwards, the conversion from compressive to tensile is observed when process time increases upto 6 hrs. From the Table 2, it is observed that the similar behavior on dislocation density and microstrain could also be observed for the Mg(OH)2 phase. In detail, high value in microstrain (11.06) and dislocation density (9.35 x1020 lin/m2) of (011) plane is observed for the film processed at 5 hrs duration. A noticeable reduction on both microstrain and dislocation density is also observed for (001) plane when the process time increases from 4 hrs to 5 hrs. Afterwards, the values are increasing for the film processed at 6 hrs durations. For (011) plane, the values are decreasing noticeably for increasing the process time from 5 hrs to 6 hrs. C. FTIR analysis The observed IR spectra of as grown and hot water processed Mg thin films are shown in Fig. 7a. As grown Mg thin films show no peaks related to their compounds. The evidence of the presence of Mg (OH)2 was observed in FTIR absorbance spectrum for all samples processed at above 4 hrs in hot water, as shown in Fig. 7(a). A sharp and intense absorption peaks observed at 3699 cm1 assigned as vibrational frequency of OH from the magnesium hydroxide compounds [19]. It seems to be the evidence of the formation of hexagonal Mg (OH)2 on the surface of Mg thin film by hot water process. But these

peaks are only observed with the films processed at above 4 hrs durations. It is evidently proved by XRD results. The peaks observed for the films processed at 1hr and 2 hrs durations may be related to the stretching vibration of OH from water molecules adsorbed on the Mg thin film surface. The intensity of the film processed at 2 hrs duration shows higher value than 1 hr process time, which may be due to the adsorption of more water molecules on the film surface. The process time plays an important role on not only changing the intensity of peak and also the peak position observed at around 3699 cm1. The change in intensity and position of the peak observed at ~ 3699 cm-1 is given in Fig. 7b. It shows that the stretching vibration peak is observed between 3699 and 3703 cm-1 for the film processed at above 4 hrs duration.

Figure 7 (a) FTIR spectra of hot water processed Mg thin films for various time duration and (b) IR spectra recorded in between 3665 and 3750 cm-1 for various process time durations.

www.ijascse.in

Page 68

DEC. 31

IJASCSE, VOL 1, ISSUE 4, 2012

The Mg thin films processed at 5 hrs and 6 hrs show intense peak at 3703 and 3699 cm-1 with broad shoulder peak at around 3712 cm-1 respectively. This may be attributed to the isolated surface OH groups of the processed films [20]. The Fig. 7(b) also shows that the film processed at 4 hrs duration shows a broad peak at 3703 cm-1 with shoulder peak (3712 cm-1). It is also noticed that the intensity of shoulder peaks diminishes as the intensity of main peak increases, which indirectly seems to be the influence of increase in hot water process

duration. Overall, the intensity get increases as the process time increases and high intense peaks are observed with the Mg films processed at above 6 hrs process time. The peak position at higher frequency is observed with only 4 and 5 hrs processed samples. The peaks (3430 cm-1) related to the transformation from free protons into a proton-conductive state in brucite could not observed for all process conditions.

Figure 8 AFM surface morphology of (a) as grown, (b) 1 hr, (c) 2 hr, (d) 4 hrs, (e) 5 hrs, and (f) 6 hrs hot water processed Mg thin films

A strong peak observed at around 3636 cm-1 and 3830 cm can be assigned to hydrogen-bonded hydroxyl groups and Mg(OH)2 [21]. It is observed only with the film processed at 6 hrs duration. In addition to this, a small absorption peak at 1406 cm-1 was attributed to the OH bond bending vibration in crystal structure [22]. Few unidentified peaks at ~1020 cm-1, 2282 cm-1, 2250 cm-1 and 2680 cm-1 could also be observed. This may be due to the impurities on the surface of the film.

-1

D. Surface analysis

TABLE 3 SURFACE ROUGHNESS AND PARTICLE SIZE OF HOT WATER PROCESSED Mg THIN FILM

In order to study the surface properties, the surface morphology of the films was recorded by AFM as given in Fig. 8. Fig. 8(a) shows the surface morphology of as grown Mg thin film. From the Fig. 8 (b-f), it depicts that the noticeable change on grain growth as well as the surface morphology of the films are observed for the hot water processed film. It clearly indicates that the hot water processed samples is more dense than the as grown. Particles agglomeration could be easily viewed for the samples processed at 1 hr duration. In addition, the surface morphology of the films processed at 4 hrs and 5 hrs shows similar properties and uniform surface could also be achieved with the film processed at 6 hrs duration. The particle size and surface roughness of the as grown and hot water processed thin films are calculated directly from the AFM image and given in Table 3. It shows that the roughness increases drastically for the sample processed at 2 hrs duration. It is also noticed

www.ijascse.in

Page 69

DEC. 31

IJASCSE, VOL 1, ISSUE 4, 2012

that the low value in surface roughness could be observed for 1 hr and 6 hrs processed samples. In particle size analysis, the table shows high value (616 nm) for the film processed at 1 hr duration and low value (166 nm) for the film processed at 5 hrs duration. Overall the particle size suddenly increases from 250 to 616 nm and gradually decreases from 616 to 166 nm as changing the process time from 1 hr to 5 hrs durations.

V.

CONCLUSION

RF sputtered Mg thin films were processed with high pure hot water at 95C for different time durations. The XRD spectra revealed the presence of (002) oriented Mg peaks in all samples and also depicted the growth of Mg (OH)2 phases in all samples processed at and above 4 hrs duration. Structural parameters showed the influence of Mg (OH)2 on the structural properties of Mg phase in processed samples. The tensile stress developed by Mg (OH)2 phase influenced the stress of Mg phase. The observed crystallite sizes of both Mg and Mg (OH)2 phases were found within 12 nm except with (001) plane of Mg (OH)2 for 5 hrs process time. Preferred growth in Mg (OH)2 phases was achieved for (001) plane in the films processed at > 4 hrs duration. FTIR spectra showed an evidence for the formation of Mg (OH)2 on the surface of the hot water processed films. AFM images revealed the improved film density for the film processed at and above 2 hrs durations. Noticeable changes in surface roughness and particle size for the hot water processed samples were achieved. Based on these results, it is suggested that the growth of preferred Mg (OH)2 phases is possible over Mg thin film by hot water process method and may be used for industrial application where the fire retardant is needed.

REFERENCES [1] R. Glang, The nature of thin films, in: L.I. Maissel, R. Glang (Eds.), Handbook of Thin Films Tech, Mc Graw-Hill, New York, 1970, chapter 8, 1994. [2] A. Vantomme, J. E. Mahan, G. Langouche, J. P. Becker, M. V. Bael, K. Temst, C. V. Haesendonck, Thin film growth of semiconducting Mg2Si by co deposition, Appl. Phys. Lett. vol. 70, 1997, pp. 1086 1088, doi: 10.1063/1.118492 [3] H. Tatsuoka, T.N. Takagi, S. Okaya, Y. Sato, T. Inaba, T. Ohishi, A. Yamamoto, T. Matsuyama, H. Kuwabara, Effect of inductively-coupled plasma assist on the crystal orientation of magnesium oxide thin films produced by reactive sputtering, Thin Solid

Films vol. 457, 2004, pp. 64 68, doi: 10.1016/j.tsf.2003.12.015 [4] K. Kondoh, H. Oginuma, A. Kimura, S. Matsukawa, T. Aizawa, JIM, In-situ Synthesis of Mg2Si Intermetallics via Powder Metallurgy Process, Mater. Trans. vol. 44, 2003, pp. 981-985, doi: [5] J. Isidorsson, I. A. M. E. Giebels, H. Arwin, R. Griessen, Optical properties of MgH2 measured in situ by ellipsometry and spectrophotometry, Phys. Rev. B, vol. 68, 2003, pp. 115112-115124 doi: 10.1103/PhysRevB.68.115112 [6] T. J. Richardson, J. L. Slack, B. Farangis and M. D. Ru-bin, Mixed metal films with switchable optical properties, Appl. Phys. Lett., vol. 80, 2002, pp. 1349 1351, doi: 10.1063/1.1454218 [7] C. Blawert, V. Heitmann, W. Dietzel, M. Staormer, Y. Bohne, S. Mandl and B. Rauschenbach, Mater. Sci. Forum, vol. 679, 2007, pp. 539-543. [8] D.M. Seeger, C. Blawert, W. Dietzel, Y. Bohne, S. Mandl, B. Rauschenbach, Magnesium Technology 2007, 134th Annual Meeting & Exhibition, San Francisco CA (USA), February, vol. 323, 2005, pp. 13-17. [9] L. Cultrera, A. Pereira, C. Ristoscu, A. Clozza, F. Tazzioli, C. Vicarion, Pulsed laser deposition of Mg thin films on Cu substrates for photocathode applications, Appl. Surf. Sci., vol. 248, 2005, pp. 397- 401, doi: 10.1016/j.apsusc.2005.03.065 [10] Y. K. Gautam1, A. K. Chawla, V. Chawla, R.D. Agrawal, R. Chandra, Influence of Sputtering Gas on Morphological and Optical Properties of Magnesium Films, J. Mater. Sci. Technol., vol. 27, 2011, pp. 5158, doi: 10.1016/S1005-0302(11)60025-X [11] M. Mckelvy, R. Sharma, A.G. Chizmeshya, R.W. Carpenter, K. Streib, Magnesium hydroxide dehydroxylation: in situ nanoscale observations of lamellar nucleation and growth, Chem. Mater. vol. 13, 2001, pp. 921-926, doi: 10.1021/cm000676t [12] http://en.wikipedia.org/wiki/Magnesium_hydroxide [13] A.K. Chawla, R. Chandra, Synthesis and structural characterization of nanostructured copper, J. Nanopart. Res., vol. 11, 2009, pp. 297-302, doi: 10.1007/s11051-008-9384-1 [14] M.H. Lee, I.Y. Bae, K.J. Kim, K.M. Moon, T.Oki, Formation mechanism of new corrosion resistance magnesium thin films by PVD method, Surf. Coat. Tech. vol. 169 170, 2003, pp. 670674, doi: 10.1016/S0257-8972(03)00054-9 [15] C.S. Barret, T.B. Massalski, Structure of Metals, Oxford, Pergamon (1980). [16] G. Gordillo, J.M. Flrez, L.C. Hernandez, Preparation and characterization of CdTe thin films deposited by

www.ijascse.in

Page 70

DEC. 31

IJASCSE, VOL 1, ISSUE 4, 2012

CSS, Sol. Energy Mater. Sol. Cells, vol. 37, 1995, pp. 273-281, doi: 10.1016/0927-0248(95)00020-8 [17] http://en.wikipedia.org/wiki/Magnesium [18] G..K.Williamson, R.E.Smallman, Dislocation densities in some annealed and cold-worked metals from measurements on the x-ray Debye-Scherrer spectrum, III. Philos. Mag. vol. 1, 1956, pp. 34-45, doi: 10.1080/14786435608238074 [19] Hong Y, Jianming W, Xuehu Z, Yan Z, and Liqiao W, Xuguang L, Bingshe X, Synthesis of magnesium hydroxide nanoneedles and short nanorods on polymer dispersant template, J. Mater. Res., vol. 22, 2007, pp. 2544-2549, doi: 10.1557/jmr.2007.0315 [20] Maxim S. Melgunov, Vladimir B. Fenelonov, Elena A. Melgunova, Alexander F. Bedilo, and Kenneth J. Klabunde, Textural Changes during Topochemical Decomposition of Nanocrystalline Mg(OH)2 to MgO, J. Phys. Chem. B, vol. 107, 2003, pp. 2427-2434, doi: 10.1021/jp021474i [21] M. O. Aboelfotoh, K. C. Park, and W. A. Parkin, Infrared and high-energy electron diffraction analyses of electron-beam-evaporated MgO films, J. Appl. Phys. vol. 48, 1977, pp. 2910-2917, doi: 10.1063/1.324102 [22] Yun-Feng Y, Xiang-Feng W, Guo-Sheng H, BiaoBing W, Effects of stearic acid on synthesis of magnesium hydroxide via direct precipitation, J. Cryst. Growth, vol. 310, 2008, pp. 3557 3560, doi: 10.1016/j.jcrysgro.2008.05.006

www.ijascse.in

Page 71

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Inter Time Series Sales ForecastingDocument12 paginiInter Time Series Sales ForecastingIJASCSEÎncă nu există evaluări

- Clustering Based Lifetime Maximizing Aggregation Tree For Wireless Sensor NetworksDocument7 paginiClustering Based Lifetime Maximizing Aggregation Tree For Wireless Sensor NetworksIJASCSEÎncă nu există evaluări

- Improving Utilization of Infrastructure CloudDocument8 paginiImproving Utilization of Infrastructure CloudIJASCSEÎncă nu există evaluări

- Four Side Distance: A New Fourier Shape SignatureDocument6 paginiFour Side Distance: A New Fourier Shape SignatureIJASCSEÎncă nu există evaluări

- A Study On The Effectiveness of Computer Games in Teaching and LearningDocument7 paginiA Study On The Effectiveness of Computer Games in Teaching and LearningIJASCSEÎncă nu există evaluări

- Improved Performance of Unsupervised Method by Renovated K-MeansDocument7 paginiImproved Performance of Unsupervised Method by Renovated K-MeansIJASCSEÎncă nu există evaluări

- Theoretical Study of Axially Compressed Cold Formed Steel SectionsDocument8 paginiTheoretical Study of Axially Compressed Cold Formed Steel SectionsIJASCSEÎncă nu există evaluări

- Design Equation For CFRP Strengthened Cold Formed Steel Channel Column SectionsPDocument7 paginiDesign Equation For CFRP Strengthened Cold Formed Steel Channel Column SectionsPIJASCSEÎncă nu există evaluări

- A Study On Thermal Behavior of Nano Film As Thermal Interface LayerDocument5 paginiA Study On Thermal Behavior of Nano Film As Thermal Interface LayerIJASCSEÎncă nu există evaluări

- Closed-Form Rate Outage Probability For OFDMA Multi-Hop Broadband Wireless Networks Under Nakagami-M ChannelsDocument11 paginiClosed-Form Rate Outage Probability For OFDMA Multi-Hop Broadband Wireless Networks Under Nakagami-M ChannelsIJASCSEÎncă nu există evaluări

- Cluster-Based Target Tracking and Recovery Algorithm in Wireless Sensor NetworkDocument6 paginiCluster-Based Target Tracking and Recovery Algorithm in Wireless Sensor NetworkIJASCSEÎncă nu există evaluări

- Analysis and Design of Lead Salt PbSe/PbSrSe Single Quantum Well in The Infrared RegionDocument6 paginiAnalysis and Design of Lead Salt PbSe/PbSrSe Single Quantum Well in The Infrared RegionIJASCSEÎncă nu există evaluări

- Evaluation of Exception Handling MetricsDocument6 paginiEvaluation of Exception Handling MetricsIJASCSEÎncă nu există evaluări

- Performance Analysis of A Model Predictive Unified Power Flow Controller (MPUPFC) As A Solution of Power System StabilityDocument7 paginiPerformance Analysis of A Model Predictive Unified Power Flow Controller (MPUPFC) As A Solution of Power System StabilityIJASCSEÎncă nu există evaluări

- An Effect of Synthesis Parameters On Structural Properties of AlN Thin Films Deposited On Metal SubstratesDocument10 paginiAn Effect of Synthesis Parameters On Structural Properties of AlN Thin Films Deposited On Metal SubstratesIJASCSEÎncă nu există evaluări

- Stable and Reliable Route Identification Scheme For Efficient DSR Route Cache in Mobile Ad Hoc NetworksDocument7 paginiStable and Reliable Route Identification Scheme For Efficient DSR Route Cache in Mobile Ad Hoc NetworksIJASCSEÎncă nu există evaluări

- Investigation of Integrated Rectangular SIW Filter and Rectangular Microstrip Patch Antenna Based On Circuit Theory ApproachDocument10 paginiInvestigation of Integrated Rectangular SIW Filter and Rectangular Microstrip Patch Antenna Based On Circuit Theory ApproachIJASCSEÎncă nu există evaluări

- Energy Aware Task Scheduling For Soft Real Time Systems Using An Analytical Approach For Energy EstimationDocument7 paginiEnergy Aware Task Scheduling For Soft Real Time Systems Using An Analytical Approach For Energy EstimationIJASCSEÎncă nu există evaluări

- Congestion Control MethodsDocument6 paginiCongestion Control MethodsIJASCSEÎncă nu există evaluări

- Portfolio Analysis in US Stock Market Using Markowitz ModelDocument6 paginiPortfolio Analysis in US Stock Market Using Markowitz ModelIJASCSEÎncă nu există evaluări

- An Approach of Substitution Method Based On Ascii Codes in Encryption TechniqueDocument7 paginiAn Approach of Substitution Method Based On Ascii Codes in Encryption TechniqueIJASCSEÎncă nu există evaluări

- Study On Momentum Density in Magnetic Semiconductor MnTe by Positron AnnihilationDocument11 paginiStudy On Momentum Density in Magnetic Semiconductor MnTe by Positron AnnihilationIJASCSEÎncă nu există evaluări

- Optimal State Assignment To Spare Cell Inputs For Leakage RecoveryDocument10 paginiOptimal State Assignment To Spare Cell Inputs For Leakage RecoveryIJASCSEÎncă nu există evaluări

- BMT With and Without GlassDocument7 paginiBMT With and Without GlassIJASCSEÎncă nu există evaluări

- Game Theory in OligopolyDocument6 paginiGame Theory in OligopolyIJASCSE100% (1)

- Delay Optimization: Use of Dynamic RoutingDocument8 paginiDelay Optimization: Use of Dynamic RoutingIJASCSEÎncă nu există evaluări

- FDI in Multi-Brand Retail in IndiaDocument5 paginiFDI in Multi-Brand Retail in IndiaIJASCSEÎncă nu există evaluări

- Architecture Approach in 3D Model For Virtual Communities From Detected FaceDocument6 paginiArchitecture Approach in 3D Model For Virtual Communities From Detected FaceIJASCSEÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Solar Street LightDocument8 paginiSolar Street LightAlizaIbrahim0% (2)

- Zombie RPGDocument30 paginiZombie RPGBo100% (3)

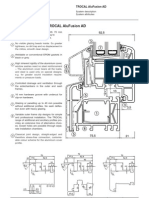

- Alufusion Eng TrocalDocument226 paginiAlufusion Eng TrocalSid SilviuÎncă nu există evaluări

- Python Setup and Usage: Release 2.7.8Document57 paginiPython Setup and Usage: Release 2.7.8dingko_34Încă nu există evaluări

- D300D Articulated Truck Electrical System: 5MG1-UPDocument2 paginiD300D Articulated Truck Electrical System: 5MG1-UPCarlos IrabedraÎncă nu există evaluări

- Drainage Service GuidelinesDocument15 paginiDrainage Service GuidelinesMarllon LobatoÎncă nu există evaluări

- PT-1971B Recomendado Spare Partes E900Document18 paginiPT-1971B Recomendado Spare Partes E900Juan Carlos MuñozÎncă nu există evaluări

- Bohol HRMD Plan 2011-2015Document233 paginiBohol HRMD Plan 2011-2015Don Vincent Bautista Busto100% (1)

- Dual Prime Source Datasheet 1Document1 paginăDual Prime Source Datasheet 1EstebanÎncă nu există evaluări

- WSO&WSP Excel Shortcuts Cheat SheetsDocument7 paginiWSO&WSP Excel Shortcuts Cheat SheetsAndy ZouÎncă nu există evaluări

- UntitledDocument50 paginiUntitledapi-118172932Încă nu există evaluări

- Neon Green and Blue Bold Cut Out Graphic Science Subject For Middle School Pollution PresentationDocument24 paginiNeon Green and Blue Bold Cut Out Graphic Science Subject For Middle School Pollution PresentationJimi CohenÎncă nu există evaluări

- Códigos de Fallas de Problemas Específicos de PEUGEOTDocument8 paginiCódigos de Fallas de Problemas Específicos de PEUGEOTJesus GarciaÎncă nu există evaluări

- 03-Instruction Set ArchitectureDocument40 pagini03-Instruction Set ArchitectureccoccoheadÎncă nu există evaluări

- GNP-GAP Installation InstructionsDocument10 paginiGNP-GAP Installation InstructionsLeonardo ValenciaÎncă nu există evaluări

- 02 Traps Management Service AdminDocument134 pagini02 Traps Management Service AdminDonovan RuizÎncă nu există evaluări

- Creating Your Online CSSD Student Profile - MA Acting ProgrammesDocument7 paginiCreating Your Online CSSD Student Profile - MA Acting ProgrammesEleanor ShawÎncă nu există evaluări

- Class 6 Ioel 2017Document8 paginiClass 6 Ioel 2017A GuptaÎncă nu există evaluări

- Norphonic VoIP D10003Document2 paginiNorphonic VoIP D10003Topcom Toki-VokiÎncă nu există evaluări

- VIJAYDocument61 paginiVIJAYYOGESH CHAUHANÎncă nu există evaluări

- Ficha Tecnica Talesun 410WDocument2 paginiFicha Tecnica Talesun 410WIes IngenieriaÎncă nu există evaluări

- 12 Smart Steps To Building A New HatcheryDocument2 pagini12 Smart Steps To Building A New HatcherytayyababÎncă nu există evaluări

- Primus Iron MachineDocument67 paginiPrimus Iron MachineKonstantinos Politis100% (1)

- Standing Seam Installation-23-11-21Document35 paginiStanding Seam Installation-23-11-21Gokulnath TgÎncă nu există evaluări

- BC-5800 Liquid SystemDocument114 paginiBC-5800 Liquid SystemДмитрийÎncă nu există evaluări

- Ram 100Document2 paginiRam 100MAT-LIONÎncă nu există evaluări

- Synposis FPGA Synthesis User GuideDocument484 paginiSynposis FPGA Synthesis User GuideVijendraKumarÎncă nu există evaluări

- File Handling in C PDFDocument86 paginiFile Handling in C PDFDeepak ShakyaÎncă nu există evaluări

- Ryan Donnelly - Artificial Intelligence in GamingDocument12 paginiRyan Donnelly - Artificial Intelligence in GamingJavier Pardo MuñozÎncă nu există evaluări

- Thermal Conductivity of Refractory Brick PDFDocument7 paginiThermal Conductivity of Refractory Brick PDFFerÎncă nu există evaluări