Documente Academic

Documente Profesional

Documente Cultură

p2p Best Practices

Încărcat de

amolkingDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

p2p Best Practices

Încărcat de

amolkingDrepturi de autor:

Formate disponibile

Best Practices in the Procure-to-Pay Cycle: Perspectives from Suppliers and Industry Experts

Rob Handfield, Bank of America University Distinguished Professor, North Carolina State University

Executive Summary

VOLUME

9

MARCH 2006

PRACTIX is available ONLY (and at no charge) via www.capsresearch.org To receive automatic notification of issue availability, send an e-mail to Debbie Maciejewski, dmaciejewski@capsresearch.org along with your name and e-mail address.

A benchmarking study of the procure-topay (P2P) process was carried out with a number of suppliers and subject matter experts. The research identified six key findings that can lead to improvement in the P2P cycle: Robust processes and training Onsite relationship managers to allow field maintenance to focus on doing its job Robust technology using single point of contact, i.e., supplier portal Improved forecasting for maintenance and planning for emergencies that can flex with different situations that arise Reduced complexity in catalogs and buying channels to streamline procurement Top management support

In addition, a suggested approach for improvement of the P2P was developed that involved securing top management support, mapping processes, understanding needs of user groups, running team redesign workshops, exploring technology solutions, defining the new process, training users, and updating the system over time. As technology and business requirements evolve, the P2P cycle will probably need to be revisited from time to time to ensure it is meeting the needs of internal customers and that suppliers are satisfied with the system.

PRACTIX | Best Practices in the Procure-to-Pay Cycle | CAPS | March 2006

Procure-to-Pay Cycle

Introduction

As companies are seeking to move beyond procurement into fully deployed supply chain systems, a key challenge for many of them is in the area of improving efficiency in their procure-to-pay cycles for many of their contracted services, especially in the area of facilities maintenance and onsite contract management. There exist multiple challenges in environments where field associates are working from manual or electronic systems, requisitioning onsite services for maintenance or other activities, and ensuring that this information is captured effectively. In addition, there exist significant challenges to ensure that the proper service level agreement is fulfilled, the correct price is charged, the purchase order is transmitted correctly, the invoice matches, and finally, that the supplier is paid the correct amount for the actual services delivered. While many enterprise systems claim that these elements are simply defined within their structural logic, the truth is that there are many opportunities for error, and that without a

planned process for managing the procure-topay cycle, the organization may be bearing significant costs due to non-compliance to system or process requirements. This benchmarking study sought to define and understand the best practices currently being employed by companies in the procure-to-pay cycle for services. Specifically, the research team focused on learning and sharing best practices in the following areas, shown in Figure 1: Forecasting and Planning of Requirements Need Clarification/Specification Sourcing Decisions in Emergency/ Non-Emergency Situations Contract PO Generation for Structured or Unstructured Requirements Receiving of Services, Materials, and Documents Settlement and Payment in Accounts Payable

Figure 1: Procure-to-Pay Generic High-Level Process Map

PROCURE-TO-PAY

Generic High-Level Process Map

START

PROJECTS

MAINTENANCE

OPERATIONS

END

Forecast Plan & Coordinate

Need Clarification/ Specification

Sourcing Decision

Contract/ PO Generation

Receive Material & Documents

Settle & Pay

Enablers: Finance, Legal, HR, IT

Supplier Need Fulfillment

PRACTIX | Best Practices in the Procure-to-Pay Cycle | CAPS | March 2006

Procure-to-Pay Cycle

Symptoms and Root Causes: A Suppliers View of the P2P Process

Researchers first began by identifying the true customer of the P2P process: the supplier who wishes its invoice to be paid quickly. Many organizations are seeking to build and extend relational capital with suppliers by building trust and becoming the customer of choice. The capital gained through this approach can result in preferred supplier delivery priorities, information sharing, participation on supplier councils, and other important rewards. An important element in becoming a customer of choice is to enable rapid payment and equitable and ethical treatment of suppliers. To address some of the major problems identified by suppliers, researchers scheduled a series of interviews with a group of suppliers, to identify their experiences with the current procure-to-pay process with some of their major customers.

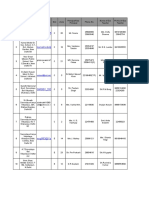

Root Causes Suppliers interviewed also noted a number of root causes associated with the P2P problems. As shown in Figure 3, the most common root causes were associated with the lack of a formally designed P2P process, the lack of a central relationship management, or problems associated with supplier interfaces with SAP. Other reasons included the increased complexity associated with SAP catalog and line items, and the lack of a forecasting process.

ROOT CAUSE

FREQUENCY OF RESPONSES

Issue Poorly designed process No relationship manager/point of contact Lack of system/portal interface Too much complexity in SAP catalog/line items No forecast or plan in place Too many suppliers drive complexity TOTAL 8 6 5 5 4 1

SYMPTOMS

FREQUENCY OF RESPONSES

Issue/Opportuntiy Manual workarounds and high manpower Long cycle time/Late payments/Aged invoices No central point of contact PO/Invoice match problem Not enough funds on PO Emergency work never properly recorded TOTAL 7 6 5 5 4 3

Figure 3: Root Causes Identified by Suppliers

Figure 2: Symptoms Identified by Suppliers

As shown in Figure 2, the most common symptoms experienced by suppliers involve high manual workarounds required to address problems, long cycle times for payment, no central point of contact, and a problem with matching the PO and invoice. Some of the typical responses from suppliers in these categories involved having to contact accounts payable multiple times, having to re-submit invoices, and waiting 90 or more days in some cases for payments.

As can be seen from these examples the fundamental root causes are 1) a lack of a process with designated roles and 2) specific processes associated with different internal and external functions are not defined. Maintenance people, buyers, planners, schedulers, accounts payable, project planners, and others are not in sync. Further, the system is not designed to be able to withstand the various approaches in which people are entering data and requesting information. When too many people are not using the system in a unified manner, it is no wonder that the system rejects the input and causes problems. This indicates that either the tolerances of such systems must be changed, or that the manner in which the system is used must be changed.

PRACTIX | Best Practices in the Procure-to-Pay Cycle | CAPS | March 2006

Procure-to-Pay Cycle

Recommended Solutions These same set of issues were identified in recommended solutions suggested by suppliers. The suppliers recommended that their customers explore the solutions shown in Figure 4.

RECOMMENDED ACTIONS

FREQUENCY OF RESPONSES

Recommended Action Redesigned P2P process deployed Dedicated relationship management position Develop supplier portal using SAP Interface Spend analysis and catalog item reduction initiative Senior executive workshop to describe requirements Develop standard forecasting process Develop supply base reduction initiative TOTAL 7 7 7 7 4 4 1

Figure 4: Recommended Actions Suggested by Suppliers

The top four elements that were identified as possible solutions included redesigning the P2P process, developing a dedicated relationship manager to work with suppliers on key areas of interface, exploring the use of a supplier portal using the CATS interface in SAP, and reducing catalog items through spend analysis, limiting the inherent complexity of entering information into the SAP system. These responses by and large provide significant insights into the problems and complexities associated with improving the P2P cycle from a suppliers perspective. Unfortunately, these issues also translate into significant problems for the purchasing organization, which is often lost in translation when the need for P2P improvement is communicated to a senior management team. Late payment and excessive workaround to obtain payment in a timely manner will definitely increase the cost to serve for companies with a broken P2P process. Typical problems that can occur when a malfunctioning P2P process is not

fixed include one or more of the following events: Deteriorating response time from suppliers who have no motivation to improve performance or respond quickly to customers who fail to pay them for 90 days or more. Lower service levels from suppliers who may choose to service their more profitable customers first in their cost-to-serve model. Deterioration as the customer of choice in the mind of suppliers senior management, which further breaks down trust and strategic alignment. Delivery delays. Higher pricing due to the costs attributed to late payment and excessive manpower allocated to the account. Increased manpower on non-value-added activities (e.g., chasing payments) to the detriment of other value-added activities that can improve customer service. Loss of the supplier as a critical link in the supply chain. Higher costs internally for the purchasing company, which must also dedicate AP people and buyers to non-value-added activities.

Subject Matter Expert Insights into the P2P Process

A number of senior procurement executives from a variety of different industries were also interviewed to understand their responses to the same problems associated with the P2P cycle. Each of these individuals provided a different perspective on how to improve the P2P process, but their combined thoughts resulted in some common themes that validated many of the suppliers suggested recommendations as well. Robust Processes and Training A critical element identified by all of the subject matter experts was the need to develop standardized processes and training around the P2P process. Specifically, roles and duties of the different people involved in the process must be clearly defined. In addition, training should emphasize how invoices and requests should be

PRACTIX | Best Practices in the Procure-to-Pay Cycle | CAPS | March 2006

Procure-to-Pay Cycle

processed, the reasons why deviation from the process is unacceptable, and the consequences involved with deviating from the process. This ensures that everyone not only is compliant, but understands the need and rationale behind the compliance. Part of the process redesign effort should also focus on simplifying processes to reduce complexity. If there is no need for a specific channel for purchasing, then eliminate it. Onsite Relationship Managers An important point that many respondents noted was the need to establish dedicated roles around onsite relationship managers from procurement who are available to manage invoices, service entries, and the like. The simple fact is that many maintenance and project managers do not think in terms of procurement, but rather are focused on people, equipment, and schedules; they do not have the time or patience required to ensure that the correct entries are put into a P2P system. The relationship manager can also act as the liaison between the supplier and the maintenance organization to ensure prompt payment, resolution of issues, and improvement of processes. Simplified Online Portals to Minimize Human Intervention A number of subject matter experts described the need to eliminate the manual intervention of multiple untrained individuals entering information into systems such as SAP. Many ERP systems have modules for purchasing and plant maintenance, but they all require significant configuration. On the other hand, a number of bolt-on packages are also available, but the experts advise against these due to the high probability of interface issues associated with deployment. Improved Forecasting for Maintenance and Planning for Emergencies that Can Flex with Different Situations that Arise The need to improve forecasting processes is a critical element in ensuring that maintenance

needs are met. While maintenance is often an emergency, there are many scheduled maintenance activities that can be planned and communicated to suppliers. Even in emergency situations, having a plan in place with a designated supplier can avoid many of the problems that occur downstream in the P2P cycle. Too often, data, invoices, service entries, and other key elements are entered incorrectly due to a fundamental lack of planning and forecasting. These elements need to be incorporated into the design of new P2P systems. Reduced Complexity in Catalogs and Buying Channels to Streamline Procurement Many of the experts also emphasized the need to reduce complexity, both in the interface systems as well as in the predefined procurement buying channels. There is no need for users to have multiple channels for procurement. However, establishing the credibility for users to only be able to use these channels also requires significant management support. Rolling Out the Initiative In re-engineering the procure-to-pay process, suppliers and experts recommend that executives apply the following approach: 1. Secure top management support for the initiative and budgeting for the project. Develop a list of key benefits and deliverables that will occur as a result of the improvements. Document the cost of leaving the system broken in its current state. 2. Map existing processes and problems with the P2P cycle. Identify where the breakdowns are occurring and why they are occurring. 3. Understand the needs and requirements of the user groups. Many of the people involved maintenance, planning, project management, suppliers, accounts payable, buyers, etc. have specific issues that prevent them from using the existing system. Also, many of the specific sites may have issues that need to be considered in designing the new system.

PRACTIX | Best Practices in the Procure-to-Pay Cycle | CAPS | March 2006

Procure-to-Pay Cycle

4. Team redesign workshops should be used to bring together key subject matters experts from each of the business units. Suppliers should also be invited to attend and participate, as they may have solutions they have adopted with other customers that may prove to be efficient and simple to use (i.e., why re-invent the wheel?). 5. Explore existing technology solutions with SAP, as well as bolt-on applications. Map out the business requirements, and ensure they are aligned with the technology solutions that are available. Begin to estimate cost of deployment, and ensure that adequate planning and due diligence is taken at this step. 6. Following the workshops, define the new process and begin to pilot using a planned technology. Ensure that it takes place in a real environment, with actual non-trained users involved in the pilot, before cutting over to the next process.

7. Train and deploy other users based on the new processes and systems. Be sure to make the training appropriate to the specific functional unit and user groups. 8. Monitor, update, and improve the system, ensuring that catalogs are kept up to date. Hold periodic meetings with suppliers and user groups to solicit input and identify problems with the systems. As technology and business requirements evolve, the P2P cycle will probably need to be revisited from time to time to ensure it is meeting the needs of internal customers, and that suppliers are satisfied with the system.

Copyright 2006 Institute for Supply ManagementTM and the W.P. Carey School of Business at Arizona State University. All rights reserved. CAPS: Center for Strategic Supply Research P.O. Box 22160 2055 E. Centennial Circle Tempe, AZ 85285-2160 Telephone (480) 752-2277 www.capsresearch.org

Send written comments to Debbie Maciejewski, Center Manager or Phillip L. Carter, Executive Director at the address listed. Or, Email to: dmaciejewski@capsresearch.org

S-ar putea să vă placă și

- Eprocurement / Sourcing Mro Environment: Utilising Lean Six SigmaDocument33 paginiEprocurement / Sourcing Mro Environment: Utilising Lean Six SigmaSumit KumarÎncă nu există evaluări

- Process Mapping in Successful ERP Implementations: Michael D. Okrent and Robert J. VokurkaDocument7 paginiProcess Mapping in Successful ERP Implementations: Michael D. Okrent and Robert J. VokurkaDidik HariadiÎncă nu există evaluări

- Re-Engineering The Supply ChainDocument42 paginiRe-Engineering The Supply Chainਸੁਖਜੀਤ ਸਿੰਘÎncă nu există evaluări

- SAP Vs ORACLEDocument5 paginiSAP Vs ORACLESohaib AliÎncă nu există evaluări

- Lecture 9Document18 paginiLecture 9Gala AlmoutiriÎncă nu există evaluări

- Test IsourcingDocument27 paginiTest Isourcingsanjeev_logica100% (1)

- Supply Chain Integration, Advanced Manufacturing Technology, and Strategic PDFDocument109 paginiSupply Chain Integration, Advanced Manufacturing Technology, and Strategic PDFAdelina RomanÎncă nu există evaluări

- The New Benchmark For World Class Procure To Pay Process EfficiencyDocument10 paginiThe New Benchmark For World Class Procure To Pay Process EfficiencyZycusIncÎncă nu există evaluări

- ERP Selection Process Survival Guide PDFDocument20 paginiERP Selection Process Survival Guide PDFasaÎncă nu există evaluări

- Oracle - 1Z0-518 Oracle EBS R12.1 Receivables EssentialsDocument5 paginiOracle - 1Z0-518 Oracle EBS R12.1 Receivables EssentialsAnurag SinghÎncă nu există evaluări

- Using Benchmarking To Drive EA ProgressDocument4 paginiUsing Benchmarking To Drive EA ProgressTrivial FaltuÎncă nu există evaluări

- Conference Room Pilot. CRP Run. ERP ImplementationDocument12 paginiConference Room Pilot. CRP Run. ERP ImplementationJyotindra Zaveri E-Library100% (1)

- GAPDocument23 paginiGAPAshish Singh100% (1)

- Oracle Payables Data SheetDocument6 paginiOracle Payables Data SheetmrssabaÎncă nu există evaluări

- BP080 Future Process ModelDocument10 paginiBP080 Future Process ModeljazharscribdÎncă nu există evaluări

- Oracle Cloud Applications A Complete Guide - 2019 EditionDe la EverandOracle Cloud Applications A Complete Guide - 2019 EditionÎncă nu există evaluări

- 1-Procure To Pay OverviewDocument6 pagini1-Procure To Pay Overviewskjayasree_6Încă nu există evaluări

- Peoplesoft Financials ImplementationDocument11 paginiPeoplesoft Financials ImplementationKesava Sumanth AÎncă nu există evaluări

- supplier segmentation A Complete Guide - 2019 EditionDe la Everandsupplier segmentation A Complete Guide - 2019 EditionÎncă nu există evaluări

- Test Documentation and Test Case Design: Qa Lead/Release Lead Vmware, IncDocument48 paginiTest Documentation and Test Case Design: Qa Lead/Release Lead Vmware, IncsysastroÎncă nu există evaluări

- ERP+Upgrade+Pre Qualification+Questionnaire+V1+Feb+2010Document4 paginiERP+Upgrade+Pre Qualification+Questionnaire+V1+Feb+2010hwidjaja88Încă nu există evaluări

- Epicor Vs Netsuite FSDocument3 paginiEpicor Vs Netsuite FSNithiyaÎncă nu există evaluări

- CBAP Application TemplateDocument22 paginiCBAP Application TemplateMohamed AwadÎncă nu există evaluări

- Key Questions For SAP Post Imp ReviewDocument1 paginăKey Questions For SAP Post Imp ReviewManu ManuÎncă nu există evaluări

- SAP HANA and Real Time Analytics - BIDocument8 paginiSAP HANA and Real Time Analytics - BIaslamharysÎncă nu există evaluări

- WP THG Source To Pay RPA enDocument8 paginiWP THG Source To Pay RPA ennoestoypanadie2000Încă nu există evaluări

- Erp Methodology PDFDocument2 paginiErp Methodology PDFBiancaÎncă nu există evaluări

- General: Question NoDocument8 paginiGeneral: Question NoGhosh2Încă nu există evaluări

- BEST PRACTICE Rethink Transaction MatchingDocument28 paginiBEST PRACTICE Rethink Transaction MatchingvanlebeauÎncă nu există evaluări

- Internet Expenses Data SheetDocument2 paginiInternet Expenses Data Sheetmiguelsias127100% (1)

- Vendor Registration Simplification - V1 7Document22 paginiVendor Registration Simplification - V1 7Kishor HandeÎncă nu există evaluări

- Procure To Pay Best PracticesDocument51 paginiProcure To Pay Best PracticesDmitry Borisov100% (1)

- QMS PDFDocument8 paginiQMS PDFkensu81Încă nu există evaluări

- Working With Requirements DocumentsDocument5 paginiWorking With Requirements DocumentsAncaVescanÎncă nu există evaluări

- P22-4493 - Part F - Functional and Non-Functional RequirementsDocument85 paginiP22-4493 - Part F - Functional and Non-Functional RequirementsRandyÎncă nu există evaluări

- QF 01 Rev18 Questionaire For Offer Preparation Updated - 637796734931738402Document6 paginiQF 01 Rev18 Questionaire For Offer Preparation Updated - 637796734931738402Santosh Kumar KurellaÎncă nu există evaluări

- Implementation Strategy: Decision Support TemplateDocument5 paginiImplementation Strategy: Decision Support TemplatePrakash PrakyÎncă nu există evaluări

- FICO Interview QuestionsDocument177 paginiFICO Interview QuestionsNagaratna ReddyÎncă nu există evaluări

- Public Cloud ERP for Small or Midsize Businesses A Complete Guide - 2019 EditionDe la EverandPublic Cloud ERP for Small or Midsize Businesses A Complete Guide - 2019 EditionÎncă nu există evaluări

- PROCDocument7 paginiPROChariomÎncă nu există evaluări

- Risk Management in Enterprise Resource Planning ImplementationDocument14 paginiRisk Management in Enterprise Resource Planning Implementationclemen_angÎncă nu există evaluări

- Business Process Banking-Cognizant PDFDocument7 paginiBusiness Process Banking-Cognizant PDFsupriyoÎncă nu există evaluări

- Implementation of An ERP at Wei CorporationDocument13 paginiImplementation of An ERP at Wei CorporationSantiago Noriega ArdilaÎncă nu există evaluări

- SAP and Oracle - A Comparison On Support StandardsDocument35 paginiSAP and Oracle - A Comparison On Support StandardsBalaji_SAPÎncă nu există evaluări

- Project PlanDocument6 paginiProject PlanShah MietyÎncă nu există evaluări

- Public Cloud ERP For Small Or Midsize Businesses A Complete Guide - 2020 EditionDe la EverandPublic Cloud ERP For Small Or Midsize Businesses A Complete Guide - 2020 EditionÎncă nu există evaluări

- SAP FICO Analyst in Wilmington NC Resume Jonathan WaltersDocument5 paginiSAP FICO Analyst in Wilmington NC Resume Jonathan WaltersJonathanWaltersÎncă nu există evaluări

- Data Migration Strategy StepsDocument7 paginiData Migration Strategy StepsadnanykhanÎncă nu există evaluări

- ERP Strategy: Why You Need One, and Key Considerations For Defining OneDocument19 paginiERP Strategy: Why You Need One, and Key Considerations For Defining OnekrismmmmÎncă nu există evaluări

- Oracle Cloud Intergration OptionsDocument1 paginăOracle Cloud Intergration Optionsvenkatrs63532Încă nu există evaluări

- RFP 744-R1913 P2PDocument42 paginiRFP 744-R1913 P2PKalyanÎncă nu există evaluări

- BPMS Implementation Approach - Elab2007 - Week 7Document44 paginiBPMS Implementation Approach - Elab2007 - Week 7Rommel Risco100% (1)

- Oracle Enterprise Resource Planning Cloud Service Implementation Leading Practice Release 11Document31 paginiOracle Enterprise Resource Planning Cloud Service Implementation Leading Practice Release 11Mohammed MaherÎncă nu există evaluări

- Ariba Implementation at MED-X:: Managing Earned ValueDocument15 paginiAriba Implementation at MED-X:: Managing Earned ValueRamesh ThangavelooÎncă nu există evaluări

- Ariba Spend VizDocument2 paginiAriba Spend Vizlarryhert_10Încă nu există evaluări

- Sample Software Dev Project WBSDocument12 paginiSample Software Dev Project WBSumyalÎncă nu există evaluări

- White Paper - The ERP Selection Process - 10 StepsDocument11 paginiWhite Paper - The ERP Selection Process - 10 StepsMohammad Danish NasimÎncă nu există evaluări

- Entry and Exit Criteria For Learning SupportDocument2 paginiEntry and Exit Criteria For Learning SupportFrancis A. Buenaventura100% (1)

- EerttDocument1 paginăEerttamolkingÎncă nu există evaluări

- MPCBDocument144 paginiMPCBamolkingÎncă nu există evaluări

- (Solving Problems at The Source Instead May Be Unfamiliar To North Americans and People of DegreesDocument1 pagină(Solving Problems at The Source Instead May Be Unfamiliar To North Americans and People of DegreesamolkingÎncă nu există evaluări

- (Solving Problems at The Source Instead May Be Unfamiliar To North Americans and People of DegreesDocument1 pagină(Solving Problems at The Source Instead May Be Unfamiliar To North Americans and People of DegreesamolkingÎncă nu există evaluări

- Ttyuu 7Document1 paginăTtyuu 7amolkingÎncă nu există evaluări

- Rand BetweenDocument2 paginiRand BetweenamolkingÎncă nu există evaluări

- Smartt GoalsDocument1 paginăSmartt GoalsamolkingÎncă nu există evaluări

- DGGHDocument2 paginiDGGHamolkingÎncă nu există evaluări

- YUutghDocument1 paginăYUutghamolkingÎncă nu există evaluări

- Certification - Certified in Human Resource ManagementDocument1 paginăCertification - Certified in Human Resource ManagementamolkingÎncă nu există evaluări

- Nagement Functions and BehaviourDocument1 paginăNagement Functions and BehaviouramolkingÎncă nu există evaluări

- Avinash Resume 1Document3 paginiAvinash Resume 1amolkingÎncă nu există evaluări

- DGGHDJDocument2 paginiDGGHDJamolkingÎncă nu există evaluări

- SMMMDocument2 paginiSMMMamolkingÎncă nu există evaluări

- IInd ListDocument38 paginiIInd ListamolkingÎncă nu există evaluări

- Article RandbetweenDocument2 paginiArticle RandbetweenamolkingÎncă nu există evaluări

- SCM Is Good Field of StudyDocument2 paginiSCM Is Good Field of StudyamolkingÎncă nu există evaluări

- ROP CalculatorDocument1 paginăROP CalculatoramolkingÎncă nu există evaluări

- Tools of TQM: Abdulla Jassim AbdullaDocument10 paginiTools of TQM: Abdulla Jassim AbdullaAkhilesh AjayanÎncă nu există evaluări

- Product Structure - Engineering Design Changes - Product Structure - Engineering Design ChangesDocument1 paginăProduct Structure - Engineering Design Changes - Product Structure - Engineering Design ChangesamolkingÎncă nu există evaluări

- ICDL ParticipantsDocument2 paginiICDL ParticipantsBrinda ReddyÎncă nu există evaluări

- 1 GoodDocument2 pagini1 GoodamolkingÎncă nu există evaluări

- Chaudhar Naresh BE, ME, Hardware & Networking SpecialistDocument4 paginiChaudhar Naresh BE, ME, Hardware & Networking SpecialistamolkingÎncă nu există evaluări

- Trainer Profile 1Document1 paginăTrainer Profile 1amolkingÎncă nu există evaluări

- Students ProfileDocument179 paginiStudents ProfileamolkingÎncă nu există evaluări

- MHCETDocument239 paginiMHCETswishrick180% (1)

- TestDocument1 paginăTestamolkingÎncă nu există evaluări

- Incotermskjn PDFDocument2 paginiIncotermskjn PDFamolkingÎncă nu există evaluări

- Region: Goa A. Architecture & Engineering - NIL State: Maharashtra B. Engg. & Tech. Sl. No. Name of AICTE Approved Institution Course(s) & IntakeDocument7 paginiRegion: Goa A. Architecture & Engineering - NIL State: Maharashtra B. Engg. & Tech. Sl. No. Name of AICTE Approved Institution Course(s) & IntakeamolkingÎncă nu există evaluări

- ManagementDocument11 paginiManagementanoop1989Încă nu există evaluări

- Design and Optimization of An XYZ Parallel Micromanipulator With Flexure HingesDocument26 paginiDesign and Optimization of An XYZ Parallel Micromanipulator With Flexure HingesVijay SakhareÎncă nu există evaluări

- Security For VPNs With IPsec Configuration Guide - 15.2MTDocument166 paginiSecurity For VPNs With IPsec Configuration Guide - 15.2MTAnonymous fIXhrYSmÎncă nu există evaluări

- Bosch Video Management System - Configuration ManualDocument260 paginiBosch Video Management System - Configuration Manualvsuneelg100% (1)

- Varec 5000 5010 PDFDocument10 paginiVarec 5000 5010 PDFEduardo Rafael Lopez LezamaÎncă nu există evaluări

- Effects of Stiffness Degradation On DuctilityDocument11 paginiEffects of Stiffness Degradation On DuctilitysalmanÎncă nu există evaluări

- (Lab Report Operation Unit) Experiment 3: Separation of An Ordinary Binary Mixture Consisting of Acetic Acid and Water by Using Simple Batch Distillation Technique.Document8 pagini(Lab Report Operation Unit) Experiment 3: Separation of An Ordinary Binary Mixture Consisting of Acetic Acid and Water by Using Simple Batch Distillation Technique.Fazsroul100% (9)

- How To Install Openbravo ERP On Debian LennyDocument4 paginiHow To Install Openbravo ERP On Debian LennyfromemÎncă nu există evaluări

- Cebo Ycc50 ManualDocument16 paginiCebo Ycc50 ManualAngelevÎncă nu există evaluări

- Structured Text CheatsheetDocument1 paginăStructured Text CheatsheetMauricio Rodriguez0% (1)

- Quake Cheat CodesDocument21 paginiQuake Cheat CodeshugtheslugÎncă nu există evaluări

- WoodwardDocument5 paginiWoodwardMuhammad UsmanÎncă nu există evaluări

- Sin EncoderDocument6 paginiSin Encoderboynew87Încă nu există evaluări

- Lane Departure Warning SystemDocument7 paginiLane Departure Warning SystemRavisingh RajputÎncă nu există evaluări

- Thermozorb Heatless Regenerative Air Dryer: TZ22 - TZ142Document2 paginiThermozorb Heatless Regenerative Air Dryer: TZ22 - TZ142Емил ГавриловÎncă nu există evaluări

- Stator Earth Fault in 200MW Generator-A Case StudyDocument5 paginiStator Earth Fault in 200MW Generator-A Case StudylrpatraÎncă nu există evaluări

- Prestressed Concrete Structures: Prepared By: Dr. Amlan K. Sengupta Dr. Devdas MenonDocument11 paginiPrestressed Concrete Structures: Prepared By: Dr. Amlan K. Sengupta Dr. Devdas MenonJeffrey Carlo Viduya AgliamÎncă nu există evaluări

- WG1AR5 Chapter08 FINAL PDFDocument82 paginiWG1AR5 Chapter08 FINAL PDFMariel YarrodÎncă nu există evaluări

- 5950 Part 1-1990Document120 pagini5950 Part 1-1990José Miguel100% (1)

- Technical Specification of Stay InsulatorDocument11 paginiTechnical Specification of Stay Insulatorraj_stuff006Încă nu există evaluări

- Qinhuangdao Red Ribbon ParkDocument18 paginiQinhuangdao Red Ribbon Parkjaya saputraÎncă nu există evaluări

- Rockwell Automation TechED 2018 - SY10 - Lab Manual - Integrating CENTERLINE® Motor Control Centers With Studio 5000® and IntelliCENTER® SoftwareDocument23 paginiRockwell Automation TechED 2018 - SY10 - Lab Manual - Integrating CENTERLINE® Motor Control Centers With Studio 5000® and IntelliCENTER® SoftwareAlex RivasÎncă nu există evaluări

- Design CalculationDocument13 paginiDesign CalculationSunil KumarÎncă nu există evaluări

- Basic Tanker Training (Oil, Chemical and Liquefied Gas Tanker)Document487 paginiBasic Tanker Training (Oil, Chemical and Liquefied Gas Tanker)Abdul Hafiz67% (3)

- Cks 180 Ton MIGAS BaruDocument46 paginiCks 180 Ton MIGAS BaruHario PramuditoÎncă nu există evaluări

- Under Balanced OperationsDocument104 paginiUnder Balanced OperationsJavier Ignacio Meriles100% (1)

- Introduction To Bounding Volume Hierarchies: Herman J. Haverkort 18 May 2004Document9 paginiIntroduction To Bounding Volume Hierarchies: Herman J. Haverkort 18 May 2004Alessandro MeglioÎncă nu există evaluări

- VECU - Manual de Producción 70312913Document33 paginiVECU - Manual de Producción 70312913RainorSS100% (2)

- 002 Danfoss PICV Energy Valve Ver 090821 r0Document2 pagini002 Danfoss PICV Energy Valve Ver 090821 r0Pattana MekkhumÎncă nu există evaluări

- MIT8 02SC Challenge Sol21Document24 paginiMIT8 02SC Challenge Sol21Gabriel TeodoroÎncă nu există evaluări