Documente Academic

Documente Profesional

Documente Cultură

Non Destructive Testing

Încărcat de

Issac GeorgeDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Non Destructive Testing

Încărcat de

Issac GeorgeDrepturi de autor:

Formate disponibile

PROPRIETARRY DATA NOT TO BE DISCLOSED OR REPRODUCED WITHOUT THE PERMISSION OF BHEL.

BHARAT HEAVY ELECTRICALS LIMITED

235-029

DEPT.235 TIRUCHIRAPALLI 620 014 Non-Destructive Testing

BHE:NDT:PB:MT- 01 Revision 11 Page 1 of 15

PROCEDURE FOR MAGNET IC PARTICLE EXAMINATION OF MATERIALS, WELDS IN BOILER COMPONENT S, PRESSURE VESSELS, HEAT EXCHANGERS AND STRUCTURAL COMPONENTS.

Prepared By M.MANIMOHAN Senior Scientific Officer LEVEL II NDT

Reviewed &Approved By R.J.PARDIKAR DGM Sr.LEVEL III NDT

EFFECTIVE FROM 21-01-2004

CONTROLLED / INFORMAT ION COPY ISSUED TO ISSUED CONTROL ON NO.

ISSUED BY

PROPRIETARRY DATA NOT TO BE DISCLOSED OR REPRODUCED WITHOUT THE PERMISSION OF BHEL.

BHARAT HEAVY ELECTRICALS LIMITED

235-029

DEPT.235 TIRUCHIRAPALLI 620 014 Non-Destructive Testing

BHE:NDT:PB:MT- 01 Revision 11 Page 2 of 15

RECORD OF REVISION Rev. Revision No Date 05 01-01-1993 Revision of Details Revised to include the requirements of ASME Section VIII, Div 1 Testing by Longitudinal Magnetisation method included. Clause 2.0,3.2,3.3,4.5,5.6 and 10.5 included. Revised to include ASME Section VIII, Div 2. Revised in entirety. Fluorescent Examination method and requirements of Structurals as per AWS D 1.1 included. Clauses 2.0,4.5,6.1.2.1 and 14.0 modified. 17.3 and 17.4 renumbered as 18.2 and 18.3 respectively. Annexure I added Clause 14.0 added and rest of the clauses renumbered. 15.1 modified. A4 added. 15.1.1 Revised. 19.4.4 Added. Annexure A incorporated in main text, revised and renumbered 14.0 Deleted

06 07 08

28-03-1994 01-08-1996 27-07-1998

09 10 11

20-03-2000 28-12-2002 21-01-2004

PROPRIETARRY DATA NOT TO BE DISCLOSED OR REPRODUCED WITHOUT THE PERMISSION OF BHEL.

BHARAT HEAVY ELECTRICALS LIMITED

235-029

DEPT.235 TIRUCHIRAPALLI 620 014 Non-Destructive Testing

BHE:NDT:PB:MT- 01 Revision 11 Page 3 of 15

1.0 1.1

SCOPE This procedure describes the method, techniques and acceptance standards for Magnetic Particle Examination of all shapes of ferromagnetic product forms in Boiler components, Pressure Vessels, Heat Exchangers and Structural Components. The examination shall include all Gas cut openings, attachment welds with a throat thickness over 6 mm and on finished surfaces of welds as required by referencing code/section. The examination includes base material 13 mm on each side of the welds. REFERENCE ASME SECTION V/I/VIII(Divn 1&2) / 2003 Addenda ASME B 31.1/ 2001 ANSI/AWS D1.1 / 2002 EQUIPMENT Equipments generating half-wave rectified alternating current employing prods at the end of magnetising cables shall be used for examination by circular magnetisation method. Direct/Alternating current electromagnetic yokes shall be used to detect discontinuities that are open to the surface of the part by longitudinal magnetisation method and to examine the surfaces where arcing is not permitted or prod method is not practicable. EXAMINATION MEDIUM The ferromagnetic particles used as examination medium shall be either wet or dry. Wet particles may be fluorescent or non-fluorescent. Dry magnetic particles black, gray or red in colour shall be used as the examination medium for examination of welds and other product forms to provide adequate contrast with the surface being examined. The surface temperature of the part examined with dry particles shall not exceed 315C. Non fluorescent wet particles will be black or reddish brown in colour that provide adequate contrast with the surface being examined. Wet particles shall be suspended in kerosene or water for application to the test surface by flowing or spraying. Suitable conditioning agents shall be added to the water to provide proper wetting and corrosion protection for the parts being examined. The temperature of the wet particle suspension and the surface of the part being examined shall not exceed 57C. The bath concentration shall be determined by measuring the settling volume through the use of pear-shaped centrifuge tube. The suspension shall be mixed thoroughly or shall be run through the re-circulating system for at least 30 minutes to ensure thorough mixing of all particles. The settling time shall be 30 minutes minimum with water based suspension or 60 minutes minimum with petroleum distillate suspension before taking the reading.

1.2

2.0 2.1 2.2 2.3 3.0 3.1

3.2

4.0 4.1

4.2

4.3

4.4

4.5

PROPRIETARRY DATA NOT TO BE DISCLOSED OR REPRODUCED WITHOUT THE PERMISSION OF BHEL.

BHARAT HEAVY ELECTRICALS LIMITED

235-029

DEPT.235 TIRUCHIRAPALLI 620 014 Non-Destructive Testing

BHE:NDT:PB:MT- 01 Revision 11 Page 4 of 15

The settling volume shall be within 1.2 to 2.4 mL for non-fluorescent particles and 0.1 to 0.4 mL for fluorescent particles, per 100 mL of vehicle or as recommended by the manufacturer. 5.0 5.1 5.1.1 SURFACE CONDITIONING Preparation As welded, as rolled, as cast or as forged surface is generally acceptable provided the surface irregularities will not mask the indications due to discontinuities. otherwise surface preparation by grinding or machining may be necessary. Undercuts, overlaps or abrupt ridges and valleys in the welds and openings shall be smoothly merged with the parent metal. Prior to magnetic particle examination, the surface to be examined and adjacent area within at least 25 mm of the area of interest shall be dry and free of any dirt, grease, lint, scale, welding flux, spatter, oil or other extraneous matter that would interfere with the examination. Cleaning may be accomplished by detergents, organic solvents, de-scaling solutions, paint removers, sand or grit blasting methods. Thin nonconductive coating such as painting will not normally interfere with the formation of indications. They must be removed at all points where electrical contact is to be made for direct magnetisation. Surface Contrast Enhancement When coatings are applied temporarily to enhance particle contrast or if coatings are left on the part being examined, it must be demonstrated that indications can be detected through the enhancement coating thickness on a test plate with machined grooves as in 15.0. If indications of required sensitivity could not be detected, the coating shall be removed. METHOD OF EXAMINATION Examination shall be made by continuous method. Dry continuous magnetisation method The magnetising current remains on while the examination medium (Dry particle) is being applied and while the excess of the examination medium is being removed. Wet continuous magnetisation method Wet magnetic particles application involves bathing the surface of the part with examination medium and terminating the bath application immediately prior to cutting off the magnetising current with two or more shots given to the part. The duration of the magnetising current is typically on the order of 1/2 seconds with two or more shots

5.1.2

5.1.3

5.1.4

5.2 5.2.1

5.2.2

6.0 6.1 6.1.1 6.1.1.1

6.1.2 6.1.2.1

PROPRIETARRY DATA NOT TO BE DISCLOSED OR REPRODUCED WITHOUT THE PERMISSION OF BHEL.

BHARAT HEAVY ELECTRICALS LIMITED

235-029

DEPT.235 TIRUCHIRAPALLI 620 014 Non-Destructive Testing

BHE:NDT:PB:MT- 01 Revision 11 Page 5 of 15

given to the part. 7.0 7.1 TECHNIQUES One of the following magnetisation techniques shall be used. a) Prod Technique 8.0 8.1 b) Yoke Technique

TYPE OF CURRENT FOR MAGNETISATION Single phase half-wave rectified current (HWAC) / (HWDC) shall be employed for testing with prod techniques. The amperage required with single-phase Half-wave rectified current shall be verified by measuring the average current during the conducting half cycle only. For yokes, the current shall be either AC or HWAC. CALIBRATION Ammeter of magnetising equipment shall be calibrated at least once a year, or after each time it has been subjected to major electrical repair, periodic overhaul or damage. If equipment has not been in use for a year or more, calibration shall be done prior to first use. The ammeter shall be got calibrated through Instrumentation section of Maintenance and Services Department. Lifting Power of Yokes The magnetising force of yokes shall be checked at least once a year or whenever a yoke has been damaged. If a yoke has not been in use for a year or more, a check shall be done prior to first use. A record shall be maintained for checking made in format No. 235-004 or equivalent. Each alternating current electromagnetic yoke shall have a lifting power of at least 4.5 kg and each direct current / permanent magnetic yoke shall have a lifting power of 18.1 kg, at the maximum pole spacing that will be used. Or the pole distance shall be the spacing at which the yoke lifts the stipulated weight. Each weight shall be weighed with a scale from a reputable manufacturer and stenciled with the applicable nominal weight prior to first use. A weight need only be verified again if damaged in a manner that could have caused potential loss of material. EXAMINATION Direction of Magnetisation At least two separate examination shall be carried out on each area. During the second examination the prods/poles are spaced so that the lines of flux are approximately perpendicular to those used during the first examination. A different technique for magnetisation may be used for the second examination.

8.2

8.3 9.0 9.1

9.2 9.2.1

9.2.2

9.2.3

10.0 10.1 10.1.1

PROPRIETARRY DATA NOT TO BE DISCLOSED OR REPRODUCED WITHOUT THE PERMISSION OF BHEL.

BHARAT HEAVY ELECTRICALS LIMITED

235-029

DEPT.235 TIRUCHIRAPALLI 620 014 Non-Destructive Testing

BHE:NDT:PB:MT- 01 Revision 11 Page 6 of 15

10.2 10.2.1

Examination Coverage Examination shall be made with sufficient field overlap to assure 100% coverage of testing. PROD TECHNIQUE: (Fig.1,2 &3) Magnetising Procedure The prod electrodes are pressed firmly against the surface in the area to be examined. In order to avoid arcing a remote control switch shall be built into the prod handles, to permit the current to be turned on after the prods have been properly positioned and to be turned off before they are removed. Magnetising Current The current shall be 100 to 125 (maximum) amperes/25 mm of prod spacing for sections 19 mm thick or greater. For sections less than 19 mm thick, the current shall be 90 to 110 amperes/25 mm of prod spacing. Prod Spacing Prod spacing shall not be less than 75 mm nor exceed a maximum of 200 mm . The prod tips shall be kept clean and dressed and the contact areas of the test surface shall be free from dirt, scale, oil etc. to minimise electrical arcing. If the open circuit voltage of the magnetising current is greater than 25 Volts, Lead, Steel or Aluminum rather than copper tipped prods shall be preferred to avoid copper deposits on the part being examined. YOKE TECHNIQUE The pole spacing shall be between 100 mm to 150 mm. The field indicator will be used to check the direction of the part magnetisation. APPLICATION OF DRY PARTICLES The dry particles shall be applied in such a manner that a light uniform dust-like coating settles on the surface of the area being examined. The application technique shall be such that the particles are suspended in air and reaches the examination surface in a uniform cloud with a minimum force, using a hand powder applicators (squeeze bulb) or specially designed mechanical blower or by a spray nozzle. Dry particles shall not be applied to a wet surface nor when there is excessive wind. The particles shall not be applied by pouring, throwing, or spreading with fingers. Any excess powder shall be removed while the magnetisation current is on and shall be with a gentle air stream without removing or disturbing particles attracted by a leakage field that may prove to be a relevant indication.

11.0 11.1 11.1.1

11.2 11.2.1

11.2.2

11.3 11.3.1 11.3.2

12.0 12.1

13.0 13.1.

13.1.1

13.1.2

PROPRIETARRY DATA NOT TO BE DISCLOSED OR REPRODUCED WITHOUT THE PERMISSION OF BHEL.

BHARAT HEAVY ELECTRICALS LIMITED

235-029

DEPT.235 TIRUCHIRAPALLI 620 014 Non-Destructive Testing

BHE:NDT:PB:MT- 01 Revision 11 Page 7 of 15

13.2 13.2.1

APPLICATION OF WET PARTICLES The application of wet particles involves the bathing of the area to be examined, by spraying or flowing during the application of magnetising current. Two or more shots shall be applied, but the last shot shall be applied while the bath still remains on the area to be examined and after the particle flow has been stopped. Care shall be taken to cut off the bath application before removing the magnetic field, to prevent high-velocity particle flow that may wash away or remove fine or weakly held indications . LIGHTING Visible Light Intensity The examination and evaluation of indications shall be performed under minimum light intensity of 100 fc (1000 lx). Black Light Black light intensity at the examination surface shall be not less than 1000 micro watt/cm square. The black light intensity shall be measured at least once every 8 hr. and whenever the work station is changed. With fluorescent particles the examination is performed in a darkened area. The examiner shall be in the darkened area for at least 5 minutes prior to performing the examination for eye adaptation. The examiners shall not wear photosensitive glasses. The black light shall be warmed up for a minimum period of 5 minutes prior to use or measurement of intensity. SYSTEM PERFORMA NCE CHECK (Fig.4) For prod magnetisation with HWAC, performance sensitivity shall be checked at least once in a shift before start of the examination on a test plate that contains machined grooves to different depths. The indication of a groove at 3 mm depth from the surface of the test plate will indicate adequate sensitivity. If the part is to be tested with contrast coat, the sensitivity shall be checked with the contrast coat on the surface of the test block. For electromagnetic yokes, the adequacy or direction of the magnetising force shall be verified by positioning the 'Magnetic Field Indicator' on the surface to be examined. The pattern in the indicator should be clearly developed on the surface of the block. DEMAGNETIS ATION No demagnetisation will be done after the test except specifically required. EVALUATION OF INDICATION

13.2.2

14.0 14.1 14.1.1

14.2 14.2.1

14.2.2 14.2.3

14.2.4

15.0 15.1

15.2

15.3

16.0 16.1 17.0

PROPRIETARRY DATA NOT TO BE DISCLOSED OR REPRODUCED WITHOUT THE PERMISSION OF BHEL.

BHARAT HEAVY ELECTRICALS LIMITED

235-029

DEPT.235 TIRUCHIRAPALLI 620 014 Non-Destructive Testing

BHE:NDT:PB:MT- 01 Revision 11 Page 8 of 15

17.1

Mechanical discontinuity at the surface would be indicated by the retention of the powder or medium. All the indications are not necessarily discontinuity indications since certain metallurgical discontinuities and magnetic permeability variations may produce similar unacceptable discontinuities. These non-relevant indications shall be re-examined by any other suitable NDT methods such as Liquid penetrant or macro etching. Relevant indications are those which result from unacceptable mechanical discontinuities. Linear indications are those indications in which the length is greater than three times the width. Rounded indications are circular or elliptical with the length equal to or less than three times the width. ACCEPTANCE STANDARDS AS PER ASME (SEC I, VIII Div 1 & 2 and B 31.1) AND OTHERS Welds and Materials An indication of an imperfection may be larger than the imperfection that causes it. However, the size of the indication is the basis for acceptance for evaluation. Only indications which have dimensions greater than relevant. 1.6 mm shall be considered as

17.1.1

17.2 17.2.1

17.2.2

18.0

18.1 18.2

18.3

18.4 18.4.1 18.4.2 18.4.3

All surfaces to be examined, except as mentioned in 19.5, 19.6 and 19.7 shall be free of Relevant linear indications. Relevant rounded indications greater than 4.8 mm Four or more relevant rounded indications in a line edge to edge. separated by 1.6 mm or less

18.4.4

Ten or more rounded indications in any 3870 mm square ( 6 sq. inch ) of surface with the major dimension of this area not to exceed 150 mm with the area taken in the most unfavourable location relative to the indication being evaluated. Cut edges and openings : All surfaces to be examined shall be free of (a) Cracks (b) Laminations exceeding 25 mm in length.

18.5 18.5.1

18.6

In welds joining nipples to drums, spheres or headers, all slag or porosity indications shall be investigated to assure that no leak-path exists.

PROPRIETARRY DATA NOT TO BE DISCLOSED OR REPRODUCED WITHOUT THE PERMISSION OF BHEL.

BHARAT HEAVY ELECTRICALS LIMITED

235-029

DEPT.235 TIRUCHIRAPALLI 620 014 Non-Destructive Testing

BHE:NDT:PB:MT- 01 Revision 11 Page 9 of 15

18.7

In attachment welds of non-load carrying class, to material separation are unacceptable.

indications from cracks or due

19.0 19.1

ACCEPTANCE STANDARD FOR STRUCTURAL COMPONENTS AS PER AWS The magnetic Particle acceptance criteria is based on the size of the actual discontinuity and not the size of the discontinuity as indicated by the magnetic particle inspection medium. Where discontinuity cannot be visually seen (with magnification if required), after removal of the indicating medium, evaluation shall be based on size and nature of the magnetic particle indication. Statically loaded Nontubular connections Cracks, Lack of Fusion, and Incomplete Penetration are not acceptable. Undercut - for material with thickness less than 25 mm, undercut shall not exceed 1.0 mm, except that a maximum 2.0 mm is permitted for an accumulated length of 50 mm in any 300 mm. For material equal to or greater than 25.0 mm thick, undercut shall not exceed 2.0 mm for any length of weld. Porosity - a complete joint penetration groove welds in butt joints transverse to the direction of computed tensile stress shall have no visible piping porosity. For all other groove welds and for fillet welds, the sum of the visible piping porosity 1.0 mm or greater in diameter shall not exceed 10.0 mm in any linear 25.0 mm of weld and shall not exceed 20mm in any 300 mm length of weld. Cyclically Loaded Nontubular Connections Undercut - In primary members, undercut shall be no more than 0.25 mm deep when the weld is transverse to tensile stress under any design loading condition. Undercut shall not be more than 1.0 mm deep for all other cases. Porosity - The frequency of piping porosity in fillet welds shall not exceed one in each 100 mm of weld length and the maximum diameter shall not exceed 2.5 mm. Exception: for fillet connecting stiffeners to web, the sum of the diameters of piping porosity shall not exceed 10mm in any linear 25mm of weld and shall not exceed 20 mm in 300 mm length of weld. Complete joint penetration groove welds in butt joints transverse to the direction of computed tensile stress shall have NO Piping Porosity. PIPING POROSITY - (General) is elongated porosity whose major dimension lies in a direction approximately normal to the weld surface. Frequently referred to as pin holes when the porosity extends to the weld surface. EDGE DISCONTINUITIES IN CUT MATERIALS No crack is acceptable. Mill induced discontinuity

20.0 20.1 20.2

20.3

21.0 21.1

21.2

21.3

21.4

22.0 22.1 22.2

PROPRIETARRY DATA NOT TO BE DISCLOSED OR REPRODUCED WITHOUT THE PERMISSION OF BHEL.

BHARAT HEAVY ELECTRICALS LIMITED

235-029

DEPT.235 TIRUCHIRAPALLI 620 014 Non-Destructive Testing

BHE:NDT:PB:MT- 01 Revision 11 Page 10 of 15

22.3 22.4 22.5 22.6

Length 25mm and less - Acceptable. Length over 25 mm and depth up to 3 mm - acceptable Length over 25 mm and depth between 3 mm and 25 mm - indications to be removed. Length over 25 mm and depth greater than 25 mm - indications to be removed to a depth up to 25 mm. REPAIR AND RE-EXAMINATION Whenever an imperfection is repaired by chipping or grinding or and subsequent repair by welding is not required, the excavated area shall be blended into the surrounding surface so as to avoid sharp notches, crevices or corners. After a defect is thought to have been removed and prior to making weld repairs, the area will be examined by suitable methods to ensure that the defect has been removed or reduced to an acceptable size of an imperfection . Where welding is required after repair of an imperfection the area shall be cleaned and repair carried out. After repairs have been made the repaired area shall be blended into the surrounding surface so as to avoid sharp notches, crevices or corners. After repairs have been made, the repaired area shall be re-examined by methods of examination that were originally required for the affected area. PERSONNEL QUALIFICATIONS All personnel carrying out the examination and evaluation shall minimum Level-1 as per BHE:NDT:G:CRT. FINAL CLEANING When the inspection is concluded, the magnetic particles shall be removed by any suitable means, leaving the product in a dry and clean condition. REPORT Copies of the report in a standard format No. 235-011 (copy attached herewith) or 49719- C, duly signed by a minimum Level II personnel shall be issued after the test. ****** be qualified to

23.0 23.1

23.2

23.3

23.4

24.0 24.1

25.0 25.1

26.0 26.1

PROPRIETARRY DATA NOT TO BE DISCLOSED OR REPRODUCED WITHOUT THE PERMISSION OF BHEL.

BHARAT HEAVY ELECTRICALS LIMITED

235-029

DEPT.235 TIRUCHIRAPALLI 620 014 Non-Destructive Testing

BHE:NDT:PB:MT- 01 Revision 11 Page 11 of 15

PROPRIETARRY DATA NOT TO BE DISCLOSED OR REPRODUCED WITHOUT THE PERMISSION OF BHEL.

BHARAT HEAVY ELECTRICALS LIMITED

235-029

DEPT.235 TIRUCHIRAPALLI 620 014 Non-Destructive Testing

BHE:NDT:PB:MT- 01 Revision 11 Page 12 of 15

PROPRIETARRY DATA NOT TO BE DISCLOSED OR REPRODUCED WITHOUT THE PERMISSION OF BHEL.

BHARAT HEAVY ELECTRICALS LIMITED

235-029

DEPT.235 TIRUCHIRAPALLI 620 014 Non-Destructive Testing

BHE:NDT:PB:MT- 01 Revision 11 Page 13 of 15

FIG (3) TECHNIQUES FOR EXAMINATION OF FILLET WELDS

0 POSITION - 1 NOTE : 1) PRODS mus t be placed on drum / header perpendicular to plate surface. 2) Inspection will be 100% of weld for each shot. X POSITION - 2 ARC BREAK LOCATION

PROPRIETARRY DATA NOT TO BE DISCLOSED OR REPRODUCED WITHOUT THE PERMISSION OF BHEL.

BHARAT HEAVY ELECTRICALS LIMITED

235-029

DEPT.235 TIRUCHIRAPALLI 620 014 Non-Destructive Testing

BHE:NDT:PB:MT- 01 Revision 11 Page 14 of 15

PROPRIETARRY DATA NOT TO BE DISCLOSED OR REPRODUCED WITHOUT THE PERMISSION OF BHEL.

BHARAT HEAVY ELECTRICALS LIMITED

235-029

DEPT.235 TIRUCHIRAPALLI 620 014 Non-Destructive Testing

BHE:NDT:PB:MT- 01 Revision 11 Page 15 of 15

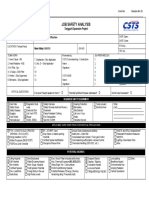

MAGNETIC PARTICLE EXAMINATION REPORT

Report No. Part Work Order No. Drawing No. Procedure & Acceptance Sl. No. : Date: : : : BHE:NDT:PB / NUC / V : MT : Rev.: Material Surface Condition Magnetisation Method: Dry / Wet Prod Spacing Demagnetisation Stage of Test Findings : : : : : : : Test No.: Circular / Long. HWDC / AC. Current: Done / Not Done Before / After SR. Remarks

Details of Part

Qty.

ACCEPTED:

DEFECTS NOTICED:

Operator s Name Level I / II

Approved/NDT in-charge Level II / III

Authorized Inspection Engineer IBR / NTPC / LLOYDS / EIL / TCE

S-ar putea să vă placă și

- 546 - MT-B3-103-01-1503 Rev 4Document13 pagini546 - MT-B3-103-01-1503 Rev 4GIOVANNIÎncă nu există evaluări

- Cutting Machine Check Sheet: Machine Set No.: Department: Contractor Name: Last Inspection Date: Inspection DateDocument1 paginăCutting Machine Check Sheet: Machine Set No.: Department: Contractor Name: Last Inspection Date: Inspection Datepartha100% (1)

- Strength of Materials ReportDocument14 paginiStrength of Materials ReportRahul JohnsonÎncă nu există evaluări

- 03 Strength Assessment of Recycled Aggregate Concrete by Ultrasonic Pulse Velocity Test PDFDocument5 pagini03 Strength Assessment of Recycled Aggregate Concrete by Ultrasonic Pulse Velocity Test PDFYati R. TankÎncă nu există evaluări

- Site Survey ReportDocument12 paginiSite Survey ReportAlvin ChoongÎncă nu există evaluări

- Transportation pROCEDUREDocument44 paginiTransportation pROCEDUREBayu AkbarÎncă nu există evaluări

- Grinding Machine Check Sheet: Machine Set No.: Department: Contractor Name: Last Inspection Date: Inspection DateDocument1 paginăGrinding Machine Check Sheet: Machine Set No.: Department: Contractor Name: Last Inspection Date: Inspection DateparthaÎncă nu există evaluări

- Hydraulics Topic 6 Hydraulic Machinery PDFDocument48 paginiHydraulics Topic 6 Hydraulic Machinery PDFVictoria JungÎncă nu există evaluări

- NIT Calicut lab compares cyclone separator efficiencyDocument13 paginiNIT Calicut lab compares cyclone separator efficiencynkar037Încă nu există evaluări

- MEC 532 Minute Meeting TemplateDocument3 paginiMEC 532 Minute Meeting TemplateSiti Zaleha HmlonÎncă nu există evaluări

- (WTC) Repair Welding in Power PlantsDocument23 pagini(WTC) Repair Welding in Power PlantsSarah FrazierÎncă nu există evaluări

- Dust Control Report 032006 PDFDocument63 paginiDust Control Report 032006 PDFFrancisco ChavezÎncă nu există evaluări

- Charpy Impact TestDocument2 paginiCharpy Impact TestGanim Shed100% (1)

- Job Hazard Analysis TemplateDocument2 paginiJob Hazard Analysis TemplateIzmeer JaslanÎncă nu există evaluări

- KNC 1101 Chemical Engineering Laboratory I Experiment ManualDocument36 paginiKNC 1101 Chemical Engineering Laboratory I Experiment ManualIzzatiHazwaniÎncă nu există evaluări

- Rockwell Hardness Test ExplainedDocument5 paginiRockwell Hardness Test ExplainedUsama Tahir100% (1)

- Manufacturing Process of SF Insulated Ring Main Unit (INS-24)Document33 paginiManufacturing Process of SF Insulated Ring Main Unit (INS-24)Yong JinÎncă nu există evaluări

- Non Destructive Testing Experiment ReportDocument15 paginiNon Destructive Testing Experiment ReportsinabirecikÎncă nu există evaluări

- Lab Material 1 (Emd4m8b-G7)Document36 paginiLab Material 1 (Emd4m8b-G7)shahril shaharoniÎncă nu există evaluări

- Strength of Materials: Fatigue TestDocument18 paginiStrength of Materials: Fatigue TestMuhammad HiwaÎncă nu există evaluări

- Electrical Insulation and Thermal Measurements For Motors and Drives AnDocument4 paginiElectrical Insulation and Thermal Measurements For Motors and Drives Anmu_ignoreÎncă nu există evaluări

- 4 - Properties of AsphaltDocument8 pagini4 - Properties of AsphalttunlajiÎncă nu există evaluări

- SlumpDocument2 paginiSlumpErikson MoralesÎncă nu există evaluări

- Distructive & Non-Destructive Testing of MaterialDocument16 paginiDistructive & Non-Destructive Testing of MaterialEngr.Hamid Ismail CheemaÎncă nu există evaluări

- Engineering Materials Lab ReportDocument18 paginiEngineering Materials Lab ReportAhmad Fakhrie ShahÎncă nu există evaluări

- Apex Steel Catalogue PDFDocument16 paginiApex Steel Catalogue PDFArifsalim0% (1)

- Pressure Testing Safety EssentialsDocument7 paginiPressure Testing Safety EssentialsSuleyman HaliciogluÎncă nu există evaluări

- ILR Bearing Housing Assembly ProcedureDocument10 paginiILR Bearing Housing Assembly ProcedureAlejandroZegarraÎncă nu există evaluări

- The Environmental Monitoring Plan For The Albertine Graben 2012-2017Document100 paginiThe Environmental Monitoring Plan For The Albertine Graben 2012-2017African Centre for Media Excellence100% (1)

- Thermodynamics Lab on Gas Compression & DepressionDocument3 paginiThermodynamics Lab on Gas Compression & DepressionAmirul AriffÎncă nu există evaluări

- Hydraulic JumpDocument5 paginiHydraulic JumpKafeel Bichu0% (1)

- Lecture1 HSE MovementDocument29 paginiLecture1 HSE MovementBhalvindrakumar MaranÎncă nu există evaluări

- BMM1811 Mechanical Laboratory 1Document2 paginiBMM1811 Mechanical Laboratory 1mohamad rizal harunÎncă nu există evaluări

- CompactionDocument15 paginiCompactionpp hsu100% (6)

- A Report On Fire Extinguisher OperationDocument3 paginiA Report On Fire Extinguisher OperationrajkotbpÎncă nu există evaluări

- 26 - Welding Machine ChecklistDocument1 pagină26 - Welding Machine ChecklistZeeshan AbbasiÎncă nu există evaluări

- Job Safety Analysis Water Ponding RectificationDocument22 paginiJob Safety Analysis Water Ponding RectificationHaris RisdianaÎncă nu există evaluări

- CES511 - LAB EXPERIMENT: INSTABILITY OF STRUTDocument13 paginiCES511 - LAB EXPERIMENT: INSTABILITY OF STRUTjajenÎncă nu există evaluări

- Isolation Permit SafetyDocument2 paginiIsolation Permit SafetyMohammed KadhimÎncă nu există evaluări

- Ppe Training Record: Department Occupation Type of Ppe Make/Model Name InitialsDocument3 paginiPpe Training Record: Department Occupation Type of Ppe Make/Model Name Initialsvlad100% (1)

- Hazard Identification and Risk AssesmentDocument4 paginiHazard Identification and Risk AssesmentSkipper SkyÎncă nu există evaluări

- Experiment No 3Document3 paginiExperiment No 3pomar026100% (1)

- Pec Basics v9 PDFDocument8 paginiPec Basics v9 PDFWayneÎncă nu există evaluări

- Hoist and Jib Crane Safety InspectionDocument3 paginiHoist and Jib Crane Safety InspectionSamsung Joseph0% (1)

- Tensile TestingDocument8 paginiTensile TestingAddrien DanielÎncă nu există evaluări

- JSA For ONGC PhotographyDocument1 paginăJSA For ONGC PhotographyPanchdev KumarÎncă nu există evaluări

- SDLINC CIVIL QA QC TRAINING: NDT METHODS FOR BRIDGESDocument12 paginiSDLINC CIVIL QA QC TRAINING: NDT METHODS FOR BRIDGESKamakhya MallÎncă nu există evaluări

- Liquid or Dye Penetrant InspectionDocument43 paginiLiquid or Dye Penetrant InspectionTrinadh Venkata Kumar NillaÎncă nu există evaluări

- Combustion Analyzer Instruction ManualDocument108 paginiCombustion Analyzer Instruction ManualalperbogaÎncă nu există evaluări

- Deflection LabDocument9 paginiDeflection LabFarid NajandÎncă nu există evaluări

- Hotwork Implementation Verification Checklist Rev 5Document3 paginiHotwork Implementation Verification Checklist Rev 5anjangandak2932100% (1)

- Dynamics Lab Sheet 3 - Forced Vibration Experiment - PKPDocument3 paginiDynamics Lab Sheet 3 - Forced Vibration Experiment - PKPfaqhrulÎncă nu există evaluări

- RCFA K-23252 Blower Trip Due Motor Overload - FinalDocument19 paginiRCFA K-23252 Blower Trip Due Motor Overload - FinalMuhd Fadzlee ZÎncă nu există evaluări

- HSE Assignment 3 FinalDocument21 paginiHSE Assignment 3 FinalLuqman HakimÎncă nu există evaluări

- Steel Lab ReportDocument14 paginiSteel Lab ReportDavid StamenovÎncă nu există evaluări

- Operate and Report On A Water Treatment PlantDocument3 paginiOperate and Report On A Water Treatment PlantMziyanda Boet-Bhayi ShumîÎncă nu există evaluări

- Job Hazard Analysis for Deep Well Drilling with HotworksDocument2 paginiJob Hazard Analysis for Deep Well Drilling with Hotworksjay RÎncă nu există evaluări

- MT ProcedureDocument8 paginiMT Procedureshabbir626100% (1)

- Nde Procedure Magnetic Particle TestingDocument20 paginiNde Procedure Magnetic Particle TestingBhisamS Salleh100% (3)

- Welding DetailsDocument5 paginiWelding DetailsIssac GeorgeÎncă nu există evaluări

- Ougen Bava BiographyDocument76 paginiOugen Bava BiographyIssac GeorgeÎncă nu există evaluări

- Prostration in Orthodox Christian WorshipDocument1 paginăProstration in Orthodox Christian WorshipIssac GeorgeÎncă nu există evaluări

- Holy MatrimonyDocument2 paginiHoly MatrimonyIssac GeorgeÎncă nu există evaluări

- Details of NDTDocument7 paginiDetails of NDTIssac GeorgeÎncă nu există evaluări

- HottapDocument6 paginiHottaprodofgodÎncă nu există evaluări

- 1934-Constitution of Malankara SabhaDocument18 pagini1934-Constitution of Malankara SabhaIssac GeorgeÎncă nu există evaluări

- Welding Theory and ApplicationDocument741 paginiWelding Theory and ApplicationGregory MankoÎncă nu există evaluări

- E8018 B8Document1 paginăE8018 B8Issac GeorgeÎncă nu există evaluări

- Post Weld Heat TreatmentDocument2 paginiPost Weld Heat TreatmentgullenariÎncă nu există evaluări

- SMAW E8015-B8 Electrode for Welding Creep-Resistant SteelsDocument1 paginăSMAW E8015-B8 Electrode for Welding Creep-Resistant SteelsIssac GeorgeÎncă nu există evaluări

- CSWIP 3.2tipsDocument16 paginiCSWIP 3.2tipsendri2000100% (1)

- MS Power Point TutorialDocument13 paginiMS Power Point TutorialHanan Shan0% (1)

- Milestones Milestones: Transfer Lin Transfer Line Protection During Cds TripDocument7 paginiMilestones Milestones: Transfer Lin Transfer Line Protection During Cds TripIssac GeorgeÎncă nu există evaluări

- SivaDocument72 paginiSivaIssac GeorgeÎncă nu există evaluări

- A - Bahasa Inggris-DikonversiDocument96 paginiA - Bahasa Inggris-DikonversiArie PurnamaÎncă nu există evaluări

- The Power of Flexibility: - B&P Pusher CentrifugesDocument9 paginiThe Power of Flexibility: - B&P Pusher CentrifugesberkayÎncă nu există evaluări

- Troubleshooting Edge Quality: Mild SteelDocument14 paginiTroubleshooting Edge Quality: Mild SteelAnonymous U6yVe8YYCÎncă nu există evaluări

- Stellar Competent CellsDocument1 paginăStellar Competent CellsSergio LaynesÎncă nu există evaluări

- Recommended lubricants and refill capacitiesDocument2 paginiRecommended lubricants and refill capacitiestele123Încă nu există evaluări

- Method StatementDocument11 paginiMethod StatementMohammad Fazal Khan100% (1)

- InvoiceDocument1 paginăInvoiceAnurag SharmaÎncă nu există evaluări

- Books 2738 0Document12 paginiBooks 2738 0vinoohmÎncă nu există evaluări

- NH School Employee Criminal Record Check FormDocument2 paginiNH School Employee Criminal Record Check FormEmily LescatreÎncă nu există evaluări

- VB 2Document11 paginiVB 2Sudhir IkkeÎncă nu există evaluări

- AP Statistics - 2014-2015 Semester 1 Test 3Document4 paginiAP Statistics - 2014-2015 Semester 1 Test 3Camden BickelÎncă nu există evaluări

- Numark MixTrack Pro II Traktor ProDocument3 paginiNumark MixTrack Pro II Traktor ProSantiCai100% (1)

- Road Safety GOs & CircularsDocument39 paginiRoad Safety GOs & CircularsVizag Roads100% (1)

- The Non Technical Part: Sample Interview Questions For Network EngineersDocument5 paginiThe Non Technical Part: Sample Interview Questions For Network EngineersblablaÎncă nu există evaluări

- 63db2cf62042802 Budget Eco SurveyDocument125 pagini63db2cf62042802 Budget Eco SurveyNehaÎncă nu există evaluări

- Examination: Subject CT5 - Contingencies Core TechnicalDocument7 paginiExamination: Subject CT5 - Contingencies Core TechnicalMadonnaÎncă nu există evaluări

- Job Hazard Analysis TemplateDocument2 paginiJob Hazard Analysis TemplateIzmeer JaslanÎncă nu există evaluări

- Iso 4624Document15 paginiIso 4624klkopopoonetdrghjktl100% (2)

- Air Cycle Refrigeration:-Bell - Coleman CycleDocument21 paginiAir Cycle Refrigeration:-Bell - Coleman CycleSuraj Kumar100% (1)

- Blum2020 Book RationalCybersecurityForBusineDocument349 paginiBlum2020 Book RationalCybersecurityForBusineJulio Garcia GarciaÎncă nu există evaluări

- Ultrasonic Examination of Heavy Steel Forgings: Standard Practice ForDocument7 paginiUltrasonic Examination of Heavy Steel Forgings: Standard Practice ForbatataÎncă nu există evaluări

- Brightline Guiding PrinciplesDocument16 paginiBrightline Guiding PrinciplesdjozinÎncă nu există evaluări

- WM3000U - WM3000 I: Measuring Bridges For Voltage Transformers and Current TransformersDocument4 paginiWM3000U - WM3000 I: Measuring Bridges For Voltage Transformers and Current TransformersEdgar JimenezÎncă nu există evaluări

- Fall Protection ANSIDocument5 paginiFall Protection ANSIsejudavisÎncă nu există evaluări

- Cantilever Retaining Wall AnalysisDocument7 paginiCantilever Retaining Wall AnalysisChub BokingoÎncă nu există evaluări

- Part 9. Wireless Communication Towers and Antennas 908.01 Purpose and IntentDocument12 paginiPart 9. Wireless Communication Towers and Antennas 908.01 Purpose and IntentjosethompsonÎncă nu există evaluări

- Difference Between Knowledge and SkillDocument2 paginiDifference Between Knowledge and SkilljmÎncă nu există evaluări

- Tambunting Pawnshop Vs CIR Re VATDocument7 paginiTambunting Pawnshop Vs CIR Re VATMark Lester Lee AureÎncă nu există evaluări

- RoboticsDocument2 paginiRoboticsCharice AlfaroÎncă nu există evaluări

- Rtlo 18918B 1202Document42 paginiRtlo 18918B 1202gustavomosqueraalbornozÎncă nu există evaluări