Documente Academic

Documente Profesional

Documente Cultură

Saudi Arabian Oil Company Neat Khuff Condensate Fractionation Project

Încărcat de

walitedisonDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Saudi Arabian Oil Company Neat Khuff Condensate Fractionation Project

Încărcat de

walitedisonDrepturi de autor:

Formate disponibile

SAUDI ARABIAN OIL COMPANY NEAT KHUFF CONDENSATE FRACTIONATION PROJECT

METHOD STATEMENT FOR GRAVITY TESTING OF UNDER GROUND SEWER SYSTEM SUB CONTRACT NO: 308200 DOCUMENT NO: 308200 -MST-PP-004 REV 0

Client : SAUDI ARAMCO SNAMPROGETTI

Project : NEAT KHUFF CONDENSATE FRACTIONATION PROJECT

Contractor : DODSAL& CO.

Date : 11.04 .2002

308200-MST-PP-004 REV 0 NEAT KHUFF CONDENSATE FRACTIONATION PROJECT

Page 1

of 6

METHOD STATEMENT FOR GRAVITY TESTING OF UNDER GROUND SEWER SYSTEM

REVISION CONTROL

Revision Status 0

Date of Issue 11.04.2002

Details of Revision INITIAL

Prepared by DODSAL V.K.SAMY

Reviewed by DODSAL S.V.RANGAN

Approved by DODSAL AB

Approved by SP

308200-MST-PP-004 REV 0 NEAT KHUFF CONDENSATE FRACTIONATION PROJECT

Page 2

of 6

METHOD STATEMENT FOR GRAVITY TESTING OF UNDER GROUND SEWER SYSTEM

INDEX

1.0 2.0 3.0 4.0 5.0 6.0

PURPOSE SCOPE REFERENCES DEFINITIONS PROCEDURE DOCUMENTATION

308200-MST-PP-004 REV 0 NEAT KHUFF CONDENSATE FRACTIONATION PROJECT

Page 3

of 6

1.0

PURPOSE To define preparation and method used to conduct GRAVITY leak testing of under ground (RTR pipes) oily water sewer system as required in the specification.

2.0

SCOPE To ensure that the under ground sewer piping system has been successfully leak tested from man hole to man hole or catch basin to the man hole according to the design limit and specification.

3.0

REFERENCE DOCUMENTS 3.1 INTERNATIONAL CODES AND STANDARDS PIP- CVS-02700 3.2 SAUDI ARAMCO DOCUMENTS ScheduleQ Saudi Aramco Engineering Standards SAES - S 020 04-SAMSS -034 SAEP - 327 G.I .2.100 3.3 Industrial Drainage and Sewers RTR (Fibre Glass) Pressure Pipe and Fittings Disposal of wastewater from cleaning, flushing and hydrostatic tests Work permit system Under Ground Gravity Sewers

SNAMPROGETTI DOCUMENTS Quality Control plan for IK activity General requirements for field quality control. Field Quality Control Plan for Piping Piping Material specification Dodsal Documents Inspection and test plan for gravity leak testing Of Sewer piping Inspection and test plan for RTR Piping ; 308200-ITP-PP-004 : 308200-ITP-CI-010

Page 4

: SPC-J64-ZA-E-9601 Rev D : SPC-J64-ZA-E-9607 Rev A : SPC-J64-ZA-E-9618 Rev A : SPC-J64-GA-E-60001 Rev B

Rev 0 Rev 2

308200-MST-PP-004 REV 0 NEAT KHUFF CONDENSATE FRACTIONATION PROJECT

of 6

4.0

DEFINITIONS COMPANY CONTRACTOR SUB CONTRACTOR OWS SAUDI ARABIAN OIL COMPANY (SAUDI ARAMCO) SNAMPROGETTI DODSAL & CO OILY WATER SEWER SYSTEM

5.0 0 5.1 5.1.1 5.1.2 5.1.3 5.1.4 5.1.5 0

PROCEDURE Responsibility The Hydro test Engineer shall be responsible for preparation of the test procedure, delivery of the approved test package to job site The Site Piping Engineer shall ensure the completeness of the piping system before testing through pre-test punch listing. Dodsal RTR QC Inspector to check the system, verify all QC documents, clears the system for Gravity leak testing and co - ordination with the inspection group. The Asst. Piping Engineer and / or Piping Foremen shall prepare the system for leak test. DODSAL RTR piping QC Inspector to check the system and he shall issue RFI to SNAMP and SAUDI ARAMCO for witness of the gravity leak test.

5.2 SAFETY 5.2.1 5.3 The piping system to be tested shall be properly supported and restrained from movements.

MATERIALS All preparatory materials PLUGS or balloon of various Sizes and vent pipe etc

5.4

GENERAL REQUIREMENTS 5.4.1 5.4.2 Prior to the conduct of b leak test, the pre-test punch lists YES ITEMS if any shall be cleared. Sewers that have not been back filled shall be watertight for a period of 4 hours. Sewers that have been back filled shall be watertight for a period of 24 hours.

308200-MST-PP-004 REV 0 NEAT KHUFF CONDENSATE FRACTIONATION PROJECT

Page 5

of 6

5.5

SEQUENCE OF OPERATION 5.5.1 The system may be separated into sub-system for testing. The Under Ground services lay-out Drawing shall show the limit and method of isolation for system or sub- system shall be prepared prior to testing. Fill the system / sub system with approved test fluid (Raw Water) All openings not included in the test shall be isolated by stopper/ plug/ balloon. Air venting shall be provided during filling the sewer pipes. The test water will be filled to the rim of man hole as per SAES- S 070 Para. 18.8. (f). If any leakage is found the system shall be dewatered. Leaks shall be repaired. Test fluid (Raw Water) shall be refilled and test will be continued.

5.5. 2

5.5. 3 5.5.4

5.5.5 Test shall be considered satisfactory if there is no evidence of leakage or loss of WATER LEVEL after the specified test period of 4 Hours / 24 Hours (FULLY BURIED LINES) 5.5.6 5.5.7 Upon completion, the system shall be drained fully. The drained water will be disposed off safely into the sewer drains/ Filled for testing other system( Re use) or safer destinations, which are acceptable to Saudi Aramco. The test result will be documented on the Pressure Test Information Sheet (2462-1-ENG).

5.5.8

DOCUMENTATION SAUDI ARAMCO Documents: Form Code 2462-1-ENG Report Dodsal Documents: 308200/DOD/F-060 REV 1 Piping Punch list Pre test checklist Title Pressure test Information Sheet

308200/DOD/F-063 REV 1

CHEMICAL ANALYSIS OF TEST FLUID (RAW WATER)

308200-MST-PP-004 REV 0 NEAT KHUFF CONDENSATE FRACTIONATION PROJECT

Page 6

of 6

S-ar putea să vă placă și

- Thermoplastic Flanges: Technical Information Weights & DimensionsDocument24 paginiThermoplastic Flanges: Technical Information Weights & DimensionsAngs TazÎncă nu există evaluări

- Fabrication ARC Rates - V1Document1 paginăFabrication ARC Rates - V1Dhvanit JoshiÎncă nu există evaluări

- Marley Aquatower: Cooling TowerDocument28 paginiMarley Aquatower: Cooling TowerMauricio Damián Padilla SalgadoÎncă nu există evaluări

- Ipex FlangeDocument1 paginăIpex FlangeNabil RamehÎncă nu există evaluări

- Equal-Friction-Method (From Engineering Toolbox)Document2 paginiEqual-Friction-Method (From Engineering Toolbox)Naw AzÎncă nu există evaluări

- AGZ026BDocument106 paginiAGZ026Bciperu55Încă nu există evaluări

- Contractor Rates: S.No. Description Unit Unit PriceDocument4 paginiContractor Rates: S.No. Description Unit Unit PriceVINODÎncă nu există evaluări

- Nut Bolt Dimension1Document1 paginăNut Bolt Dimension1Nabil RamehÎncă nu există evaluări

- Side Stream Filteration PDFDocument1 paginăSide Stream Filteration PDFAshwani MishraÎncă nu există evaluări

- NEPROPLAST FlowGuard PipesDocument12 paginiNEPROPLAST FlowGuard PipesperezismaelÎncă nu există evaluări

- Brosur Reckat 2017 PDFDocument12 paginiBrosur Reckat 2017 PDFRidwanda HimawanÎncă nu există evaluări

- 20 Ft. Office ContainerDocument5 pagini20 Ft. Office ContainerAhnley Keith Serna RobinoÎncă nu există evaluări

- GS P&D Archsd 2012Document127 paginiGS P&D Archsd 2012Andy Lee100% (1)

- SIDE STREAM FILTRATION HIGH CAPACITY AND LOW FLUSH WATER LOSSDocument1 paginăSIDE STREAM FILTRATION HIGH CAPACITY AND LOW FLUSH WATER LOSSAmit ChaudharyÎncă nu există evaluări

- Toc 2Document1 paginăToc 2snikkirose17Încă nu există evaluări

- Procedure for Application of Foam Protection SystemDocument9 paginiProcedure for Application of Foam Protection SystemmÎncă nu există evaluări

- 70t MOD 70 Spreader Beam SpecsDocument2 pagini70t MOD 70 Spreader Beam SpecsWes NowakÎncă nu există evaluări

- CPVCDocument9 paginiCPVCgrasimlook50% (2)

- W P Ss 004Document12 paginiW P Ss 004BETLAHOREÎncă nu există evaluări

- Uk Mod 24 Ui - Jul 15Document2 paginiUk Mod 24 Ui - Jul 15yogihardÎncă nu există evaluări

- Plumbing Design for a 4-Storey Mixed-Use BuildingDocument65 paginiPlumbing Design for a 4-Storey Mixed-Use BuildingCharles Kaven Dela Cruz100% (1)

- GM3SEK's Amateur Radio Technical Notebook: RF Power AmplifiersDocument2 paginiGM3SEK's Amateur Radio Technical Notebook: RF Power Amplifierssree479Încă nu există evaluări

- CC-F17847-KJI-ABM-001 - RevC, Structural Calculation Skimmer Tank B (Approved)Document3 paginiCC-F17847-KJI-ABM-001 - RevC, Structural Calculation Skimmer Tank B (Approved)adonara_jeÎncă nu există evaluări

- JMS Operating Manual Niftylift HR 21Document46 paginiJMS Operating Manual Niftylift HR 21Ивайло ДимитровÎncă nu există evaluări

- Manitou 200 AtjDocument2 paginiManitou 200 AtjNeil Desai100% (1)

- 010 Subsea Hose PDFDocument16 pagini010 Subsea Hose PDFJhonatan FerreiraÎncă nu există evaluări

- GasPipelineSafetyOIR Plea WildGoose 20130628 280481 PDFDocument320 paginiGasPipelineSafetyOIR Plea WildGoose 20130628 280481 PDFcartarÎncă nu există evaluări

- Pipe Wall ThicknessDocument1 paginăPipe Wall ThicknessFurkan Burak MuhammedÎncă nu există evaluări

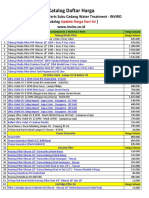

- Katalog Daftar Harga Suku Cadang Komponen Spare Part Water Treatment INVIRODocument6 paginiKatalog Daftar Harga Suku Cadang Komponen Spare Part Water Treatment INVIROTha BonietaÎncă nu există evaluări

- $huldo :run 3odwirupv 'Lhvho $uwlfxodwhg With - Le: 7hfkqlfdo VKHHWDocument2 pagini$huldo :run 3odwirupv 'Lhvho $uwlfxodwhg With - Le: 7hfkqlfdo VKHHWManitouÎncă nu există evaluări

- Fuel Oil, Auxiliary Steam & Condensate Return System Piping Flushing ProcedureDocument13 paginiFuel Oil, Auxiliary Steam & Condensate Return System Piping Flushing ProcedureepbamdadÎncă nu există evaluări

- Tank Fabrication & ErectionDocument72 paginiTank Fabrication & ErectionPramod GrÎncă nu există evaluări

- Industrial Boiler Schematic DiagramDocument1 paginăIndustrial Boiler Schematic DiagramjosebaldesÎncă nu există evaluări

- TII-HZI-50021981 - 1.0 - TII 16.10 Colour ConceptDocument18 paginiTII-HZI-50021981 - 1.0 - TII 16.10 Colour ConceptBorn ToSinÎncă nu există evaluări

- Resource Dependent Activity Type in P6Document7 paginiResource Dependent Activity Type in P6MuhammadIqbalMughalÎncă nu există evaluări

- ZA14J/ZA18J: Articulating Boom LiftsDocument2 paginiZA14J/ZA18J: Articulating Boom Liftskarthik bhatÎncă nu există evaluări

- YANBU REFINERY PROJECTDocument8 paginiYANBU REFINERY PROJECTJanakiraman MalligaÎncă nu există evaluări

- Price EstimationDocument6 paginiPrice EstimationJosua Ferry ManurungÎncă nu există evaluări

- Field Trip Report - FinalDocument9 paginiField Trip Report - Finaldmscott10Încă nu există evaluări

- Output File S3 R5 Z4Document72 paginiOutput File S3 R5 Z4Ankush JainÎncă nu există evaluări

- Pressure Vessel Dimension InspectionDocument17 paginiPressure Vessel Dimension InspectionEqubal KhanÎncă nu există evaluări

- Gas Company Shutdown Spade Installation List 2018Document1 paginăGas Company Shutdown Spade Installation List 2018andidipayadnyaÎncă nu există evaluări

- FW Line List Area 59Document7 paginiFW Line List Area 59darwayne_316346Încă nu există evaluări

- Hyundai Electric ESS Project List-1Document2 paginiHyundai Electric ESS Project List-1Rachmat HermawanÎncă nu există evaluări

- EZR RegulatorDocument40 paginiEZR RegulatorBranko BabicÎncă nu există evaluări

- Inspection Test Record (Itr) - A Jacket Pre-Loadout ST08-A Inspection / TestDocument1 paginăInspection Test Record (Itr) - A Jacket Pre-Loadout ST08-A Inspection / TestMomo ItachiÎncă nu există evaluări

- Chemtrol PVC CPVCDocument60 paginiChemtrol PVC CPVCAnees Olasseril100% (1)

- Appendix B Engineering DrawingsDocument32 paginiAppendix B Engineering DrawingsProtheuss01Încă nu există evaluări

- Staad Space Start JOB Information Engineer Date END JOB Information Input Width Unit Meter KN Joint CoordinatesDocument8 paginiStaad Space Start JOB Information Engineer Date END JOB Information Input Width Unit Meter KN Joint CoordinatesKakashi KenkaishiÎncă nu există evaluări

- Flanges - Introduction: Flanges I Boltings I Gaskets I Flanged Fittings FlangesDocument6 paginiFlanges - Introduction: Flanges I Boltings I Gaskets I Flanged Fittings FlangesshyamÎncă nu există evaluări

- How To Do A Tie-InDocument2 paginiHow To Do A Tie-Inrenjithv_4100% (1)

- USS - Clairton Battery CDocument10 paginiUSS - Clairton Battery CRay KelleyÎncă nu există evaluări

- CLRC 08-09 & 09-10Document54 paginiCLRC 08-09 & 09-10Krishan Kumar SharmaÎncă nu există evaluări

- MS Piping and Fittings Rates ListDocument12 paginiMS Piping and Fittings Rates Listshawanqureshi1706160Încă nu există evaluări

- PFI PROFILTER Activated Carbon Filter With Mild Steel TankDocument1 paginăPFI PROFILTER Activated Carbon Filter With Mild Steel Tankbennypartono407Încă nu există evaluări

- Construction Checklist for Rabab Flow Line InstallationDocument3 paginiConstruction Checklist for Rabab Flow Line InstallationDaniel MartinezÎncă nu există evaluări

- Stainless Steel Pipes - Pressure RatingsDocument1 paginăStainless Steel Pipes - Pressure RatingsNicolaSaviliÎncă nu există evaluări

- Water SoftenersDocument11 paginiWater Softenersadel rihanaÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Mech-Review Procedure - Lay-Up of Piping Systems or Vessels SAIC-A-2007 1-Dec-06Document23 paginiSaudi Aramco Inspection Checklist: Mech-Review Procedure - Lay-Up of Piping Systems or Vessels SAIC-A-2007 1-Dec-06ரமேஷ் பாலக்காடுÎncă nu există evaluări

- Reviewing Lay-Up Procedures for Piping SystemsDocument12 paginiReviewing Lay-Up Procedures for Piping Systemsimrankhan22Încă nu există evaluări

- Senior Welding InspectorDocument1 paginăSenior Welding InspectorwalitedisonÎncă nu există evaluări

- Installation of Tripper Gallery PWIDocument14 paginiInstallation of Tripper Gallery PWIwalitedisonÎncă nu există evaluări

- Hydrostatic Test Procedure PDFDocument2 paginiHydrostatic Test Procedure PDFLuis Pullas86% (43)

- Boiler and Piping ToolsDocument4 paginiBoiler and Piping ToolswalitedisonÎncă nu există evaluări

- AGP Welder List - Nov.032017Document7 paginiAGP Welder List - Nov.032017walitedisonÎncă nu există evaluări

- T0rque Value of A193 B7Document2 paginiT0rque Value of A193 B7walitedisonÎncă nu există evaluări

- List of Inspection Report For Turnover Package For WWTDocument1 paginăList of Inspection Report For Turnover Package For WWTwalitedisonÎncă nu există evaluări

- Valve List Test LimitDocument37 paginiValve List Test LimitwalitedisonÎncă nu există evaluări

- Gag For Pressure Safety Valve JimCaseyDocument1 paginăGag For Pressure Safety Valve JimCaseywalitedisonÎncă nu există evaluări

- Final Alignment Monitoring ReportDocument2 paginiFinal Alignment Monitoring ReportwalitedisonÎncă nu există evaluări

- Yuhan Welder List - Nov.22017 PDFDocument2 paginiYuhan Welder List - Nov.22017 PDFwalitedisonÎncă nu există evaluări

- Yuhan Welder List - Nov.22017Document2 paginiYuhan Welder List - Nov.22017walitedisonÎncă nu există evaluări

- T0rque Value of A193 B7Document2 paginiT0rque Value of A193 B7walitedisonÎncă nu există evaluări

- Yuhan Welder List - Nov.22017Document1 paginăYuhan Welder List - Nov.22017walitedisonÎncă nu există evaluări

- Final Alignment Monitoring ReportDocument2 paginiFinal Alignment Monitoring ReportwalitedisonÎncă nu există evaluări

- Woolim Welder List - Oct.302017Document1 paginăWoolim Welder List - Oct.302017walitedisonÎncă nu există evaluări

- NDT TrainingDocument1 paginăNDT TrainingwalitedisonÎncă nu există evaluări

- Yuhan Welder List - Oct.312017Document3 paginiYuhan Welder List - Oct.312017walitedisonÎncă nu există evaluări

- Tension Test Plate: G-Gage Length W-Width 200 0.25 MM 40 +3 - 6 MMDocument4 paginiTension Test Plate: G-Gage Length W-Width 200 0.25 MM 40 +3 - 6 MMwalitedisonÎncă nu există evaluări

- Xwell StickerDocument1 paginăXwell StickerwalitedisonÎncă nu există evaluări

- Xwell StickerDocument1 paginăXwell StickerwalitedisonÎncă nu există evaluări

- Ut Formate1Document187 paginiUt Formate1walitedisonÎncă nu există evaluări

- Correct Welding of Main Steam LineDocument2 paginiCorrect Welding of Main Steam LinewalitedisonÎncă nu există evaluări

- Welding Properties and Chemical Composition SelectionDocument84 paginiWelding Properties and Chemical Composition SelectionwalitedisonÎncă nu există evaluări

- Equipment Inventory SummaryDocument16 paginiEquipment Inventory SummarywalitedisonÎncă nu există evaluări

- B31.1 Nde RequirementsDocument1 paginăB31.1 Nde RequirementswalitedisonÎncă nu există evaluări

- Steel Material Thickness RequestDocument1 paginăSteel Material Thickness RequestwalitedisonÎncă nu există evaluări

- Review of Radiographic Examination ReportDocument1 paginăReview of Radiographic Examination ReportwalitedisonÎncă nu există evaluări

- NDT Advantage and DisadvantageDocument4 paginiNDT Advantage and DisadvantagewalitedisonÎncă nu există evaluări

- Review of Radiographic Examination ReportDocument1 paginăReview of Radiographic Examination ReportwalitedisonÎncă nu există evaluări

- Formaatbeschrijving MT202 SWIFT FINDocument7 paginiFormaatbeschrijving MT202 SWIFT FINAnonymous qLzEgXOsÎncă nu există evaluări

- Process Industry Practices Coatings: PIP CTSE2001 External Coating Systems Data Sheet Inorganic ZincDocument4 paginiProcess Industry Practices Coatings: PIP CTSE2001 External Coating Systems Data Sheet Inorganic ZincRichard TorrivillaÎncă nu există evaluări

- Department of Defense Standard Practice Avionics Integrity Program (Avip)Document26 paginiDepartment of Defense Standard Practice Avionics Integrity Program (Avip)AliÎncă nu există evaluări

- Process Industry Practices PipingDocument5 paginiProcess Industry Practices Pipingabdo samadÎncă nu există evaluări

- CB 2020 - Furniture - Packaging - GuidelinesDocument31 paginiCB 2020 - Furniture - Packaging - Guidelines44abcÎncă nu există evaluări

- Bulletin 55 Dec01Document16 paginiBulletin 55 Dec01jjÎncă nu există evaluări

- Qualifying Analytical Instruments: General Chapter Clarifies Terminology, Classifies InstrumentsDocument5 paginiQualifying Analytical Instruments: General Chapter Clarifies Terminology, Classifies InstrumentsRiyan Nur RizalÎncă nu există evaluări

- AGC, ASA, ASC - Guidelines For A Successful Construction ProjectDocument0 paginiAGC, ASA, ASC - Guidelines For A Successful Construction Projectmote34Încă nu există evaluări

- 18 Series Manual RevB English PDFDocument216 pagini18 Series Manual RevB English PDFMuhammad Sadiq Asgher SiddiqiÎncă nu există evaluări

- QCS-2010 Section 21 Part 31 Power Distribution Transformers PDFDocument3 paginiQCS-2010 Section 21 Part 31 Power Distribution Transformers PDFbryanpastor106Încă nu există evaluări

- Astm C-430Document3 paginiAstm C-430Anderson CorcueraÎncă nu există evaluări

- SBD Procurement of Works Large (Above 5 Million), 2019 (Revised) PDFDocument107 paginiSBD Procurement of Works Large (Above 5 Million), 2019 (Revised) PDFLekey WangchukÎncă nu există evaluări

- Sop SalesDocument4 paginiSop SalesBiolytic LifesciencesÎncă nu există evaluări

- DBS3900 Product Description (V200 - 01)Document60 paginiDBS3900 Product Description (V200 - 01)Elaine Tan-DiazÎncă nu există evaluări

- Muhammad Feraldi Yulizar: PT. Takenaka Indonesia (Secondment To TAKENAKA-TOTAL J.O)Document3 paginiMuhammad Feraldi Yulizar: PT. Takenaka Indonesia (Secondment To TAKENAKA-TOTAL J.O)aldiemozÎncă nu există evaluări

- Online ExaminationDocument30 paginiOnline ExaminationArihant BothraÎncă nu există evaluări

- CanningDocument79 paginiCanningRimil GeorgeÎncă nu există evaluări

- Astm D 897 - 01 - RDG5NWDocument3 paginiAstm D 897 - 01 - RDG5NWphaindikaÎncă nu există evaluări

- Consultancy Agreement Design ServicesDocument15 paginiConsultancy Agreement Design ServicesMahata PriyabrataÎncă nu există evaluări

- Process Industry Practices Coatings: PIP CTSE2002 External Coating Systems Data Sheet Inorganic Zinc/Epoxy PolyamideDocument4 paginiProcess Industry Practices Coatings: PIP CTSE2002 External Coating Systems Data Sheet Inorganic Zinc/Epoxy PolyamideRichard TorrivillaÎncă nu există evaluări

- Surface Cleaning and PaintingDocument3 paginiSurface Cleaning and PaintingTridib Dey100% (1)

- Question BankDocument11 paginiQuestion Bankjain100% (2)

- ACI 347R-14 Guide To Formwork For Concrete PDFDocument40 paginiACI 347R-14 Guide To Formwork For Concrete PDFHassan Syed82% (11)

- Equipment Erection, Static and RotaryDocument8 paginiEquipment Erection, Static and RotaryHamada ELaraby60% (5)

- Annex2 DetailedRequirementsspreadsheetDocument39 paginiAnnex2 DetailedRequirementsspreadsheetmonanglgaolÎncă nu există evaluări

- Ethiopian Standards ES Catalogue 2021 - 1Document623 paginiEthiopian Standards ES Catalogue 2021 - 1Henok Dire100% (3)

- 6 - Testing & Commissioning Data - ItpDocument10 pagini6 - Testing & Commissioning Data - ItpzainahmedscribdÎncă nu există evaluări

- Ehouse MCC Switchgear BuildingDocument15 paginiEhouse MCC Switchgear BuildingSARAVANA100% (1)

- Analog and Networking Systems: ASM-16 Addressable Switch ModuleDocument2 paginiAnalog and Networking Systems: ASM-16 Addressable Switch ModuleenriquealugovÎncă nu există evaluări

- Guide To Better Geotextile Specifying US FABRICSDocument19 paginiGuide To Better Geotextile Specifying US FABRICSOladunni AfolabiÎncă nu există evaluări