Documente Academic

Documente Profesional

Documente Cultură

Mechanical Engineering Curriculum

Încărcat de

aoguDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Mechanical Engineering Curriculum

Încărcat de

aoguDrepturi de autor:

Formate disponibile

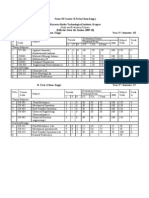

LIST OF COURSES TAKEN BY MECHANICAL ENGINEERING STUDENTS YEAR 1 OF BSc IN MECHANICAL ENGINEERING 156 Credits SEMESTER 1 1 1 1 1 1 1 1 MODULE Engineering

g Mathematics I Engineering Drawing Physics for Physical Sciences I Computing Fundamentals Workshop Practice Fundamentals of Engineering Fundamentals of Electrical Engineering Contemporary Social Issues CODE TEGM3591 TEGT3591 SPHY3511 TCME3521 TEGT3590 TEGT3521 TEGT3541 UCSI3529 NQF LEVEL 5 5 5 5 5 5 5 5 NQF CREDITS 12 12 16 8 4 8 8 8 76 CODE TEGM3592 TEGT3562 SPHY3512 TEGT3592 SCHM3512 ULEA3519 NQF LEVEL 5 5 5 5 5 5 NQF CREDITS 12 8 16 12 16 16 80 PRE& CO-REQUISITE TEGM3591 None SPHY3511 SPHY3511 None None PRE& CO-REQUISITE None None None None None None None None

Total Credits Semester I SEMESTER MODULE

2 Engineering Mathematics II 2 Materials Science 2 Physics for Physical Sciences II 2 Engineering Mechanics I 2 Chemistry 1B 2 English for Academic Purposes Total Credits Semester II

NB: Students who have done UCSI3529, ULEA3519, TEGT3521, SPHY3511, SPHY3512 and SCHM3512 will be exempted from taking them in this year. YEAR 2 OF BSc IN MECHANICAL ENGINEERING 144 Credits SEMESTER 1 1 1 1 MODULE Engineering Mathematics III Engineering Mechanics II Computer Science for Engineers Computer Aided Drawing CODE TEGT3671 TEGT3641 TCME3621 TEGT3661 SSTS3691 TMEE3661 TMEE3611 NQF LEVEL 6 6 6 6 6 6 6 NQF CREDITS 16 8 8 8 12 8 16 76 NQF CREDITS 16 8 8 8 8 12 8 68 PRE& CO-REQUISITE TEGM3591 TEGM3592 TEGT3592 TCME3521 TCME3521 TEGT3591 TEGM3591 SCHM3512 TEGT3592

1 Statistics for Engineers 1 Engineering Thermodynamics I 1 Fluid Mechanics Total Credits Semester III SEMESTER MODULE

CODE TEGT3672 TMEE3642 TMEE3622 TMEM3642 TMEM3622 TCME3692 TECE3622 TEGT3600

2 Engineering Mathematics IV 2 Solid Mechanics I 2 Strength of Materials 2 Mechanical Engineering Design I 2 Engineering Materials 2 Object Oriented Programming 2 Electrical Machines & Drives 2 Industrial Attachment I Total Credits Semester IV

NQF LEVEL 6 6 6 6 6 6 6 6

PRE& CO-REQUISITE TEGM3592/TEGT3671 TEGT3592 TEGT3592 TEGT3592 TEGT3562 TCME3621 TEGT3541 TEGT3590

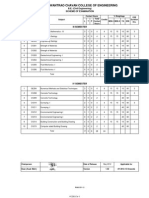

YEAR 3 OF BSc IN MECHANICAL ENGINEERING 144 Credits SEMESTER 1 MODULE Manufacturing Technology CODE TMEM3731 TEGT3761 TMEM3741 TMEE3741 TMEE3731 TMEM3721 TMEM3791 NQF LEVEL 7 7 7 7 7 7 7 NQF CREDITS 16 8 8 8 16 8 12 76 NQF CREDITS 8 8 12 8 8 12 12 68 PRE& COREQUISITE TMEM3622 TEGT3562 None TMEE3661 TEGT3671 TMEM3642 TEGT3592 TMEE3642

1 Fundamentals of Economics 1 Engineering Thermodynamics II 1 Principles of Control Engineering 1 Mechanical Engineering Design II 1 Machine Tools 1 Solid Mechanics II Total Credits Semester V SEMESTER MODULE

CODE TEGT3762 TEGT3742 TMEE3792 TMEM3742 TEGT3722 TMEM3792 TMED3792 TEGT3700

NQF LEVEL 7 7 7 7 7 7 7 7

2 Experimental and Research Methods 2 Entrepreneurship 2 Measurements and Control 2 Fundamentals of Mechatronics 2 Operations Management 2 Computer Aided Manufacturing 2 Rigid Body Dynamics 2 Industrial Attachment II Total Credits Semester VI

PRE& COREQUISITE SSTS3691 TEGT3761 TETE3622 TMEE3741 SSTS3691 TEGT3661 TEGT3641 TEGT3600

YEAR 4 OF BSc IN MECHANICAL ENGINEERING 140 Credits SEMESTER 1 MODULE Society and the Engineer CODE TEGT3821 TEGM3861 TMEE3821 TMEE3841 TMEE3831 TMEE3851 TMEM3821 TMER3891 NQF LEVEL 8 8 8 8 8 8 8 8 NQF CREDITS 8 8 8 8 16 16 8 4 72 PRE & COREQUISITE TEGT3521 TEGT3742 TEGT3761 TMED3792 TMEE3661 TMEM3741 TMEE3611 TMEE3731 TEGT3762

1 Project Management 1 Mechanical Vibrations 1 Renewable Energy 1 Thermal Machines 1 Fluid Machinery 1 Mechanical Engineering Design III 1 Research Proposal Total Credits Semester VII

SEMESTER 2 2

MODULE Research Project

CODE TMER3892 TMED3892 TEGT3800

NQF LEVEL 8 8 8

NQF CREDITS 30 34 68 584

Mechanical Engineering Design Project 2 Industrial Attachment III Total Credits Semester VIII

PRE& COREQUISITE All 3rd Year Modules TMER3891 All 3rd Year Modules TEGT3700

TOTAL CREDITS FOR THE DEGREE OF BSc IN MECHANICAL ENGINEERING (HONOURS)

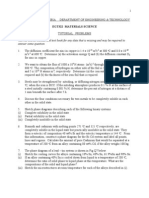

MECHANICAL ENGINEERING COUSES REQUIRING LABORATORY EXERCISES Module Title: ENGINEERING THERMODYNAMICS I Code TMEE3661 NQF Level 6 Contact Hours 2L + 1T or 1PS/Week NQF Credits 8 Assessment Continuous 50%; Examination 50% (1 x 2 hour paper) Co-requisite(s) SCHM3512 Chemistry 1B Contents: Definitions; system, process, state, property of a system, cycle, pressure, volume, temperature, work, heat. First law of thermodynamics: internal energy; non-flow energy equation; energy equation and reversibility. Application of first law to non-flow processes; constant volume, constant pressure, polytrophic, adiabatic and isothermal processes. Application of first law to flow processes; continuity equation, application to boilers, condensers, turbines, compressors, nozzles, diffusers and throttling devices. Second law of thermodynamics: concept of the heat engine; cycle efficiency; Reversibility and irreversibility. Engine efficiency. The Carnot cycle. Absolute temperature scale. Entropy; determination and property diagrams. Working fluids: properties of fluids and vapours; thermodynamic properties of steam; properties diagrams. Avogadros law, the equation of state of a perfect gas, specific heats and non-flow gas processes. Learning Outcomes: Upon completion of this module, students should be able to: o Describe the first law of thermodynamics and its applications to non-flow and flow processes. o Describe the second law of thermodynamics and its applications to the heat engine, the Carnot cycle and entropy. o Describe and quantify the properties of working fluids. o Interpret and use thermodynamic property diagrams. o Describe the equation of state of a perfect gas. Revision 1: Next Revision: September 2011 September 2015

Module Title: FLUID MECHANICS Code TMEE3611 NQF Level 6 Contact Hours 4L + 2T or 1PS/Week NQF Credits 16 Assessment Continuous 50%; Examination 50% (1 x 3 hour paper) Co-requisite(s) TEGT3592 Engineering Mechanics I Content: Introduction to fluid mechanics; properties of fluids (density, viscosity, vapour pressure); fluid equilibrium; units. Fluid Statics: The governing differential equations; pressure distributions, manometric pressure measurement; fluids in relative equilibrium (constant acceleration); forces on submerged surfaces; buoyancy. One-dimensional flows with inertia: 1-D mass conservation; 1-D momentum conservation (Bernoulli equation); total head diagrams; free liquid jets; flow measurement. Hydraulic systems: Energy changes in systems; pipe friction (laminar and turbulent friction factors, Moody diagram); general loss coefficients; Laminar viscous flow: Differential equations of motion; torsional viscometer. Applications: flow with pressure gradient between parallel plate and pipe flow. Learning Outcomes: Upon completion of this module, students should be able to: o Describe properties of fluids and conditions for relative equilibrium in fluids. o Analyse one-dimensional mass and momentum conservation and applications of Bernoullis equation o Demonstrate skills for flow measurements o Analyse general hydraulic systems with respect to energy changes, pipe friction, loss coefficient. o Analyse laminar viscous flow using differential equations of motion and its applications to flow with pressure gradient between plate and pipe flow. Revision 1: Next Revision: September 2011 September 2015

Module Title: SOLID MECHANICS I Code TMEE3642 NQF Level 6 Contact Hours 2L + 1T or 1PS/Week NQF Credits 8 Assessment Continuous 50%; Examination 50% (1 x 2 hour paper) Pre-requisite(s) TEGT3592 Engineering Mechanics I Content: Statics: Properties of three-dimensional force systems. Equilibrium of rigid bodies subjected to two- and three- dimensional force systems. Application of principles of rigid body equilibrium to trusses, frames, and machines. Method of virtual work: application to equilibrium and stability analysis of interconnected systems. Statically indeterminate problems. Geometric compatibility. Moments and products of inertia: first and second moments of area, polar moment of inertia, parallel axis theorem, radius of gyration, composite area method, product of inertia. Mechanics of Solids: Analysis of thermal and assembly stresses. Theories of failure. Deflection of beams: Slope and deflection by integration, Discontinuity functions, statically indeterminate beams, method of superposition. Energy methods: Strain energy for various types of loading, Deflection by conservation of energy, Impact loading, Castiglianos theorem. Learning Outcomes: Upon completion of this module, students should be able to: o Analyse equilibrium of rigid bodies subjected to two and three dimensional force systems and demonstrate application to trusses, frames and machines. o Apply the method of virtual work for equilibrium and stability analysis. o Analyse and solve statically indeterminate problems. o Calculate area moments and products of inertia and apply them to mechanics problems. o Analyse thermal and assembly stresses and describe general theories of failure. o Analyse deflection of beams using integration, discontinuity functions and method of superposition. o Apply energy methods in stress and strain analysis, deflection and impact loading. o Describe and apply Castiglianos theorem to determine deflection of beams. Revision 1: Next Revision: September 2011 September 2015

Module Title: STRENGTH OF MATERIALS Code TMEE3622 NQF Level 6 Contact Hours 2L + 1T or 1PS/Week NQF Credits 8 Assessment Continuous 50%; Examination 50% (1 x 2 hour paper) Pre-requisite(s) TEGT3592 Engineering Mechanics I Content: Stress and strain: Internal effects of forces, axial tension test; Hookes Law; Modulus of elasticity; Stress-strain relations. Normal stress and strain, shear stress and strain, thermal stress and strain. Analysis of stress and strain. Plane stress and plane strain. Bending: Revision of shear force/bending moment distributions, bending stress. Symmetrical and unsymmetrical bending. Inelastic bending. Residual stresses.Transverse shear: Shear stresses in beams, Shear flow in built-in members, Shear flow in thin-walled members, Shear centre. Torsion: Torsion of circular sections, solid non-circular shafts, Thin-walled tubes. Combined Loading: bending and direct stresses, bending and torsional stresses. Transformation of stresses and strains. Mohrs circle. Learning Outcomes: Upon completion of this module, students should be able to: o Demonstrate the application of Hookes Law to normal and shear stresses. o Analyse stresses and s o trains in two and three dimensions with cases of plane stress and plane strain. o Analyse bending stresses in beams under symmetrical and unsymmetrical loading. o Solve problems involving shear stresses and shear flow in beams. o Analyse stresses and strains in circular shafts and tubes subjected to torsion. o Analyses cases of combined loading involving bending, direct and torsional stresses. o Apply the principles of transformation of stresses and analyse stresses and strains using Mohrs circle. Revision 1: Next Revision: September 2011 September 2015

Module Title: ENGINEERING THERMODYNAMICS II Code TMEM3741 NQF Level 7 Contact Hours 2L + 1T or 1PS/Week NQF Credits 8 Assessment Continuous 50%; Examination 50% (1 x 2 hour paper) Pre-requisite(s) TMEE3661 Engineering Thermodynamics I Contents: Vapour power systems. Steam calculations. Boiler systems. Introduction to refrigeration and air conditioning systems. Heat pump systems. Non reacting gas mixtures and psychometrics. Heat transfer: Thermal conductivity. Steady state one-dimensional conduction. Forced and natural convection. Black and grey body thermal radiation. Thermal insulation. Lagging materials. Laboratory work. Learning Outcomes: Upon completion of this module, students should be able to: o Analyse vapour systems and perform calculations on steam, refrigeration and air conditioning o Analyse and perform calculations on heat pump systems o Describe the principles of forced and natural convection and perform calculations on the same o Describe the principles of heat radiation o Describe the principles of heat insulation and appropriate insulation materials Revision 1: September 2011 Next Revision: September 2015 Module Title: PRINCIPLES OF CONTROL ENGINEERING Code TMEE3741 NQF Level 7 Contact Hours 2L + 1T or 1PS/Week NQF Credits 8 Assessment Continuous 50%; Examination 50% (1 x 2 hour paper) Pre-requisite(s) TEGT3671 Engineering Mathematics III Contents: Basic principles of systems control: Definition of a system, open and closed loop; Methods for system representation and analysis; Mathematical models of control systems: Laplace transform, block diagrams, transfer function, characteristic equations; Applications to simple spring-damper system; Dynamic response of systems: polar and Bode plots; stability analysis: Routh-Hurwitz method, root locus method, polezero location on s-plane; Design of closed loop systems: P, PI and PID controllers. Laboratory exercises. Learning Outcomes: Upon completion of this module, students should be able to: o Describe a control system and distinguish between an open loop and a closed loop system o Apply mathematical modelling with transforms and block diagrams to control systems o Produce polar and Bode plots for control systems o Describe the Routh-Hurwitz method and the root locus method o Design closed loop systems and demonstrate the use of P, PI and PID controllers Revision 1: September 2011 Next Revision: September 2015 Module Title: SOLID MECHANICS II Code TMEM3791 NQF Level 7 Contact Hours 3L + 2T or 1PS/Week NQF Credits 12 Assessment Continuous 50%; Examination 50% (1 x 3 hour paper) Pre-requisite(s) TMEE3642 Solid Mechanics I Content: Mechanics of composite bodies: Materials; Manufacturing methods; Micromechanics; Macro-mechanics of a lamina; Failure criteria; Laminate analysis; Design of composite structures. Stress analysis of asymmetric solids: Thick-walled and compound cylinders; Rotating discs and cylinders; Autofrettage. Fracture Mechanics: Theories of linear-elastic and elastic-plastic fracture mechanics and their applications. Crack propagation models. Failure criteria. Learning Outcomes: Upon completion of this module, students should be able to: o Analyse composite bodies using the principles of engineering mechanics. o Describe design features of composite structures. o Analyse stresses in asymmetric solids including cylinders and rotating discs. o Demonstrate an understanding of linear elastic fracture mechanics and failure criteria. Revision 1: Next Revision: September 2011 September 2015

Module Title: MEASURMENTS AND CONTROL Code TMEE3792 NQF Level 7 Contact Hours 3L + 2T or 1PS/Week NQF Credits 12 Assessment Continuous 50%; Examination 50% (1 x 3 hour paper) Co-requisite(s) TETE3622 Electrical Machines and Drives Content: Measurement theory and analysis: The General measurement system: Measuring pressure, force and torque. Measuring position and orientation. Static characteristics of measurement system elements. Propagation of errors and accuracy of measurement systems in steady state. Dynamic characteristics of measurement system elements. Transferring and processing sensor signals and protecting signals from noise. Using sensors in feedback circuits. Sensing elements in measurement systems: Transducers and Sensors: performance, terminology. Systems measuring displacement, position, proximity, velocity, force, fluid pressure, fluid flow, liquid level, temperature and light. Thermocouples, ultrasonic measuring devices, optical measuring instruments. Selection and positioning of sensors. Mechanical and electrical drives and actuators: Pneumatic and hydraulic actuation systems, regulating valves, cylinders, motors. Mechanical Actuation Systems: Elementary kinematic chains; gear trains; belt and chain drives. Electrical Actuation Systems: Relays, solid state switches, solenoids, the permanent magnet DC motor, mechanical aspects of electric motors. Design of simple actuation systems. Signal conditioning: Amplification, filtering, sampling. A/D, D/A conversion. Pulse width modulation. Learning Outcomes: Upon completion of this module, students should be able to: o Describe the principles behind various techniques for measuring physical quantities o Describe the various sensors used in measurement systems o Describe various mechanical and electrical drives and actuators used in machine automation o Describe the principles of signal conditioning Revision 1: Next Revision: September 2011 September 2015

Module Title: FUNDAMENTALS OF MECHATRONICS Code TMEM3742 NQF Level 7 Contact Hours 2L + 1T or 1PS/Week NQF Credits 8 Assessment Continuous 50%; Examination 50% (1 x 2 hour paper) Co-requisite(s) TMEE3741 Principles of Control Engineering Contents: Modelling of mechatronical systems. Modelling of kinematic and dynamic mechanisms. Calculation of set value. Sensors in back feed systems. Regulating units which are adapted to servo-systems. Intelligent devices. Hydraulic servo-systems. Digital control in regulating units. Distributed control. Lab design exercises. Learning Outcomes: Upon completion of this module, students should be able to: o Apply knowledge of mechanisms, electronics and computer technology to model mechatronical systems o Describe the principles of hydraulic servo systems o Describe the application of digital control in mechatronical systems o Design simple mechatronical systems or machines Revision 1: Next Revision: September 2011 September 2015

Module Title: RIGID BODY DYNAMICS Code TMED3792 NQF Level 7 Contact Hours 3L + 2T or 1PS/Week NQF Credits 12 Assessment Continuous 50%, Examination 50% (1 x 3 hour paper) Pre-requisite(s) TEGT3641 Engineering Mechanics II Content: Revision of kinematics and kinetics of a system of particles. Kinematics of rigid bodies: Translational motion, rotational motion, absolute Motion. Relative and absolute velocity, instantaneous centre of zero velocity. Plane kinematics of a rigid body. Plane Kinetics of a rigid Body. Rotation of a rigid body about a fixed axis. General plane motion. Work- relationships for rigid bodies.

Learning Outcomes: Upon completion of this module, students should be able to: o Describe the kinematic principles of rigid bodies and perform calculations on the motion of rigid bodies o Describe the kinetic principles of rigid bodies and perform calculations on plane kinetics o Apply the work-energy principle to describe the dynamics of rigid bodies Revision 1: Next Revision: September 2011 September 2015

Module Title: MECHANICAL VIBRATIONS Code TMEE3821 NQF Level 8 Contact Hours 2L + 1T or 1PS/Week NQF Credits 8 Assessment Continuous 50%; Examination 50% (1 x 2 hour paper) Pre-requisite(s) TMED3792 Rigid Body Dynamics Content:Fundamentals of vibrations: Basic Concepts and definitions. Vibration Analysis, Harmonic Motion. Single degree-of-freedom systems: Equation of motion, Lagranges equation, free vibration of undamped and damped systems; logarithmic decrement, other forms of damping. Forced vibration: Equation of motion, response to harmonic excitation, resonance, rotating unbalanced, base motion excitation, response to general non-periodic excitation, impulse response function. Design for vibration control: Vibration isolation, critical speeds of rotating shafts; practical isolation design. Multiple degree-of-freedom systems: Equations of motion; Lagranges equations, free vibration, natural frequencies and mode shapes, forced vibration, response to harmonic excitations and normal-mode approach. Continuous systems: Introduction to continuous systems. Vibration absorption:. Balancing of rotating machines. Learning Outcomes: Upon completion of this module, students should be able to: o Describe the fundamentals of vibration analysis o Distinguish between the various forms of vibration o Describe methods used to control vibration in practice including balancing techniques o Describe techniques used in vibration absorption Revision 1: Next Revision: September 2011 September 2015

Module Title: THERMAL MACHINES Code TMEE3831 NQF Level 8 Contact Hours 4L + 2T or 1PS/Week NQF Credits 16 Assessment Continuous 50%; Examination 50% (1 x 3 hour paper) Co-requisite(s) TMEM3741 Engineering Thermodynamics II Content: Vapour power cycles. Analysis of aavailable energy. Heat pump cycles. Gas power cycles. Internal combustion engines. Principles and applications. Principles of steam and gas turbines. Energy analysis in the steam cycle in steam and gas turbines. Vapour flow in turbine blades and turbine phases. Turbine losses. Turbine performance. Multi-phase turbines. Thermal calculations of the gas turbine scheme. Load regulation system. Control and safety. Power plants. Refrigeration: Basic components, refrigeration agents. Refrigeration systems and their applications. Calculations on refrigeration machines. Air-conditioning: Basic components, air-conditioning systems and applications. Air-conditioning calculations. Fault diagnosis and maintenance. Environmental problems, alternative refrigerants. Learning Outcomes: Upon completion of this module, students should be able to: o Describe and analyse vapour power cycles o Describe the principles and characteristics of internal combustion engines o Describe the principles and characteristics of steam turbines o Describe the principles and characteristics of gas turbines o Perform thermal calculations on thermal machines o Describe the general design principle of power plants o Perform calculations involving refrigeration and air conditioning o Demonstrate knowledge of the various factors that are used to select or determine an appropriate air conditioning system Revision 1: Next Revision: September 2011 September 2015

Module Title: FLUID MACHINERY Code TMEE3851 NQF Level 8 Contact Hours 4L + 2T or 1PS/Week NQF Credits 16 Assessment Continuous 50%; Examination 50% (1 x 3hour paper) Pre-requisite(s) TMEE3611 Fluid Mechanics Content: Momentum principles applied to fluids. Jet propulsion. Design of fluid machinery: Centrifugal and axial flow machines, pipemachine characteristics, cavitation, water hammer. Inclined and tilting hydrodynamic thrust bearings, journal bearings. Hydrostatic thrust bearings. Nozzles. Power hydraulics. Turbulent flow. Supersonic flow. Pressure and temperature measurements. Learning Outcomes: Upon completion of this module, students should be able to: o Describe the principles used in the design of jet engines and general fluid machinery o Describe the principles and characteristics of centrifugal and axial flow machines o Describe the principles and characteristics of power hydraulics Revision 1: Next Revision: September 2011 September 2015

S-ar putea să vă placă și

- CO2 Depressurisation OLGADocument8 paginiCO2 Depressurisation OLGAMaheshÎncă nu există evaluări

- Chapter 6. ThermodynamicsDocument7 paginiChapter 6. Thermodynamicshoney1002Încă nu există evaluări

- Redesign of Scott Bicycle Frame AnalysisDocument11 paginiRedesign of Scott Bicycle Frame Analysisraghunath670743Încă nu există evaluări

- Scheme and Syllabus For Naval Archetect - and Ship Buildg EnggDocument140 paginiScheme and Syllabus For Naval Archetect - and Ship Buildg EnggpramodÎncă nu există evaluări

- Motion of Particles in FluidDocument26 paginiMotion of Particles in FluidSubakti HungÎncă nu există evaluări

- PCAB List of Licensed Contractors For CFY 2017-2018 As of 19 Sep 2017 - Web2Document175 paginiPCAB List of Licensed Contractors For CFY 2017-2018 As of 19 Sep 2017 - Web2Paige Lim76% (21)

- Introduction to Bond Graphs and their ApplicationsDe la EverandIntroduction to Bond Graphs and their ApplicationsEvaluare: 5 din 5 stele5/5 (1)

- Power Electronics Applied to Industrial Systems and Transports, Volume 1: Synthetic Methodology to Converters and Components TechnologyDe la EverandPower Electronics Applied to Industrial Systems and Transports, Volume 1: Synthetic Methodology to Converters and Components TechnologyÎncă nu există evaluări

- B.Tech 6th Sem ME Final 1Document14 paginiB.Tech 6th Sem ME Final 1World TodayÎncă nu există evaluări

- Nitc Mechanical Btech Syllabus and CurriculumDocument110 paginiNitc Mechanical Btech Syllabus and Curriculumpikasoc1Încă nu există evaluări

- Assam Science and Technology University Guwahati: B.Tech Civil Engineering 3 SemesterDocument13 paginiAssam Science and Technology University Guwahati: B.Tech Civil Engineering 3 SemesterKF KF360Încă nu există evaluări

- UG Syllabus Corrected PDFDocument63 paginiUG Syllabus Corrected PDFsujithrengan_9019266Încă nu există evaluări

- Basic Thermodynamics (BTME-305-18)Document14 paginiBasic Thermodynamics (BTME-305-18)Surjit Kumar GandhiÎncă nu există evaluări

- B.Tech Mechanical Engineering 4 Semester: Assam Science and Technology University GuwahatiDocument17 paginiB.Tech Mechanical Engineering 4 Semester: Assam Science and Technology University GuwahatiPrasanta GogoiÎncă nu există evaluări

- B Tech Semester 5 2015-19Document30 paginiB Tech Semester 5 2015-19api-294538209Încă nu există evaluări

- Chinna CMMDocument3 paginiChinna CMMvenkat843Încă nu există evaluări

- UWA C EngDocument3 paginiUWA C EngMatthew Leatt-HayterÎncă nu există evaluări

- EE-260 Electrical Machines Ver1Document5 paginiEE-260 Electrical Machines Ver1Skiwordy MediaÎncă nu există evaluări

- Mechatronic 2013Document2 paginiMechatronic 2013Mohd Hilmi IzaanÎncă nu există evaluări

- M.E. Internal Combustion Engineering SyllabusDocument35 paginiM.E. Internal Combustion Engineering SyllabusJoswa CaxtonÎncă nu există evaluări

- B.tech Mechatronics PDFDocument106 paginiB.tech Mechatronics PDFSandeep KotaÎncă nu există evaluări

- B.tech Mechatronics PDFDocument106 paginiB.tech Mechatronics PDFSandeep KotaÎncă nu există evaluări

- MechanicalDocument104 paginiMechanicalNguyễn Khánh Tùng100% (1)

- Ench3mt Outline 2012Document4 paginiEnch3mt Outline 2012wendellr_frank7Încă nu există evaluări

- IC EngineDocument52 paginiIC EngineShreepal ChilaÎncă nu există evaluări

- CNA Chemical Process Engineering Technology (Co-Op)Document1 paginăCNA Chemical Process Engineering Technology (Co-Op)Audrey Patrick KallaÎncă nu există evaluări

- ChE SyllabusDocument30 paginiChE SyllabusSubodh DwivediÎncă nu există evaluări

- Power Electronics and Drive Course OverviewDocument6 paginiPower Electronics and Drive Course OverviewashkaryÎncă nu există evaluări

- Civil Soe and Syllabus 2014-15 For Old Course PDFDocument104 paginiCivil Soe and Syllabus 2014-15 For Old Course PDFYogesh KherdeÎncă nu există evaluări

- ChE SyllabusDocument30 paginiChE SyllabusRavindra Kumar NiranjanÎncă nu există evaluări

- SASTRA UNIVERSITY B.Tech. Mechanical Engineering Programme Objective and 3rd Semester CoursesDocument130 paginiSASTRA UNIVERSITY B.Tech. Mechanical Engineering Programme Objective and 3rd Semester CourseskrishnaÎncă nu există evaluări

- B.tech 6th Sem EE FinalDocument24 paginiB.tech 6th Sem EE FinalRohit DuttaÎncă nu există evaluări

- Assam University Civil Engineering Course SyllabusDocument15 paginiAssam University Civil Engineering Course SyllabusMedalson RonghangÎncă nu există evaluări

- 0401Document15 pagini0401Victor Виктор OtoborÎncă nu există evaluări

- EEE112 Engineering Mechanics and Thermodynamics PECDocument6 paginiEEE112 Engineering Mechanics and Thermodynamics PECAnosh BangashÎncă nu există evaluări

- Syllabus Vjti Structural EnggDocument276 paginiSyllabus Vjti Structural EnggPravin AwalkondeÎncă nu există evaluări

- Jharkhand University of Technology 2nd Year UG Mechanical Engineering 4th Semester Course StructureDocument14 paginiJharkhand University of Technology 2nd Year UG Mechanical Engineering 4th Semester Course Structure507 20L SK DarainÎncă nu există evaluări

- MEC2405 Unit Guide 2010Document24 paginiMEC2405 Unit Guide 2010Kugan MohanÎncă nu există evaluări

- Rajasthan Technical University (RTU) Mechanical Engineering YEAR II / SEMESTER III THEORY AND PRACTICALSDocument52 paginiRajasthan Technical University (RTU) Mechanical Engineering YEAR II / SEMESTER III THEORY AND PRACTICALSappannusaÎncă nu există evaluări

- ME Final Upto 4th Year Syllabus 04-06-13Document58 paginiME Final Upto 4th Year Syllabus 04-06-13zenithtutorials12Încă nu există evaluări

- Beng (Hons) Chemical and Renewable Energy Engineering - E401Document8 paginiBeng (Hons) Chemical and Renewable Energy Engineering - E401HAmad ZackÎncă nu există evaluări

- Assam Science and Technology University Course Structure and Syllabus for B.Tech 5th Semester Electrical EngineeringDocument25 paginiAssam Science and Technology University Course Structure and Syllabus for B.Tech 5th Semester Electrical EngineeringRohit DuttaÎncă nu există evaluări

- ABET Course Syllabus Template: ECE341: Energy ConversionDocument6 paginiABET Course Syllabus Template: ECE341: Energy Conversionchristine booduanÎncă nu există evaluări

- ENSC 388 OutlineDocument4 paginiENSC 388 OutlineEnriqueTamayoValenzuelaÎncă nu există evaluări

- B.Tech MECH-FT-2013Document72 paginiB.Tech MECH-FT-2013Anonymous p8bHAAxÎncă nu există evaluări

- B.Tech-4th-Sem-CE-final-2 2Document16 paginiB.Tech-4th-Sem-CE-final-2 2Bhaswat KashyapÎncă nu există evaluări

- Course Outcomes COs For All Programmes - 2021 22 Reference MiteDocument108 paginiCourse Outcomes COs For All Programmes - 2021 22 Reference MiteNischitha PÎncă nu există evaluări

- Mechanical EngineeringDocument23 paginiMechanical EngineeringAntony AshleyÎncă nu există evaluări

- Units Description (Petroleum)Document6 paginiUnits Description (Petroleum)Amar BenAmarÎncă nu există evaluări

- ME MECHANICAL - Energy Systems and Management PDFDocument39 paginiME MECHANICAL - Energy Systems and Management PDFpreeti.vbÎncă nu există evaluări

- Me4183 Part ADocument2 paginiMe4183 Part AasadqhseÎncă nu există evaluări

- BME Course Data SheetDocument5 paginiBME Course Data SheetBasilÎncă nu există evaluări

- MIST MSC-ME SyllabusDocument30 paginiMIST MSC-ME SyllabusSajidÎncă nu există evaluări

- Geo Schemes y LLDocument26 paginiGeo Schemes y LLchethangowda50Încă nu există evaluări

- Anna Univ Part Time Mech SylabusDocument69 paginiAnna Univ Part Time Mech SylabusmayilsamythangarajuÎncă nu există evaluări

- Heat Transfer Lab ManualDocument95 paginiHeat Transfer Lab ManualMohan Kumar KÎncă nu există evaluări

- Electrical Power and Machines Course OutlineDocument4 paginiElectrical Power and Machines Course OutlinePrabu ÑÖnïtzÎncă nu există evaluări

- Course Outline - DJJ2093 - Latest PDFDocument1 paginăCourse Outline - DJJ2093 - Latest PDFThaneswaran BaluÎncă nu există evaluări

- DSE2014-15 - Information BrochureFinal - 0507201407082014122143Document25 paginiDSE2014-15 - Information BrochureFinal - 0507201407082014122143jivan tidakeÎncă nu există evaluări

- Reliability Investigation of LED Devices for Public Light ApplicationsDe la EverandReliability Investigation of LED Devices for Public Light ApplicationsÎncă nu există evaluări

- Embedded Mechatronic Systems 2: Analysis of Failures, Modeling, Simulation and OptimizationDe la EverandEmbedded Mechatronic Systems 2: Analysis of Failures, Modeling, Simulation and OptimizationÎncă nu există evaluări

- Practical Control of Electric Machines: Model-Based Design and SimulationDe la EverandPractical Control of Electric Machines: Model-Based Design and SimulationÎncă nu există evaluări

- Mechanical Practicals: Course Action Labs Time Required Personnel ThermodynamicsDocument2 paginiMechanical Practicals: Course Action Labs Time Required Personnel ThermodynamicsaoguÎncă nu există evaluări

- Research ProposalDocument2 paginiResearch Proposalaogu0% (1)

- Fluid MechanicsDocument4 paginiFluid MechanicsaoguÎncă nu există evaluări

- Renewable EnergyDocument60 paginiRenewable EnergyaoguÎncă nu există evaluări

- Environmental Science AssignmentDocument5 paginiEnvironmental Science AssignmentaoguÎncă nu există evaluări

- Materials Science Manual Chapter 7Document14 paginiMaterials Science Manual Chapter 7aoguÎncă nu există evaluări

- Material ScienceDocument4 paginiMaterial ScienceaoguÎncă nu există evaluări

- Fluid Mechanic Assignment on Boundary Layer FormationDocument7 paginiFluid Mechanic Assignment on Boundary Layer FormationaoguÎncă nu există evaluări

- Materials Science Manual Chapter 4Document21 paginiMaterials Science Manual Chapter 4aoguÎncă nu există evaluări

- Environmental Science AssignmentDocument5 paginiEnvironmental Science AssignmentaoguÎncă nu există evaluări

- Materials Science problems and conceptsDocument4 paginiMaterials Science problems and conceptsaoguÎncă nu există evaluări

- Material ScienceDocument5 paginiMaterial ScienceaoguÎncă nu există evaluări

- Mechanical Engineering CurricilumDocument23 paginiMechanical Engineering CurricilumaoguÎncă nu există evaluări

- Calculate Area and Volume Using Survey DataDocument3 paginiCalculate Area and Volume Using Survey Dataaogu100% (2)

- IT & Eng ReportDocument4 paginiIT & Eng ReportaoguÎncă nu există evaluări

- Cost of Cucurbits 2010Document8 paginiCost of Cucurbits 2010aoguÎncă nu există evaluări

- MODULE TCVE 3542 Exam 1 Answer SheetDocument3 paginiMODULE TCVE 3542 Exam 1 Answer SheetaoguÎncă nu există evaluări

- Material Science ManualDocument7 paginiMaterial Science ManualaoguÎncă nu există evaluări

- UNIVERSITY OF NAMIBIA ENGINEERING MECHANICS I TUTORIAL SESSIONSDocument51 paginiUNIVERSITY OF NAMIBIA ENGINEERING MECHANICS I TUTORIAL SESSIONSaoguÎncă nu există evaluări

- Self Review Report Templates 1Document18 paginiSelf Review Report Templates 1aoguÎncă nu există evaluări

- TCVI3752 Transport Planning and Engineering I ExamDocument4 paginiTCVI3752 Transport Planning and Engineering I Examaogu33% (3)

- Module Tcve 3542 Exam 1Document1 paginăModule Tcve 3542 Exam 1aoguÎncă nu există evaluări

- Wind ErosionDocument5 paginiWind ErosionaoguÎncă nu există evaluări

- 2012 - Management Planning TemplateDocument15 pagini2012 - Management Planning TemplateaoguÎncă nu există evaluări

- Bertha Contill Presentation 19 Sept 2011Document46 paginiBertha Contill Presentation 19 Sept 2011aoguÎncă nu există evaluări

- Excel QuestionsDocument4 paginiExcel QuestionsaoguÎncă nu există evaluări

- OPM QuestionsDocument4 paginiOPM QuestionsaoguÎncă nu există evaluări

- Wind ErosionDocument5 paginiWind ErosionaoguÎncă nu există evaluări

- Channel Flow and Erosion ControlDocument1 paginăChannel Flow and Erosion ControlaoguÎncă nu există evaluări

- Assignment MetrologyDocument8 paginiAssignment MetrologyPratama sudibyo0% (1)

- Docc 1990Document7 paginiDocc 1990swchenÎncă nu există evaluări

- VTU - B.E B.Tech - 2019 - 4th Semester - July - CBCS 17 Scheme - MECH - 17ME44 Fluid PDFDocument2 paginiVTU - B.E B.Tech - 2019 - 4th Semester - July - CBCS 17 Scheme - MECH - 17ME44 Fluid PDFFakhruddin AnsariÎncă nu există evaluări

- Functional Requirements and Concepts of Frequency Converter's Oil Application Control ProgramDocument78 paginiFunctional Requirements and Concepts of Frequency Converter's Oil Application Control ProgramRigoberto José Martínez CedeñoÎncă nu există evaluări

- PDFDocument36 paginiPDFvishwasdeepjoshiÎncă nu există evaluări

- Lab Instruments GuideDocument19 paginiLab Instruments GuideDesQuina DescoÎncă nu există evaluări

- Offshore Pipeline Hydraulic and Mechanical AnalysesDocument25 paginiOffshore Pipeline Hydraulic and Mechanical AnalysesEslam RedaÎncă nu există evaluări

- Helm (2008) : Section 32.4: Parabolic PdesDocument24 paginiHelm (2008) : Section 32.4: Parabolic Pdestarek mahmoudÎncă nu există evaluări

- Chapter 2 1 - Linear EquationsDocument23 paginiChapter 2 1 - Linear Equationsapi-263209117Încă nu există evaluări

- V 082 N 04 P 112Document6 paginiV 082 N 04 P 112Romi FadliÎncă nu există evaluări

- A Fractal Dimension Is A Ratio Providing A Statistical Index of Complexity Comparing How Detail in A PatternDocument1 paginăA Fractal Dimension Is A Ratio Providing A Statistical Index of Complexity Comparing How Detail in A PatternBaribari BalÎncă nu există evaluări

- Mody Institute of Technology and Science, Lakshmangarh Faculty of Engineering and TechnologyDocument3 paginiMody Institute of Technology and Science, Lakshmangarh Faculty of Engineering and TechnologyAtul GaurÎncă nu există evaluări

- Vibration assignment on 3DOF cantilever beam systemDocument5 paginiVibration assignment on 3DOF cantilever beam systemIzzah 'AtirahÎncă nu există evaluări

- 12 Class Physics 1-Chapter Sample Paper PDFDocument9 pagini12 Class Physics 1-Chapter Sample Paper PDFharshÎncă nu există evaluări

- The Basic Differential Equation For Radial Flow in A Porous MediumDocument8 paginiThe Basic Differential Equation For Radial Flow in A Porous MediumrestofficalÎncă nu există evaluări

- Ricapito-1 PbLi-T DatabaseDocument16 paginiRicapito-1 PbLi-T DatabaseSasa DjordjevicÎncă nu există evaluări

- Isaacs. Differential GamesDocument13 paginiIsaacs. Differential GamescrovaxIIIÎncă nu există evaluări

- MechanicsDocument558 paginiMechanicsfejiloÎncă nu există evaluări

- MIT2 080JF13 Lecture2 PDFDocument26 paginiMIT2 080JF13 Lecture2 PDFAbhilashJanaÎncă nu există evaluări

- Revision Notes Grade 11Document3 paginiRevision Notes Grade 11anuelisajoseÎncă nu există evaluări

- Lecture2 Semiconductor StatisticsDocument13 paginiLecture2 Semiconductor StatisticsRakib KhanÎncă nu există evaluări

- The Weighted Histogram Analysis Method (WHAM) : Michael AndrecDocument14 paginiThe Weighted Histogram Analysis Method (WHAM) : Michael AndrecWilliam AgudeloÎncă nu există evaluări

- Cara SamplingDocument8 paginiCara SamplingAngga Dwi PutrantoÎncă nu există evaluări

- NCHRP RPT 242 PDFDocument85 paginiNCHRP RPT 242 PDFDavid Drolet TremblayÎncă nu există evaluări

- Installation Operation Maintenance Manual (Harvest Series)Document36 paginiInstallation Operation Maintenance Manual (Harvest Series)berkahharianÎncă nu există evaluări