Documente Academic

Documente Profesional

Documente Cultură

Filmtec Manual

Încărcat de

momanzoorTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Filmtec Manual

Încărcat de

momanzoorDrepturi de autor:

Formate disponibile

Tech Manual Excerpt

FILMTEC Membranes System Design: Membrane System Design Guidelines

Membrane System Design Guidelines The factor which has the greatest influence on the membrane system design is the fouling tendency of the feed water. Membrane fouling is caused by particles and colloidal material which are present in the feed water and are concentrated at the membrane surface. The Silt Density Index (SDI) value of the pretreated feed water correlates fairly well with the amount of fouling material present. The concentration of the fouling materials at the membrane surface increases with increasing permeate flux (the permeate flow rate per unit membrane area) and increasing FILMTEC element recovery (the ratio of permeate flow rate to feed flow rate for a single element). A system with high permeate flux rates is, therefore likely to experience higher fouling rates and more frequent chemical cleaning. A membrane system should be designed such that each element of the system operates within a frame of recommended operating conditions to minimize the fouling rate and to exclude mechanical damage. These element operating conditions are limited by the maximum recovery, the maximum permeate flow rate, the minimum concentrate flow rate and the maximum feed flow rate per element. The higher the fouling tendency of the feed water the stricter are the limits of these parameters. The proposed limits are recommended guidelines based on many years of experience with FILMTEC membranes. The average flux of the entire system, i.e. the system permeate flow rate related to the total active membrane area of the system, is a characteristic number of a design. The system flux is a useful number to quickly estimate the required number of elements for a new project. Systems operating on high quality feed waters are typically designed at high flux values whereas systems operating on poor quality feed waters are designed at low flux values. However, even within the same feed water category, systems are designed with higher or lower flux values, depending on the focus being either on minimizing the capital expenses or minimizing the long term operational expenses. The ranges of flux values given in the tables below are typical numbers for the majority of systems, but they are not meant to be limits. A continuous RO/NF process designed according to the system design guidelines and with a well-designed and operated pretreatment system will show stable performance with no more than about four cleanings per year in standard applications. Exceeding the recommended limits may result in more frequent cleanings, reduced capacity, increased feed pressure and reduced membrane life. A moderate violation of the limits for a short time may be acceptable as long as the physical limits the maximum pressure drop and the maximum feed pressure are not exceeded. On the other hand, a conservative approach is to anticipate a higher fouling tendency and to design the system according to the stricter limits in order to enjoy a trouble free system operation and an increased membrane life.

Page 1 of 4

Trademark of The Dow Chemical Company (Dow) or an affiliated company of Dow

Form No. 609-02054-604

Membrane System Design Guidelines for 8-Inch FILMTEC Elements

Feed source

The following tables show the recommended guidelines for designing RO systems with 8inch FILMTEC elements according to feed water type. Table 3.4 Design guidelines for 8-inch FILMTEC elements in water treatment applications

RO Permeate Well Water Surface Supply Wastewater (Filtered Municipal Effluent) MF1 Conventional SDI < 3 10-14 17-24 14 SDI < 5 8-12 14-20 12 Seawater Well or MF1 SDI < 3 8-12 13-20 15 Open intake SDI < 5 7-10 11-17 13

Feed silt density index Average gfd system flux l/m2h Maximum element recovery % Active Membrane Area 320 ft2 elements 365 ft2 elements 380 ft2 elements 390 ft2 elements 400 ft2 elements 440 ft2 elements

SDI < 1 21-25 36-43 30

SDI < 3 16-20 27-34 19

SDI < 3 13-17 22-29 17

SDI < 5 12-16 20-27 15

9,000 (34) 10,000 (38) 10,600 (40) 10,600 (40) 11,000 (42) 12,000 (45)

7,500 (28) 8,300 (31) 8,600 (33) 8,900 (34) 9,100 (34) 10,000 (38)

Maximum permeate flow rate, gpd (m3/d) 6,500 5,900 5,300 4,700 (18) (25) (22) (20) 7,200 6,500 5,900 5,200 (20) (27) (25) (22) 7,500 6,800 5,900 5,200 (20) (28) (26) (22) 7,700 7,000 6,300 5,500 (21) (29) (26) (24) 7,900 7,200 6,400 5,700 (22) (30) (27) (24) 8,700 7,900 7,100 6,300 (24) (33) (30) (27) Minimum concentrate flow rate2, gpm (m3/h) 13 (3.0) 15 (3.4) 16 (3.6) 18 (4.1) 13 (3.0) 15 (3.4) 18 (4.1) 20 (4.6) 13 (3.0) 15 (3.4) 18 (4.1) 18 (4.1) 25 (5.7) 25 (5.7) 25 (5.7) 25 (5.7) 13 (3.0) 15 (3.4) 16 (3.6) 18 (4.1)

6,700 (25)

6,100 (23)

7,900 (30)

7,200 (27)

Element type BW elements (365 ft2) BW elements (400 ft2 and 440 ft2) NF elements Full-fit elements SW elements Active area ft2 (m2) 365 (33.9) 400 (37.2) 440 (40.9) 390 (36.2) 320 (29.7) 380 (35.3)

10 (2.3) 10 (2.3) 10 (2.3) 25 (5.7) 10 (2.3)

13 (3.0) 13 (3.0) 13 (3.0) 25 (5.7) 13 (3.0)

13 (3.0)

15 (3.4)

Element type BW elements BW or NF elements BW elements Full-fit elements SW elements SW elements

1 2

65 (15) 75 (17) 75 (17) 85 (19) 65 (15) 72 (16)

65 (15) 75 (17) 75 (17) 75 (17) 65 (15) 72 (16)

Maximum feed flow rate2, gpm (m3/h) 63 (14) 58 (13) 52 (12) 52 (12) 73 (17) 67 (15) 61 (14) 61 (14) 73 (17) 67 (15) 61 (14) 61 (14) 73 (17) 67 (15) 61 (14) 61 (14) 63 (14) 58 (13) 52 (12) 52 (12) 70 (16) 64 (15) 58 (13) 58 (13)

63 (14) 70 (16)

56 (13) 62 (14)

MF: Microfiltration - continuous filtration process using a membrane with pore size of <0.5 micron. The maximum recommended pressure drop across a single element is 15 psid (1bar) or 50 psid (3.5 bar) across multiple elements in a pressure vessel, whichever value is more limiting. We recommend designing at maximum of 80% (12 psid) for any element in a system.

Note: The limiting values listed above have been incorporated into the ROSA (Reverse Osmosis System Analysis) software. Designs of systems in excess of the guidelines results in a warning on the ROSA printout.

Page 2 of 4

Trademark of The Dow Chemical Company (Dow) or an affiliated company of Dow

Form No. 609-02054-604

Membrane System Design Guidelines for Midsize FILMTEC Elements

The following tables show the recommended guidelines for designing RO systems with 2.5 and 4-inch FILMTEC elements in light industrial and small commercial applications. Light industrial systems in Table 3.5 have the same requirements as for large systems, requiring stable performance over several years. They are typically for piloting large systems, with continuous operation, CIP facilities and none (or minimal) concentrate recirculation. The expected membrane lifetime is more than 3 years. Table 3.5 Design guidelines for FILMTEC elements in light industrial and small seawater applications

Feed source

RO permeate Well water

Softened Municipal SDI < 3 16 (27) 17

Surface

Feed silt density index Typical target flux, gfd (l/m2h) Maximum element recovery % Element diameter 2.5-inch 4.0-inch Element type 2.5-inch diameter 4.0-inch diameter (except full-fits) Full-fit 4040

SDI < 1 22 (37) 30

SDI < 3 18 (30) 19

SDI < 5 14 (24) 15

Wastewater (filtered tertiary effluent) MF1 Conventional SDI < 3 SDI < 5 13 (22) 11 (19) 14 12

Seawater Well or MF1 Open intake SDI < 3 SDI < 5 13 (22) 11 (19) 15 13

800 (3.0) 2,300 (8.7)

700 (2.6) 1,900 (7.2)

Maximum permeate flow rate, gpd (m3/d) 600 (2.3) 500 (1.9) 500 (1.9) 400 (1.5) 1,700 (6.4) 1,500 (5.7) 1,400 (5.3) 1,200 (4.5) Minimum concentrate flow rate, gpm (m3/h)1 1 (0.2) 1 (0.2) 1 (0.2) 1 (0.2) 3 (0.7) 3 (0.7) 4 (0.9) 5 (1.1) 6 (1.4) 6 (1.4) 6 (1.4) 6 (1.4) Maximum pressure drop per element psig (bar) 13 (0.9) 15 (1.0) 13 (0.9) 13 (0.9) 13 (0.9) 15 (1.0) 15 (1.0) 15 (1.0)

700 (2.6) 1,800 (6.8)

600 (2.3) 1,500 (5.7)

0.7 (0.16) 2 (0.5) 6 (1.4) Active area ft2 (m2) 28 (2.6) 28 (2.6) 29 (2.7) 87 (8.1) 82 (7.6) 82 (7.6) 80 (7.4) 85 (7.9)

1 (0.2) 3 (0.7) 6 (1.4)

1 (0.2) 3 (0.7) NA

1 (0.2) 4 (0.9) NA

Element type Tape-wrapped 2540 Fiberglased 2540 Seawater 2540 Tape-wrapped 4040 TW30-4040 Fiberglassed 4040 SW Fiberglassed 4040 Full-fit 4040

1 2

Maximum feed flow rate U.S. gpm (m3/h) 6 (1.4) 6 (1.4) 6 (1.4) 14 (3.2) 14 (3.2) 16 (3.6) 16 (3.6) 18 (4.1)

Maximum feed pressure psig (bar) 600 (41) 600 (41) 1,000 (69) 600 (41) 600 (41) 600 (41) 1,000 (69) 600 (41)

MF: Microfiltration - continuous filtration process using a membrane with pore size of <0.5 micron. 2We recommend that the pressure drop for new/clean elements be at least 20% below the maximum.

Note: The limiting values listed above have been incorporated into the ROSA (Reverse Osmosis System Analysis) software. Designs of systems in excess of the guidelines results in a warning on the ROSA printout.

Page 3 of 4

Trademark of The Dow Chemical Company (Dow) or an affiliated company of Dow

Form No. 609-02054-604

Membrane System Design Guidelines for Midsize FILMTEC Elements (cont.)

Feed source Feed silt density index Typical target flux, gfd (l/m2h) Maximum element recovery %

In Table 3.6, the small commercial systems are typically between 16 elements that are either regularly replaced or else cleaned (every half year or year) or performance loss is acceptable. The expected element lifetime is not more than 3 years. This is a low-cost, compact solution for intermittently operated systems. Table 3.6 Design guidelines for FILMTEC elements in small commercial applications

RO permeate SDI < 1 30 (51) 30 Softened Municipal SDI < 3 30 (51) 30 Well water SDI < 3 25 (42) 25 Surface or Municipal Water SDI < 5 20 (34) 20

Maximum permeate flow rate, gpd (m3/d) 2.5-inch diameter 4.0-inch diameter Minimum concentrate flow rate1, gpm (m3/h) 2.5-inch diameter 4.0-inch diameter Active area ft2 (m2) 28 (2.6) 28 (2.6) 29 (2.7) 87 (8.1) 82 (7.6) 82 (7.6) 80 (7.4)

1,100 (4.2) 3,100 (11.7)

1,100 (4.2) 3,100 (11.7)

900 (3.4) 2,600 (9.8)

700 (2.7) 2,100 (7.9)

0.5 (0.11) 2 (0.5) Maximum feed flow rate U.S. gpm (m3/h) 6 (1.4) 6 (1.4) 6 (1.4) 14 (3.2) 14 (3.2) 16 (3.6) 16 (3.6)

0.5 (0.11) 2 (0.5)

0.7 (0.16) 3 (0.7)

0.7 (0.16) 3 (0.7) Maximum feed pressure psig (bar) 600 (41) 600 (41) 1,000 (69) 600 (41) 600 (41) 600 (41) 1,000 (69)

Element type Tape-wrapped 2540 Fiberglased 2540 Seawater 2540 Tape-wrapped 4040 TW30-4040 Fiberglassed 4040 SW Fiberglassed 4040

1

Maximum pressure drop per element1 psig (bar) 13 (0.9) 15 (1.0) 13 (0.9) 13 (0.9) 13 (0.9) 15 (1.0) 15 (1.0)

We recommend that the pressure drop for new/clean elements be at least 20% below the maximum.

Note: The limiting values listed above have been incorporated into the ROSA (Reverse Osmosis System Analysis) software. Designs of systems in excess of the guidelines results in a warning on the ROSA printout.

FILMTEC Membranes

For more information about FILMTEC membranes, call the Dow Water Solutions business: North America: 1-800-447-4369 Latin America: (+55) 11-5188-9222 Europe: (+32) 3-450-2240 Pacific: +60 3 7958 3392 Japan: +813 5460 2100 China: +86 21 2301 9000 http://www.filmtec.com

Notice: The use of this product in and of itself does not necessarily guarantee the removal of cysts and pathogens from water. Effective cyst and pathogen reduction is dependent on the complete system design and on the operation and maintenance of the system. Notice: No freedom from any patent owned by Seller or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, Customer is responsible for determining whether products and the information in this document are appropriate for Customers use and for ensuring that Customers workplace and disposal practices are in compliance with applicable laws and other governmental enactments. Seller assumes no obligation or liability for the information in this document. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

Page 4 of 4

Trademark of The Dow Chemical Company ("Dow") or an affiliated company of Dow

Form No. 609-02054-604

S-ar putea să vă placă și

- System Design: Membrane System Design Guidelines For Commercial ElementsDocument3 paginiSystem Design: Membrane System Design Guidelines For Commercial ElementsJose Marval RodriguezÎncă nu există evaluări

- Data Sheet Sw30hrle-400Document2 paginiData Sheet Sw30hrle-400Alexis Antonio Jara VidalÎncă nu există evaluări

- Reverse Osmosis Design GuidelinesDocument2 paginiReverse Osmosis Design Guidelineswacsii ccasullaÎncă nu există evaluări

- Ecosafe Ro Membrane CatalogDocument11 paginiEcosafe Ro Membrane CatalogecosafeÎncă nu există evaluări

- 10 - Filmtech MembraneDocument2 pagini10 - Filmtech MembraneAnonymous XbmoAFtIÎncă nu există evaluări

- System Design Membrane System Design Guidelines For 8" Filmtec™ ElementsDocument4 paginiSystem Design Membrane System Design Guidelines For 8" Filmtec™ ElementsfarshadÎncă nu există evaluări

- System Design Membrane System Design Guidelines For 8" Filmtec™ ElementsDocument4 paginiSystem Design Membrane System Design Guidelines For 8" Filmtec™ ElementsJuan MendozaÎncă nu există evaluări

- Performance and Characteristics of Reverse Osmosis MembranesDocument11 paginiPerformance and Characteristics of Reverse Osmosis Membranestata_77Încă nu există evaluări

- CH 09 Processdesignof ROsystemsDocument23 paginiCH 09 Processdesignof ROsystems2402 2003Încă nu există evaluări

- Sequencing Batch Reactor SystemsDocument5 paginiSequencing Batch Reactor SystemsAl Patrick Dela CalzadaÎncă nu există evaluări

- TF4 Mar 20 06Document6 paginiTF4 Mar 20 06DANIZACHÎncă nu există evaluări

- Sequence Batch ReactorDocument4 paginiSequence Batch ReactorKwang Je LeeÎncă nu există evaluări

- Reverse Osmosis Model #R44 Installation InstructionsDocument40 paginiReverse Osmosis Model #R44 Installation InstructionsWatts100% (1)

- DOW FILMTEC™ Membranes: Product Data SheetDocument3 paginiDOW FILMTEC™ Membranes: Product Data SheetPT Purione MegatamaÎncă nu există evaluări

- Filmtec™ Fiberglassed Elements For Light Industrial Systems: Product Data SheetDocument4 paginiFilmtec™ Fiberglassed Elements For Light Industrial Systems: Product Data SheetfasihulÎncă nu există evaluări

- Hydac HandbookDocument22 paginiHydac Handbookrajayu20002724Încă nu există evaluări

- Ibp1668 12Document13 paginiIbp1668 12Marcelo Varejão CasarinÎncă nu există evaluări

- Filtration in Brief: How The Contamination Is MeasuredDocument7 paginiFiltration in Brief: How The Contamination Is MeasuredArhant PathardeÎncă nu există evaluări

- Dupont Filmtec Xle Pro 4040 LDocument2 paginiDupont Filmtec Xle Pro 4040 Ldavid andres sandi ovaresÎncă nu există evaluări

- MBR-Tertiary UF ComparisonDocument9 paginiMBR-Tertiary UF ComparisonAkhmad RidhaniÎncă nu există evaluări

- Controlling Contamination in Hydraulic FluidsDocument3 paginiControlling Contamination in Hydraulic FluidsMrEngenhariaMecanicaÎncă nu există evaluări

- Reverse Osmosis R24-SERIES Installation InstructionsDocument44 paginiReverse Osmosis R24-SERIES Installation InstructionsWattsÎncă nu există evaluări

- Reverse Osmosis Model # R48 Installation InstructionsDocument30 paginiReverse Osmosis Model # R48 Installation InstructionsWatts0% (1)

- HFD Catalog RF7Document8 paginiHFD Catalog RF7PartsGopher.comÎncă nu există evaluări

- Examine Inlet Separation Technologies For Increased Reliability (Nexo Solutions)Document16 paginiExamine Inlet Separation Technologies For Increased Reliability (Nexo Solutions)DWNLD USRMLÎncă nu există evaluări

- 03.15 BW30-400-FR enDocument2 pagini03.15 BW30-400-FR enRobby Agam PahlavanÎncă nu există evaluări

- Vantage UFI Feb2011 SiemensDocument4 paginiVantage UFI Feb2011 SiemenssirtrungÎncă nu există evaluări

- Netafim Greywater Drip Irrigation Design ManualDocument16 paginiNetafim Greywater Drip Irrigation Design ManualwengruelÎncă nu există evaluări

- IwsmDocument3 paginiIwsmJAN JERICHO MENTOYÎncă nu există evaluări

- Sea WaterDocument39 paginiSea WaterArun GuptaÎncă nu există evaluări

- OTC-27746-MS cMIST™: Novel, Compact Dehydration System For Reducing Size and WeightDocument14 paginiOTC-27746-MS cMIST™: Novel, Compact Dehydration System For Reducing Size and WeightSARTHAK BAPATÎncă nu există evaluări

- LT36499 Hydraulic Filters 0Document43 paginiLT36499 Hydraulic Filters 0khans21840Încă nu există evaluări

- 3M High Flow Series Filer SystemsDocument12 pagini3M High Flow Series Filer SystemsRahimd Fox100% (1)

- AP Seri S: Extreme Low Pressure Brackish Water RO ElementsDocument1 paginăAP Seri S: Extreme Low Pressure Brackish Water RO ElementshermanÎncă nu există evaluări

- Foaming in EP Industry - A Global PerspectiveDocument18 paginiFoaming in EP Industry - A Global Perspectivearunperth100% (1)

- Efficiency Improvement and Trouble-Shooting: Separation SystemsDocument8 paginiEfficiency Improvement and Trouble-Shooting: Separation SystemsAlberto darianÎncă nu există evaluări

- WWTP Synopsis1Document14 paginiWWTP Synopsis1malgendy0Încă nu există evaluări

- Adv 885 Ro Pac M QuickrefguideDocument8 paginiAdv 885 Ro Pac M QuickrefguideAlejandroOdioCastilloÎncă nu există evaluări

- Reverse Osmosis Model R4X40 Installation InstructionsDocument16 paginiReverse Osmosis Model R4X40 Installation InstructionsWattsÎncă nu există evaluări

- DS TW30 4040Document3 paginiDS TW30 4040caparedeszÎncă nu există evaluări

- With Membrane Technolgy For Oil Sands and Power Generation ApplicationsDocument8 paginiWith Membrane Technolgy For Oil Sands and Power Generation ApplicationsMarcelo Varejão CasarinÎncă nu există evaluări

- DR Emad Zero TDS 4m3 Per Hour Projection DetailsDocument5 paginiDR Emad Zero TDS 4m3 Per Hour Projection Detailsاحمد همامÎncă nu există evaluări

- Condition Monitoring of Steam Turbines by Performance AnalysisDocument25 paginiCondition Monitoring of Steam Turbines by Performance Analysisabuhurairaqazi100% (1)

- Polisher RO: Permeate & Condensate PolishingDocument1 paginăPolisher RO: Permeate & Condensate PolishingAnonymous 3fTYXaW7WÎncă nu există evaluări

- MATTEN SWRO Catalogue PDFDocument12 paginiMATTEN SWRO Catalogue PDFJuhendi Bidangan100% (1)

- HF2D06Document69 paginiHF2D06juangar1992Încă nu există evaluări

- FILMTEC™ Membranes: Product Data SheetDocument3 paginiFILMTEC™ Membranes: Product Data SheetAshish GulrandheÎncă nu există evaluări

- Stock and Water Systems of The Paper MachineDocument64 paginiStock and Water Systems of The Paper MachineEnrico75% (4)

- Sprinkler DesignDocument11 paginiSprinkler DesignJohn Son GÎncă nu există evaluări

- 15P/30P Series: High Pressure FiltersDocument12 pagini15P/30P Series: High Pressure FiltersPartsGopher.comÎncă nu există evaluări

- Membrana Filmtec Sw30xle-400iDocument3 paginiMembrana Filmtec Sw30xle-400iBuenaventura Jose Huamani TalaveranoÎncă nu există evaluări

- H2 FLOW - DAF - Process - DescriptionDocument8 paginiH2 FLOW - DAF - Process - DescriptionPriyaÎncă nu există evaluări

- Consideration For Approval of ATU For Use in Trinidad and TobagoDocument5 paginiConsideration For Approval of ATU For Use in Trinidad and TobagoJeffrey James100% (1)

- WR WQ Pub Design Criteria Ch5Document10 paginiWR WQ Pub Design Criteria Ch5Teena AlawadÎncă nu există evaluări

- Optimized One-Step Pretreatment Enhancing The Benefits of Air Flotation and Media FiltrationDocument18 paginiOptimized One-Step Pretreatment Enhancing The Benefits of Air Flotation and Media FiltrationMunir AbdullahÎncă nu există evaluări

- DOW FILMTEC™ SW30ULE-440i Element: DescriptionDocument4 paginiDOW FILMTEC™ SW30ULE-440i Element: DescriptionMaria SilvaÎncă nu există evaluări

- Corrosion and Fouling Control in Desalination IndustryDe la EverandCorrosion and Fouling Control in Desalination IndustryÎncă nu există evaluări

- Pulp and Paper Industry: Emerging Waste Water Treatment TechnologiesDe la EverandPulp and Paper Industry: Emerging Waste Water Treatment TechnologiesEvaluare: 5 din 5 stele5/5 (1)

- Damages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsDe la EverandDamages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsEvaluare: 4.5 din 5 stele4.5/5 (2)

- Eu Complaint Form enDocument7 paginiEu Complaint Form enLuis PiresÎncă nu există evaluări

- Shale Gas IntroDocument3 paginiShale Gas IntromomanzoorÎncă nu există evaluări

- Natural Gas Hydrates A Guide For Engineers Table of ContentsDocument7 paginiNatural Gas Hydrates A Guide For Engineers Table of ContentsSrinivas BobbyÎncă nu există evaluări

- Request To Obtain Stickers For Private Hire VehicleDocument1 paginăRequest To Obtain Stickers For Private Hire VehiclemomanzoorÎncă nu există evaluări

- 113-123 ST Georges Road, Bolton Bl1 2by: Former Funeral DirectorsDocument2 pagini113-123 ST Georges Road, Bolton Bl1 2by: Former Funeral DirectorsmomanzoorÎncă nu există evaluări

- SSD18M 34E FW Upgrade Tool Only For 18M 34E 0407Document6 paginiSSD18M 34E FW Upgrade Tool Only For 18M 34E 0407momanzoorÎncă nu există evaluări

- JukeDocument2 paginiJukemomanzoorÎncă nu există evaluări

- Nato Phonetic AlphabetDocument1 paginăNato Phonetic AlphabetIsaiah Ray Dela CruzÎncă nu există evaluări

- Filmtec ManualDocument4 paginiFilmtec ManualmomanzoorÎncă nu există evaluări

- 22616pricelist 2012Document80 pagini22616pricelist 2012derenmagnoÎncă nu există evaluări

- Phone Software Update FAQDocument3 paginiPhone Software Update FAQmomanzoorÎncă nu există evaluări

- A4 - Types of FasteningsDocument1 paginăA4 - Types of FasteningsmomanzoorÎncă nu există evaluări

- 22616pricelist 2012Document80 pagini22616pricelist 2012derenmagnoÎncă nu există evaluări

- Enhanced Nissan GT-RDocument1 paginăEnhanced Nissan GT-RmomanzoorÎncă nu există evaluări

- Age and EmissonaGE AND EMISSIONS POLICYDocument6 paginiAge and EmissonaGE AND EMISSIONS POLICYmomanzoorÎncă nu există evaluări

- Darcy Weisbach FormulaDocument3 paginiDarcy Weisbach Formulasairam2234Încă nu există evaluări

- Salary Guide 2013Document17 paginiSalary Guide 2013sorin_1234Încă nu există evaluări

- Rosa 2Document1 paginăRosa 2momanzoorÎncă nu există evaluări

- Phone Software Update FAQDocument3 paginiPhone Software Update FAQmomanzoorÎncă nu există evaluări

- NPSH SimplifiedDocument4 paginiNPSH Simplifiedtexwan_Încă nu există evaluări

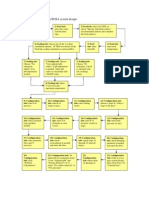

- Flow Chart For Creating A ROSA System DesignDocument2 paginiFlow Chart For Creating A ROSA System DesignmomanzoorÎncă nu există evaluări

- 22616pricelist 2012Document80 pagini22616pricelist 2012derenmagnoÎncă nu există evaluări

- EM 1110-3-173 - Sanitary and Industrial Waste Water Pumping - Mobilization Construction - WebDocument38 paginiEM 1110-3-173 - Sanitary and Industrial Waste Water Pumping - Mobilization Construction - WebPDHLibraryÎncă nu există evaluări

- Contro Valve Inherent Flow CharacteristicDocument6 paginiContro Valve Inherent Flow CharacteristictcarpiÎncă nu există evaluări

- 22616pricelist 2012Document80 pagini22616pricelist 2012derenmagnoÎncă nu există evaluări

- Rigorously Size Relief Valves For Critical FluidsDocument10 paginiRigorously Size Relief Valves For Critical Fluidsashirwad shetty100% (2)

- Some Control SchemeDocument10 paginiSome Control SchemeS_hassan_16Încă nu există evaluări

- Processcontrol PDFDocument13 paginiProcesscontrol PDFSIVAÎncă nu există evaluări

- Evaluation of Newly Developed MBR Systems For Water ReclamationDocument174 paginiEvaluation of Newly Developed MBR Systems For Water ReclamationmomanzoorÎncă nu există evaluări

- Expansion JointsDocument29 paginiExpansion Jointsvarma101100% (1)

- Sany S800S ReviewDocument11 paginiSany S800S ReviewJuna PasaribuÎncă nu există evaluări

- Aluminium Composite PanelsDocument46 paginiAluminium Composite PanelsSashwat GhaiÎncă nu există evaluări

- Townsend Labs Sphere L22 Microphone System User GuideDocument59 paginiTownsend Labs Sphere L22 Microphone System User GuideGuillermoMazaÎncă nu există evaluări

- Arduino Bluetooth Ralay 4chDocument5 paginiArduino Bluetooth Ralay 4chRaul Lara RochaÎncă nu există evaluări

- Chapter Eighteen: Creating Competitive AdvantageDocument34 paginiChapter Eighteen: Creating Competitive AdvantageSana MehmoodÎncă nu există evaluări

- Fuzzy LogicDocument27 paginiFuzzy LogicvibhutiÎncă nu există evaluări

- 9-4130 - Loose Stepper MotorDocument2 pagini9-4130 - Loose Stepper MotorarasÎncă nu există evaluări

- Presented To:prof. Rashmi Menon & Class Prepared By: Valay Chaya (07) Nikul Maheshwari (28) Anis Vohra (56) Ravi Vyas (57) Nilesh JainDocument57 paginiPresented To:prof. Rashmi Menon & Class Prepared By: Valay Chaya (07) Nikul Maheshwari (28) Anis Vohra (56) Ravi Vyas (57) Nilesh JainAnis VohraÎncă nu există evaluări

- USA Cutter Suction Dredger Simulator TrainingDocument2 paginiUSA Cutter Suction Dredger Simulator TrainingAbdullah Badawi BatubaraÎncă nu există evaluări

- Security Audit Technology Training Report To PresentDocument1 paginăSecurity Audit Technology Training Report To PresentLewis Kang'araÎncă nu există evaluări

- Donald McLean Automatic Flight Control SystemsDocument610 paginiDonald McLean Automatic Flight Control SystemsAndra Radu100% (3)

- Uber Strategy TeardownDocument44 paginiUber Strategy Teardownskouti9100% (3)

- Resume - Abishek AntonyDocument4 paginiResume - Abishek AntonyabishekantonyÎncă nu există evaluări

- Job Miller AbstractDocument5 paginiJob Miller AbstractTelika RamuÎncă nu există evaluări

- Week 03 Network Concepts and Network Media PDFDocument63 paginiWeek 03 Network Concepts and Network Media PDFikonÎncă nu există evaluări

- Yamaha Acoustic GuitarsDocument18 paginiYamaha Acoustic Guitarsrusf123100% (5)

- YALE (C878) GDP135VX LIFT TRUCK Service Repair Manual PDFDocument20 paginiYALE (C878) GDP135VX LIFT TRUCK Service Repair Manual PDFfjskekdmmemÎncă nu există evaluări

- Primus Iron MachineDocument67 paginiPrimus Iron MachineKonstantinos Politis100% (1)

- Machine Guarding PDFDocument133 paginiMachine Guarding PDFbrsharmaÎncă nu există evaluări

- Install OpenERP On UbuntuDocument9 paginiInstall OpenERP On UbuntuQuynh NguyenÎncă nu există evaluări

- Letter Calling For State Department of Oil and Gas To Investigate Gas LeakDocument4 paginiLetter Calling For State Department of Oil and Gas To Investigate Gas LeakLos Angeles Daily NewsÎncă nu există evaluări

- Capacitor and InductorDocument19 paginiCapacitor and Inductorerynnguyen1110Încă nu există evaluări

- IP10G-CLI User Guide Version 6.7 March2011Document124 paginiIP10G-CLI User Guide Version 6.7 March2011JorgIVariuS100% (1)

- Draft Tech Proposal NTB UtmDocument20 paginiDraft Tech Proposal NTB Utmdudi hidayatÎncă nu există evaluări

- Jeppesen PowerplantDocument255 paginiJeppesen PowerplantWilliam Palma100% (1)

- How To Choose Circuit Breakers For Electric MotorsDocument2 paginiHow To Choose Circuit Breakers For Electric Motorsحسن التميميÎncă nu există evaluări

- Three-Phase Induction MotorsDocument32 paginiThree-Phase Induction MotorsDimitriu CarmenÎncă nu există evaluări

- Trafo Manual ABBDocument104 paginiTrafo Manual ABBMarcos SebastianÎncă nu există evaluări

- Kode Simbol Rate TVDocument10 paginiKode Simbol Rate TVAndri PÎncă nu există evaluări