Documente Academic

Documente Profesional

Documente Cultură

Hvac KWH Consumption: Solid State Lighting

Încărcat de

Agustin A.Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Hvac KWH Consumption: Solid State Lighting

Încărcat de

Agustin A.Drepturi de autor:

Formate disponibile

Solid State Lighting

A Manufacturers Approach to Sustainable Operations

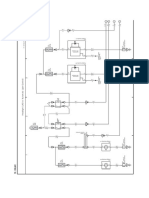

OYL Manufacturing Company Sdn Bhd & J&E Hall is one of the top manufacturers of HVAC (Heating, Ventilation and Air Conditioning) units in Malaysia. They are a member of the Daikin group which produces models under the Acson, York, American Air Filters, J&E Hull, McQuay HVAC kWh Consumption and Daikin product brands for use in residential, commercial and industrial applications. 1400 OYL/Daikin has a strong commitment to 1278 1200 environment performance of their products. The units themselves are large consumers of end use 1000 963 920 electrical power. The company has taken 863 800 numerous steps to minimize their products use 600 of energy including using inverter compressors, 400 more efficient heat exchanger and automatic filter cleaning. These product changes have 200 allowed OYL/Daikin to reduce the average 0 energy consumption of their units under JIS 1995 2000 2005 2010 conditions by 32% over the past 15 years.

2.8 kW residential air conditioner under JIS standards

Not content with only optimizing the energy consumption of their end products, OYL also places a strong focus on sustainable manufacturing. OYL has a sustainability team which continuously reviews their operations and identifies opportunity areas where the plants impact on the environment can be reduced. The site has executed many sustainable manufacturing projects at the plant with simple payback periods from 2.5 months to over 3 years including;

Project Description Installation of air curtains at doorways Inverter on air handling blower at canteen Inverter on cooling tower fans Utilities auto switch-off during non-operating periods Local air blowers to switch off main air compressor during low demand Rain water harvesting for process water and toilets High Bay metal halide to induction lamp retrofit and noncritical over lighting removal Fluorescent Tube T8 to T5 retrofit and noncritical over lighting removal

Payback Period 9.4 months 2.3 years 1.5 years 3.7 months 7 months 3.1 years 2.1 years 1.6 years

"Lighting retrofits are good candidates for energy saving projects because they are easy to implement, visible, and simple to calculate and verify the results.

Hj. Muhammad Razif Facility Manager OYL Manufacturing

Even though the plant changed a portion of their fluorescent T8 tubes to T5, they still had over 2,000 T8 x 1200mm fluorescent tubes in the plant. These remaining T8 fluorescent tubes were identified by the sustainability team as an opportunity to reduce energy consumption further. Most of the tubes were located in people centric areas such as in the offices, conference rooms, canteen, etc. Maintaining the lighting levels and lighting quality were identified as an important aspect during this retrofit project.

22-October-2012

This white paper is brought to you by Osprey Engineering Sdn. Bhd.

Page 1 of 3

Solid State Lighting

A Manufacturers Approach to Sustainable Operations

The sustainability and electrical team evaluated 2 options for the retrofit, changing to T5 fluorescent tubes (copy the previous fluorescent lighting retrofit project) and changing to T8 LED tubes. The team decided to implement the LED tubes for the following reasons; LED tubes have larger energy savings than corresponding T5 tubes. One of the reasons the previous T8 to T5 retrofit had such a short payback time is that many of the original T8 tubes were not replaced but removed for delamping. This was not possible with this retrofit. LED tubes have no harmful substances (RoHS certified) while T5 tubes contain mercury and are classified as a scheduled waste. LED tubes are of sturdy aluminum/polycarbonate construction while T5 tubes are made of glass and subject to breakage

OYL Manufacturing engaged Osprey Engineering to source the T8 LED tubes. A small set of LED tubes were initially tested. The samples had a clear cover so the tubes would be seen as an LED tube and easily identified as an energy saving project. However, feedback from the staff was that the brightness from the small, individual, LED chips were too strong when viewed directly. Based on this feedback, frosted covers were specified for the retrofit project. Full specifications of the LED Tubes are below. LED Specifications

Dimensions Material Specification LED Specification Number LED Chips LED Beam Angle Electrical Specification Cover Type Color Temperature Luminous Flux Installed LED Tube T8 x 1200mm Aluminum Frame, Polycarbonate Cover SMD 3528, High Bright 286 170 degrees AC 85-270 VAC, 19 Watts Frosted Cool White, 6000k 1,700 lm

To minimize project investment, OYL in-house technicians installed the LED tubes over a 3 month duration. During the installation, the ballast and starter were bypassed with the Line and Neutral wired directly to the bi-pin sockets. The old fluorescent tubes were sent to a managed disposal company.

Results

The main success criteria for this energy saving project are the delivery of equivalent or better lighting quality than the existing fluorescent tubes and realization of significant energy savings. Lighting Quality: A detailed lighting level study was done in the workshop office area of the plant. For this study, the lighting levels at the desk top height (1,800mm below the luminaire height) with the existing fluorescent tubes were compared with the new LED tubes. The measurements show that the lighting levels produced by the LED tubes averaged 27% higher than the fluorescent tubes.

22-October-2012

This white paper is brought to you by Osprey Engineering Sdn. Bhd.

Page 2 of 3

Solid State Lighting

A Manufacturers Approach to Sustainable Operations

Workshop Office Illuminance Diagram Fluorescent Tube vs. LED

28 '

96 vs. 98 35 vs. 44 174 vs. 170 45 vs. 60 224 vs. 323 179 vs. 110 47 vs. 34 118 vs. 96 31 vs. 35 96 vs. 58 240 vs. 261 100 vs. 172 256 vs. 296 245 vs. 278 190 vs. 275 109 vs. 182 270 vs. 273 250 vs. 318 150 vs. 283 230 vs. 273 200 vs. 272 224 vs. 295 257 vs. 327 147 vs. 286 265 vs. 303 164 vs. 182 193 vs. 298 140 vs. 310 279 vs. 323 105 vs. 174 210 vs. 367

18 '

XXX

2 Lamp Recessed Troffer Fixture for T8 x 1200mm lamp Illuminance at Desktop Level, lux. RED = Fluorescent Tube, GREEN = LED

During the retrofit execution, there were times when a room had a temporary mix of old fluorescent and new LED tubes at the same time. Some of the staff noted the color temperature difference between the 2 types of lamps. However, when the retrofit execution was complete, the OYL team was very satisfied with the increased lighting levels from the new LED tubes.

Project Savings: The energy consumption of a lighting circuit with 8 luminaires (16 tubes) was analyzed before and after the retrofit. It was found that the LED tubes used only half of the power as the existing fluorescent tubes, 18.3W vs. 35.3W. The project financials show an annual savings of over RM 53,000 due to energy savings and lower maintenance cost due to longer lamp life. This savings occurs with a higher delivered illuminance. Additional savings are expected when Malaysia rationalizes the current energy subsidies which will substantially increase the electric rates.

Annual Lighting Operating Cost, RM

Investment 2,200 Tubes including in-house installation Annual Electric Demand Savings (37.5 kW) Annual Electric kWh Savings (08:00 18:00, 6 days/week, 117 MWhr) Annual Maintenance Savings Total Annual Savings Simple Pay Back Period RM 255,000 RM 14,400 RM 36,100 RM 3,200 RM 53,700 4.7 years

120,000 100,000 80,000 60,000 40,000 20,000 0

Fluorescent LED

Mar

OYL Manufacturing Sdn Bhd & J&E Hall is the premier air-conditioning manufacturer in Malaysia producing a wide range of HVAC equipment for the Malaysian and global export markets from basic residential air-conditioners to high technology light commercial and commercial heat pump, air-cooled and water-cooled chillers with larger capacity of up to 75HP. ww w. o yl .c om .m y

Osprey Engineering provides engineering and consulting services to the process and manufacturing industries. Ospreys core areas of expertise are automation, control, real time performance monitoring and optimization. They have completed works for companies including Petronas, Shell, BASF, P&G and Kelloggs over the past 15 years. ww w. os p r e y- e ng i n eer i ng .c om

22-October-2012

This white paper is brought to you by Osprey Engineering Sdn. Bhd.

May

Nov

Jan

Sep

Jul

Page 3 of 3

S-ar putea să vă placă și

- IESNADocument44 paginiIESNAManola Alejandra Modragon SalazarÎncă nu există evaluări

- Maximize: GE Energy-Efficient T5 Linear Fluorescent SystemsDocument16 paginiMaximize: GE Energy-Efficient T5 Linear Fluorescent SystemsabangudaÎncă nu există evaluări

- Harlan Wyton Lighting SurveyDocument10 paginiHarlan Wyton Lighting Surveymirali74Încă nu există evaluări

- Analisis de Ahorro Energético en Iluminación LED IndustrialDocument9 paginiAnalisis de Ahorro Energético en Iluminación LED IndustrialHugo BarredaÎncă nu există evaluări

- Energy Efficient SolutionsDocument49 paginiEnergy Efficient Solutionsbellis26Încă nu există evaluări

- Cbca GuideDocument38 paginiCbca Guideamith_kmÎncă nu există evaluări

- Carga Térmica LedDocument6 paginiCarga Térmica LedJoão M. FoladorÎncă nu există evaluări

- Climaveneta - 350 Euston RoadDocument20 paginiClimaveneta - 350 Euston RoadrobasiÎncă nu există evaluări

- Energy Conservation Tips for Lighting and HVAC SystemsDocument2 paginiEnergy Conservation Tips for Lighting and HVAC SystemsRohit ShresthaÎncă nu există evaluări

- Larsen & Toubro Limited: Heavy Engineering Division, Powai, Mumbai (Maharashtra)Document24 paginiLarsen & Toubro Limited: Heavy Engineering Division, Powai, Mumbai (Maharashtra)zelani9625Încă nu există evaluări

- Led PresentationDocument28 paginiLed PresentationhemadribabuÎncă nu există evaluări

- Led Light at Velcro Canada.Document1 paginăLed Light at Velcro Canada.Tulsiram MohabirÎncă nu există evaluări

- LED PresentationDocument36 paginiLED PresentationYashwanth MnÎncă nu există evaluări

- LED vs. Fluorescent: The ROI AdvantageDocument12 paginiLED vs. Fluorescent: The ROI AdvantagePubudu Charaka KudahettiÎncă nu există evaluări

- Bayer Ashrae HPBDocument3 paginiBayer Ashrae HPBDhirendra Singh RathoreÎncă nu există evaluări

- T-Bar LED Smartlight: The Next Generation of The Light For Visible Structure Suspended CeilingsDocument6 paginiT-Bar LED Smartlight: The Next Generation of The Light For Visible Structure Suspended CeilingsAlejandro MoralesÎncă nu există evaluări

- Energy Efficiency Best Operating Practices Guide For FoundriesDocument32 paginiEnergy Efficiency Best Operating Practices Guide For FoundriesChitranjan KumarÎncă nu există evaluări

- Kingspan Daylighting SystemsDocument48 paginiKingspan Daylighting SystemsJuverdeanu Ioana-LoredanaÎncă nu există evaluări

- Orient LightingDocument24 paginiOrient LightingRajbir Singh YadavÎncă nu există evaluări

- TrickleStar Energy Saving LED Lighting SolutionsDocument20 paginiTrickleStar Energy Saving LED Lighting SolutionsBernard EmbyÎncă nu există evaluări

- Thermal Analysis of Extruded Aluminum Fin Heat Sink For LED Cooling ApplicationDocument4 paginiThermal Analysis of Extruded Aluminum Fin Heat Sink For LED Cooling ApplicationDilip SwamiÎncă nu există evaluări

- 05 WiproDocument26 pagini05 WiprogbaludbÎncă nu există evaluări

- Truline Industries LED Lighting Case StudyDocument1 paginăTruline Industries LED Lighting Case StudyKyle ChandlerÎncă nu există evaluări

- Great Lakes Cold Storage LED Lighting Case StudyDocument1 paginăGreat Lakes Cold Storage LED Lighting Case StudyKyle ChandlerÎncă nu există evaluări

- Level 1 Energy Audit Report (Scoping Study) : Prepared byDocument12 paginiLevel 1 Energy Audit Report (Scoping Study) : Prepared byFarwa MalikÎncă nu există evaluări

- Nava Bharat Ventures LTD SamalkotDocument49 paginiNava Bharat Ventures LTD SamalkotSantosh KapilÎncă nu există evaluări

- Indira Parivaran Bhawan An Energy Efficient BuildingDocument12 paginiIndira Parivaran Bhawan An Energy Efficient BuildingAyushree SharmaÎncă nu există evaluări

- Model Energy Audit ReportDocument25 paginiModel Energy Audit ReportjoechengshÎncă nu există evaluări

- A Review of Passive Thermal Management of LED ModuleDocument4 paginiA Review of Passive Thermal Management of LED ModuleJuan DinhÎncă nu există evaluări

- Vedanta Limited: Second Prize AluminiumDocument4 paginiVedanta Limited: Second Prize AluminiumTanaya SahaÎncă nu există evaluări

- GE-Light Book 2013Document168 paginiGE-Light Book 2013Suhas AcharyaÎncă nu există evaluări

- 43 (Evacuated Solar Tube)Document22 pagini43 (Evacuated Solar Tube)Nehul PatilÎncă nu există evaluări

- E.energy Product Brochure 7.0 - English - 071009Document8 paginiE.energy Product Brochure 7.0 - English - 071009joechengshÎncă nu există evaluări

- Bulbtiger - Philips Green LED BrochureDocument1 paginăBulbtiger - Philips Green LED BrochureBulbtigerÎncă nu există evaluări

- LED LED CTLG EN 052012 PG47 APAC - tcm281 33329Document47 paginiLED LED CTLG EN 052012 PG47 APAC - tcm281 33329FreddyOlanoÎncă nu există evaluări

- GrasimDocument10 paginiGrasimGaurav SinghÎncă nu există evaluări

- Industrial Energy Efficiency: Fast, Simple, ProvenDocument77 paginiIndustrial Energy Efficiency: Fast, Simple, ProvenLim BrandonÎncă nu există evaluări

- Section 16500 - Lighting: Whole Building Design Guide Federal Green Construction Guide For SpecifiersDocument8 paginiSection 16500 - Lighting: Whole Building Design Guide Federal Green Construction Guide For SpecifiersAnonymous NMytbMiDÎncă nu există evaluări

- Wong & Ouyang Holdings Ltd. Case StudyDocument55 paginiWong & Ouyang Holdings Ltd. Case Studyahtin618Încă nu există evaluări

- Domestic Heating Main Brochure SAP 210486Document36 paginiDomestic Heating Main Brochure SAP 210486Jennifer PattonÎncă nu există evaluări

- Green: Is Not Just About Environmental Sustainability. Green Is About Business SustainabilityDocument4 paginiGreen: Is Not Just About Environmental Sustainability. Green Is About Business SustainabilityJorge AlvarezÎncă nu există evaluări

- TB 90520091157467157 PDFDocument13 paginiTB 90520091157467157 PDFHarshitKhannaÎncă nu există evaluări

- Brochure ACCDocument8 paginiBrochure ACCbabis1980Încă nu există evaluări

- Brochure Air Cooled CondenserDocument8 paginiBrochure Air Cooled CondenserFathur Rahman Handoko100% (1)

- 2010 2011spectrum CatalogueDocument190 pagini2010 2011spectrum CatalogueDavid Covarrubias FarfanÎncă nu există evaluări

- CoreLine Brochure LR INTDocument17 paginiCoreLine Brochure LR INTDinutGigiÎncă nu există evaluări

- Frontline LED Janssen Case StudyDocument5 paginiFrontline LED Janssen Case StudyfrontlineledÎncă nu există evaluări

- Suzlon One Earth PDFDocument5 paginiSuzlon One Earth PDFNupur BhadraÎncă nu există evaluări

- SENTRO Technologies Online Chemical Cleaning PresentationDocument8 paginiSENTRO Technologies Online Chemical Cleaning Presentation조기현Încă nu există evaluări

- Rohde2020erf PaperID 1174Document8 paginiRohde2020erf PaperID 1174daongocvu792002Încă nu există evaluări

- PH Ue Ledtube Uet8 Leaflet A4 q3 2023 LRDocument2 paginiPH Ue Ledtube Uet8 Leaflet A4 q3 2023 LRcandidodealmeida10Încă nu există evaluări

- GE Lighting Systems Filterglow & Econoglow Brochure 1966Document24 paginiGE Lighting Systems Filterglow & Econoglow Brochure 1966Alan MastersÎncă nu există evaluări

- LMZ TechDocument29 paginiLMZ TechGajanan JagtapÎncă nu există evaluări

- GE Spectrum Katalóg 2013 Ledky Pre Spolocnost IMAC - SKDocument190 paginiGE Spectrum Katalóg 2013 Ledky Pre Spolocnost IMAC - SKinfokleidiÎncă nu există evaluări

- Building Services and System (III) : TopicDocument6 paginiBuilding Services and System (III) : TopicAyesha JavaidÎncă nu există evaluări

- Lighting: LED Lighting For UAFDocument2 paginiLighting: LED Lighting For UAFSamson KhambhampatiÎncă nu există evaluări

- Sustainable Renovation: Strategies for Commercial Building Systems and EnvelopeDe la EverandSustainable Renovation: Strategies for Commercial Building Systems and EnvelopeÎncă nu există evaluări

- Electrical Energy Efficiency: Technologies and ApplicationsDe la EverandElectrical Energy Efficiency: Technologies and ApplicationsÎncă nu există evaluări

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementDe la EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementÎncă nu există evaluări

- The Essential Buying Guide - Austin-Healey 3000Document24 paginiThe Essential Buying Guide - Austin-Healey 3000Agustin A.Încă nu există evaluări

- Austin-Healey 3000 Buying GuideDocument14 paginiAustin-Healey 3000 Buying GuideAgustin A.Încă nu există evaluări

- DS2175-44 Petrochemical PumpDocument1 paginăDS2175-44 Petrochemical PumpAgustin A.Încă nu există evaluări

- Shaft Rotation Affects Oiler - Reliabilityweb - A Culture of ReliabilityDocument3 paginiShaft Rotation Affects Oiler - Reliabilityweb - A Culture of ReliabilityAgustin A.Încă nu există evaluări

- Module 3 - Risk Based Inspection (RBI) Based On API and ASMEDocument4 paginiModule 3 - Risk Based Inspection (RBI) Based On API and ASMEAgustin A.Încă nu există evaluări

- AHSTC-Tech26A 1Document31 paginiAHSTC-Tech26A 1Agustin A.Încă nu există evaluări

- Alternative methods for balancing fans and rotorsDocument3 paginiAlternative methods for balancing fans and rotorsAgustin A.Încă nu există evaluări

- Understanding and Avoiding Lube Problems in Pump Bearing HousingsDocument9 paginiUnderstanding and Avoiding Lube Problems in Pump Bearing HousingsAgustin A.Încă nu există evaluări

- Artikel Specifying Magnetic Bearings PDFDocument2 paginiArtikel Specifying Magnetic Bearings PDFAgustin A.100% (1)

- Centrifugal Compressors 101: Part 1: Mark J. KuzdzalDocument8 paginiCentrifugal Compressors 101: Part 1: Mark J. KuzdzalAgustin A.Încă nu există evaluări

- Can We Go Wireless in Hazardous AreasDocument7 paginiCan We Go Wireless in Hazardous AreasAgustin A.Încă nu există evaluări

- API - ICP Schedules & FeesDocument3 paginiAPI - ICP Schedules & FeesAgustin A.Încă nu există evaluări

- In Situ Field Testing PDFDocument17 paginiIn Situ Field Testing PDFluiscastroprietoÎncă nu există evaluări

- RBI certification prepDocument6 paginiRBI certification prepAgustin A.Încă nu există evaluări

- API RP 580 RBI Certification Training - 95%+ First Time Pass RateDocument2 paginiAPI RP 580 RBI Certification Training - 95%+ First Time Pass RateAgustin A.Încă nu există evaluări

- Fundamental Principles of Comprehensive 2D GCDocument31 paginiFundamental Principles of Comprehensive 2D GCAgustin A.Încă nu există evaluări

- CASTI - Getting Started - API 580 Risk Based Inspection CertificationDocument1 paginăCASTI - Getting Started - API 580 Risk Based Inspection CertificationAgustin A.Încă nu există evaluări

- IPST01 Paper 125Document6 paginiIPST01 Paper 125hpanandikarÎncă nu există evaluări

- In Situ ProcedureDocument19 paginiIn Situ Procedurekannagi198Încă nu există evaluări

- 5GAA T 170219 Whitepaper EdgeComputing 5GAADocument19 pagini5GAA T 170219 Whitepaper EdgeComputing 5GAAAgustin A.Încă nu există evaluări

- A Transparent Indenter Measurement Method For Mechanical Property EvaluationDocument13 paginiA Transparent Indenter Measurement Method For Mechanical Property EvaluationAgustin A.Încă nu există evaluări

- Equipment Failure Model and Data For Substation TransformersDocument54 paginiEquipment Failure Model and Data For Substation TransformersAgustin A.100% (1)

- Using Portable/In-Situ Stress-Strain Microprobe System To Measure Mechanical Properties of Steel Bridges During ServiceDocument11 paginiUsing Portable/In-Situ Stress-Strain Microprobe System To Measure Mechanical Properties of Steel Bridges During ServiceAgustin A.Încă nu există evaluări

- Gas ChromatographyDocument4 paginiGas ChromatographyAgustin A.Încă nu există evaluări

- Jonathan Williams - HERA FFS PresentationDocument22 paginiJonathan Williams - HERA FFS PresentationMohamed AlkhiatÎncă nu există evaluări

- Pervasive Sensing and Health - Human-Centered and Ubiquitous Computing LabDocument6 paginiPervasive Sensing and Health - Human-Centered and Ubiquitous Computing LabAgustin A.Încă nu există evaluări

- Field Metallography: By: Dr. E. MogireDocument5 paginiField Metallography: By: Dr. E. MogireAgustin A.Încă nu există evaluări

- User-Driven Distributed Pervasive Sensing: Themes: High Tech, Software Technology & Intelligent SystemsDocument4 paginiUser-Driven Distributed Pervasive Sensing: Themes: High Tech, Software Technology & Intelligent SystemsAgustin A.Încă nu există evaluări

- Resonance Revealed - Vibrations MagazineDocument8 paginiResonance Revealed - Vibrations MagazineAgustin A.100% (1)

- Ml14088a001 See ClampDocument34 paginiMl14088a001 See ClampAgustin A.Încă nu există evaluări

- Hubungan Intensitas Pencahayaan, Kelelahan Mata dan Gangguan Ketajaman Penglihatan pada Pekerja Bagian InspectingDocument7 paginiHubungan Intensitas Pencahayaan, Kelelahan Mata dan Gangguan Ketajaman Penglihatan pada Pekerja Bagian InspectingYeni SeptianiÎncă nu există evaluări

- Growing Together: Moll Catalog 2015Document46 paginiGrowing Together: Moll Catalog 2015Catalin TudoseÎncă nu există evaluări

- ProposalDocument36 paginiProposalteck yuÎncă nu există evaluări

- 15 HILUX: LED HeadlightsDocument10 pagini15 HILUX: LED Headlightsgabrielzinho43Încă nu există evaluări

- Columbia Lighting Product Selection Guide Edition 3 1996Document116 paginiColumbia Lighting Product Selection Guide Edition 3 1996Alan MastersÎncă nu există evaluări

- Electrical Installation and MaintenanceDocument27 paginiElectrical Installation and Maintenanceelaine jane carreonÎncă nu există evaluări

- Annexe 6 - Sample RDS Room XXXDocument3 paginiAnnexe 6 - Sample RDS Room XXXFarhan Shaikh100% (1)

- Intake Interview Room Design GuideDocument34 paginiIntake Interview Room Design GuideBernadeth Riansy LumembangÎncă nu există evaluări

- Kimbell Art Museum 30th Anniversary LightingDocument2 paginiKimbell Art Museum 30th Anniversary LightingTaher Kachwala100% (1)

- NORSOK E 001 Requirements PDFDocument9 paginiNORSOK E 001 Requirements PDFP Venkata SureshÎncă nu există evaluări

- Worksheet No. 4.1A Detailed Lesson Plan in Eim T. V. L.: I. ObjectivesDocument3 paginiWorksheet No. 4.1A Detailed Lesson Plan in Eim T. V. L.: I. Objectivesramel gedorÎncă nu există evaluări

- Explore Signlight LED's Product CatalogDocument24 paginiExplore Signlight LED's Product Catalogsignlightled.lightsÎncă nu există evaluări

- Savio TPS760/762/764/770/772: Tps764 2X49W/840 HFD ND Ac-Mlo Acl SmsDocument2 paginiSavio TPS760/762/764/770/772: Tps764 2X49W/840 HFD ND Ac-Mlo Acl SmsChaitanya ChÎncă nu există evaluări

- Brochure 3F Linda LED enDocument30 paginiBrochure 3F Linda LED enHarris SouglerisÎncă nu există evaluări

- Nota Kursus Lampu JalanDocument142 paginiNota Kursus Lampu JalanMohammad Rafnie Arif100% (1)

- Led, Led Pro, G-Home LedDocument170 paginiLed, Led Pro, G-Home Ledvinayak deshpandeÎncă nu există evaluări

- FarosDocument31 paginiFarosAnonymous 0omT4xhXÎncă nu există evaluări

- Product-Brochure ENERGYDocument20 paginiProduct-Brochure ENERGYLETSOGILEÎncă nu există evaluări

- Hotel Management & Catering Technology SyllabusDocument81 paginiHotel Management & Catering Technology SyllabusYelesh LanjewarÎncă nu există evaluări

- Assignment-Green Building-Case StudyDocument25 paginiAssignment-Green Building-Case Studysmcsaminda50% (2)

- NECB-2011 and CAN-QUEST: The New Energy Code and The Tools Available For ComplianceDocument159 paginiNECB-2011 and CAN-QUEST: The New Energy Code and The Tools Available For CompliancesimonsahiÎncă nu există evaluări

- LED Magazine 2019-03Document44 paginiLED Magazine 2019-03mtomescuÎncă nu există evaluări

- Restaurant Services - Mark SchemeDocument15 paginiRestaurant Services - Mark Schemekins petetÎncă nu există evaluări

- Dekalb Brown Product-Guide Cage Production Systems Vs1408a PDFDocument20 paginiDekalb Brown Product-Guide Cage Production Systems Vs1408a PDFEdison SioÎncă nu există evaluări

- CIE S 025 Test Method and Interlaboratory ComparisonDocument39 paginiCIE S 025 Test Method and Interlaboratory ComparisonLab KliteÎncă nu există evaluări

- Juno Lighting Trac-Master Catalog 1988Document48 paginiJuno Lighting Trac-Master Catalog 1988Alan MastersÎncă nu există evaluări

- Socratic Teaching Approach to Architectural DesignDocument29 paginiSocratic Teaching Approach to Architectural DesignhemaliÎncă nu există evaluări

- Electrical E BrochureDocument12 paginiElectrical E BrochuresafinditÎncă nu există evaluări

- WP02Document1 paginăWP02sbas.supplier.electrical.tcÎncă nu există evaluări