Documente Academic

Documente Profesional

Documente Cultură

Quotation - RefrigDryer D600IN-A To D5400IN-A

Încărcat de

biberiusDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Quotation - RefrigDryer D600IN-A To D5400IN-A

Încărcat de

biberiusDrepturi de autor:

Formate disponibile

Ref: Page: Date:

D600IN-A TO D5400IN-A 1 of 9

4-Nov-08

QUOTATION: DRYERS D600IN-A TO D5400IN-A

Refrigerated Air Dryers

D600IN-A to D5400IN-A

1.

GENERAL DESCRIPTION.............................................................................................. 2 1.1. Introduction ............................................................................................................... 2

1.2. Operating principle.................................................................................................... 2 1.2.1. Compressed air circuit....................................................................................... 2 1.2.2. Refrigeration circuit............................................................................................ 2 2. COMPONENTS AND CONSTRUCTION ........................................................................ 4 2.1. 2.2. 2.3. 2.4. 2.5. 2.6. 2.7. 2.8. 2.9. Refrigerant Compressor ........................................................................................... 4 R507 Refrigerant ...................................................................................................... 5 Heat Exchanger ........................................................................................................ 5 Liquid Separator ....................................................................................................... 5 Condenser ................................................................................................................ 5 Cooling Fan............................................................................................................... 5 Fan pressure switch.................................................................................................. 6 Hot Gas By-pass Valve............................................................................................. 6 No Loss Condensate Drain....................................................................................... 6

2.10. Control Panel ............................................................................................................ 6 3. 4. 2.11. Enclosure .................................................................................................................. 6 TESTING.......................................................................................................................... 7 COMMERCIAL OFFER ................................................................................................... 7 4.1. 4.2. 4.3. 4.4. 4.5. 4.6. 5. 6. Delivery Terms.......................................................................................................... 8 Payment Terms......................................................................................................... 8 Warranty ................................................................................................................... 8 Start up ..................................................................................................................... 8 Standard packaging.................................................................................................. 8 Validity of the offer .................................................................................................... 8

4.7. Other conditions........................................................................................................ 8 EXCLUSIONS FROM THE SUPPLY .............................................................................. 8 TERMS & CONDITIONS OF SALE................................................................................. 9

Ingersoll Rand Company Confidential

Ref: Page: Date:

D600IN-A to D5400IN-A 2 of 9 4-Nov-08

QUOTATION: DRYERS D600IN-A to D5400IN-A

1. General Description

1.1. Introduction

The D series refrigerated dryer models D600IN-A to D5400IN-A are non-cycling compressed air dryer designed for superior and reliable performance in a compressed air solution. The purpose of this document is to describe the operating principle and the principal components of refrigerated dryers. This range of dryers has three frames. The smaller frame is designed for models D600IN-A to D950IN-A. The second frame is build for models D1300IN-A to D2520IN-A. The larger frame is for models D3000IN-A to D5400INA. 1.2. Operating principle

D600IN-A to D950IN-A D1300IN-A to D2520IN-A

D3000IN-A to D5400IN-A

Dryers are split into a compressed air circuit and a refrigeration circuit. 1.2.1. Compressed air circuit Saturated compressed air enters the dryers heat exchanger, where it is pre-cooled by the cold compressed air exiting the dryer. Then it passes to the evaporator, where it is further cooled by the cold evaporating refrigerant. Ingersoll Rand uses environmentally friendly refrigerant R507. The cold air and condensed liquids flow to the de-mister separator, where the liquids are separated out of the air-stream by the de-misters mesh filter. The liquids are then drained away by a no-loss condensate drain. The now dry but still cold compressed air exits the dryer via the air-to-air heatexchanger. As it cools the incoming air, it is itself warmed up, thereby eliminating condensation accumulation on the outside of the air piping and decreasing the relative humidity. 1.2.2. Refrigeration circuit The refrigeration circuit begins at the discharge of the refrigerant compressor; the hot high pressure gas flows through towards the air-cooled condenser. Here the refrigerant is cooled by ambient air flowing across the condenser coil, causing the gas to condense into a liquid state. On exiting the condenser the liquid refrigerant passes through the filter/dryer, where any moisture and impurities within the refrigerant are

Ref: Page: Date:

D600IN-A to D5400IN-A 3 of 9 4-Nov-08

QUOTATION: DRYERS D600IN-A to D5400IN-A

removed. Next the refrigerant passes through the capillary. The capillary expands the high pressure refrigerant before entering the evaporator. The cold liquid refrigerant then enters the evaporator, where it exchanges heat with hot compressed air. It adsorbs heat from the compressed air and cools the compressed air to the required dew point. As the refrigerant flows through the evaporator it transforms from a cold liquid to a warm (and superheated) gas. The warm refrigerant gas then exits the evaporator and returns back to the refrigerant compressor, where it repeats the whole above cycle again. The dew point performance is accurately controlled by a hot gas bypass valve which is combined to a fan system. In the following table you can find the flow associated with each dryer model at a C Pressure Dew Point: (ISO 8573-1: 2001) 3

Model D600IN-A D780IN-A D950IN-A D1300IN-A D1410IN-A D1890IN-A D2520IN-A D3000IN-A D4200IN-A D4800IN-A D5400IN-A

ISO 8573-1: 2001 Class 4 < 3 C Pressure Dew Point m3/min m3/hr 10,0 600,0 13,0 780,0 15,8 950,0 21,7 1300,0 23,5 1410,0 31,5 1890,0 42,0 2520,0 50,0 3000,0 70,0 4200,0 80,0 4800,0 90,0 5400,0

Data refers to the following conditions: Ambient temperature = 25 C Air inlet temperature = 35 C Pressure = 7 bar g Operating Capabilities Maximum operating pressure D600IN-A Maximum operating pressure D780IN-A to D5400IN-A Maximum air inlet temperature Ambient temperature D600IN-A to D950IN-A Min/Max Ambient temperature D1300IN-A to D5400IN-A Min/Max Electrical protection = 14 bar (g) = 12 bar (g) = +60 C = +2 /+50 C = +2 /+45 C = IP42

Ref: Page: Date:

D600IN-A to D5400IN-A 4 of 9 4-Nov-08

QUOTATION: DRYERS D600IN-A to D5400IN-A

2. Components and construction

Each dryer are designed with the following components: 1. Refrigerant compressor 2. Heat exchanger 3. Liquid separator 4. Condenser 5. Hot gas by-pass valve 6. No loss condensate drain 7. Control Panel 8. Motor Fan 9. Fan pressure switch 10. Enclosure

2.1.

Refrigerant Compressor

A hermetically sealed reciprocating compressor is utilized throughout the design. All compressors have an oil sump heater with primary external motor temperature protection and internal, secondary motor temperature protection. A primary, external sensor with secondary, internal protection protects compressor discharge temperature. Installing the compressor on isolation mounts to the baseplate reduces noise and vibration.

Ref: Page: Date:

D600IN-A to D5400IN-A 5 of 9 4-Nov-08

QUOTATION: DRYERS D600IN-A to D5400IN-A

2.2.

R507 Refrigerant

Environmentally friendly R507, a non-ozone depleting refrigerant, is used. 2.3. Heat Exchanger

Each dryer uses aluminum cross flow heat exchanger, with a high surface area which is used to cool the air to the desired dew point. The ultra compact aluminum version includes an air-to-air heat exchanger, evaporator and service-free demister separator, all in one. Larger models feature up to 6 exchanger modules. Removal of the condensed moisture is accomplished through the high efficiency, demister type moisture separator, fitted with a condensate no-loss drain. The dry, cold air passes through the air air reheater, where the air is warmed, Thereby eliminating condensation accumulation on the outside of the air piping and decreasing the relative humidity. The Ingersoll Rand aluminum heat exchanger offers compactness, robustness and energy efficiency which reduce the operating costs of dryers.

2.4.

Liquid Separator

The liquid separator has the task of ensuring that no liquid refrigerant enters the compressor. It improves the stability of the dew point and it reduces the energy consumption of the unit. 2.5. Condenser

Parallel flow aluminum condensers and axial fans provide cooling to the refrigerant. The condensers are made of aluminum. Industrial Grade Axial fans provide cooling airflow across the condenser. 2.6. Cooling Fan

Dryers are cooled by an axial fan(s) installed in the top of each unit. Depending on the unit size, number of fan may vary. The fan dissipates heat of the dryer and is controlled by the fan pressure switch. Fans are located on the top of the units to improve air flow and ease of maintenance.

Ref: Page: Date:

D600IN-A to D5400IN-A 6 of 9 4-Nov-08

QUOTATION: DRYERS D600IN-A to D5400IN-A

2.7. Fan pressure switch

The fan pressure switch allows the cooling fan(s) to adjust the dryer's cooling capacity at different working conditions. Condensation pressure is controlled by the control panels activation and deactivation of the fans. The fan pressure switch deactivates the fan when the pressure is lower than 16 bar g and reactivates it when the pressure is higher than 20 bar g. 2.8. Hot Gas By-pass Valve

To ensure that there is no risk of freezing within the dryer a hot gas by-pass valve acts as the controller for the whole refrigeration circuit. The hot gas by-pass operates according to the refrigerant pressure within the evaporator. It reacts by taking a percentage of the refrigerant exiting the refrigerant compressor, and re-injecting it into the compressor inlet. In this way the hot gas by-pass can ensure that the pressure of the refrigerant entering the evaporator is always constant. This ensures a stable refrigeration circuit regardless of changes in operating conditions. 2.9. No Loss Condensate Drain

Dryers come equipped with a no-loss drain as a standard feature. This no loss drain eliminates the need for pre-setting the unit. The system uses state-of-the-art software combined with a special transducer interface to measure the presence of condensate. The condensate is released only when needed. There is no loss of compressed air. Continuous monitoring ensures fast, effective discharge of the condensate ate reliably without wasting any power. 2.10. Control Panel A full feature electronic control panel system ensures proper dryer operation. Individual alarms are provided for high and low dew point and probe failure. The control board is equipped with a dry contact for common alarm. Alarm history is available for review. For model D600IN-A to D950IN-A, a history of 10 alarms is available. For models D1300IN-A to D5400IN-A, and history of 50 alarms is available. The control panel comes with a terminal for remote alarm signal and for models D1300IN-A to D5400INA the control panel comes with an additional terminal for remote alarm for the no-loss drain. For models D600IN-A to D950IN-A, a visual display is used to indicate dryer conditions. Three LEDs are provided to indicate compressor, drain and condenser fan status. For models D1300IN-A to D5400IN-A the control panel come with 11 icons to indicate different status and modes of the dryers. An energy saving/anti-freezing mode will shut the dryer off during periods of low demand

2.11. Enclosure The cabinet is designed to safely contain components yet offer an aesthetically pleasing appearance and ergonomically planned maintenance access. The sheet metal enclosure is steel and is painted with electro-statically applied powder coat paint.

Ref: Page: Date:

D600IN-A to D5400IN-A 7 of 9 4-Nov-08

QUOTATION: DRYERS D600IN-A to D5400IN-A

3. Testing

Final package and functional testing is performed on all dryers: Electrical functionality test Helium leak test to the refrigeration side Refrigeration leak test at designed system pressure

4. Commercial Offer

Qty Description Dryer model XXX supplied as per description of the technical proposal Ultracare Part Kit zzz Filter model YYY supplied as per description of the technical proposal Unit Price [] Total Price []

Ref: Page: Date:

D600IN-A to D5400IN-A 8 of 9 4-Nov-08

QUOTATION: DRYERS D600IN-A to D5400IN-A

4.1.

Delivery Terms

Ex-works Ingersoll Rand facility (Unicov, Czech Republic). Lead time: {complete as appropriate} Lead time begins after official order acceptance by Ingersoll Rand or, if requested, from the date of the letter of credit. In case the Buyer has to delay the shipment or does not provide clearance to ship the material after the readiness for shipment of the material, a storage fee will be applied. 4.2. Payment Terms

20% at order 80% at shipment 4.3. Warranty

Ingersoll Rand warrants that the equipment will be free of defects in material and workmanship for a period of twelve months from the date of placing the equipment in operation or eighteen months from the date of shipment, whichever occurs first. Extended warranties (beyond above period) are available with Ingersoll Rands UltraCare programs. Please contact Ingersoll Rand Services Dept. for further details. 4.4. Start up

Excluded. If requested, Ingersoll Rands supervision at start up will be invoiced according the local rates in force at the time of the intervention. 4.5. Standard packaging

The dryer will ship in a plastic wrap with a cardboard box mounted on a wooden skid. 4.6. Validity of the offer

30 days 4.7. Other conditions

For what not specifically mentioned the attached Ingersoll Rand Terms & Conditions of Sale apply.

5. Exclusions from the Supply

Everything not explicitly listed in this offer is intended as excluded from Ingersoll Rand scope of supply.

Ref: Page: Date:

D600IN-A to D5400IN-A 9 of 9 4-Nov-08

QUOTATION: DRYERS D600IN-A to D5400IN-A

In particular, unless otherwise specified in this proposal, Customer liabilities are: Foundation working Piping and installation outside of package for air, cooling water and condensate Piping and connections between the package and loose items Interconnecting piping and cabling to Customer network Handling/lifting devices for customer installation Compliance with standards or specifications not clearly mentioned in this offer or attached to the quotation request

6. Terms & Conditions of Sale

{Attach as appropriate}

S-ar putea să vă placă și

- Deno Air Dryer Manual SD210 16757Document58 paginiDeno Air Dryer Manual SD210 16757ImmorthalÎncă nu există evaluări

- KobelionII-VS420-730A Instruction Manual (English) (4H50ZC4577P1-01)Document78 paginiKobelionII-VS420-730A Instruction Manual (English) (4H50ZC4577P1-01)Nguyen Anh SangÎncă nu există evaluări

- IR Water-Dryer: Ingersoll-Rand (Shanghai) Co., LTDDocument36 paginiIR Water-Dryer: Ingersoll-Rand (Shanghai) Co., LTDJohn SimancaÎncă nu există evaluări

- Detroit Screw Compressor Manual A4 FINAL NocroDocument52 paginiDetroit Screw Compressor Manual A4 FINAL NocroDaniel Fernando Bernal PescaÎncă nu există evaluări

- Kaeser BoosterDocument5 paginiKaeser Boostercasv9100% (1)

- Ingersoll Rand Tms 380Document28 paginiIngersoll Rand Tms 380Marlon Geronimo100% (2)

- Spesifikasi Atlas Copco ZT 30Document5 paginiSpesifikasi Atlas Copco ZT 30Fithrul MubarokÎncă nu există evaluări

- Compressor Ingersool PDFDocument52 paginiCompressor Ingersool PDFFabripreta Santos100% (1)

- VMC UnloadersDocument2 paginiVMC UnloaderssÎncă nu există evaluări

- SL-E Air End Service Manual Compressor ScrollDocument35 paginiSL-E Air End Service Manual Compressor ScrollLucky Karunia Setyawan PratamaÎncă nu există evaluări

- Osp 150v5adDocument11 paginiOsp 150v5adQuy HoangÎncă nu există evaluări

- MAM6070Document45 paginiMAM6070Vitor FreitasÎncă nu există evaluări

- Ingersoll Irn 55k CC PartlistDocument37 paginiIngersoll Irn 55k CC PartlistUbanAirlangga100% (2)

- Sierra ManualDocument104 paginiSierra ManualSean GilsenanÎncă nu există evaluări

- Kolbeko PDFDocument68 paginiKolbeko PDFDanh ThànhÎncă nu există evaluări

- DSP 37 55 (V) A (R) N2 - e - Dsa 630Document140 paginiDSP 37 55 (V) A (R) N2 - e - Dsa 630PhuNguyenHoangÎncă nu există evaluări

- SLAD-MXf ManualDocument10 paginiSLAD-MXf ManualReiky Aji ShaputraÎncă nu există evaluări

- Brochure Secador NVCDocument7 paginiBrochure Secador NVCByron PanchiÎncă nu există evaluări

- Manual Aircel Ahld-750Document44 paginiManual Aircel Ahld-750Robert Cid de Leon0% (1)

- Screw Compressor Controller PDFDocument28 paginiScrew Compressor Controller PDFMohan Raj100% (1)

- Atlas Copco Bedieiningshandleiding GA-75-90-110 21711600Document153 paginiAtlas Copco Bedieiningshandleiding GA-75-90-110 21711600arun kumarÎncă nu există evaluări

- TYPE: MAM-880 B : Screw Air CompressorDocument22 paginiTYPE: MAM-880 B : Screw Air CompressorKader SllÎncă nu există evaluări

- Installation and Maintenance ManualDocument60 paginiInstallation and Maintenance ManualAbdulSattar100% (2)

- 2 NEOS Parameter and Fault Code Overview 2946 1858 00Document12 pagini2 NEOS Parameter and Fault Code Overview 2946 1858 00Mohit Panchal100% (1)

- User Manual: Screw Air Compressor TYPE: MAM-KY12S B - LCD DISPLAY-260Document18 paginiUser Manual: Screw Air Compressor TYPE: MAM-KY12S B - LCD DISPLAY-260Samuel OchigboÎncă nu există evaluări

- Ed 01 (EN) Creemers KompressorDocument31 paginiEd 01 (EN) Creemers KompressorsebastianÎncă nu există evaluări

- Demand Manager Manual TG TH TI PDFDocument28 paginiDemand Manager Manual TG TH TI PDFjuan carlosÎncă nu există evaluări

- CompressorDocument7 paginiCompressorelrajilÎncă nu există evaluări

- 125Document72 pagini125lhphong021191Încă nu există evaluări

- Curtis Compressor Challenge Air PDFDocument44 paginiCurtis Compressor Challenge Air PDFSamy SamyÎncă nu există evaluări

- Operation and Maintenance Manual: IRN37-160K - CC, IRN50-200H-CC, IRN75-160K-2S, IRN100-200H-2S, R190-225NEDocument102 paginiOperation and Maintenance Manual: IRN37-160K - CC, IRN50-200H-CC, IRN75-160K-2S, IRN100-200H-2S, R190-225NEclavergara50% (2)

- Asd 30TDocument6 paginiAsd 30TAnonymous 6Mb7PZjÎncă nu există evaluări

- Manual RLR 300 A 700 UKDocument49 paginiManual RLR 300 A 700 UKLucyan Ionescu100% (1)

- Filters Ingersoll-RandDocument4 paginiFilters Ingersoll-RandAnonymous bcdUbxoÎncă nu există evaluări

- Manual Kaeser DSD 171Document96 paginiManual Kaeser DSD 171Gabo Solano100% (1)

- Csa Rotordryer PDFDocument8 paginiCsa Rotordryer PDFpeterpunk75Încă nu există evaluări

- Dec40 - User Service Rev5-0Document42 paginiDec40 - User Service Rev5-0Racob FherdzÎncă nu există evaluări

- Compressed Air Pages Compresor Mm75 IRDocument87 paginiCompressed Air Pages Compresor Mm75 IRPablo Andres Espin MartinÎncă nu există evaluări

- Hitachi Osp 75s5anDocument2 paginiHitachi Osp 75s5anUbanAirlangga100% (1)

- User Manual Modi5Document22 paginiUser Manual Modi5MJ AvalardÎncă nu există evaluări

- Instruction Manual: Hitachi Oil-Flooded Rotary Screw Air Compressor OSP-90M5AX OSP-90M5WXDocument48 paginiInstruction Manual: Hitachi Oil-Flooded Rotary Screw Air Compressor OSP-90M5AX OSP-90M5WXRamachandra Reddy ChinthamreddyÎncă nu există evaluări

- I R Xhp1170fcat C18 WFT Manual PDFDocument78 paginiI R Xhp1170fcat C18 WFT Manual PDFnafta ecopetrolÎncă nu există evaluări

- User'S, Maintenance and Spare Parts Manual: Refrigerating Air DryerDocument67 paginiUser'S, Maintenance and Spare Parts Manual: Refrigerating Air DryerValentin Bogdan100% (1)

- JN18 Parts Manual PDFDocument42 paginiJN18 Parts Manual PDFDionisio Ivan Martinez Mercado100% (1)

- 24 11 15 Engineering Data Gardnerdenver GDD76HS GDD1800HS 50HZ Iso PDFDocument29 pagini24 11 15 Engineering Data Gardnerdenver GDD76HS GDD1800HS 50HZ Iso PDFNhân NgọcÎncă nu există evaluări

- 2015 - Hankison Price ListDocument124 pagini2015 - Hankison Price ListFrancisco López50% (2)

- Almig Flex GB Web 1 2Document8 paginiAlmig Flex GB Web 1 2sebastianÎncă nu există evaluări

- Compair Cyclon 300Document66 paginiCompair Cyclon 300aris100% (1)

- Parts List: Model 2340,2475,2545Document22 paginiParts List: Model 2340,2475,2545Saadi AkhterÎncă nu există evaluări

- Instruction Book IMD DryerDocument44 paginiInstruction Book IMD DryerRajagopal Ganapathy0% (2)

- Large Recip Intellisys® SG: Operators / Instruction ManualDocument24 paginiLarge Recip Intellisys® SG: Operators / Instruction ManualCesar HernandezÎncă nu există evaluări

- Ingersoll-Rand X Series Compressor 80443864 2008 Dec Instruction ManualDocument116 paginiIngersoll-Rand X Series Compressor 80443864 2008 Dec Instruction ManualCykhong KhongÎncă nu există evaluări

- Screw Compressors: Model: VE22-10BDocument30 paginiScrew Compressors: Model: VE22-10BVoştinar IoanÎncă nu există evaluări

- CN Manu Sg303745557590a41 e 1000164105-03Document60 paginiCN Manu Sg303745557590a41 e 1000164105-03heruono sitorusÎncă nu există evaluări

- Catalogo Booster n753Document77 paginiCatalogo Booster n753Ferney Martinez Romero Martinez Romero100% (1)

- Manual Compresor RENNERDocument12 paginiManual Compresor RENNERRigoberto Villafuerte100% (1)

- Carel C2Document68 paginiCarel C2Anonymous 18zBW0UPÎncă nu există evaluări

- Ge Inlet Air CoolingDocument4 paginiGe Inlet Air Coolinggeorge gabriel100% (1)

- Air Cooled ChillerDocument4 paginiAir Cooled Chilleraad_180Încă nu există evaluări

- Donaldson CoolerDocument4 paginiDonaldson CoolerabuahnfÎncă nu există evaluări

- Aerius Brochure enDocument8 paginiAerius Brochure enbiberiusÎncă nu există evaluări

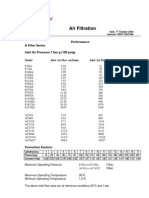

- Air Filtration: Performance A Filter Series Inlet Air Pressure 7 Bar G (100 Psig)Document1 paginăAir Filtration: Performance A Filter Series Inlet Air Pressure 7 Bar G (100 Psig)biberiusÎncă nu există evaluări

- A - General Description PDFDocument1 paginăA - General Description PDFbiberiusÎncă nu există evaluări

- Detailed DescriptionM75 M3502SDocument9 paginiDetailed DescriptionM75 M3502SbiberiusÎncă nu există evaluări

- Evaporador de Columna Ascendente - Manual-1Document44 paginiEvaporador de Columna Ascendente - Manual-1Andrea Lorenzo MartínezÎncă nu există evaluări

- Operation Manual: Lqs-Iicsa Refrigerating Hydrogen DryerDocument35 paginiOperation Manual: Lqs-Iicsa Refrigerating Hydrogen Dryerdsinghrpd100% (1)

- Refrigeration Engineering PDFDocument85 paginiRefrigeration Engineering PDFanilkumarÎncă nu există evaluări

- Week 2 - The General Strategy For Solving Material Balance ProblemsDocument19 paginiWeek 2 - The General Strategy For Solving Material Balance ProblemsNisrina HuttiÎncă nu există evaluări

- Energetics: Pharmaceutical Enzymes Kraft PulpingDocument6 paginiEnergetics: Pharmaceutical Enzymes Kraft Pulping박우진Încă nu există evaluări

- 100 Questions On EvaporationDocument43 pagini100 Questions On EvaporationFran Lee75% (4)

- Refrigeration and Liquefaction: Instructor: Engr. Caressa Marie Frial-De JesusDocument22 paginiRefrigeration and Liquefaction: Instructor: Engr. Caressa Marie Frial-De JesusEmmanuel PlazaÎncă nu există evaluări

- Sugar IndustryDocument61 paginiSugar IndustryRaashi BhutaniÎncă nu există evaluări

- Mango ProcessingDocument8 paginiMango ProcessingelgibinÎncă nu există evaluări

- Determination and Correlation of Heat Transfer Coefficients in A Falling Film EvaporatorDocument7 paginiDetermination and Correlation of Heat Transfer Coefficients in A Falling Film EvaporatorSeyit AvcuÎncă nu există evaluări

- 4.expansion DevicesDocument18 pagini4.expansion DevicesAbdullahÎncă nu există evaluări

- System Component: 3.1. Selection of The Heat Exchanger (Air Handling Unit)Document1 paginăSystem Component: 3.1. Selection of The Heat Exchanger (Air Handling Unit)Skill IndiaÎncă nu există evaluări

- Monostadio HorizonDocument44 paginiMonostadio HorizonMichele MaselliÎncă nu există evaluări

- HvacDocument6 paginiHvacHashimIdreesÎncă nu există evaluări

- CH Heat TransferDocument18 paginiCH Heat TransferVinayKumarÎncă nu există evaluări

- Domestic Water ChillersDocument85 paginiDomestic Water ChillersMY KÎncă nu există evaluări

- Heat Pump DryerDocument8 paginiHeat Pump DryerIvan LourensÎncă nu există evaluări

- Frick CompressorDocument66 paginiFrick Compressoronkarrathee67% (3)

- Performance Analysis of Ice Plants PDFDocument9 paginiPerformance Analysis of Ice Plants PDFpallav gupta100% (1)

- Ii. Iii. Iv.: Cascade SystemsDocument6 paginiIi. Iii. Iv.: Cascade SystemsBaravan A. İsmailÎncă nu există evaluări

- Process Equipment and Plant Design MCQs PDFDocument45 paginiProcess Equipment and Plant Design MCQs PDFRizwan Ali100% (2)

- Absorption Cooling and On - Energy Dynamics LimitedDocument122 paginiAbsorption Cooling and On - Energy Dynamics Limitedjamesbrown100100% (2)

- Production of Ethylene Glycol PDFDocument89 paginiProduction of Ethylene Glycol PDFwahab aliÎncă nu există evaluări

- RH - Series Manual Secador Esprayado 1Document271 paginiRH - Series Manual Secador Esprayado 1José E Ortiz RÎncă nu există evaluări

- Innova Series 3 Service ManualDocument92 paginiInnova Series 3 Service ManualAnonymous JYz90tr100% (1)

- Mesg Calculation For Gas MesgDocument7 paginiMesg Calculation For Gas Mesgcristiano meiÎncă nu există evaluări

- Irreversibility Analysis of Two and Three Stage Vapour Compression Refrigeration Systems With Multi Evaporators and Flash-Intercooler UsingDocument8 paginiIrreversibility Analysis of Two and Three Stage Vapour Compression Refrigeration Systems With Multi Evaporators and Flash-Intercooler UsingIjrei JournalÎncă nu există evaluări

- Rototherm PDFDocument2 paginiRototherm PDFcnaren67Încă nu există evaluări

- M03-014 - HVAC Variable Refrigerant Flow (VRF) SystemsDocument38 paginiM03-014 - HVAC Variable Refrigerant Flow (VRF) Systemsjadewest100% (1)

- Brochure Orc Organic Rankine Cycle Technology - EN PDFDocument7 paginiBrochure Orc Organic Rankine Cycle Technology - EN PDFdolphinÎncă nu există evaluări