Documente Academic

Documente Profesional

Documente Cultură

Deal With Systems That Produce Power in Which The Working Fluid Remains A Gas Throughout The Cycle, I.e., No Change in Phase

Încărcat de

Pushpa Mohan RajDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Deal With Systems That Produce Power in Which The Working Fluid Remains A Gas Throughout The Cycle, I.e., No Change in Phase

Încărcat de

Pushpa Mohan RajDrepturi de autor:

Formate disponibile

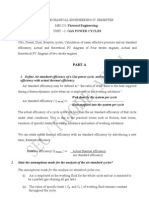

Gas Power Cycles

Deal with systems that produce power in which the

working fluid remains a gas throughout the cycle, i.e., no

change in phase.

Internal Combustion (IC) Engine

There are two types of reciprocating engines:

1) Spark ignition Otto cycle

2) Compression Diesel cycle

Terminology:

167

Engine displacement =

(# of cylinders)

x (stroke length)

x (bore area)

(usually given in cc or liters)

1 stroke = revolution

of the crank shaft

Crank shaft

(BDC)

(TDC)

Compression ratio =

cylinder volume (BDC)

cylinder volume (TDC

Four stroke Spark Ignition Engine: Cycle consists of

four distinct strokes (processes)

A complete cycle (4 strokes) requires two revolutions of

the crank shaft

168

Intake

valve

opens

A

I

R

Exhaust valve

opens

Combustion

Products

Ignition

Intake

Stroke

Compression

Stroke

Power

Stroke

Exhaust

Stroke

FUEL

Fuel/Air

Mixture

x

Ignition

1 atm

A comprehensive study of IC engines requires

consideration of the details of the air intake, combustion,

and exhaust processes (MECH 435 4

th

year elective)

Thermodynamic Air-Standard Analysis

Used to perform elementary analyses of IC engines.

Simplifications to the real cycle include:

1) Fixed amount of air (ideal gas) for working fluid

2) Combustion process replaced by constant volume

heat addition with piston at TDC

3) Intake and exhaust not considered, cycle completed

with constant volume heat removal with piston at

BDC

4) All processes considered internally reversible

Air-Standard Otto cycle

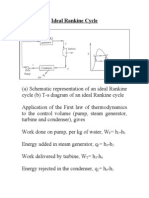

Process 1 2 Isentropic compression

Process 2 3 Constant volume heat addition

Process 3 4 Isentropic expansion

Process 4 1 Constant volume heat removal

169

compression ratio

3

4

2

1

V

V

V

V

r

since fixed mass

3

4

2

1

v

v

v

v

r

170

(2)

(3) (1)

(2) (3)

(4) (4)

(1)

AIR AIR

AIR

AIR

Q

in

Q

out

v

2

TDC

v

1

BDC

BDC

BDC

TDC

Q

in

Q

out

Apply First Law (

)

m

W

m

Q

u

to each process:

12 Isentropic Compression

) ( ) (

1 2

m

W

m

Q

u u

in

) (

1 2

u u

m

W

in

r v

v

v

v

r

r

1

1

2

1

2

2

1

1

2

1

2

1

1 1

2

2 2

v

v

T

T

P

P

T

v P

T

v P

R

23 Constant Volume Heat Addition

m

W

m

Q

u u

in

+ ) ( ) (

2 3

) (

2 3

u u

m

Q

in

2

3

2

3

3

3

2

2

T

T

P

P

RT

P

RT

P

v

171

AIR

AIR

Q

in

3 4 Isentropic Expansion

) ( ) (

3 4

m

W

m

Q

u u

out

+

) (

4 3

u u

m

W

out

r

v

v

v

v

r

r

3

4

3

4

4

3

3

4

3

4

3

3 3

4

4 4

v

v

T

T

P

P

T

v P

T

v P

4 1 Constant Volume Heat Removal

m

W

m

Q

u u

out

) ( ) (

4 1

) (

1 4

u u

m

Q

out

1

1

4

4

1

1

4

4

T

P

T

P

RT

P

RT

P

v

172

AIR

AIR

Q

out

Otto cycle thermal efficiency is

( ) ( )

( )

2 3

1 2 4 3

u u

u u u u

m Q

m W m W

m Q

m W

in

in out

in

cycle

cycle

( ) ( )

2 3

1 4

2 3

1 4 2 3

1

u u

u u

u u

u u u u

cycle

otto

Cold Air-Standard Analysis

The specific heats are assumed to be constant at their

ambient temperature values.

For the two isentropic processes in the cycle, assuming

constant specific heat yields:

1 2 :

1

1

2

1

1

2

,

_

k

k

r

v

v

T

T

and

k

k

P

P

T

T

1

1

2

1

2

,

_

3 4 :

1

1

4

3

3

4

1

,

_

,

_

k

k

r v

v

T

T

and

k

k

P

P

T

T

1

3

4

3

4

,

_

where k= 1.4 for air at ambient temperature.

173

Furthermore, for constant specific heats

T c u

V

so

( )

( )

,

_

,

_

1

1

1 1 1

2

3

2

1

4

1

2 3

1 4

2 3

1 4

T

T

T

T

T

T

T T c

T T c

u u

u u

V

V

cycle

otto

but

2

3

1

4

4

3

1

2

1

T

T

T

T

T

T

T

T

r

k

so

1

2

1

1

1 1

k

const c

otto

r

T

T

V

For high thermal efficiency want a high compression ratio

174

Current

spark ICE

7 < r < 10

Spark ignition engine compression ratio limited due to a

phenomenon known as knock

Knock refers to the noise produced when combustion

occurs explosively damaging to engine.

In order to reduce knock between 1920 and 1975

tetraethyl lead added to gasoline r = 12 possible

Also, larger r higher T

2

higher T

3

more emissions

such as NOx and Sox

175

Engine Power W

(horse power)

(rev/s) speed shaft crank N re whe

2

cycle per revs shaft crank 2 engine, stroke 4 a For

sec sec

N

W W

revs crank

revs crank

cycles

cycle

work cycles

cycle

work

time

work

cycle

Increase power by increasing the engine speed N

Another way to increase power is to increase the net work

output per cycle W

cycle

by either:

(i) Increasing the compression ratio, or

(ii) Increase Q

in

(increase the engine displacement).

176

V

Another Parameter used to indicate engine performance is

the mean effective pressure (mep) the theoretical

constant pressure that, if it acted on the piston during the

power stroke, would produce the same net work as

actually developed in one cycle, i.e.,

2 1

nt volume displaceme

cycle per net work

V V

W

mep

cycle

For two engines with same displacement volume, the one

with a higher mep produces more net work, and at the

same engine speed would produce more power.

177

Four stroke Compression Engine

No spark plug for ignition, rely on autoignition at high

temperature for initiating combustion

When piston approaches TDC when air is near its

maximum temperature fuel injection is started

combustion initiated.

Continue to inject fuel as the piston is moving down

(mixture volume is increasing) at the same time liquid

fuel evaporates and reacts as it passes through the

standing flame combustion occurs at roughly constant

pressure

178

Intake

valve

opens

A

I

R

Exhaust valve

opens

Combustion

Products

Intake

Stroke

Compression

Stroke

Power

Stroke

Exhaust

Stroke

Air

Fuel Injector

Air-Standard Diesel cycle

Process 1 2 Isentropic compression

Process 2 3 Constant pressure heat addition

Process 3 4 Isentropic expansion

Process 4 1 Constant volume heat removal

179

(2)

(3) (1)

(2) (3)

(4) (4)

(1)

AIR AIR

AIR

AIR

Q

in

Q

out

BDC

TDC

Recall compression ratio

2

1

v

v

r

Define the cut-off ratio

2

3

2

3

v

v

V

V

r

c

Apply First Law (

)

m

W

m

Q

u

to each process:

12 Isentropic Compression

) ( ) (

1 2

m

W

m

Q

u u

in

) (

1 2

u u

m

W

in

180

Q

in

Q

out

v

1

BDC

v

2

TDC

AIR

r v

v

v

v

r

r

1

1

2

1

2

2

1

1

2

1

2

1

1 1

2

2 2

v

v

T

T

P

P

T

v P

T

v P

R

181

23 Constant Pressure Heat Addition

( )

m

V V P

m

Q

u u

in 2 3 2

2 3

) ( ) (

+

) ( ) (

2 2 2 3 3 3

v P u v P u

m

Q

in

+ +

) (

2 3

h h

m

Q

in

c

r

v

v

T

T

v

RT

v

RT

P

2

3

2

3

3

3

2

2

3 4 Isentropic Expansion

) ( ) (

3 4

m

W

m

Q

u u

out

+

) (

4 3

u u

m

W

out

3

4

3

4

v

v

v

v

r

r

note v

4

=v

1

c

r

r

v

v

v

v

v

v

v

v

v

v

3

2

2

1

3

2

2

4

3

4

c r

r

r

r

v

v

v

v

3

4

3

4

and

c

r

r

T

T

P

P

T

v P

T

v P

3

4

3

4

3

3 3

4

4 4

182

AIR

Q

in

AIR

4 1 Constant Volume Heat Removal

m

W

m

Q

u u

out

) ( ) (

4 1

) (

1 4

u u

m

Q

out

1

1

4

4

1

1

4

4

T

P

T

P

RT

P

RT

P

v

Diesel cycle thermal efficiency is

m Q

m Q m Q

m Q

m W m W

m Q

m W

in

out in

in

in out

in

cycle

cycle

2 3

1 4

1 1

h h

u u

m Q

m Q

in

out

cycle

Diesel

183

AIR

Q

out

Cold Air-Standard Analysis

The specific heats are assumed to be constant at their

ambient temperature values.

For the two isentropic processes in the cycle, assuming

constant specific heat yields:

1 2 :

1

1

2

1

1

2

,

_

k

k

r

v

v

T

T

and

k

k

P

P

T

T

1

1

2

1

2

,

_

3 4 :

1

1

4

3

3

4

,

_

,

_

k

c

k

r

r

v

v

T

T

and

k

k

P

P

T

T

1

3

4

3

4

,

_

where k= 1.4 for air at ambient temperature.

For constant specific heats

T c u

V

and

T c h

P

so

( )

( )

,

_

,

_

1

1

1

1 1 1

2

3

2

1

4

1

2 3

1 4

2 3

1 4

T

T

T

T

T

T

k T T c

T T c

h h

u u

P

V

cycle

Diesel

184

recall:

1

2

1

1

k

r

T

T

c

r

T

T

2

3

1

3

4

,

_

k

c

r

r

T

T

k

c

k

c

k

c

r r r

r

r

T

T

T

T

T

T

T

T

,

_

1

1

1

2

2

3

3

4

1

4

substituting yields

( )

( )

1

]

1

1

1 1 1

1

1

c

k

c

k

const c

Diesel

r

r

k

r

V

For given r

c

higher thermal efficiency is obtained via

higher compression ratio r

For a given r higher thermal efficiency is obtained via

lower cut-off ratio r

c

However a smaller r

c

yields less net work per cycle, so to

achieve the same power need higher engine speeds

185

Compare Efficiency of Otto and Diesel Cycles

( )

( )

1

]

1

1

1 1 1

1

1

1

1 1

c

k

c

k

const k

Diesel

k

const k

Otto

r

r

k

r r

Note: for a given compression ratio the diesel engine is

less efficient than the spark ignition engine

[ ] 1

1

1

1

1

1 1

>

k

const c

Diesel

k

const c

Otto

r r

V V

186

Current Diesel ICE

12 < r < 23

Compare the Otto cycle (1-2-3O-4O) and the Diesel cycle

(1-2-3D-4D) for:

- the same compression ratio,

( ) ( )

Diesel Otto

v v v v

2 1 2 1

- the same heat input,

O D

Tds Tds

3

2

3

2

(same area

under the curve 2-3 for both cycles)

187

1

4D

3D

2

4O

3O

V= const

V= const

P= const

The heat rejected by the Otto cycle Q

out

is less than that

for the Diesel cycle:

<

1

4

1

4 D O

Tds Tds

Since W

cycle

= Q

in

Q

out

the net cycle work for the Otto

cycle is greater than that for the Diesel since Q

out

is

smaller for the Otto cycle

Since

in

cycle

cycle

Q

W

cycle

Diesel

cycle

Otto

>

However, since one can use a higher compression ratio

for the Diesel one can achieve obtain a higher cycle

efficiency!

188

S-ar putea să vă placă și

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDe la EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGÎncă nu există evaluări

- Thermodynamic CyclesDocument32 paginiThermodynamic CyclessunitbhaumikÎncă nu există evaluări

- Internal Combustion Engines: LecturDocument32 paginiInternal Combustion Engines: LecturPuneet GargÎncă nu există evaluări

- Air Standard CyclesDocument28 paginiAir Standard CyclesAditya Krishnakumar100% (1)

- Diesel CycleDocument7 paginiDiesel CycleJayaprakash S MechÎncă nu există evaluări

- Otto Diesel Dual Ideal Cycle - PPT (Compatibility Mode)Document16 paginiOtto Diesel Dual Ideal Cycle - PPT (Compatibility Mode)Danang Wahdiat Aulia Ishaq0% (1)

- Ideal Rankine CycleDocument27 paginiIdeal Rankine Cycleslv_prasaadÎncă nu există evaluări

- Diesel CycleDocument20 paginiDiesel CycleShafiq ShapianÎncă nu există evaluări

- Vapour Power CycleDocument12 paginiVapour Power Cyclelakshmikanth97Încă nu există evaluări

- Internal Combustion EngineDocument5 paginiInternal Combustion EnginenidhidarklordÎncă nu există evaluări

- Thermodynamic Analysis of Internal Combustion EnginesDocument26 paginiThermodynamic Analysis of Internal Combustion EnginesKatu2010Încă nu există evaluări

- Diesel Cycle For Mechanical EngineersDocument21 paginiDiesel Cycle For Mechanical Engineerszega5394Încă nu există evaluări

- Thermodynamics of Internal Combustion EngineDocument66 paginiThermodynamics of Internal Combustion EnginealagurmÎncă nu există evaluări

- Ic Engine Ignou NotesDocument16 paginiIc Engine Ignou NotesRakesh JhaÎncă nu există evaluări

- Mechanical Engineering Thermodynamics II - Lecture 03 - 27 SepDocument25 paginiMechanical Engineering Thermodynamics II - Lecture 03 - 27 SepThineshraaj Naidu Jaya RamanÎncă nu există evaluări

- Analisa Siklus OttoDocument9 paginiAnalisa Siklus OttochandraÎncă nu există evaluări

- Web6 Combuction SystemDocument11 paginiWeb6 Combuction SystemeswarbobbyÎncă nu există evaluări

- Lecture 3 Air CyclesDocument32 paginiLecture 3 Air CyclesMemo KhalidÎncă nu există evaluări

- Thermal Engineering Unit I For BE StudentsDocument44 paginiThermal Engineering Unit I For BE Studentsba27100% (8)

- Gas Cycles Otto, Diesel, Dual CyclesDocument43 paginiGas Cycles Otto, Diesel, Dual Cyclesprasad5034100% (1)

- Gas Power Cycles Study Guide in Powerpoint: To AccompanyDocument68 paginiGas Power Cycles Study Guide in Powerpoint: To AccompanyManjunatha TnÎncă nu există evaluări

- Gas Power Cycle - Part 1Document46 paginiGas Power Cycle - Part 1Shahran IezzatÎncă nu există evaluări

- Otto CycleDocument10 paginiOtto CycleAshly OchoaÎncă nu există evaluări

- Principle of TurbomachineryDocument159 paginiPrinciple of TurbomachinerySharath ChandraÎncă nu există evaluări

- Ideal Engine CycleDocument20 paginiIdeal Engine CycleMulugeta WoldeÎncă nu există evaluări

- Gas Power CyclesDocument32 paginiGas Power CyclesZachary NgÎncă nu există evaluări

- Introduction To Gas Power CyclesDocument48 paginiIntroduction To Gas Power CyclesN S SenanayakeÎncă nu există evaluări

- Gas Power CyclesDocument76 paginiGas Power CyclesJuan JoseÎncă nu există evaluări

- S (Hot Reservoir) - Q S (Cold Reservoir) + - Q: - / T - / T S (Engine) 0 (Cyclic Process)Document51 paginiS (Hot Reservoir) - Q S (Cold Reservoir) + - Q: - / T - / T S (Engine) 0 (Cyclic Process)കൂട്ടുകാരിയെ സ്നേഹിച്ച കൂട്ടുകാരൻÎncă nu există evaluări

- Evaluating Air-Standard Diesel Cycle For Compression Ignition EnginesDocument13 paginiEvaluating Air-Standard Diesel Cycle For Compression Ignition Enginessamhameed2Încă nu există evaluări

- CH 01Document6 paginiCH 01MagehartÎncă nu există evaluări

- AERO ENGINE ch2-1Document40 paginiAERO ENGINE ch2-1Dennis Padec BwochengoÎncă nu există evaluări

- Chapter 3 - Engine Cycles 2Document18 paginiChapter 3 - Engine Cycles 2Zaidan AlsallalÎncă nu există evaluări

- Unit - 1 16 Marks Questions and Answers PDFDocument24 paginiUnit - 1 16 Marks Questions and Answers PDFGopi RaguÎncă nu există evaluări

- ME 50400 / ECE 59500 Automotive Control: Lecture Notes: 2Document39 paginiME 50400 / ECE 59500 Automotive Control: Lecture Notes: 2nawinnawmu1026Încă nu există evaluări

- Gas Power Cycles Study Guide in Powerpoint: To AccompanyDocument68 paginiGas Power Cycles Study Guide in Powerpoint: To AccompanyAbraham HutomoÎncă nu există evaluări

- Engineering Council Certificate Level Thermodynamic, Fluid and Process Engineering C106 Tutorial 5 - Ideal Engine CyclesDocument14 paginiEngineering Council Certificate Level Thermodynamic, Fluid and Process Engineering C106 Tutorial 5 - Ideal Engine CyclesDipeshÎncă nu există evaluări

- Applied Thermodynamics and Heat Transfer - Unit IDocument37 paginiApplied Thermodynamics and Heat Transfer - Unit IArun ShankarÎncă nu există evaluări

- Internal Combustion Engines ME 4143: Dr. Saif Ur Rahman Department of Mechanical EngineeringDocument26 paginiInternal Combustion Engines ME 4143: Dr. Saif Ur Rahman Department of Mechanical EngineeringSyma ShaheenÎncă nu există evaluări

- Gas - Turbine - CycleDocument41 paginiGas - Turbine - CycleKalpaniÎncă nu există evaluări

- CH 13Document32 paginiCH 13hirenpatel_universalÎncă nu există evaluări

- Stirling Heat Engine - Internal Combustion Engine (Otto Cycle) - Diesel Engine - Steam Engine (Rankine Cycle) - Kitchen RefrigeratorDocument11 paginiStirling Heat Engine - Internal Combustion Engine (Otto Cycle) - Diesel Engine - Steam Engine (Rankine Cycle) - Kitchen RefrigeratormarzinusÎncă nu există evaluări

- Internal Combustion EngineDocument6 paginiInternal Combustion Engineazrim02Încă nu există evaluări

- Me6404 Te Even QBDocument32 paginiMe6404 Te Even QBBala NarayanasamyÎncă nu există evaluări

- CH 02Document20 paginiCH 02Pauline Nguyen100% (1)

- Air Standard CycleDocument15 paginiAir Standard CyclePrakhar Deep RanaÎncă nu există evaluări

- ThermodynamicsDocument79 paginiThermodynamicstixy2013Încă nu există evaluări

- Chapter 8: Gas Power Cycles: TH Net inDocument50 paginiChapter 8: Gas Power Cycles: TH Net inSures RezÎncă nu există evaluări

- Chapter 9Document84 paginiChapter 9ERCAN ÖZERDENÎncă nu există evaluări

- 4200:225 Equilibrium Thermodynamics: Unit I. Earth, Air, Fire, and WaterDocument11 pagini4200:225 Equilibrium Thermodynamics: Unit I. Earth, Air, Fire, and WaterRiky IkhwanÎncă nu există evaluări

- Gas Power Cycles Sivakumar.E VITDocument47 paginiGas Power Cycles Sivakumar.E VITmohan govindasamyÎncă nu există evaluări

- 2131905Document36 pagini2131905inam vfÎncă nu există evaluări

- Cycles PDFDocument10 paginiCycles PDFratchagarajaÎncă nu există evaluări

- Lecture 6Document31 paginiLecture 6Anil BhagureÎncă nu există evaluări

- 9 EÈ Ú ºÃ ÄÑ Ï°×ÊÁÏDocument80 pagini9 EÈ Ú ºÃ ÄÑ Ï°×ÊÁÏnabil160874100% (2)

- 01 - 202-Civil-Part-2Document10 pagini01 - 202-Civil-Part-2Mayra BarradasÎncă nu există evaluări

- Gas Power Cycles: Final State Gaseous State All ThroughtDocument26 paginiGas Power Cycles: Final State Gaseous State All Throughtboj VillanuevaÎncă nu există evaluări

- Mindset General Trading L.L.CDocument1 paginăMindset General Trading L.L.CPushpa Mohan RajÎncă nu există evaluări

- Daily Time Sheet: Your Business NameDocument1 paginăDaily Time Sheet: Your Business NamePushpa Mohan RajÎncă nu există evaluări

- Project Management Office at UaeDocument1 paginăProject Management Office at UaePushpa Mohan RajÎncă nu există evaluări

- Biryaniwala (LH)Document1 paginăBiryaniwala (LH)Pushpa Mohan RajÎncă nu există evaluări

- Ibtikarat Office Need 2Document2 paginiIbtikarat Office Need 2Pushpa Mohan RajÎncă nu există evaluări

- Priyanka Appointment LetterDocument2 paginiPriyanka Appointment LetterPushpa Mohan RajÎncă nu există evaluări

- Rules For EmployeeDocument6 paginiRules For EmployeePushpa Mohan Raj50% (2)

- Ibtikaarat Engineering IndustriesDocument2 paginiIbtikaarat Engineering IndustriesPushpa Mohan RajÎncă nu există evaluări

- Expences Details (Upto 07-1-16)Document1 paginăExpences Details (Upto 07-1-16)Pushpa Mohan RajÎncă nu există evaluări

- Ibtikarat Engineering Industries: Rasa Al KhaimaDocument1 paginăIbtikarat Engineering Industries: Rasa Al KhaimaPushpa Mohan RajÎncă nu există evaluări

- Subject Code Grade ResultDocument63 paginiSubject Code Grade ResultPushpa Mohan RajÎncă nu există evaluări

- Tools New 2Document7 paginiTools New 2Pushpa Mohan RajÎncă nu există evaluări

- Ibtikarat Engineering Industries Mechanical Tools 29/11/2015Document2 paginiIbtikarat Engineering Industries Mechanical Tools 29/11/2015Pushpa Mohan RajÎncă nu există evaluări

- Functions of Various DepartmentsDocument3 paginiFunctions of Various DepartmentsPushpa Mohan RajÎncă nu există evaluări

- Book of Abstracts: Philippine Projects To The Intel International Science and Engineering FairDocument84 paginiBook of Abstracts: Philippine Projects To The Intel International Science and Engineering FairJimarie BithaoÎncă nu există evaluări

- Singh 1959 Adam Smith's Theory of Economic DevelopmentDocument27 paginiSingh 1959 Adam Smith's Theory of Economic DevelopmentBruce WayneÎncă nu există evaluări

- User's Guide: Smartpack2 Master ControllerDocument32 paginiUser's Guide: Smartpack2 Master Controllermelouahhh100% (1)

- Teit Cbgs Dmbi Lab Manual FH 2015Document60 paginiTeit Cbgs Dmbi Lab Manual FH 2015Soumya PandeyÎncă nu există evaluări

- Lust V Animal Logic MSJ OppositionDocument34 paginiLust V Animal Logic MSJ OppositionTHROnlineÎncă nu există evaluări

- Aerated Static Pile Composting (ASP) VS Aerated (Turned) Windrow CompostingDocument2 paginiAerated Static Pile Composting (ASP) VS Aerated (Turned) Windrow CompostingRowel GanzonÎncă nu există evaluări

- Thermo King CG 2000Document155 paginiThermo King CG 2000Connie TaibaÎncă nu există evaluări

- Vocabulary List Year 6 Unit 10Document2 paginiVocabulary List Year 6 Unit 10Nyat Heng NhkÎncă nu există evaluări

- Presentation - 02 Reliability in Computer SystemsDocument24 paginiPresentation - 02 Reliability in Computer Systemsvictorwu.ukÎncă nu există evaluări

- Diesel Oil Matters 70 YrsDocument1 paginăDiesel Oil Matters 70 YrsingsespinosaÎncă nu există evaluări

- Ojsadmin, 12 ZhangG 19Document14 paginiOjsadmin, 12 ZhangG 19Kristel MitraÎncă nu există evaluări

- Battlab Report 12 FinalDocument48 paginiBattlab Report 12 FinalLianÎncă nu există evaluări

- Balanced Scorecard Approach ReportDocument8 paginiBalanced Scorecard Approach ReportGeryes E. Haddad100% (1)

- AttitudeDocument24 paginiAttitudeisratazimÎncă nu există evaluări

- Precision Probability Index (Elf)Document20 paginiPrecision Probability Index (Elf)EdsonnSPBrÎncă nu există evaluări

- Notes in Judicial AffidavitDocument11 paginiNotes in Judicial AffidavitguibonganÎncă nu există evaluări

- BF2207 Exercise 6 - Dorchester LimitedDocument2 paginiBF2207 Exercise 6 - Dorchester LimitedEvelyn TeoÎncă nu există evaluări

- Questionnaire On EthnocentrismDocument14 paginiQuestionnaire On Ethnocentrismkalpa vrikshaÎncă nu există evaluări

- M.Tech VLSI SyllabusDocument10 paginiM.Tech VLSI SyllabusAshadur RahamanÎncă nu există evaluări

- Metrologic Colombia S.A.S. Medellín Medellín Colombia: Oferta Economica CO20233ADocument3 paginiMetrologic Colombia S.A.S. Medellín Medellín Colombia: Oferta Economica CO20233AJulian MoraÎncă nu există evaluări

- SIConitDocument2 paginiSIConitJosueÎncă nu există evaluări

- SRB 301 Ma Operating Instructions Safety-Monitoring ModulesDocument6 paginiSRB 301 Ma Operating Instructions Safety-Monitoring ModulesMustafa EranpurwalaÎncă nu există evaluări

- Strategic Issues of Information TechnologyDocument23 paginiStrategic Issues of Information TechnologySamiksha SainiÎncă nu există evaluări

- XXX RadiographsDocument48 paginiXXX RadiographsJoseph MidouÎncă nu există evaluări

- Relational NotationDocument3 paginiRelational NotationTweetrudi WhyteÎncă nu există evaluări

- Jurnal Stamina: E-ISSN 2655-2515 P-ISSN 2655-1802Document9 paginiJurnal Stamina: E-ISSN 2655-2515 P-ISSN 2655-1802Yogi TioÎncă nu există evaluări

- Am Bio PhonicsDocument21 paginiAm Bio PhonicsLaura Nataly VillaÎncă nu există evaluări

- Green Tyre TechnologyDocument4 paginiGreen Tyre TechnologyAnuj SharmaÎncă nu există evaluări

- Ebook Principles of Corporate Finance PDF Full Chapter PDFDocument67 paginiEbook Principles of Corporate Finance PDF Full Chapter PDFmichelle.haas303100% (28)

- Ashirvad SWR and SWR PLUS - Price List - 02nd April 2022Document14 paginiAshirvad SWR and SWR PLUS - Price List - 02nd April 2022Magnum ConstructionsÎncă nu există evaluări