Documente Academic

Documente Profesional

Documente Cultură

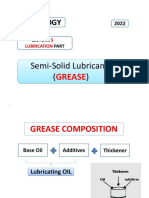

Grease Selection Chart

Încărcat de

mirali74Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Grease Selection Chart

Încărcat de

mirali74Drepturi de autor:

Formate disponibile

SKF lubricants

Selecting a grease can be a delicate process. SKF has developed several tools in order to facilitate the selection of the most suitable lubricant. The wide range of tools available includes those from easy-to-use application driven tables to advanced software allowing for grease selection based upon detailed working conditions. The basic bearing grease selection chart provides you with quick suggestions on the most commonly used greases in typical applications.

SKF bearing grease selection chart

Grease Description General purpose industrial and automotive Application examples Automotive wheel bearings Conveyors and fans Small electric motors Bearings with d>100 mm Vertical shaft or outer bearing ring rotation Car, truck and trailer wheel bearings Forming and press section of paper mills Work roll bearings in steel industry Heavy machinery, vibrating screens Wheel bearings in cars, trailers and trucks Washing machines Electric motors Food processing equipment Wrapping machines Bottling machines Agricultural and forestry equipment Construction and earthmoving equipment Water treatment and irrigation

Temperature range 1)

LTL HTPL

Temp.

Speed

LGMT 2 LGMT 3 LGEP 2 LGWA 2

30 C (20 F)

120 C (250 F)

General purpose industrial and automotive

30 C (20 F)

120 C (250 F)

Extreme pressure

20 C (5 F)

110 C (230 F)

L to M

Wide temperature 4), extreme pressure

30 C (20 F)

140 C (285 F)

M to H

L to M

LGFP 2 LGGB 2 LGBB 2 LGLT 2 LGWM 1 LGWM 2 LGEM 2 LGEV 2 LGHB 2 LGHP 2

Food compatible

20 C (5 F)

110 C (230 F)

Biodegradable, low toxicity 3)

40 C (40 F)

90 C (195 F)

L to M

L to M

Wind turbine blade and yaw bearing grease

Wind turbine blade and yaw slewing bearings

40 C (40 F)

120 C (250 F)

L to M

VL

Low temperature, extremely high speed

Textile and machine tool spindles Small electric motors and robots Printing cylinders Main shaft of wind turbines Centralised lubrication systems Spherical roller thrust bearing applications Main shaft of wind turbines Heavy duty off road or marine applications Snow exposed applications Jaw crushers Construction machinery Vibrating machinery Trunnion bearings Support and thrust rollers on rotary kilns and dryers Slewing ring bearings Steel on steel plain bearings Dryer section of paper mills Work roll bearings and continuous casting in steel industry Sealed spherical roller bearings up to 150 C (300 F) Electric motors Fans, even at high speed High speed ball bearings at medium and high temperatures Bakery equipment (ovens) Wafer baking machines Textile dryers

50 C (60 F)

110 C (230 F)

L to M

M to EH

Extreme pressure, low temperature

30 C (20 F)

110 C (230 F)

L to M

L to M

High load, wide temperature

40 C (40 F)

110 C (230 F)

L to M

L to M

High viscosity plus solid lubricants

20 C (5 F)

120 C (250 F)

VL

Extremely high viscosity with solid lubricants

10 C (15 F)

120 C (250 F)

VL

EP high viscosity, high temperature 5)

20 C (5 F)

150 C (300 F)

M to H

VL to M

High performance polyurea grease

40 C (40 F)

150 C (300 F)

M to H

M to H

LGET 2

Extreme temperature

40 C (40 F)

3) LGGB 2 can withstand peak temperatures of 120 C (250 F) 4) LGWA 2 can withstand peak temperatures of 220 C (430 F) 5) LGHB 2 can withstand peak temperatures of 200 C (390 F)

260 C (500 F)

VH

L to M

1) LTL = Low Temperature Limit HTPL = High Temperature Performance Limit 2) mm/s at 40 C (105 F) = cSt.

Load

Thickener / Base Oil

NLGI

Base oil viscosity 2)

Vertical shaft

Fast outer ring rotation

Oscillating movements

Severe Vibrations

Shock load or frequent start up

Rust inhibiting properties

L to M

Lithium soap / mineral oil

110

+

l

+

l

Wide applications greases

L to M

Lithium soap / mineral oil

120

+

l

+

l

Lithium soap / mineral oil

200

+

l

+ +

+ + +

Special requirements

L to H

Lithium complex soap / mineral oil

185

L to M

Aluminium complex / medical white oil

130

M to H

Lithium-calcium soap / synthetic ester oil

110

+ +

+ +

+ +

l

M to H

Lithium complex soap / synthetic PAO oil

68

+

l

Lithium soap / synthetic PAO oil

18

Low temperatures

Lithium soap / mineral oil Complex calcium sulphonate / synthetic PAO oil / mineral oil Lithium soap / mineral oil

200

+

l l

+ + + + +

l

+ + + + + +

l

High loads

L to H

80

+ + +

+ + + +

l

H to VH

500

H to VH

Lithium-calcium soap / mineral oil

1020

L to VH

Complex calcium sulphonate / mineral oil

400

High temperatures

L to M

Di-urea / mineral oil

2 to 3

96

+

l

H to VH

PTFE / synthetic fluorinated polyether oil

400

+

l = Suitable

+ = Recommended

3

Basic bearing grease selection

Generally use if: Speed = M, Temperature = M and Load = M Unless: Expected bearing temperature continuously >100 C (210 F) Expected bearing temperature continuously >150 C (300 F), demands for radiation resistance Low ambient 50 C (60 F), expected bearing temperature <50 C (120 F) Shock loads, heavy loads, frequent start-up / shut-down Food processing industry Biodegradable, demands for low toxicity

Note: For areas with relatively high ambient temperatures, use LGMT 3 instead of LGMT 2 For special operating conditions, refer to the SKF bearing grease selection chart

LGMT 2 LGHP 2 LGET 2 LGLT 2 LGEP 2 LGFP 2 LGGB 2

General purpose

High temperature

Extremely high temperature

Low temperature

High load

Food processing

Biodegradable

With additional information like speed, temperature, and load conditions, LubeSelect for SKF greases is the easiest way to select the right grease. For additional information, visit www.aptitudeexchange.com.

Additionally, the SKF bearing grease selection chart provides you with a complete overview of SKF greases. The chart includes the main selection parameters, such as temperature, speed and load, as well as basic additional performance information.

Bearing operating parameters

Temperature L M H EH = Low = Medium = High = Extremely high <50 C 50 to 100 C >100 C >150 C (120 F) (120 to 230 F) (210 F) (300 F) Load VH H M L = Very high = High = Medium = Low C/P <2 C/P ~4 C/P ~8 C/P 15

C = basic dynamic load rating, kN P = equivalent dynamic bearing load, kN

C/P = Load ratio

Speed EH VH H M L = Extremely high = Very high = High = Medium = Low

for ball bearings n dm over 700 000 n dm up to 700 000 n dm up to 500 000 n dm up to 300 000 n dm below 100 000

Speed H M L VL = High = Medium = Low = Very low

for roller bearings SRB/TRB/CARB n dm over 210 000 n dm up to 210 000 n dm up to 75 000 n dm below 30 000

CRB n dm over 270 000 n dm up to 270 000 n dm up to 75 000 n dm below 30 000

n dm = rotational speed, r/min x 0,5 (D+d), mm

SKF is a registered trademark of the SKF Group. SKF Group 2012 The contents of this publication are the copyright of the publisher and may not be reproduced (even extracts) unless prior written permission is granted. Every care has been taken to ensure the accuracy of the information contained in this publication but no liability can be accepted for any loss or damage whether direct, indirect or consequential arising out of the use of the information contained herein. PUB MP/P8 13238 EN October 2012

www.mapro.skf.com skf.com/mount skf.com/lubrication

S-ar putea să vă placă și

- Turbine Maintenance BookDocument223 paginiTurbine Maintenance Bookbarrunsiswo100% (9)

- Hydraulic Breaker PDFDocument69 paginiHydraulic Breaker PDFRofie Tritho100% (1)

- LGLT 2: Grease SelectionDocument4 paginiLGLT 2: Grease SelectionNguyen ChuyenÎncă nu există evaluări

- A Review On Grease Lubrication in Rolling BearingsDocument12 paginiA Review On Grease Lubrication in Rolling BearingsRepositorio MantenimientoÎncă nu există evaluări

- Lubricant Base Stocks: OutlineDocument23 paginiLubricant Base Stocks: OutlineJahmia Coralie100% (1)

- Generator Testing Project ReportDocument95 paginiGenerator Testing Project ReportSindhu ManchukondaÎncă nu există evaluări

- Mobil Industrial - Product Guide - 2015Document107 paginiMobil Industrial - Product Guide - 2015Massimiliano VolaÎncă nu există evaluări

- 8 Mobil Grease Selection GuideDocument2 pagini8 Mobil Grease Selection GuideJose De la CruzÎncă nu există evaluări

- Funtion of Lubricants by Laxman Singh Sankhla, Jodhpur, IndiaDocument2 paginiFuntion of Lubricants by Laxman Singh Sankhla, Jodhpur, IndiaLaxman Singh SankhlaÎncă nu există evaluări

- MP3510E - FINAL (Lubrication Catalogue)Document106 paginiMP3510E - FINAL (Lubrication Catalogue)Farhan AnwarÎncă nu există evaluări

- Lubricants Lubrication FinalDocument56 paginiLubricants Lubrication FinalArushi SthapakÎncă nu există evaluări

- Lubrication & Lubrication SystemsDocument21 paginiLubrication & Lubrication Systemss_mohankumarÎncă nu există evaluări

- NLGI Grease Technical DocumentDocument10 paginiNLGI Grease Technical Documentho-faÎncă nu există evaluări

- Aadhyatmic Sandesh Year 5 Issue 1Document16 paginiAadhyatmic Sandesh Year 5 Issue 1ssdhamÎncă nu există evaluări

- LUBRICANTING OilDocument18 paginiLUBRICANTING OilChetan AgroyaÎncă nu există evaluări

- Grease BasicsDocument6 paginiGrease BasicsnagbabuiÎncă nu există evaluări

- Fatty Acids and Antioxidant Effects On Grease MicrostructuresDocument7 paginiFatty Acids and Antioxidant Effects On Grease MicrostructuresAlex RichardÎncă nu există evaluări

- SHELL Product Data Guide Industry 2013Document78 paginiSHELL Product Data Guide Industry 2013Edgar Real ViúlaÎncă nu există evaluări

- Chapter Three Lubricants & Mechanism of LubricationDocument28 paginiChapter Three Lubricants & Mechanism of LubricationMuket AgmasÎncă nu există evaluări

- Lubrication SystemsDocument9 paginiLubrication SystemsCeno EdwinÎncă nu există evaluări

- Chemistry Manual NewDocument44 paginiChemistry Manual NewRACHETA BHARATÎncă nu există evaluări

- Pocket - Guide Mineral X SinteticoDocument9 paginiPocket - Guide Mineral X SinteticoJako MishyÎncă nu există evaluări

- SKF NGUYEN XUONG - SKF Bearing Grease Selection ChartDocument2 paginiSKF NGUYEN XUONG - SKF Bearing Grease Selection ChartbkprodhÎncă nu există evaluări

- MECH2410 - Lecture 7 Shaft DesignDocument21 paginiMECH2410 - Lecture 7 Shaft Designaaarid1Încă nu există evaluări

- Machinery Lubrication Brochure EDocument2 paginiMachinery Lubrication Brochure Eho-faÎncă nu există evaluări

- A Review On Grease Lubrication in Rolling BearingsDocument12 paginiA Review On Grease Lubrication in Rolling Bearingsfeni4kaÎncă nu există evaluări

- Lubricant Condition Monitoring: Why The Lubricants MonitoringDocument14 paginiLubricant Condition Monitoring: Why The Lubricants Monitoringrbdubey2020Încă nu există evaluări

- Lubrication ChartDocument4 paginiLubrication Chartjorge DiazÎncă nu există evaluări

- Course: B.Tech. Subject: Engineering Chemistry Unit: III (A)Document25 paginiCourse: B.Tech. Subject: Engineering Chemistry Unit: III (A)sri aknth100% (1)

- GreasesDocument4 paginiGreasesAnil BalanÎncă nu există evaluări

- 100 MW Solar Farm Pre-Feasibility Study For Investment PDFDocument11 pagini100 MW Solar Farm Pre-Feasibility Study For Investment PDFmirali74Încă nu există evaluări

- 100 MW Solar Farm Pre-Feasibility Study For Investment PDFDocument11 pagini100 MW Solar Farm Pre-Feasibility Study For Investment PDFmirali74Încă nu există evaluări

- LubricationDocument22 paginiLubricationEvílBoyViswaÎncă nu există evaluări

- Kluber Lubrication Gear Greases: Portfolio and Grease SelectionDocument31 paginiKluber Lubrication Gear Greases: Portfolio and Grease SelectionErick AvilaÎncă nu există evaluări

- Heat Stress at WorkplaceDocument4 paginiHeat Stress at Workplacemirali74Încă nu există evaluări

- SKF Bearing Grease Selection Chart: LGMT 3Document1 paginăSKF Bearing Grease Selection Chart: LGMT 3compaore dramaneÎncă nu există evaluări

- UNIT III: Lubricants: Soami P. Satsangee CHM 181 7/10/2015Document46 paginiUNIT III: Lubricants: Soami P. Satsangee CHM 181 7/10/2015anjali sharmaÎncă nu există evaluări

- How To Design Lubrication Task RoutesDocument8 paginiHow To Design Lubrication Task RoutesHector JÎncă nu există evaluări

- Pump Vibration-Case StudiesDocument10 paginiPump Vibration-Case StudiesGyogi MitsutaÎncă nu există evaluări

- Chapter Two - 2 LubricationDocument29 paginiChapter Two - 2 LubricationBaslielÎncă nu există evaluări

- Centralized Lubrication SystemsDocument12 paginiCentralized Lubrication SystemsroquirogaÎncă nu există evaluări

- 49 Apu PDFDocument110 pagini49 Apu PDFyogaga100% (2)

- 1.2. BTR - Lubrication NotesDocument17 pagini1.2. BTR - Lubrication Notesvishnu vishnu G.T.Încă nu există evaluări

- Lubrication 160826150651Document78 paginiLubrication 160826150651santoshÎncă nu există evaluări

- Lubricants Final 1Document32 paginiLubricants Final 1onkar nikamÎncă nu există evaluări

- Wastewater Treatment Plants-Part 1: General Construction PrinciplesDocument16 paginiWastewater Treatment Plants-Part 1: General Construction Principlesdaprc100% (1)

- Shovel Lubrication PDFDocument2 paginiShovel Lubrication PDFSounak SasmalÎncă nu există evaluări

- 2014 609 - Mobil SHC 524 Synthetic Hydraulic Oil Success StoryDocument1 pagină2014 609 - Mobil SHC 524 Synthetic Hydraulic Oil Success StoryMudabbir Shan Ahmed100% (1)

- Nuaire Commercial Useful InfoDocument10 paginiNuaire Commercial Useful InfoYaser AkarÎncă nu există evaluări

- Axletech Manual de ServicioDocument44 paginiAxletech Manual de ServiciothermodynevialÎncă nu există evaluări

- LEC5 Lubrication 2022Document37 paginiLEC5 Lubrication 2022mohamed hodiriÎncă nu există evaluări

- Daylighting CALCULATIONS. - Kroelinger, MikeDocument29 paginiDaylighting CALCULATIONS. - Kroelinger, MikeJohn Evans100% (2)

- Bearing Importance of LubricationDocument5 paginiBearing Importance of LubricationgeppaÎncă nu există evaluări

- Types of Lubrication SystemDocument13 paginiTypes of Lubrication SystemPawan Paramanandan100% (2)

- The Right Lubricant For Each Component - Product Selection - eDocument32 paginiThe Right Lubricant For Each Component - Product Selection - eevelulahir2115Încă nu există evaluări

- Swimming Pool Ventilation DesignDocument49 paginiSwimming Pool Ventilation Designmirali74Încă nu există evaluări

- Legionella Bacteria ChecklistDocument21 paginiLegionella Bacteria Checklistmirali74Încă nu există evaluări

- Final Idler and Roller CatalogDocument6 paginiFinal Idler and Roller CatalogShubham Khurana100% (1)

- 05-IZMIT-COW-PRE-DD-GEN-0010 - 1.0 - IABSE Denmark Mini-Seminar 2013.pptx (Read-Only) PDFDocument37 pagini05-IZMIT-COW-PRE-DD-GEN-0010 - 1.0 - IABSE Denmark Mini-Seminar 2013.pptx (Read-Only) PDFmirali74Încă nu există evaluări

- B.5 MillMAX 3x2-14x12 IOM (July 2015)Document67 paginiB.5 MillMAX 3x2-14x12 IOM (July 2015)Alief FadilÎncă nu există evaluări

- Polyurea Greases TLT Article March14Document1 paginăPolyurea Greases TLT Article March14ivan agustinoÎncă nu există evaluări

- LubricantsDocument21 paginiLubricantsGourav KumarÎncă nu există evaluări

- A Comprehensive Solution For Extreme and Specialty ApplicationsDocument7 paginiA Comprehensive Solution For Extreme and Specialty ApplicationsAmjedÎncă nu există evaluări

- STD 11 Eng WorkbookDocument167 paginiSTD 11 Eng Workbookalparamani420% (1)

- lUBRICATION SYSTEM PDFDocument22 paginilUBRICATION SYSTEM PDFSasi aeroÎncă nu există evaluări

- Critical Success Factor of LEANDocument5 paginiCritical Success Factor of LEANThanh TrinhÎncă nu există evaluări

- Synthetic Gear Oil SelectionDocument9 paginiSynthetic Gear Oil Selectionsmallik3Încă nu există evaluări

- Product Information Navigo 6 So: DescriptionDocument2 paginiProduct Information Navigo 6 So: DescriptionCOMITYÎncă nu există evaluări

- PH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)Document4 paginiPH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)dfbdfbfdbfbÎncă nu există evaluări

- Grease 2Document4 paginiGrease 2arunÎncă nu există evaluări

- Comparison of Shell Gadus S5 V100 2 Vs Tribol GR 100Document1 paginăComparison of Shell Gadus S5 V100 2 Vs Tribol GR 100Hirendra GodeÎncă nu există evaluări

- 01.03.01 Coolant TR0199991209109 - enDocument18 pagini01.03.01 Coolant TR0199991209109 - enEbied Yousif AlyÎncă nu există evaluări

- Technology Forum - Indoneusa - Gas Engines (Oct.2014) V2Document42 paginiTechnology Forum - Indoneusa - Gas Engines (Oct.2014) V2Frana HadiÎncă nu există evaluări

- Technical Comparison of RUBIA TIR and DELO GOLDDocument1 paginăTechnical Comparison of RUBIA TIR and DELO GOLDbilal50% (2)

- Petro Canada Duron HP - 15w-40 PDFDocument10 paginiPetro Canada Duron HP - 15w-40 PDFPubcrawl100% (1)

- Clean Oil GuideDocument28 paginiClean Oil GuideAlex VulpeÎncă nu există evaluări

- Tribology InternationalDocument9 paginiTribology InternationalBragasÎncă nu există evaluări

- SKF GreaseDocument3 paginiSKF GreaseKumar SwamiÎncă nu există evaluări

- Lot 108 Drainage & WaterDocument18 paginiLot 108 Drainage & Watermirali74Încă nu există evaluări

- Lot 108 Auction ContractDocument11 paginiLot 108 Auction Contractmirali74Încă nu există evaluări

- Gatton Place AC ReportDocument22 paginiGatton Place AC Reportmirali74Încă nu există evaluări

- Friction Chart For Airflow in Ducting (Sea Level) : 90 80 70 60 VE LO CI TY, M /s VE LO CI TY, M /sDocument1 paginăFriction Chart For Airflow in Ducting (Sea Level) : 90 80 70 60 VE LO CI TY, M /s VE LO CI TY, M /sMizan SarkarÎncă nu există evaluări

- Circular Equivalents of Rectangular Duct For Equal Friction and CapacityDocument1 paginăCircular Equivalents of Rectangular Duct For Equal Friction and CapacitybappabatliboiÎncă nu există evaluări

- Darcy Friction Factor Formulae in Turbulent Pipe FlowDocument11 paginiDarcy Friction Factor Formulae in Turbulent Pipe FlowbadecoteÎncă nu există evaluări

- Modified Cable Sizing Strategies - Egemin - Publication 2014 JanuaryDocument54 paginiModified Cable Sizing Strategies - Egemin - Publication 2014 Januarymirali74Încă nu există evaluări

- 3 IDB SuccessStory3 Azerbaijan Khanarc CanalDocument4 pagini3 IDB SuccessStory3 Azerbaijan Khanarc Canalmirali74Încă nu există evaluări

- The Product and Quotient RulesDocument1 paginăThe Product and Quotient Rulesmirali74Încă nu există evaluări

- Guide To Technical ReportDocument6 paginiGuide To Technical Reportkumaraswamy reddyÎncă nu există evaluări

- Guide To Technical ReportDocument6 paginiGuide To Technical Reportkumaraswamy reddyÎncă nu există evaluări

- Guide To Technical ReportDocument6 paginiGuide To Technical Reportkumaraswamy reddyÎncă nu există evaluări

- RestitutionDocument1 paginăRestitutionmirali74Încă nu există evaluări

- Exponentials and Logarithms: The Exponential FunctionDocument2 paginiExponentials and Logarithms: The Exponential Functionmirali74Încă nu există evaluări

- TopplingDocument1 paginăTopplingmirali74Încă nu există evaluări

- Mass CentreDocument4 paginiMass Centremirali74Încă nu există evaluări

- Decision Mathematics 1: MEI Structured Mathematics Module Summary SheetsDocument7 paginiDecision Mathematics 1: MEI Structured Mathematics Module Summary Sheetsmirali74Încă nu există evaluări

- WorkDocument3 paginiWorkmirali74Încă nu există evaluări

- FP2 MeiDocument11 paginiFP2 Meimirali74Încă nu există evaluări

- FunctionsDocument3 paginiFunctionsmirali74Încă nu există evaluări

- MEI Structured Mathematics Module Summary Sheets: C3, Methods For Advanced MathematicsDocument10 paginiMEI Structured Mathematics Module Summary Sheets: C3, Methods For Advanced Mathematicsmirali74Încă nu există evaluări

- C2 MeiDocument8 paginiC2 Meimirali74Încă nu există evaluări

- SD Plummer Block Housings: MaterialDocument10 paginiSD Plummer Block Housings: MaterialDen BillÎncă nu există evaluări

- Jerms G 3113Document21 paginiJerms G 3113NicolaMasteÎncă nu există evaluări

- 译文 - 摆线针轮减速机Cycloidal pin wheel reducerDocument10 pagini译文 - 摆线针轮减速机Cycloidal pin wheel reducerVocal SamirÎncă nu există evaluări

- Sterndrive Unit: Section 3A - Drive Shaft HousingDocument50 paginiSterndrive Unit: Section 3A - Drive Shaft HousingАлександр ГершукÎncă nu există evaluări

- SKF SAF and SAFS Installation and Maintenance OMs English 1 PDFDocument4 paginiSKF SAF and SAFS Installation and Maintenance OMs English 1 PDFjaime San Martin PulgarÎncă nu există evaluări

- Manual Reductor Dodge TDT7Document8 paginiManual Reductor Dodge TDT7DANIELÎncă nu există evaluări

- Air BearingDocument2 paginiAir BearingMohAnVinÎncă nu există evaluări

- Slurry High Pressure PumpDocument15 paginiSlurry High Pressure PumpOhmar Jamon LuzanoÎncă nu există evaluări

- Cornell MANURE 2016Document8 paginiCornell MANURE 2016MatoÎncă nu există evaluări

- Lubrication System: Internal Combustion EnginesDocument24 paginiLubrication System: Internal Combustion EnginesAnonymous LFgO4WbIDÎncă nu există evaluări

- CENERG RR Bit Catalogue FinalDocument12 paginiCENERG RR Bit Catalogue FinalRAJIV GandhiÎncă nu există evaluări

- TRB Wheel Hub Units For Ford Super Duty Models - 10856Document2 paginiTRB Wheel Hub Units For Ford Super Duty Models - 10856jack661688Încă nu există evaluări

- HAL MPD GBA CustomerGuideDocument24 paginiHAL MPD GBA CustomerGuidetxcrudeÎncă nu există evaluări

- Fundamentals of Rotating EquipmentDocument61 paginiFundamentals of Rotating EquipmentFery HartantoÎncă nu există evaluări

- Betopan Betopanplus Eng KKDocument48 paginiBetopan Betopanplus Eng KKkashmir_sefÎncă nu există evaluări

- Evr Instruction Manual enDocument8 paginiEvr Instruction Manual enKjsÎncă nu există evaluări

- Professional IndustrialproductsDocument32 paginiProfessional IndustrialproductsEscurçó NegreÎncă nu există evaluări

- Parker Screw Driven Positioners and ActuatorsDocument136 paginiParker Screw Driven Positioners and ActuatorsCarlos Eduardo JaenÎncă nu există evaluări

- Flywheel AtzDocument5 paginiFlywheel AtzRakesh Bhaktha RÎncă nu există evaluări

- Bridge Articulation and Bearing SpecificationDocument16 paginiBridge Articulation and Bearing SpecificationSamuel AntobamÎncă nu există evaluări