Documente Academic

Documente Profesional

Documente Cultură

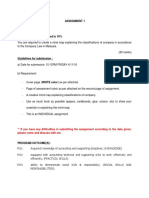

Market Research Survey On Body Wash

Încărcat de

sahil1312Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Market Research Survey On Body Wash

Încărcat de

sahil1312Drepturi de autor:

Formate disponibile

Introduction of the company: 1. 2. 3. 4. 5. 6.

Date/year of incorporation Founder Vision/Mission statement The hierarchy of the organization (production process only) Main products Competition

The production Process with focus on quality How do you define quality in the said production activity? Procurement of raw materials: 1. What are the main components/raw materials? 2. What kind of quality is required for its use in the factory? <Strength, purity, quantity? Technical details> 3. Who are the suppliers and how many suppliers for each of the listed raw material a. Electricity supplier b. Water supplier c. Main raw material supplier d. Fuel supplier 4. The selection process for suppliers? 5. Supply chain process? 6. How often is the raw material obtained from the supplier weekly/monthly basis, or an order is placed as and when the stock depletes 7. Any back up plan for supplier of raw materials? Is the supplier fixed or it changes after a period of time? 8. How many suppliers are contacted before fixing an agreement with the final supplier? 9. Basis of inspection of raw materials once raw materials are delivered by supplier? 10. Frequency of inspection whether its inspected only once when raw material reaches the factory or its inspected at every level of production process 11. Process of inspection? 12. Who does the inspection? Whether an in-house quality control manager or the workers are trained in this function or by supervisors or inspection process is outsourced? 13. How do you maintain supplier relation? 14. If any defaults in payments by suppliers? 15. Difficulties encountered while transportation and purchase of raw materials 16. Are there problems handling raw materials from storage room to the processing room? 17. How are the raw materials stored on the premises? (Warehouse/open, any specific temperature required, any specific storage equipment?) 18. Are the goods internally inspected even though they are certified by the supplier?

19. Trust level between supplier and your company?

Customers of the factory products: 20. Who are the customers? 21. Are there any traders/dealers involved? 22. How are the products marketed to potential customers? Influence of other departments on the quality of the product: 23. Logistic 24. Finance 25. Design HR related quality aspects: 1. What is the Workforce employed 2. No. of Shifts : 3. Wage rate system or other method ? (Hourly basis , piece rate system , daily wage) and also the wage , no. of working days , overtime hours allowed? 4. Incentives or rewards involved for workers as a motivation factor? 5. If bonus given, on what basis , the mode of calculation 6. The kind of facilities provided to workers : no. of breaks , resting area , canteen , permitted holidays 7. If a worker defects, the degree of penalty , negative reinforcement used or not ? 8. rate of attrition, how does it affect the production process and its quality? 9. levels of safety maintained : a. safety kits for the workers b. continuous exposure to furnaces c. uniform 10. Are all the workers skilled or are they trained after joining? 11. Are the employees aware of the entire production process or do they have knowledge of their specific production process? 12. How are the employees/workers addressed at the factory site (designation for every class of worker)?

Operational aspects:

Quality Policy / Manual Equipment & Instrument Validation / Qualification Program Y/N

Internal Audit / Self-Inspection Program Y/N Supplier Evaluation / Qualification Program Y/N - Comment Does your company operate a supplier-auditing system?

Training Program if yes please elaborate

Change Control Deviation / Investigation Reporting please elaborate the process and solutions undertaken to avoid the same Non-Conformance Reporting Documentation Control Do you have a recall system/procedure in place?

1. 2. 3. 4. 5. 6. 7.

What are the quality management techniques employed by the personnel? Are there any targets set for the workers? Are there any meetings convened to discuss the quality issues? Comment Frequency of training session Are the employees evaluated before-after training session? Do the workers work in teams or individually? How are the workers appraised? How often? Eg: after x number of years

Production process: 8. How often is the quality check/inspection done during production process? 9. Is the inspection mass inspection/individual inspection/or inspection on random sampling? 10. Whom is the quality check reported to and is the process of quality planning, control and improvement followed regularly? 11. level of tolerance for variation of the product from the standard norm, ratio of acceptance to rejection (eg: 10:1, 25:1) 12. What are the defects deficiencies which are encountered in the production of the specified product (with reference to the industry and not specifically to your factory) 13. What do youll do with the rejected products? 14. Do youll have a machine/method/technique to detect defected pieces? 15. Could you specify the time period after which: a. The machine is changed b. Technology is changed c. Method of production is changed 16. What is done to the waste materials? 17. Can the waste material be reused again in the production process? 18. How is the customer feedback acted upon? 19. How is the employee/worker feedback acted upon? Legal Aspects:

1. Do the products of your factory or the manufacturing process come under the purview of BIS standards? If yes, to what extent? 2. Any ISO certification awarded for the products/manufacturing process?

S-ar putea să vă placă și

- Audit ChecklistDocument6 paginiAudit ChecklistApoloTrevinoÎncă nu există evaluări

- History of Bangladesh Bangladesh EconomyDocument14 paginiHistory of Bangladesh Bangladesh EconomyAl Faruque0% (1)

- ADM-I Module 1 KeynoteDocument32 paginiADM-I Module 1 KeynoteAradhya SrivastavaÎncă nu există evaluări

- LMT ArellanoDocument57 paginiLMT ArellanoboomblebeeÎncă nu există evaluări

- Version For Microsoft Windows Includes:: SpreadsheetDocument19 paginiVersion For Microsoft Windows Includes:: SpreadsheetDeepak BujahiÎncă nu există evaluări

- Supplier Evaluation FormDocument12 paginiSupplier Evaluation FormMoiz NaeemÎncă nu există evaluări

- Internal Audit Checklist For Mechanical Maintenance Department AuditDocument9 paginiInternal Audit Checklist For Mechanical Maintenance Department AuditSandeep Kaundinya100% (1)

- National Construction Industry Policy - January 2010Document66 paginiNational Construction Industry Policy - January 2010acidrisamuel2656100% (2)

- 20 Aug MOA Template For Work Immersion Private Company MADDocument7 pagini20 Aug MOA Template For Work Immersion Private Company MADAllan Palma Gil100% (4)

- Ecommerce 11streetDocument27 paginiEcommerce 11streetkharizsÎncă nu există evaluări

- History of Bangladesh Bank & Central Banks Arount The WorldDocument7 paginiHistory of Bangladesh Bank & Central Banks Arount The WorldZahin SarwarÎncă nu există evaluări

- Case 1Document1 paginăCase 1Farzana Akter 2125062660Încă nu există evaluări

- Management Assignment On Motivational Theory (On Context of Bangladesh)Document4 paginiManagement Assignment On Motivational Theory (On Context of Bangladesh)gunners888100% (1)

- Deployment Cycle Readiness HandbookDocument165 paginiDeployment Cycle Readiness HandbookU.S. Army's Family and Morale, Welfare and Recreation ProgramsÎncă nu există evaluări

- 12 Comm 308 Final Exam (Winter 2012) SolutionsDocument18 pagini12 Comm 308 Final Exam (Winter 2012) SolutionsAfafe ElÎncă nu există evaluări

- Marketing Mix Strategy of AarongDocument12 paginiMarketing Mix Strategy of AarongFahim AhmedÎncă nu există evaluări

- Notes - Principles of Personality DevelopmentDocument10 paginiNotes - Principles of Personality Developmentdharak100% (2)

- BUS 500 Skills in Business Communication PDFDocument8 paginiBUS 500 Skills in Business Communication PDFrakin tajwarÎncă nu există evaluări

- Esquire GroupDocument3 paginiEsquire GroupNazmul Hasan OmeÎncă nu există evaluări

- JJJJJJJJJJJJJDocument5 paginiJJJJJJJJJJJJJLycel Baloaloa GeyrozagaÎncă nu există evaluări

- MS AccessDocument28 paginiMS AccessJeric SoliwegÎncă nu există evaluări

- Essential Training For MS Word 2016Document19 paginiEssential Training For MS Word 2016Deoband MediaÎncă nu există evaluări

- University of Oxford: Dumitru Florentina Neacsu TheodoraDocument38 paginiUniversity of Oxford: Dumitru Florentina Neacsu TheodoraFlori 789Încă nu există evaluări

- Preparing The Philippines For The 4th Industrial Revolution PDFDocument26 paginiPreparing The Philippines For The 4th Industrial Revolution PDFSean CelonesÎncă nu există evaluări

- "Ha-Meem Group and Supply Chain Management": An Internship Report OnDocument28 pagini"Ha-Meem Group and Supply Chain Management": An Internship Report OnAR RafiÎncă nu există evaluări

- Linguistics History of IndiaDocument28 paginiLinguistics History of IndiaChandranshu Garg100% (1)

- Mis Search EngineDocument16 paginiMis Search EngineAmeya Ranadive100% (1)

- HR Case On BanglalinkDocument34 paginiHR Case On BanglalinkRiaz EmuÎncă nu există evaluări

- Glorious History of India: Our Sanatana DharmaDocument71 paginiGlorious History of India: Our Sanatana Dharmanlalam100% (1)

- Ethical View of A Company According To Stakeholder TheoryDocument26 paginiEthical View of A Company According To Stakeholder TheoryAl-Rafi AhmedÎncă nu există evaluări

- PICE NatCon VILLEGAS 2019 PDFDocument46 paginiPICE NatCon VILLEGAS 2019 PDFSantiago Carig Reyna Isabela0% (1)

- How Can Internet Help Students To Improve Their StudiesDocument2 paginiHow Can Internet Help Students To Improve Their StudiesMohd Zahead75% (4)

- Evolution of Internet PDFDocument2 paginiEvolution of Internet PDFCheraghearzuÎncă nu există evaluări

- How Would You Evaluate Benefast Partners' Strategy?Document3 paginiHow Would You Evaluate Benefast Partners' Strategy?FatemaÎncă nu există evaluări

- Internationalisation of The Dune Group - Written ReportDocument24 paginiInternationalisation of The Dune Group - Written Reportgemmahagan92100% (1)

- CSR in Global Supply ChainsDocument12 paginiCSR in Global Supply ChainsChahat Sosa Mayor100% (1)

- Essay Natural Science and SociologyDocument4 paginiEssay Natural Science and SociologyBob Jiggins100% (1)

- NSU Admission Test: MGT 314 Section: 06 Submitted To: Shaila Jahan Mona (JMS)Document11 paginiNSU Admission Test: MGT 314 Section: 06 Submitted To: Shaila Jahan Mona (JMS)inna tasneemÎncă nu există evaluări

- MEM SCM Exam Case Study Spring 2018 - Porta Cabin-1Document3 paginiMEM SCM Exam Case Study Spring 2018 - Porta Cabin-1Hassan KhanÎncă nu există evaluări

- Knapsack ProblemDocument11 paginiKnapsack ProblemVijay TrivediÎncă nu există evaluări

- UTAUT Model For Understanding The Teacher Perceptions Using Frog VLEDocument6 paginiUTAUT Model For Understanding The Teacher Perceptions Using Frog VLEMaria MashorÎncă nu există evaluări

- The Cataclysm of RevolutionDocument32 paginiThe Cataclysm of Revolutionnjiokmlp100% (1)

- Sharing Pedagogy Through Open Educational Resources: AbstractDocument5 paginiSharing Pedagogy Through Open Educational Resources: AbstractRekha BhatiaÎncă nu există evaluări

- Assignment TheoryDocument4 paginiAssignment Theorybigevil_151190Încă nu există evaluări

- International Marketing - Assignment OneDocument7 paginiInternational Marketing - Assignment OneBelle TaylorÎncă nu există evaluări

- Google Site Teacher BasicsDocument28 paginiGoogle Site Teacher BasicsDigitalMaestroMagazineÎncă nu există evaluări

- Research Proposal On The Topic FMCG Market in ChennaiDocument7 paginiResearch Proposal On The Topic FMCG Market in Chennaialligater_00775% (4)

- Assignment Booklet: Programme Code: CcssDocument6 paginiAssignment Booklet: Programme Code: Ccssdiljot4051Încă nu există evaluări

- Global Footprint of Pran RFL GroupDocument23 paginiGlobal Footprint of Pran RFL GroupShaffyÎncă nu există evaluări

- International Business: Master TEWDocument15 paginiInternational Business: Master TEWequitytraderÎncă nu există evaluări

- Week 1 2 - Foundation of Information System in BusinessDocument58 paginiWeek 1 2 - Foundation of Information System in BusinessFahmi_mukhtarÎncă nu există evaluări

- Project On Videocon d2hDocument51 paginiProject On Videocon d2hmayankÎncă nu există evaluări

- FinAct-Major-Questions - Assessment Test - NSUDocument10 paginiFinAct-Major-Questions - Assessment Test - NSURafina Aziz 1331264630Încă nu există evaluări

- Markets For Product Modification Information: Ganesh Iyer - David SobermanDocument23 paginiMarkets For Product Modification Information: Ganesh Iyer - David SobermanRishab MehtaÎncă nu există evaluări

- Lesson Plan Computer Misuse ActDocument3 paginiLesson Plan Computer Misuse Actapi-169562716Încă nu există evaluări

- IKEADocument7 paginiIKEAnarmin mammadliÎncă nu există evaluări

- Assgn InnovationDocument13 paginiAssgn InnovationNicks CheanÎncă nu există evaluări

- Case Study AcmDocument23 paginiCase Study AcmYouichiHirumaÎncă nu există evaluări

- Assignment 1Document4 paginiAssignment 1rajes wariÎncă nu există evaluări

- Habib Bank Limited (HBL) : HBL Was The First Commercial Bank To Be Established in Pakistan in 1947Document7 paginiHabib Bank Limited (HBL) : HBL Was The First Commercial Bank To Be Established in Pakistan in 1947Muhammad ShakeelÎncă nu există evaluări

- AssignmentDocument4 paginiAssignmentumar156Încă nu există evaluări

- Case 8 Sunsweet Growers Cultivates Its Supply ChainDocument3 paginiCase 8 Sunsweet Growers Cultivates Its Supply ChainNorain Baharuddin100% (1)

- On Advertising IndustryDocument31 paginiOn Advertising IndustryMamta Shah71% (7)

- AdJuggler GuidetoonlineadvDocument24 paginiAdJuggler GuidetoonlineadvsendilvÎncă nu există evaluări

- Ethics in Marketing'Document16 paginiEthics in Marketing'sahil1312Încă nu există evaluări

- Hul Rural StrategyDocument12 paginiHul Rural Strategyxgame2100% (1)

- Total Quality Management in SailDocument15 paginiTotal Quality Management in SailyashmeetbhamraÎncă nu există evaluări

- Capital MarketsDocument28 paginiCapital Marketssahil1312Încă nu există evaluări

- Licenses PermitsDocument1 paginăLicenses Permitssahil1312Încă nu există evaluări

- Total Quality Management in SailDocument15 paginiTotal Quality Management in SailyashmeetbhamraÎncă nu există evaluări

- Non Conventional Sources of EnergyDocument12 paginiNon Conventional Sources of Energysahil1312Încă nu există evaluări

- Tax Benfits Laws in IndiaDocument2 paginiTax Benfits Laws in Indiasahil1312Încă nu există evaluări

- Business Communications: Interpersonal SkillsDocument24 paginiBusiness Communications: Interpersonal Skillssahil1312Încă nu există evaluări

- Origin and Development of Public HistoryDocument14 paginiOrigin and Development of Public HistoryAngela J. SmithÎncă nu există evaluări

- Industrial DemocracyDocument48 paginiIndustrial DemocracySiddhanth MunjalÎncă nu există evaluări

- Factors Affecting Employee Retention and Turnover - Darsh DhyaniDocument86 paginiFactors Affecting Employee Retention and Turnover - Darsh DhyaniDarsh DhyaniÎncă nu există evaluări

- 13Document489 pagini13সঞ্জয় মাহাতোÎncă nu există evaluări

- ConfidentialityDocument7 paginiConfidentialityMarcio FilipeÎncă nu există evaluări

- Seema ProjectDocument66 paginiSeema ProjectSurender Dhuran PrajapatÎncă nu există evaluări

- Solved Acme Realty A Real Estate Development Company Is A Limited PDFDocument1 paginăSolved Acme Realty A Real Estate Development Company Is A Limited PDFAnbu jaromiaÎncă nu există evaluări

- Rolito Calang and Philtranco Service Enterprises, Inc., Petitioners, vs. People of The PHILIPPINES, RespondentDocument7 paginiRolito Calang and Philtranco Service Enterprises, Inc., Petitioners, vs. People of The PHILIPPINES, RespondentKrystal Grace D. PaduraÎncă nu există evaluări

- Postal Ballot Notice: TH TH TH TH STDocument20 paginiPostal Ballot Notice: TH TH TH TH STvenkateshÎncă nu există evaluări

- Labor 1 - Laws - 091015Document8 paginiLabor 1 - Laws - 091015Karla BeeÎncă nu există evaluări

- Rural Prosperity ReportDocument44 paginiRural Prosperity ReportEncik BadrulÎncă nu există evaluări

- We Need More Engagement Around Here22Document4 paginiWe Need More Engagement Around Here22Rianne Wong0% (2)

- TEMPLATE - Employee Starter Checklist Rev3Document2 paginiTEMPLATE - Employee Starter Checklist Rev3Toomas TarvoÎncă nu există evaluări

- Resource Specialist - Job Description (Campus Drive) PDFDocument2 paginiResource Specialist - Job Description (Campus Drive) PDFAnandu PillaiÎncă nu există evaluări

- Chapter 1 PowerPointDocument39 paginiChapter 1 PowerPointBritney BowersÎncă nu există evaluări

- ProjectDocument73 paginiProjectLinsha ShajahanÎncă nu există evaluări

- 02 VistasDocument56 pagini02 VistasfadligmailÎncă nu există evaluări

- A Quasi-Experimental Study On Flexible Work ArrangementsDocument13 paginiA Quasi-Experimental Study On Flexible Work ArrangementsmosabinoÎncă nu există evaluări

- Currently Working in Flikerhood An Export Brand of RPPL As Sr. HRDocument3 paginiCurrently Working in Flikerhood An Export Brand of RPPL As Sr. HRChitransh Kumar SaxenaÎncă nu există evaluări

- Iess 303Document26 paginiIess 303Pinto GamerÎncă nu există evaluări

- Herbert Morris LTD V Saxelby That It Is Not Adequate Only That The Employee May Use The Skills AcquiredDocument6 paginiHerbert Morris LTD V Saxelby That It Is Not Adequate Only That The Employee May Use The Skills Acquiredranbirkkapoor1976Încă nu există evaluări

- A Study On SWOT Analysis of Pharmaceutical Industry - The Bangladesh ContextDocument9 paginiA Study On SWOT Analysis of Pharmaceutical Industry - The Bangladesh ContextsaeednahianÎncă nu există evaluări

- HR Case Studies Part IDocument9 paginiHR Case Studies Part Ihappyhero86Încă nu există evaluări

- Manila Hotel Corp. vs. NLRCDocument15 paginiManila Hotel Corp. vs. NLRCNxxxÎncă nu există evaluări

- Chapter 4 Selection of EmployeesDocument17 paginiChapter 4 Selection of EmployeesRosan YaniseÎncă nu există evaluări

- Employee TestingDocument28 paginiEmployee TestingMUHAMMAD TALATÎncă nu există evaluări

- Edited Labor LawsDocument185 paginiEdited Labor LawsAMIDA ISMAEL. SALISAÎncă nu există evaluări