Documente Academic

Documente Profesional

Documente Cultură

Shear

Încărcat de

Chetan B ArkasaliDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Shear

Încărcat de

Chetan B ArkasaliDrepturi de autor:

Formate disponibile

Shear

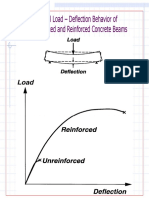

While bending is most often the critical failure mechanism for RC sections shear should always be considered. Shear forces are present wherever the bending moment in a member varies along its length, since

V=

dM dx

Lets consider the behaviour or an RC beam without shear reinforcement. The key to understanding the behaviour of such a beam lies in remembering a) concrete is very weak in tension b) within the beam there are principal planes along which the tensile and compressive forces are a maximum Consider the figures on the next page showing the isoclines associated with three simple loading conditions. The solid isoclines indicate the tangential direction of the principal tensile stresses. Similarly the dashed lines indicate the tangential direction of the principal compressive stresses. The principal compressive and principal tensile isoclines intersect one another at 90o. If cracks are to occur in a concrete section they are most likely to develop along the most heavily stressed tensile isocline. Thus the development of a tensile crack follows the following sequence. The crack starts off as a tensile crack which develops at right angles to the tensile face of the beam.

As the load increases the tensile crack follows the path of the tensile isocline and curves.

This crack may develop in a number of ways each of which leads to a shear failure. Diagonal tension failure: The diagonal crack extends over the entire depth of the beam, causing the beam to split into two parts. Final failure for this type of crack may be dowel failure. Shear tension or shear bond failure: if the applied load is close to the support then the diagonal crack may stabilise at some point but a secondary crack may develop along the tension steel, causing some loss of bond. As the steel begins to slip, it induces tensile stresses in the concrete adjoining the bars, causing the concrete cover to split. This process continues until failure occurs due to loss of anchorage. Shear compression failure: if the diagonal crack does extend deeply into the compression zone then the concrete above the crack may fail due to crushing.

Shear Transfer Mechanism

Consider the beam shown below which has a flexural/shear crack running from C to B, i.e. from the extreme tension fibre to the neutral axis. Shear transferred across the plane ABC by a combination of the following three actions

1) Direct shear transfer by uncracked concrete in the compression zone 2) Mechanical interlocking of the aggregate along the diagonal crack. This is called aggregate interlock or interface shear transfer 3) Dowel action of the longitudinal tension steel Shear is resisted by a combination of these three actions,

Vcu = Vcz + Vag + Vd

The overall shear resistance of a section without shear reinforcement is a function of

Vc = f ( f cu , As , bv , d )

Different codes have different expressions for Vc . The British code BS8110 gives,

0.79 100 As 3 f cu 3 400 4 Vc = vcbv d = bd 25 d v m bv d

where bv = b for rectangular sections and bv = bw for flanged sections

100 As should not be taken greater than 3 bv d

400 should not be taken less than 1 d f cu should not be taken greater than 40

The equivalent EC2 formula is,

Vc = rd k (12 + 40 l ) + 015 cp bwd . .

where l = lesser of the longitudinal tension reinforcement ratio,

As , and 0.02. (with As taken as the min. value within bwd

d+anchorage length

k = 1+ (200/d)1/2 < or = 2, d is in mm

rd = the basic design shear strength

cp =

N , where N is the factored design axial force either Ag

from an external force or from a prestress force (compression positive).

S-ar putea să vă placă și

- ACI Specification For Pervious Concrete PavementDocument11 paginiACI Specification For Pervious Concrete PavementVirginiaEPO90% (10)

- STRUT AND TIE MODELLING BACKGROUND AND NEW AS 3600 PROVISIONSDocument27 paginiSTRUT AND TIE MODELLING BACKGROUND AND NEW AS 3600 PROVISIONSVincent Teng100% (1)

- Flexural Analysis1Document76 paginiFlexural Analysis1Muhammad Waleed KhanÎncă nu există evaluări

- Deflection Due To PrestressDocument85 paginiDeflection Due To PrestresscamilleÎncă nu există evaluări

- Aircraft Structural AnalysisDocument65 paginiAircraft Structural AnalysisSebastian CarterÎncă nu există evaluări

- CVL Final Exam Past YearDocument3 paginiCVL Final Exam Past YearApril SkyÎncă nu există evaluări

- Jib Crane Design SellDocument13 paginiJib Crane Design Selljafary100% (3)

- 1.design For Shear For Prestressed ConcreteDocument34 pagini1.design For Shear For Prestressed ConcretealexÎncă nu există evaluări

- CE 308 - Lec 9 - Flexural Analysis and Design of BeamsDocument62 paginiCE 308 - Lec 9 - Flexural Analysis and Design of BeamsAli BajwaÎncă nu există evaluări

- 2 - Flexural Beam (WSD or ASD)Document24 pagini2 - Flexural Beam (WSD or ASD)Yusf RwandzyÎncă nu există evaluări

- Ce4014 - 1 Bond Anchorage & Development LengthDocument31 paginiCe4014 - 1 Bond Anchorage & Development Lengthprakashcg123100% (1)

- Lec 5 CE 806 RCM Development, Anchorage and Splicing of ReinforcementDocument69 paginiLec 5 CE 806 RCM Development, Anchorage and Splicing of ReinforcementwasimkhaliqÎncă nu există evaluări

- CIV6235 - Shear (MG)Document26 paginiCIV6235 - Shear (MG)friendycalls100% (1)

- Failures Due To ShearDocument70 paginiFailures Due To ShearEr Saurabh Shah100% (1)

- Chapter 3Document18 paginiChapter 3gossayeÎncă nu există evaluări

- Torsion in RC BeamsDocument33 paginiTorsion in RC BeamsMesfin DerbewÎncă nu există evaluări

- RCI Hand Out Chapter 3Document12 paginiRCI Hand Out Chapter 3Nathnael JiaÎncă nu există evaluări

- Chap.4.torsion DesignDocument45 paginiChap.4.torsion DesignChalachew MesfinÎncă nu există evaluări

- RCC Lecture Series 4 2018-19Document33 paginiRCC Lecture Series 4 2018-19Mansa ArthurÎncă nu există evaluări

- INTRO-RCD NOTESDocument6 paginiINTRO-RCD NOTESRam CaniculaÎncă nu există evaluări

- Madvi Ko Behjna HaiDocument7 paginiMadvi Ko Behjna Haibhavyakumar26Încă nu există evaluări

- Flexural Analysis1Document66 paginiFlexural Analysis1hannan mohsinÎncă nu există evaluări

- Flexural Analysis of BeamsDocument15 paginiFlexural Analysis of BeamsameerÎncă nu există evaluări

- 2) Introduction To WSD, Rectangular BeamsDocument10 pagini2) Introduction To WSD, Rectangular BeamsVanessa Rosal PalerÎncă nu există evaluări

- CE 419 Lec 1 Bond and Developement LengthDocument55 paginiCE 419 Lec 1 Bond and Developement LengthwasimkhaliqÎncă nu există evaluări

- Design Shear Reinforcement BeamsDocument37 paginiDesign Shear Reinforcement BeamsYigezu YehombaworkÎncă nu există evaluări

- TDS Iii 2Document28 paginiTDS Iii 2Mikiyas TibebuÎncă nu există evaluări

- Design of Rc-Beams For ShearDocument36 paginiDesign of Rc-Beams For ShearAkli Ale ManÎncă nu există evaluări

- Designing Beams for Shear ResistanceDocument7 paginiDesigning Beams for Shear ResistancestarykltÎncă nu există evaluări

- CE 4014 Design of Concrete Structures (Bond, Anchorage and Development Length) Part (IDocument31 paginiCE 4014 Design of Concrete Structures (Bond, Anchorage and Development Length) Part (IAbu ZaforÎncă nu există evaluări

- Shear Strength of SlabDocument3 paginiShear Strength of Slabaleena4Încă nu există evaluări

- CEE485 Lect5 2009Document6 paginiCEE485 Lect5 2009Jack IanÎncă nu există evaluări

- Tension StiffeningDocument13 paginiTension StiffeningRahul BhatiaÎncă nu există evaluări

- Flexural Analysis of BeamsDocument13 paginiFlexural Analysis of BeamsRandy PolicarpioÎncă nu există evaluări

- RCD 02 Flexural Analysis of BeamDocument13 paginiRCD 02 Flexural Analysis of BeamJohn Kenneth RuizÎncă nu există evaluări

- Bond Development LengthDocument8 paginiBond Development LengthAbhinav Sethi100% (1)

- 2lec3&4 With Assignment 2 Reinf Conc 412Document42 pagini2lec3&4 With Assignment 2 Reinf Conc 412Emmanuel MwabaÎncă nu există evaluări

- Lecture Notes RC DesignDocument53 paginiLecture Notes RC DesignchandrasekarÎncă nu există evaluări

- Yield Line Analysis For SlabsDocument9 paginiYield Line Analysis For Slabshghjjjk100% (1)

- Prc-I Lec 7 - 18th March 014 - Flexural Analysis of BeamsDocument51 paginiPrc-I Lec 7 - 18th March 014 - Flexural Analysis of BeamsDavidm AndosÎncă nu există evaluări

- Reinforced Concrete Beam DesignDocument8 paginiReinforced Concrete Beam DesignLindy Kho100% (1)

- Design and Behavior of Deep BeamsDocument27 paginiDesign and Behavior of Deep BeamsniroÎncă nu există evaluări

- 5-Shear Design of BeamsDocument53 pagini5-Shear Design of Beamshamadamjad047Încă nu există evaluări

- Chapter Five, Torsion of BeamsDocument7 paginiChapter Five, Torsion of BeamsTemesgenAbiyÎncă nu există evaluări

- Chapter 2 Strain PDFDocument20 paginiChapter 2 Strain PDFOsama ShukurÎncă nu există evaluări

- Vlasov Torsion Theory CT5141 Chap7Document12 paginiVlasov Torsion Theory CT5141 Chap7Anonymous 1rLNlqUÎncă nu există evaluări

- Beam Shear BehaviourDocument10 paginiBeam Shear BehaviourEr Saurabh ShahÎncă nu există evaluări

- Chapter 5: Shear in Beams: Figure 5.1: Shear in Beams: (A) Loaded Beam (B) Internal Forces at Section A-ADocument20 paginiChapter 5: Shear in Beams: Figure 5.1: Shear in Beams: (A) Loaded Beam (B) Internal Forces at Section A-Aravi1214Încă nu există evaluări

- Chapter 5: Shear in Beams: Figure 5.1: Shear in Beams: (A) Loaded Beam (B) Internal Forces at Section A-ADocument20 paginiChapter 5: Shear in Beams: Figure 5.1: Shear in Beams: (A) Loaded Beam (B) Internal Forces at Section A-AIraya DavidÎncă nu există evaluări

- Design of SlabDocument30 paginiDesign of Slabmuonekechibukeleonard52Încă nu există evaluări

- RCD Lecture 1Document26 paginiRCD Lecture 1Walter CatapangÎncă nu există evaluări

- Lesson 8Document6 paginiLesson 8MIKE ARTHUR DAVIDÎncă nu există evaluări

- Limit State of Collapse in ShearDocument21 paginiLimit State of Collapse in ShearNavi RengarajanÎncă nu există evaluări

- Reinforced Concrete Design BS 8110Document15 paginiReinforced Concrete Design BS 8110Kutty Mansoor75% (4)

- (11801321032) Ce (PC) 501 PDFDocument18 pagini(11801321032) Ce (PC) 501 PDFArjun BhattacharjeeÎncă nu există evaluări

- Shear DesignDocument40 paginiShear DesignKausalya PurushothamanÎncă nu există evaluări

- 12-BOND Anchorage LenthDocument29 pagini12-BOND Anchorage LenthRushiÎncă nu există evaluări

- CLASS NOTES Chap 10 1 Bond & AnchorageDocument13 paginiCLASS NOTES Chap 10 1 Bond & Anchoragekohatian27796105Încă nu există evaluări

- Lecture Notes on Reinforced Concrete DesignDe la EverandLecture Notes on Reinforced Concrete DesignÎncă nu există evaluări

- Instructions on Modern American Bridge BuildingDe la EverandInstructions on Modern American Bridge BuildingÎncă nu există evaluări

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910De la EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910Încă nu există evaluări

- Drawing1 ModelDocument1 paginăDrawing1 ModelChetan B ArkasaliÎncă nu există evaluări

- ICJ Guidelines To Authors 2016 PDFDocument2 paginiICJ Guidelines To Authors 2016 PDFoundhakarÎncă nu există evaluări

- Indian Standard: Code of Practice For Determination of Breaking Capacity of Shallow Foundations (Document20 paginiIndian Standard: Code of Practice For Determination of Breaking Capacity of Shallow Foundations (api-19754583100% (1)

- BEARING CAPACITYDocument35 paginiBEARING CAPACITYhact72100% (3)

- Final ReportDocument36 paginiFinal Reportasthanarahul2050Încă nu există evaluări

- Ansys Shell 63 Elementansys Shell 63 Elementansys Shell 63 ElementDocument10 paginiAnsys Shell 63 Elementansys Shell 63 Elementansys Shell 63 ElementvilukÎncă nu există evaluări

- CE 100 Civil Engineering Drawing Sessional (Lab Manual)Document72 paginiCE 100 Civil Engineering Drawing Sessional (Lab Manual)Niyitegeka SimonÎncă nu există evaluări

- Chapter 2Document16 paginiChapter 2Chetan B ArkasaliÎncă nu există evaluări

- Stringer Beam Staircase DesignDocument6 paginiStringer Beam Staircase DesignChetan B ArkasaliÎncă nu există evaluări

- 2006 Beam Column Joint ICJDocument9 pagini2006 Beam Column Joint ICJBrian LamÎncă nu există evaluări

- Is 1892Document48 paginiIs 1892Danish AhmadÎncă nu există evaluări

- 2911 1 3+CONCRETE+PILES+Driven+Precast+Concrete+PilesDocument55 pagini2911 1 3+CONCRETE+PILES+Driven+Precast+Concrete+Pilesc2anÎncă nu există evaluări

- Solid 65 AnsysDocument5 paginiSolid 65 AnsysChetan B ArkasaliÎncă nu există evaluări

- Initialize modeling in EtabsDocument68 paginiInitialize modeling in EtabsBenny Sofyan HartadiÎncă nu există evaluări

- ch04Document15 paginich04Balaji ElanchezhiyanÎncă nu există evaluări

- Tiles TypeDocument1 paginăTiles TypeChetan B ArkasaliÎncă nu există evaluări

- Structural Consultant Fee Structure by ISSEDocument4 paginiStructural Consultant Fee Structure by ISSEAnonymous ciKyr0tÎncă nu există evaluări

- Estimating & CostingDocument83 paginiEstimating & CostingSrinath Bonakurthi100% (4)

- Ma Lab Manual PDFDocument70 paginiMa Lab Manual PDFChetan B ArkasaliÎncă nu există evaluări

- Conversion of UnitsDocument2 paginiConversion of UnitsChetan B ArkasaliÎncă nu există evaluări

- ETABS-Example-RC Building With Shear WallDocument58 paginiETABS-Example-RC Building With Shear WallJason Guzman85% (53)

- Seismic design forces for a four-storey RC buildingDocument26 paginiSeismic design forces for a four-storey RC buildingjonnyprem100% (1)

- My Home Layout1 PDFDocument1 paginăMy Home Layout1 PDFChetan B ArkasaliÎncă nu există evaluări

- DR D K Paul Former Professor IIT RoorkeeDocument57 paginiDR D K Paul Former Professor IIT Roorkeejacs127Încă nu există evaluări

- Ansys FileDocument7 paginiAnsys FileChetan B ArkasaliÎncă nu există evaluări

- 4 Elevation PDFDocument1 pagină4 Elevation PDFChetan B ArkasaliÎncă nu există evaluări

- CivilFEM 2016 .Beam - DesignDocument29 paginiCivilFEM 2016 .Beam - DesignSharathBanakarÎncă nu există evaluări

- RCC Box Culvert - Methodology and Designs Including Computer MethodDocument31 paginiRCC Box Culvert - Methodology and Designs Including Computer Methodmohan1441Încă nu există evaluări

- ch04Document15 paginich04Balaji ElanchezhiyanÎncă nu există evaluări

- Beam Layout & Schedule of ReinforcementDocument1 paginăBeam Layout & Schedule of ReinforcementChetan B ArkasaliÎncă nu există evaluări

- Site Class B Response Spectrum GraphDocument8 paginiSite Class B Response Spectrum Graphsudhir12345100% (1)

- Building Construction TechniquesDocument2 paginiBuilding Construction TechniquesDharshan KÎncă nu există evaluări

- TENSACCIAI - Slab Post-Tensioning SystemDocument0 paginiTENSACCIAI - Slab Post-Tensioning Systemnovakno1Încă nu există evaluări

- HB Ground Improvement Solutions MatrixDocument3 paginiHB Ground Improvement Solutions MatrixSheik Mohamed LiakathÎncă nu există evaluări

- Description of Tilt-Up Concrete Wall ConstructionDocument8 paginiDescription of Tilt-Up Concrete Wall ConstructionnevinkoshyÎncă nu există evaluări

- DQS251 - Piling - Spun Piles - Tutorial-Drwgs-Dec 2019 - pg11Document8 paginiDQS251 - Piling - Spun Piles - Tutorial-Drwgs-Dec 2019 - pg11MUHAMMAD DANIAL AMRAMÎncă nu există evaluări

- Fatigue of MaterialsDocument44 paginiFatigue of MaterialsAnilÎncă nu există evaluări

- MFE Accessories Brochure (Old)Document8 paginiMFE Accessories Brochure (Old)David LawÎncă nu există evaluări

- ISMEP Seismic GuidelineDocument155 paginiISMEP Seismic GuidelinearpÎncă nu există evaluări

- Civil - Final KTMDocument103 paginiCivil - Final KTMKrijan MaliÎncă nu există evaluări

- Is.2185.1.2005 Solid Block PDFDocument17 paginiIs.2185.1.2005 Solid Block PDFrajeshji_000Încă nu există evaluări

- Regulator TypesDocument58 paginiRegulator Typesramkumar121Încă nu există evaluări

- High-Strength Concrete Columns: State of The Art: Repor Ted by Joint ACI-ASCE Committee 441Document13 paginiHigh-Strength Concrete Columns: State of The Art: Repor Ted by Joint ACI-ASCE Committee 441DIDIER ANGEL LOPEZ RINCONÎncă nu există evaluări

- The Flow Chart Below Can Be Used As A Guide To Design A Steel Beam MemberDocument27 paginiThe Flow Chart Below Can Be Used As A Guide To Design A Steel Beam MemberIrfan SyafriÎncă nu există evaluări

- Reinforcement Requirements for Flexural Members of Special Moment FramesDocument39 paginiReinforcement Requirements for Flexural Members of Special Moment FramesJenny MorenoÎncă nu există evaluări

- On FRCDocument59 paginiOn FRCpraful0% (1)

- Chapter 5 BridgesDocument78 paginiChapter 5 BridgesWendimu TolessaÎncă nu există evaluări

- Bar Bending Schedule of Box CulvertDocument1 paginăBar Bending Schedule of Box CulvertganmalÎncă nu există evaluări

- Failure Modes and Criteria of Plastic Structures Under Intense Dynamic Loading: A ReviewDocument9 paginiFailure Modes and Criteria of Plastic Structures Under Intense Dynamic Loading: A ReviewyasameenÎncă nu există evaluări

- 1082 Rawlplug en R Hptii ZF Zinc Flake ThroughboltDocument8 pagini1082 Rawlplug en R Hptii ZF Zinc Flake Throughboltmaniamjad321Încă nu există evaluări

- Bella Sky - Taking Precast Concrete To The LimitDocument62 paginiBella Sky - Taking Precast Concrete To The Limitd_i_z_zÎncă nu există evaluări

- Reinforced Concrete Beam DesignDocument12 paginiReinforced Concrete Beam DesignstylistikÎncă nu există evaluări

- Install Hollow Core Floor SlabsDocument24 paginiInstall Hollow Core Floor SlabsVishant ChandraÎncă nu există evaluări

- Statically Indeterminate Beams Differential EquationsDocument10 paginiStatically Indeterminate Beams Differential EquationsRafael Sánchez CrespoÎncă nu există evaluări

- Section 04 Concrete WorksDocument32 paginiSection 04 Concrete WorksMarvin MessiÎncă nu există evaluări

- Cement Reconciliation ExampleDocument4 paginiCement Reconciliation ExampleDevenderÎncă nu există evaluări

- BoQ - Final Railway Over BridgesDocument22 paginiBoQ - Final Railway Over Bridgesrajiv kumarÎncă nu există evaluări