Documente Academic

Documente Profesional

Documente Cultură

Bradshaw George Pmi 1996

Încărcat de

Anam ChandraDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Bradshaw George Pmi 1996

Încărcat de

Anam ChandraDrepturi de autor:

Formate disponibile

Prudency, Project Management and the Utility Industry

George B. Bradshaw, PE PMP; William B. Derrickson, PE; and Robert E. Sweeney; the IBEX Group, Inc., Arlington, Virginia

Keywords: Leadership, Culture, Responsibility

Background

During the 1970s and 1980s the utility industry was severely challenged to manage their nuclear power plant construction projects in a prudent manner. Most of the articles in the Wall Street Journal, Forbes [1] and others told of the horror stories about out of control costs, schedules and quality. The consequences included: cancellations, conversions, mothballing, redesign and reconstruction, rate impacts, litigation, and bankruptcies. In most cases, management prudence was called into question. [Prudence a: wisdom shown in the exercise of reason, forethought, and self-control b: sagacity or shrewdness in the management of affairs shown in the skillful selection, adaptation, and use of means to a desired end c: providence in the use of resources d: attentiveness to possible hazard or disadvantage] Websters Dictionary During the 90s and into the 2000s the utility industry will continue to be severely challenged to manage their power plants and operations prudently during the transition toward a market driven, competitive, deregulated business [2]. Despite these dynamics and new challenges, fundamental and sound management principles must prevail for individual utilities to survive. In the 1960s and 70s electric utilities were looking to diversify their fuel mix and meet environmental standards. Many choose nuclear power as a way to meet their rapidly growing electric demand. Although hundreds of plants planned were canceled during the mid and late 70s, the industry is currently comprised of 48 utilities operating 110 reactors which provide over 20 percent of the countrys electric power. These reactors represent embedded costs of well over $300 billion, and it is the role of utility management to deploy these capital resources effectively using prudent management practices. However, the wide variation in the performance of these plants, combined with current cost slashing zeal, calls into question whether or not prudent practices are being followed in all cases. In discussing the safety of these reactors Ivan Selin (past Chairman of the NRC) stated that a particular frustration

of his has been to see comparable plants run with noncomparable results. There is, he added, a very wide range of performance between the best plants in the United States and the worst plants. I dont think there is any excuse for that. Bulletin of the Atomic Scientist, 11-12/94 In order to explore why certain nuclear utilities have been more successful than others, and to identify workable and prudent practices, let us examine the history of some of the larger nuclear utilities.

Introduction

Over the last decade, the electric utility industry has clearly bitten into the apple of competition. We have also seen significant forces affecting utilities due to federal and state rate regulator transition from the traditional cost based recovery schemes to market price driven. This transition was being made at the same time that nuclear power was working out the bugs in its operations and management. While these times have added new dimensions and challenges to utility managers, a few utilities have met significant challenges that led to turnabouts in operations and maturation of their nuclear operations using prudent management and project management tools. These utilities not only addressed short-term challenges, but also address their corrective action on ensuring long-term health and prosperity of company assets, both personnel and generating plant capital. A few of these utilities are identified in the sections that follow.

Differences between the two largest nuclear utilities

Duke Power Co. has seven operating reactors at three different sites and is the second largest nuclear utility. Not only have they had a reputation for some of the lowest capital costs, they have consistently run their plants well.

1 PROJECT MANAGEMENT INSTITUTE 27th Annual Seminar/Symposium Boston, Massachusetts: Papers Presented October 7 to 9, 1996

In a recent issue of Nuclear News [3] Dukes plants had a combined capacity factor of 79.9 percent between 93-95 and were ranked sixth among multiple site utilities. More significantly, Duke has maintained these relatively high standards year after year. By contrast, the nations largest nuclear utility, Commonwealth Edison (ComEd), has twelve units at six different sites and, although a leader in the industry, has been consistently plagued by operating problems. Two units are on the NRCs watch list and most of their other plants have been fined for NRC violations. The combined capacity of their 12 units was 67.4 percent between 93-95, was ranked twelfth out of 15 multiple site utilities, and had half their plants in the lowest quartile of performance. Why has one utility been consistently better than the other? Has ComEd been prudent in managing its nuclear fleet? Why hasnt Duke experienced setbacks like many of the nuclear utilities? Have they done a better job of managing their investments? Do they have more corporate pride? How have they avoided becoming complacent or neglecting one unit at the expense of another? Are they employing the same prudency standards used to construct their units? The answers may be related to how prudently decisions are being made in one case verses the other.

seemed related to people operating in an imprudent manner, such as ignoring safety regulations. The root cause may be lack of involvement by senior management in plant operations, resulting in a lack of follow through on corrective action plans. Florida Power & Light is another utility experiencing recent problems at its previously heralded St. Lucie nuclear units [4]. Some of these problems have been directly attributed to excessive staff reductions and management complacency, impacting critical operating and maintenance activities. This is particularly surprising in light of recent acclaim received for improvements in operation of their Turkey Point nuclear units (unit 3 had the greatest improvement in capacity factor of any reactor in 93-95). Does this represent management neglecting one plant at the expense of another? Overconfidence based on prior years of successful operation? Or just indiscriminate cost reduction by management? Regardless of the specific reason, management prudence becomes an issue.

Some of the success stories

The nuclear industry has many heroes [5] and examples of prudently managed nuclear programs and companies. For instance, Northern States Powers three units placed first, sixth and ninth in capacity factor out of 108 units over the past two years. It would be hard to refute that NSP achieved these results through prudent management decisions. Similar high performance was obtained by Southern Nuclears Vogtle units. The utility given the highest accolades for recent improvements in its nuclear operations was PECO Energy System (formerly Philadelphia Electric Co.) This is particularly relevant to the issue of prudence, since this turnaround was largely due to a new management team which was put in place following the 1987 shutdown of the Peach Bottom units triggered by reactor operators sleeping on duty. In this case management had a major challenge in changing the culture that led to shutdown of their units. This challenge was met primarily by opening lines of communications between corporate and plant management. PECO Energy has also been aggressive in cutting staff and costs [6], but not at the expense of ignoring employee anxiety [7], and evidently not at the expense of effectively managing their four large nuclear units - Peach Bottom and Limerick. Virginia Power company had overcome significant difficulties in its early days with their Surry units, but in May 1989 the station was placed on the NRC watch list. This unexpected event shook management and led to significant internal changes and initiatives at both the Surry and

Utilities with recent nuclear woes

Northeast Utilities is the largest utility in New England and one of the bigger nuclear plant operators, having five units located at three different sites. Over the past two years all five units were in the bottom half of the capacity factor rating and the utility was ranked ninth out of 15 with an average capacity factor of 72.7 percent. This was a significant improvement over the performance in 90-92 of 56.8 percent and would indicate a positive trend. However, something went wrong as the following headlines and articles indicate: NUCLEAR WARRIORS, Time, Special Investigation, March 4, 1996 NRC Is Threatening to Revoke License For Northeast Utilities Nuclear Reactor, WSJ, April 8, 1996 Regulatory Woes Push Northeasts Stock Down 13 percent, WSJ April 9, 1996 Violation of operating rules and other safety concerns prompted the NRC to shut down NUs three Millstone nuclear power plants. With nearly all of their nuclear units shutdown, which is a major portion of their generating capacity, these acts of apparent imprudence will have a significant effect on their operating costs and possibly impact the current management. In NUs case the problem

2 PROJECT MANAGEMENT INSTITUTE 27th Annual Seminar/Symposium Boston, Massachusetts: Papers Presented October 7 to 9, 1996

North Anna stations. Swift management attention resulted in the NRC taking Surry off the watch list in six months, as compared to some 18 to 36 months for other facilities. Over the last five years, Virginia Power has developed into one of the worlds premier nuclear operators. and has received top ratings by INPO, the industrys oversight organization. Baltimore Gas & Electric was faced with significant challenges during the transition from construction to operations. During this period many good practices of project management were not followed on the operations side; prudent management was seen more as a get it in the rate base and keep our operations costs to a minimum. In late 1988 their practice of not meeting commitments to the regulators, led the NRC to place the two unit Calvert Cliffs station on the agencys watch list. It took nearly three years and several management changes and decisions on improving plant systems and programs before the units were removed from the NRC watch list. Since that early wake up call, BG&E has taken the two units from the near bottom of the NRCs problem list to one of the best operated facilities in the region. By its recent record of accomplishments, BG&E has shown that it is possible to operate both safely and economically. In the recent Nuclear News capacity factor rating, Calvert Cliffs Units 1 and 2 had the second and fifth greatest improvement in capacity factor of 36.7 percent and 32.6 percent. Perhaps, overall improvements in the operation of nuclear units may simply reflect building on successful experience; or, greater acceptance and implementation of Institute of Nuclear Power Operations (INPO) recommendations, as suggested by Nuclear News. However, as the pressures mount to reduce operating costs, and thus staffing levels and funds for major maintenance, the challenges to make prudent decisions will increase. Failure will result in problems such as those being experienced by NU and FP&L.

What are some things that work?

It is strongly believed that the things that work for a prudently managed project also work for prudently managing an operating nuclear plant, or even a company. Some of these beliefs are based on highly successful experiences building large complex projects [8,9] and serving as expert witnesses during numerous rate hearings and litigated disputes over large projects. At the completion of the St. Lucie Unit 2 construction project (built on-schedule in 1983) the project team identified 12 success ingredients (which have been used as prudence standards). Some were unique to that project; how-

ever, three of these standout as the most crucial for any project: 1. management commitment, 2. clear decision making authority, and 3. organizational flexibility. In the way of illustration, during construction of St. Lucie Unit 2, FP&Ls management was committed to completing the plant on schedule due to the need for generating capacity. This management commitment was severely tested at various times for such things as: (a) obtaining congressional action to overcome licensing obstacles, (b) recovering from major hurricane inflicted damage, and (c) expediting safety equipment and critical materials. No enterprise can succeed without similar management commitment to all elements of the organization, especially their major capital assets. Clear decision making authority is the essence of prudent management. Confusion over roles and responsibilities is one of the most damaging factors toward overcoming obstacles and achieving project objectives. In the case of St. Lucie 2 the owner (FP&L) took the lead and designated a Project General Manager (PGM) to be responsible for the overall project management. All of the contractors reported to the PGM, and were accountable to him for performance - no exceptions! At first blush, organizational flexibility may not seem to be as critical as management commitment and clear decision making authority, but in the authors opinion this ingredient can be as crucial. For example, can a major project such as steam generator replacement be handled by the maintenance department? Probably not. In the case of St. Lucie 2 there became a time when the PGM placed the startup manager in the lead due to the phase of the project. At other times various organizational units took the lead, such as planning and scheduling when the project was shutdown and needed a new schedule baseline. Similar organizational flexibility was essential to complete construction of the Seabrook project, on-schedule and within stringent cash constraints, after a forced shutdown in early 1984. Applying these ingredients to achieve specific results, the FP&L PGM ascribed to the mother theory (this theory was cited in a Wall Street Journal article on St. Lucie [10]). During system completion on St. Lucie 2, project management assigned responsible individuals as mothers for full accountability in completing major systems. These system mothers provided for the care, feeding and nurturing of the equipment toward plant acceptance. In fact, any temporary plant position, such as Outage Manager, fits this description. For further research on the nuclear industry management assessments, readers are referred to the NRC publi-

3 PROJECT MANAGEMENT INSTITUTE 27th Annual Seminar/Symposium Boston, Massachusetts: Papers Presented October 7 to 9, 1996

cation NUREG-1055 [11], as well as Clelands many fine articles in PMI proceedings [12]. The NRC report was truly a landmark study of the design and construction of nuclear power plants, and found that deep utility (owner) involvement in project controls and quality were essential ingredients for success. This study also cited St. Lucie 2s experience (as Case Study E) and notes that a spirit of teamwork, commitment and loyalty to the project was achieved, and that the project experienced no major quality problems (a condition that plagued many other nuclear projects). The NRC concluded - Good management practices can produce quality amidst commitment to schedule.

Knowledge for time honored project management techniques.

What are some things that may not work?

Many companies are looking to reengineering as the silver bullet to cure all of their ills, however, two out of three re-engineering efforts fail to produce the results expected [13]. In the article cited, the author gives five examples with the following titles: Failing to keep information technology (IT) from driving change, rather than enabling it Failing to re-engineer entire customer-to-customer processes Failing to anticipate peoples resistance to change Failing to support re-engineered processes with management structures, and Failing to revamp compensation and training programs in restructured organizations. The author [13] also notes that re-engineering is not a worthless exercise and can, and does, work when implemented properly. The point here is that there are no magic cures, and that possibly management need only to do what they know is right and prudent and not abdicate their responsibilities by deferring to another study or become enamored with the latest IT tools to fix everything. Remember that when all else fails, read the instructions.

Other things that work - use of performance indicators

Successful completion of large complex projects is often associated with heavy emphasis placed on the use of performance indicators (e.g., reference 8). This is related to the principle - if you cant (or dont) measure it, you cant improve it. In addition to formal measures of performance (such as percent complete, critical path variance, number of automatic trips, equipment out of service, capacity factor, etc.), prudent management uses informal indicators (see Table A). Informal indicators are those things gleaned by talking to project and plant personnel, by walking around observing, or by reading between the lines. Possibly a book could be written on informal indicators, but ones commonly used by the authors include: increases in the number of cars in the parking lot, changes in housekeeping, not following procedures, material conditions, excessive complaining, absenteeism, etc. - see Table A. Each of these may require root cause analyses for proper explanation. Nonetheless, it is strongly believed that these informal indicators present a wake-up call well ahead of the formal indicators. Hence, prudent management will learn to proactively respond to these early warning signs. In support of the above, it has been observed that many serious problems got that way because someone ignored the early signs that the project, plant or company was in trouble. An example of a proactive measure is to direct an independent review of a suspected condition adverse to quality. For these to be successful, the organization must be open to outside advice. Another technique used successfully is the suggestion box in which management responds to all requests for information. Obviously, there are many other things that work and are important to project success, and the reader is referred to PMIs A Guide for Project Management Book of

Some other issues

In a free market economy the market place establishes the value of things and industries that fail to respond to the consumer pay a large price, such as the American automobile industry did over the past 20 to 30 years. In the case of regulated utilities the Public Service (or Utility) Commissions represent the consumers in lieu of competition. As state PSCs push utilities to become more cost effective with the use of incentives and other devices, one questions if they are acting prudently, or unwittingly contributing to long-range problems, such as causing utilities to defer plant improvements. Are PSCs becoming part of the problem by encouraging staff reductions that cut-into nuclear O&M experience base? Is there so much pressure to reduce outage durations that quality or safety could be compromised? Are PSCs applying the same standards to independent power producers as to the large utilities? Are PSCs now penalizing utilities for nuclear plant costs they approved? These pressures must by countered with pru-

4 PROJECT MANAGEMENT INSTITUTE 27th Annual Seminar/Symposium Boston, Massachusetts: Papers Presented October 7 to 9, 1996

dent management practices by the utilities in the operation of their major capital assets. As pressures mount on the utilities they must not let one set of problems distract them and neglect their other plants or projects. In the case of PECO, did management focus too much attention toward completing construction of the Limerick units at the expense of attention to the operations of Peach Bottom? Did FP&L ignore St. Lucie operations while correcting those at Turkey Point after Hurricane Andrew? To be successful, managements role is to manage the entire enterprise, not just the acute problem areas. Power plants should be run from the plant, not the home office; but corporate management is responsible for incorporating checks and balances, and promoting team work and good communications. Using the mother theory, utility management must assign qualified resources as plant managers, and then provide them the necessary support to run the plant effectively, and monitor their performance frequently. Responsible and qualified managers (mothers) worry more about their projects and plants. They expend the necessary energy to see that everything that can be done is done. When it comes to prudently managing an operating nuclear plant, the basics of management by walking around may still be one of the best approaches.

Conclusions

Prudent management practices apply to projects just as they do to nuclear plant operations. Successes in managing projects can spill over into operations and vice versa. Turning around a problem operation is a project, and should be prudently managed in much the same way, using management commitment, clear decision making authority, flexible organizations, and monitor with appropriate formal and informal indicators. Lastly, it should be noted that the opinions stated herein are technical rather than legal. Readers interested in legal opinions relative to utilities and prudence are referred to articles by Randall L. Spek [14]. References

1. Nuclear Follies. 1985. Forbes. (Feb. 11). 2. Is there light at the end of the nuclear powers tunnel?, 1995. Electric World. (Nov.). [This is only one out of many, many articles on the subject.] 3. Nuclear News. 1996. American Nuclear Society. (May.). 4. As Lunch Heated, So Did Reactor 1996. Palm Beach Post. p. 1. (March) and Stuart News. January 1996.

5. It should be noted that many utilities have made major strides recently to improve their nuclear plants, outage times, O&M costs, etc. and it is with regret that we cannot site all the heroes. 6. Is PECOs $450-million outsourcing pact the beginning of a trend? 1995. Electrical World. (January). 7. Stop employee anxiety by retraining managers. 1995. Electrical World. (September). 8. St. Lucie Unit 2 - A Nuclear Plant Built On Schedule. 1983. Proceedings. Project Management Institute (PMI). 9. Achieving Project Goals in Contrasting Environments: The Value of a Strong Management Philosophy. 1987. Proceedings PMI. 10. Atomic Speed, Utility Cuts Red Tape, Builds Nuclear Plant Almost on Schedule. 1984. Wall Street Journal. (Feb. 22). [Almost refers to the commercial operation date which was achieved August 8, 1983 vs. the scheduled date in March 1977 of May 31, 1983 - a two month variance.] 11. Improving Quality and the Assurance of Quality in the Design and Construction of Nuclear Power Plants. 1984. A Report to Congress. US Nuclear Regulatory Commission. NUREG1055. (May). 12. David I. Cleland. Measuring Success: The Owners Viewpoint. 1986. Proceedings. PMI. 13. Why re-engineering fails. Electrical World. 1995. (Nov.) 14. Spek, Randall L. 1987. The Legal Standards for Prudent Project Management. PM Network. (Oct.) and The Buck Stops Here: the Owners Legal and Practical Responsibility for Strategic Project Management. 1988. Project Management Journal. (Vol. 19, Sept.). [also see Project Management Handbook, Sec. Ed. ed. by Cleland and King. Van Nostrand Reinhold.]

5 PROJECT MANAGEMENT INSTITUTE 27th Annual Seminar/Symposium Boston, Massachusetts: Papers Presented October 7 to 9, 1996

S-ar putea să vă placă și

- ISCC EU 205 Greenhouse-Gas-Emissions-v4.0Document61 paginiISCC EU 205 Greenhouse-Gas-Emissions-v4.0juan carlos100% (2)

- Addressing Solar Photovoltaic Operations and Maintenance ChallengesDocument22 paginiAddressing Solar Photovoltaic Operations and Maintenance Challengesathanasios_ghikasÎncă nu există evaluări

- AbstractDocument3 paginiAbstractRamachandran RajaramÎncă nu există evaluări

- A Case For Distributed Power Generation Beyond CHP: John C.Y. LeeDocument32 paginiA Case For Distributed Power Generation Beyond CHP: John C.Y. LeeJose FavaÎncă nu există evaluări

- EWEC07 PaperDocument10 paginiEWEC07 PaperdalalhelmiÎncă nu există evaluări

- Davis and Wolfram (2012) Nuclear PowerDocument33 paginiDavis and Wolfram (2012) Nuclear PowerFreyÎncă nu există evaluări

- Meeting: Improving Power System Resilience in The 21 CenturyDocument12 paginiMeeting: Improving Power System Resilience in The 21 Centurymayalasan1Încă nu există evaluări

- Lect 1-3Document19 paginiLect 1-3Abdu HmÎncă nu există evaluări

- Disallowances and Overcapitalization in The US Electric Utility IndustryDocument11 paginiDisallowances and Overcapitalization in The US Electric Utility IndustryMuhammad RezaÎncă nu există evaluări

- Microgrid Policy Review of Selected Major Countries, Regions, and OrganizationsDocument34 paginiMicrogrid Policy Review of Selected Major Countries, Regions, and OrganizationsAlessandro Harry LaterzaÎncă nu există evaluări

- Corporate Profit and Nuclear Safety: Strategy at Northeast Utilities in the 1990sDe la EverandCorporate Profit and Nuclear Safety: Strategy at Northeast Utilities in the 1990sEvaluare: 1 din 5 stele1/5 (3)

- Science and Technology Literature Survey of Wind Power Integration With Hydroelectric EnergyDocument8 paginiScience and Technology Literature Survey of Wind Power Integration With Hydroelectric EnergyRaunaq SinghÎncă nu există evaluări

- Southern Economic Association Southern Economic JournalDocument15 paginiSouthern Economic Association Southern Economic JournalbacnmichaelÎncă nu există evaluări

- Prognostics and Health Management in Nuclear Power PlantsDocument124 paginiPrognostics and Health Management in Nuclear Power PlantsAsociatia Proprietari Bloc M116100% (1)

- Retiring Coal Plants While Protecting System ReliabilityDocument5 paginiRetiring Coal Plants While Protecting System ReliabilityJohn Henry PittsÎncă nu există evaluări

- Northwestern Kirshon Miles Aff Wake Round2Document23 paginiNorthwestern Kirshon Miles Aff Wake Round2Ben CrossanÎncă nu există evaluări

- Financing Solar Thermal Power Plants: Rainer Kistner and Henry W. Price National Renewable Energy LaboratoryDocument8 paginiFinancing Solar Thermal Power Plants: Rainer Kistner and Henry W. Price National Renewable Energy LaboratoryDa VuÎncă nu există evaluări

- Maintenance Management For Photovoltaic Power System SurveyDocument16 paginiMaintenance Management For Photovoltaic Power System SurveyLutfie HidayatullahÎncă nu există evaluări

- MIT LL DoD Microgrid Study TR-1164 18jun12Document104 paginiMIT LL DoD Microgrid Study TR-1164 18jun12navidelecÎncă nu există evaluări

- Reliability-Centered Maintenance A Case StudyDocument8 paginiReliability-Centered Maintenance A Case StudyflavianosamelÎncă nu există evaluări

- Progress in Nuclear Energy: Pawel Terlikowski, Józef Paska, Karol Pawlak, Jakub Kali Ński, Dawid Urbanek TDocument4 paginiProgress in Nuclear Energy: Pawel Terlikowski, Józef Paska, Karol Pawlak, Jakub Kali Ński, Dawid Urbanek TYohanes AnggoroÎncă nu există evaluări

- 1AC - NukesDocument32 pagini1AC - NukesDan LermanÎncă nu există evaluări

- Us Er Deloitte Power and Utilities PracticeDocument20 paginiUs Er Deloitte Power and Utilities PracticeAnanthakumar AÎncă nu există evaluări

- Reliability and ResilienceDocument12 paginiReliability and ResilienceMarysol AyalaÎncă nu există evaluări

- Nuclear Power Literature ReviewDocument5 paginiNuclear Power Literature Reviewknoiiavkg100% (1)

- Electric Power Industry Operational and Public PolDocument40 paginiElectric Power Industry Operational and Public PolKo Ko PaingÎncă nu există evaluări

- Gallagher, Carol: Subject: AttachmentsDocument25 paginiGallagher, Carol: Subject: AttachmentsEnformableÎncă nu există evaluări

- Deployment of Grid-Scale Batteries in The United StatesDocument30 paginiDeployment of Grid-Scale Batteries in The United StatesKirn ZafarÎncă nu există evaluări

- Ac Reily 2Document14 paginiAc Reily 2Rafsan Al- AminÎncă nu există evaluări

- Demand Side Management Benefits and Challenges - Goran StrbacDocument8 paginiDemand Side Management Benefits and Challenges - Goran StrbacHamid KhanÎncă nu există evaluări

- 2014 Demsee SDocument8 pagini2014 Demsee SДенис ЛяпуновÎncă nu există evaluări

- Nuclear Electric Power: Safety, Operation, and Control AspectsDe la EverandNuclear Electric Power: Safety, Operation, and Control AspectsÎncă nu există evaluări

- Kadoya2005 PDFDocument10 paginiKadoya2005 PDFkaren dejoÎncă nu există evaluări

- Probabilistic Assessment of Power SystemsDocument23 paginiProbabilistic Assessment of Power SystemsedrevolloÎncă nu există evaluări

- Accelerating Deep Decarbonization PDFDocument159 paginiAccelerating Deep Decarbonization PDFRaquel CadenasÎncă nu există evaluări

- Wind Turbine Drivetrain Condition Monitoring - An: S. Sheng and P. VeersDocument21 paginiWind Turbine Drivetrain Condition Monitoring - An: S. Sheng and P. VeersanteoprivatoÎncă nu există evaluări

- Taming The Power GridDocument20 paginiTaming The Power Gridlisused100% (1)

- Drivetrain Conditions MonitoringDocument21 paginiDrivetrain Conditions MonitoringanteoprivatoÎncă nu există evaluări

- MaintenanceofaSmall ScaleParabolicTroughDocument9 paginiMaintenanceofaSmall ScaleParabolicTroughjbb_sitÎncă nu există evaluări

- Cal Berkeley-Pramanik-Sergent-Leventhal-1AC-2AC-1AR-NDT-Round1Document52 paginiCal Berkeley-Pramanik-Sergent-Leventhal-1AC-2AC-1AR-NDT-Round1Ben CrossanÎncă nu există evaluări

- A Reliability Perspective of The Smart GridDocument8 paginiA Reliability Perspective of The Smart GridtyaskartikaÎncă nu există evaluări

- General Electric Research PaperDocument8 paginiGeneral Electric Research Paperyscgudvnd100% (1)

- Analysis of Spot Prices Arrangements Electricity: IN Deregulated MarketDocument6 paginiAnalysis of Spot Prices Arrangements Electricity: IN Deregulated MarketumairÎncă nu există evaluări

- Understanding Variability and Uncertainty of PhotoDocument19 paginiUnderstanding Variability and Uncertainty of Photoyeprem82Încă nu există evaluări

- IET Educational (Xiao-Ping Zhang)Document17 paginiIET Educational (Xiao-Ping Zhang)Mayita ContrerasÎncă nu există evaluări

- Life Cycle ManagementDocument17 paginiLife Cycle ManagementIsrael DanielÎncă nu există evaluări

- G PST Vision For The Control Room of The Future V0.5 FinalDocument27 paginiG PST Vision For The Control Room of The Future V0.5 FinalNataliaÎncă nu există evaluări

- 2009-04-25 SEC Petition For Executive OrderDocument15 pagini2009-04-25 SEC Petition For Executive OrderThomas SaporitoÎncă nu există evaluări

- Dynamic Energy Response WPDocument12 paginiDynamic Energy Response WPwidayat81Încă nu există evaluări

- Small Modular Reactors: A Call For Action, by William J. Madia, Gary Vine, and Regis MatzieDocument61 paginiSmall Modular Reactors: A Call For Action, by William J. Madia, Gary Vine, and Regis MatzieHoover InstitutionÎncă nu există evaluări

- Economic Regulation of Utility Infrastructure 0Document39 paginiEconomic Regulation of Utility Infrastructure 0Favio MontenegroÎncă nu există evaluări

- Selling SolarDocument7 paginiSelling SolarwhennÎncă nu există evaluări

- Flexible Operation of Thermal Power Plants - NTPCDocument57 paginiFlexible Operation of Thermal Power Plants - NTPCmarishankar46115Încă nu există evaluări

- Power Plan: Rethinking Policy To Deliver ADocument32 paginiPower Plan: Rethinking Policy To Deliver Ashadydogv5Încă nu există evaluări

- Regulatory Impact of The 2021 Texas Energy CrisisDocument12 paginiRegulatory Impact of The 2021 Texas Energy CrisisjgravisÎncă nu există evaluări

- Creating An International Forum-The Success Story of The International Forum For Reactor Aging Management (IFRAM)Document8 paginiCreating An International Forum-The Success Story of The International Forum For Reactor Aging Management (IFRAM)SHEREEN RAMIREZÎncă nu există evaluări

- Integratingelec PDFDocument40 paginiIntegratingelec PDFRobbie ThompsonÎncă nu există evaluări

- RenewDocument120 paginiRenewkandavel71Încă nu există evaluări

- Nuclear Power Stations CourseworkDocument8 paginiNuclear Power Stations Courseworkbcqta9j6100% (2)

- Least-Cost Planning: Issues and Methods: Fred C. Schweppe, M. William J. Burke, MerrlllDocument9 paginiLeast-Cost Planning: Issues and Methods: Fred C. Schweppe, M. William J. Burke, MerrlllzhaobingÎncă nu există evaluări

- Sustainable Energy Technologies and AssessmentsDocument16 paginiSustainable Energy Technologies and AssessmentsOsama QaziÎncă nu există evaluări

- David Lochbaum House Testimony 05-13-2011Document32 paginiDavid Lochbaum House Testimony 05-13-2011montagesÎncă nu există evaluări

- EEL6936 Homework - 2: Submitted By-Ratik Mittal U37601955Document9 paginiEEL6936 Homework - 2: Submitted By-Ratik Mittal U37601955Ratik MittalÎncă nu există evaluări

- 300 - CHP - EPA (Final) W-Apps PDFDocument244 pagini300 - CHP - EPA (Final) W-Apps PDFAndres GonzalezÎncă nu există evaluări

- Tariff Order 9 of 2014-TANGEDCODocument316 paginiTariff Order 9 of 2014-TANGEDCOkkarthi20Încă nu există evaluări

- Final Report SecondDocument37 paginiFinal Report Secondswedana.stock6221Încă nu există evaluări

- sw8 chp06Document22 paginisw8 chp06api-115560904Încă nu există evaluări

- Steca Solarix PRS Instruction English - Uputstvo Solarni PaneliDocument10 paginiSteca Solarix PRS Instruction English - Uputstvo Solarni PaneliAleksandar StankovićÎncă nu există evaluări

- Mec 108 Exam Jan 2022Document1 paginăMec 108 Exam Jan 2022Inyiama CynthiaÎncă nu există evaluări

- Assignment 1Document6 paginiAssignment 1TommyVercettiÎncă nu există evaluări

- Ee9al Ee5d Ballesteros Mariano PDF File 1Document3 paginiEe9al Ee5d Ballesteros Mariano PDF File 1jenixson tamondongÎncă nu există evaluări

- Energy Transformations: Hydroelectric Power ModelDocument2 paginiEnergy Transformations: Hydroelectric Power ModelJuaymah Maureen FajardoÎncă nu există evaluări

- Effect of Dust On Performance of Solar CellDocument4 paginiEffect of Dust On Performance of Solar CellEditor IJTSRDÎncă nu există evaluări

- Design and Layout Problem For A Combined Gas-Vapor Power Plant GeneralDocument68 paginiDesign and Layout Problem For A Combined Gas-Vapor Power Plant GeneralEphraim RamosÎncă nu există evaluări

- SPF 4000-12000T DVM User ManualDocument33 paginiSPF 4000-12000T DVM User ManualJohnny Alberto GaleanoÎncă nu există evaluări

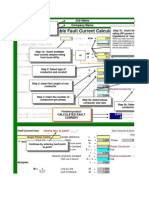

- Fault Current CalculationDocument11 paginiFault Current CalculationSaroj Kumar MallickÎncă nu există evaluări

- A Fundamental Perspective On Chilled Water SystemsDocument25 paginiA Fundamental Perspective On Chilled Water SystemsAntonio LebrunÎncă nu există evaluări

- NiMH Charger Application ManualDocument4 paginiNiMH Charger Application ManualFred BohnÎncă nu există evaluări

- Specsizer 201: Intermediate: Tips & ToolsDocument49 paginiSpecsizer 201: Intermediate: Tips & Toolsrolito342010Încă nu există evaluări

- Combustion Chamber Design and Modern DevelopmentDocument7 paginiCombustion Chamber Design and Modern DevelopmentNidushan NethsaraÎncă nu există evaluări

- Considerations of Photovoltaic System Structure Design For Effective Lightning ProtectionDocument9 paginiConsiderations of Photovoltaic System Structure Design For Effective Lightning ProtectionRodrigoÎncă nu există evaluări

- Urban Planning Portfolio 1Document1 paginăUrban Planning Portfolio 1api-525985532Încă nu există evaluări

- Air Track WS - 9200504Document8 paginiAir Track WS - 9200504Angela BradleyÎncă nu există evaluări

- User Manual: Touch Control LED LampDocument1 paginăUser Manual: Touch Control LED LampHector LuisÎncă nu există evaluări

- Danfoss Sc18clDocument2 paginiDanfoss Sc18clYosephanderÎncă nu există evaluări

- 3 QuestionDocument7 pagini3 Questionمحمد مسعدÎncă nu există evaluări

- YfyufDocument2 paginiYfyufSabariyantoÎncă nu există evaluări

- FP500 Top Calgary Based Companies by Employees 2017 06Document3 paginiFP500 Top Calgary Based Companies by Employees 2017 06anon_196354931Încă nu există evaluări

- Quest Circuits 2 KeyDocument4 paginiQuest Circuits 2 KeyCarlos OrtizÎncă nu există evaluări

- Faculty of Engineering & Technology Seventh Semester B.E. (Electrical Engg.) (C.B.S.) Examination Elective-I: I.T. & Its Application in Power System Control ORDocument2 paginiFaculty of Engineering & Technology Seventh Semester B.E. (Electrical Engg.) (C.B.S.) Examination Elective-I: I.T. & Its Application in Power System Control ORlalitkumar bannagareÎncă nu există evaluări