Documente Academic

Documente Profesional

Documente Cultură

BSEB

Încărcat de

Aditya Kislay0 evaluări0% au considerat acest document util (0 voturi)

211 vizualizări118 paginiTender Details

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentTender Details

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

211 vizualizări118 paginiBSEB

Încărcat de

Aditya KislayTender Details

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 118

8InAk S1A1L LLLC1C1kICI1 8CAkD, A1NA

DLAk1MLN1 CI kUkAL LLLC1kIIICA1ICN

nC1lCL lnvl1lnC 1LnuL8

Sealed Lenders are lnvlLed by Chlef Lnglneer (8L) for 8ural LlecLrlflcaLlon work whlch comprlses of

Supply of maLerlals & equlpmenLs and ConsLrucLlon of 33/11 kv SS, 33 kv, 11 kv & L1 Llne,

11/0.433 kv uSS & 8L servlce connecLlons for Lhe followlng dlsLrlcLs on 1urn-key basls:-

Sl.

no

.

nl1 no. name of

ulsLL.

1oLal

LsLlmaLed

cosL

( 8s. ln

Lakh)

LarnesL

Money (

8s. ln Lakh)

CosL of

Lender

documenLs

( 8s. ln

Lakh)

LasL daLe of

Submlsslon

of bld

( upLo 1.00

M)

8ld

openlng

daLe

( arL-l)

aL 3.00

M

1 nl1-71/8/8SL8/2012 Ararla 33864.68 677.2936 1.00 09.08.12 09.08.12

2 nl1-72/8/8SL8/2012 8anka 23131.60 302.6320 1.00 09.08.12 09.08.12

3 nl1-73/8/8SL8/2012 8ho[pur 19083.20 381.66394 1.00 09.08.12 09.08.12

4 nl1-74/8/8SL8/2012 Caya 37640.70 1132.8140 1.00 09.08.12 09.08.12

3 nl1-73/8/8SL8/2012 klshangan[ 23728.82 474.3764 1.00 09.08.12 09.08.12

6 nl1-76/8/8SL8/2012 nalanda 43646.70 912.9339 1.00 09.08.12 09.08.12

7 nl1-77/8/8SL8/2012 nawada 26012.74 320.2348 1.00 10.08.12 10.08.12

8 nl1-78/8/8SL8/2012 aLna 36113.64 1122.3128 1.00 10.08.12 10.08.12

9 nl1-79/8/8SL8/2012 urnea 38423.93 768.3186 1.00 10.08.12 10.08.12

10 nl1-80/8/8SL8/2012 8ohLas 30390.38 611.8117 1.00 10.08.12 10.08.12

11 nl1-81/8/8SL8/2012 Slwan 38679.91 773.3982 1.00 10.08.12 10.08.12

LllglblllLy CrlLerla for 1ender documenLs, eLc are avallable ln downloadable form aL webslLes

hLLp,//bseb.blh.nlc.ln uownloaded Lender documenL musL be accompanled wlLh uemand urafL ln

favour of 8SL8, 8L AccounLs payable aL aLna Lowards Lhe cosL of 8CC falllng whlch Lhe Lender

shall summarlly be re[ecLed. 1ender documenL can also be purchased from Lhe offlce of Lhe

underslgned agalnsL Lhe paymenL of cosL of 8.C.C. upLo 08.08.2012 Llll 3.00 M by demand drafL

as above. re-bld meeLlng ls scheduled on 23.07.12 aL 11.00 AM aL 8lhar SLaLe LlecLrlclLy 8oard,

vldyuL 8hawan, aLna.

Sd/-

Ch|ef Lng|neer (kL)

lor complalnLs regardlng corrupLlon 8lhar SLaLe LlecLrlclLy 8oard help llne no. 9431821483/0612-

2304969

Consumer can deposlL elecLrlclLy bllls vla Sahaz vasudha CenLer or vla bsebbllls.org

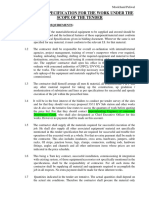

(DEPARTMENT

N

TE

THE WORK OF VILLAG

DISTRICT OF 121231 121231 121231 121231,

(General Cond

NT OF RURAL ELECTRIFIC

NIT No. 71/PR/BSEB/ /2012

TENDER SPECIFICATION

FOR

GE ELECTRIFICATION ON TURN KEY

STATE OF BIHAR UNDER RAJIV GAN

VIDYUTIKARAN YOJANA

onditions and General Technical Requiremen

COST

VOLUME-I

ICATION)

Y BASIS IN THE

NDHI GRAMMIN

ents)

T - 1,00,000/-

Page 1 of 67

BIHAR STATE ELECTRICITY BOARD

(DEPARTMENT OF RURAL ELECTRIFICATION)

PREAMBLE

TO

TENDER NOTICE NO. 71 /PR/BSEB /2012

FOR THE WORK OF VILLAGE ELECTRIFICATION ON TURN KEY BASIS IN

THE DISTRICT OF ARARIA, STATE OF BIHAR UNDER RAJIV GANDHI

GRAMMIN VIDYUTIKARAN YOJANA

1.1 General

1.1.1 This tender paper relates to composite work of supply of materials and equipments,

Erection, testing and commissioning of 33/11 KV P/S/S, 33 KV Line, 11 KV Line,

LT Line and Distribution Sub Station for electrification of villages and to provide

BPL connections in the district Araria on TURNKEY basis under RGGVY:

1.1.2 The total estimated cost of the tender is Rs. 33864.68 lakhs (For Part-A- Rs.

22147.69 lakhs and for Part-B Rs. 11716.98 lakhs)

The estimated cost has been furnished in the NIT, which is tentative and

may vary depending upon the actual volume of work. However, payment will be

made for the actual work done based upon the item wise unit rates. The Board

reserves the right to include or exclude any village and habitations.

1.1.3 The tenderer should submit their offer for the complete works of the package,

subject to fulfillment of the requisite eligibility criteria.

1.1.4 The Board will provide no foreign exchange or import license to the contractor in

connection with this contract.

1.1.5 Full technical as well as financial credentials of the tenderer should be furnished.

1.1.6 The tenderer will be deemed to have made themselves acquainted with any special

difficulty associated with the site and work indicated in the tender including any

additional cost or expense which need to be incurred to ensure full compliance with

current statutory regulation in force. The prices quoted shall include the cost of

Right of way, way leave, crop/tree compensation, forest clearance, any statutory

Page 2 of 67

fees, whatsoever, for charging of equipments and lines etc, if any. All expenditures

towards the above shall be borne by the contractor/tenderer. However, BSEB shall

extend all assistance in obtaining the clearances from the Govt. Deptt.

1.1.7 The tenderer and all others receiving enquiry documents (whether they submit the

tender or not) shall treat specification and other documents attached there on as

confidential.

1.1.8 The tenderer shall have to keep a minimum strength of manpower at site for

execution of the project as given below:-

1 Team Leader

He will reside at Patna on a full time basis throughout the

execution of the project.

Qualifications and Experience:

Team Leader will be a graduate Electrical engineer with

minimum 15 years of experience in power sector in

erection/commissioning/ operation/ maintenance/ project

management in 33 KV Distribution system including PSS,

DSS, ABC, U/G cable, O/H, lines etc.

2 Project Engineer Project Engineer will be the in-charge of the District where

village electrification work under RGGVY scheme is being

implemented.

Qualifications and Experience: Project Engineer will be a

graduate Electrical engineer having minimum 7 years of

experience in power sector in erection/commissioning/

operation/ maintenance/ project management in 33 KV

Distribution system including PSS, DSS, ABC, U/G cable,

O/H, lines etc.

He should be stationed on full time basis in his area of

jurisdiction for entire contract period.

3 Quality Control

Engineer

Quality Control Engineer will work in close co-ordination with

the site supervisor, Project Engineer to effectively control the

quality for the execution of the work.

Qualifications and Experience:

Quality Control Engineer/material Management Engineer

will be a graduate Electrical engineer having minimum 4 years

of experience in power sector in erection/commissioning/

operation/ maintenance/ project management upto 33 KV

Distribution system including PSS, DSS, ABC, U/G cable,

O/H, lines etc.

Page 3 of 67

4 Site Supervisors Minimum one for each block. He will supervise the

electrification work.

Qualifications and Experience:

He should be a diploma holder with a minimum 4 years

of experience in supervision of line/Station works of any

electrical utility.

The tenderer shall keep sufficient experienced strength of man power in

consistence with the target of completion of the villages and power sub-stations and

to be kept at site during the period of execution.

1.1.9 The tender price should include all expenses relating to labour and shall include

shift working, overtime, incentive etc. to ensure completion of work within the time

fixed by the Purchaser/ BSEB.

1.1.10 Any restriction of working hour due to regulation requirement applicable at site

shall have to be adhered to by the tenderer. All boarding, lodging, traveling

allowance, transportation cost, labour cost etc. shall have to be borne by the

tenderer.

1.1.11 No claim on account of labour problems and other types of hindrances in work at

site will be entertained by BSEB.

1.1.12 The tenderer will have to create proper storing facility as well as office facility at

site of their own.

1.1.13 The tenderer will have to make their own security arrangement for protection of

men and material.

1.1.14 Unless warranted by the utility, post bid opening correspondences will not be

allowed.

1.2 Technical

1.2.1 The work shall be executed strictly as per REC specifications & guidelines.

Specification not provided by REC, if any, will have to be got approved by BSEB.

1.2.2 All equipments to be supplied should conform to REC specifications with latest

amendment. Deviation may be got approved by BSEB.

1.2.3 For any item not covered in REC specifications, Board's specifications shall be

adopted or may be got approved by BSEB.

Page 4 of 67

1.2.4 All clearance as per Indian Electricity Act and modern practices as amended up to

date will have to be achieved and maintained.

1.2.5 Pre-dispatch inspection of materials & equipments shall be carried out as per REC

guidelines. Materials may be inspected by authorized representative/ authorized

agency of BSEB either at place of manufacturing or at work site.

1.2.6 Complete technical data and particulars of the equipments offered should

accompany Part-l of the tender.

1.3 Commercial

1.3.1 The payment of work for Part A will be done under RGGVY scheme while for

Part- B will be done under State Plan/ BSEB.

1.3.2 Modalities of payment to the tenderer will be as per REC guidelines. No deviation

shall be allowed.

1.3.3 a. The tenderer participating in this tender must satisfy the conditions as stipulated

in paragraph 4.0.

1.3.3 b. Rate for BPL connection has been approved by REC as maximum upto Rs.

2200/- per connection. As such the rate of BPL connection is limited to a maximum

of Rs. 2200/- per connection.

1.3.4 B.S.E.B. reserves the right to assess or get assessed the financial and technical

capability of the tenderer independently.

1.3.5 OWNER SUPPLIED ITEMS

If any equipment or material is supplied by the Board, the contractor will have to

arrange the loading of material from the stores of the Board and its safe transportation to

the site stores of the contractor. The unloading, storing, security, insurance etc of the

Board's supplied materials will be the responsibility of the contractor. The cost of such

supplied materials by the Board will be deducted from the contractor's bill. The rates

applicable for the purpose of deduction will be the awarded rates or the issue rates of the

Board whichever is higher.

The contractor will furnish indemnity bond for safe custody of materials / equipments

supplied by the Board.

Page 5 of 67

BIHAR STATE ELECTRICITY BOARD

(DEPARTMENT OF RURAL ELECTRIFICATION)

INVITATION OF BID FOR RURAL ELECTRIFICATION WORK AGAINST NIT NO.

71/PR/BSEB/2012.

2.1 GENERAL

Sealed Tenders in duplicate from experienced and eligible firm / agency / person

for construction of 33/11 KV PSS, 33 KV Lines, 11 KV Lines, LT lines and to

provide BPL connections and allied works on TURN KEY BASIS in the District

of Araria Bihar State under RGGVY scheme are invited on behalf of the Bihar

State Electricity Board, Vidyut Bhawan, J.N. Nehru Marg, Patna-800021.

SCOPE-

Sr.

No.

Item of Work Unit

Quantity

in Part-A

(under

RGGVY)

Quantity

in Part-B

(under

State

Plan/

BSEB)

Total

Quantity

Estimated

Cost (Rs. in

Lakh)

1 2 3 4 5 6

7

Blocks covered Nos

9

Un-electrified village (UEV)

covered

Nos 30

30

Electrified village (EV) covered Nos 669

669

BPL covered Nos 267352 20107 287459

Habitations covered including

villages

Nos 2271

2271

A 33 KV Works:

1 New 33/11 kV S/s

(a) New 1 x 5.0 MVA S/s Nos.

(b) New 2 x 5 MVA S/s Nos. 3 2.00 5.00

(c) New 3 x 5 MVA S/s Nos. 1.00 1.00

2

Augmentation of Ex. 33/11kV

S/S

Page 6 of 67

(a) 2 x 3 to 2 x 5 MVA Nos. 5 5.00

33864.68

(b) 1 x 3.15 to 1 x 5 MVA Nos. 1 1.00

3

New 33 KV Lines with ACSR

DOG Conductor

Kms 75 39.00 114.00

4

Reconductoring of 33kV line

with ACSR Dog

Kms 9.75 9.75

5

Reconductoring of 33kV line

with ACSR Dog on rail pole

double ckt

Kms

6 33 kV Bay extension Nos. 6 6.00

7 11 kV Bay extension Nos. 10 10.00

8 33 KV New Bay Nos.

11 KV New Bay No. 11.00 11.00

Sub-Total (A) : 33 KV Works

B. 11 KV Works:

1

New Distribution Sub-

Station(s)

(a) 25 KVA (3Ph) Nos. 2944 2558 5502

(b) 63 KVA (3Ph) Nos.

20 20

(c) 100 KVA (3Ph) Nos.

10 10

(d) Section DP with 11 kV

TPMO

Nos. 136

136.00

2 New 11 KV Lines

(a) Main line with ACSR

Weasel on PSC

Kms 601.08 248.91 849.99

(b) Main line with ACSR

Rabbit on PSC

Kms 128 128.00

(c) Spur line with ACSR

Weasel on PSC

Kms 901.58 373.54 1275.12

(d) Reconductoring of Ex. 11

KV Line

Kms 250 250.00

(e) 11kV line with insulated

cable equivalent to ACSR

Weasel conductor

Kms

5 5.00

C. LT Works

1 New LT Lines

(a) 1Ph 2W with AAAC

Squirrel

Kms 470.22 248.68 718.90

(b) 3Ph 4W with AAAC

Squirrel

Kms 313.483 165.78 479.26

(c) ABC (3x50 + 1x16 + 1x35) Kms 313.483 265.25 578.73

(d) ABC (2x16 + 25) Kms 208.985 176.83 385.81

(e) 3Ph 4W with insulated

cable equivalent to ACSR

Squirrel

Kms

5 5.00

Page 7 of 67

(f) Conversion of 1Ph 2W LT

line to 3Ph 4W LT Line on

ACSR squirrel conductor

Kms

5 5.00

Sub-Total (C) : LT Works

D. Service Connections

1 BPL Service Connection(s) Nos. 267352 20107 287459

Sub-Total (D) : BPL Service

Connection(s)

33 or 11kV Road Crossing Nos. 5 5.00

Conversion of 11kV line from

2Ph 2W to 3Ph 3W on ACSR

Weasel conductor

Kms 56 56.00

2.2 The volume of work indicated above is tentative and may vary. The Board reserves

the right to change the volume of work/ villages/ tolas as per actual field

requirement to be decided by BSEB.

The project aims at electrification of leftover villages/ tolas & BPL households. As

such, Board reserves the right to include any village/ tola & BPL household which

has not been covered in the project.

Any discrepancy between specification and bid if not specifically / clearly brought

out in the schedule will not be considered as a valid deviation.

2.3 GENERAL INFORMATIONS

2.3.1 Bihar State Electricity Board, herein after called Purchaser /Board/Owner will

receive tenders on turnkey basis for complete work of construction of 33/11 KV

PSS, 33 KV Lines, 11 KV Lines, LT lines and to provide BPL connections, Bay

extensions and allied works including supply of all related materials as per REC

specification on Turnkey basis for trouble free and successful operation as set forth

in this tender specification. All tenders shall be prepared and submitted in

accordance with these instructions after due physical inspection of site. Tenders

shall not be accepted after the time and date fixed for receipt of tenders as set out in

the tender documents/ NIT.

Page 8 of 67

2.3.2 Sealed tenders for each districts in duplicate in two parts containing Technical and

Commercial offer (Part-l) and Price Offer (Part-Il) both in separate sealed covers

clearly superscribing Part-I or Part-II on the cover are invited by BSEB from

eligible, bonafide and experienced contractors having sound financial and technical

background and management capacity and who have record of successful

engineering, manufacturing, supply, delivery, storing, erection, supervision, testing

& commissioning of the equipments & materials required for the works herein. The

eligibility criteria have been detailed separately in the tender specification.

Separate tenders have been invited for village electrification in 11 districts in the

State of Bihar by the Board bearing NIT No. 71/PR/BSEB/2012 to

81/PR/BSEB/2012 under single notice. Tenderer can participate maximum for two

districts. In case tenderer submits bids for more than two districts, the bids will be

opened for two districts only. Other bids of the same tenderer will not be

considered.

The tenders will be opened NIT No. wise in ascending order.

2.3.3 DETAILS OF TENDER

a) Tender Notice No. 71 /PR/BSEB /12

b) Cost of Tender document (non refundable) Rs.1,00,000.00

C) Amount of Earnest Money Rs. 677.2936 lakhs

d) Last Date for sale of Tender document Up to 5.00 PM of 08.08.2012

e) Last Date for submission of Tender Upto 13.00 Hrs. on 09.08.2012

f) Date and time of opening of Tender ( Part- I ) At 15.00 Hrs. on 09.08.2012

g) Date of Pre-bid meeting At 11.00 hrs. on 25.07.2012

h) Receipt of query for Pre-bid meeting Upto 21.07.2012

2.3.4 (a) Tender documents alongwith technical specifications etc. are available in

downloadable form at website http://www.bseb.org or http://www.bseb.bih.nic.in

Downloadable tender documents must be accompanied with Demand Draft issued

not later than the date of sale and drawn in favour of BSEB, RE Accounts payable

at Patna towards cost of BOQ, failing which the tender shall summarily be rejected.

Tender document can also be purchased from the office of the Chief Engineer (RE),

Bihar State Electricity Board, Vidyut Bhawan, Jawahar Lal Nehru Marg, Patna-

800021 on application together with a money receipt of Rs. 1,00,000.00 ( One

Lakh) only ( non-refundable) for each copy. The amount should be deposited

with Accounts Officer (RE), Bihar State Electricity Board, Patna by

Page 9 of 67

Bank Draft issued by any Nationalized Bank of India or scheduled bank in favour

of BSEB, RE Accounts payable at Patna.

(b) Pre-bid Meetings:-Pre bid meetings will be organised with the prospective tenderers on

25.07.12 at 11:00 Hrs. for understanding and clarifications at Vidyut Bhawan,

Jawaharlal Nehru Marg, Patna. The tenderers may send their queries upto 21.07.12 to

CE (RE) on e-mail cere.bseb@gmail.com .

2.3.5 Board shall not be responsible for non-receipt of the tender by the tenderer in case of delay

by postal department, if the tender is sent by post.

2.3.6 The tender documents are not transferable and the tenders received after expiry of

prescribed date and time will not be considered.

2.3.7 Issue of tender specification/documents will not be construed to mean that such tenderers

are automatically considered qualified. The Board reserves the right to accept/reject any or

all tenders without assigning any reason whatsoever. The Board, however, does not bind

itself to accept the lowest tender.

2.3.8 Not withstanding as stated above, B.S.E.B reserves the right to assess the tenderers

capacity and capability to perform the contract and relax the qualifying requirements at any

stage.

2.3.9 The Board will not be responsible for or pay for expenses or losses, which may be

incurred by any tenderer in the purchase and preparation of the tender.

2.3.10 Telegraphic tender will not be accepted.

2.3.11 The tenderers shall quote their prices as well as all types of taxes, duties, freight &

insurance, (as per Bid Proposal) except State and local taxes etc. like octori/entry

tax.

The prices for each item as per schedule should be furnished along with the tender.

For the erection part of the bid, the tenderer should not quote less than 20% of total

contract price. If for erection part of the bid a tenderer quotes less than 20% of total

contract price, the price for the erection part shall be deemed to be 20% of total

contract price and accordingly the payment of supply portion shall be restricted to

80% of total contract price.

2.3.12 The contractor shall supply the necessary drawing /shop drawings and

specifications of all parts.

2.3.13 The contractor will have to provide suitable erection, supervision personnel to

supervise the work of erection of the equipment/ lines undertaken by him/them.

Page 10 of 67

2.3.14 The contractor shall quote the price for complete erection, testing &

commissioning of the power sub-station, distribution sub-station, line, BPL

Connection and associated works with all equipments needed for village

electrification works on Total Turnkey Basis.

2.3.15 Tenders not covering the entire scope of work as detailed in the tender specification

shall be treated incomplete and hence rejected.

2.3.16 (i) Contractor shall have to arrange his own workshop if required within the work

site.

(ii) All security arrangement for watch and guard at work site shall be made by

tenderer at his own cost.

2.3.17 The following works & services shall also be provided by the contractor.

i) Unloading the equipments from the rail or road transport and moving

those to storage area. Demurrage / wharf age charge, if any incurred, shall

be paid by the contractor.

ii) Opening of packing cases, inspection and checking of materials for any

damage or loss in transit shall be the responsibility of the contractor. All

claims with the concerned authorities e.g. rail, transport, insurance etc.

shall be lodged by the contractor.

iii) Complete erection of equipments, etc covered under the contract, final

preparation for testing, commissioning, final run and acceptance tests and

putting the sub-stn./ plant/line into operation.

iv) All consumable, stores required for the above erection and

commissioning works.

v) Watch and guard to ensure security and safety of materials under his

custody and at works site.

vi) All erection tools, lifting tackles, also all equipments, tools & tackles for

transportation at site.

vii) Third party insurance at site and insurance of personnel employed at site

as required under workman's compensation act.

viii) Necessary Engineers and supervision personnel with approved licenses as

per provision of IE Rules as amended up to date.

Page 11 of 67

ix) Contractor shall take all safety precautions during work and the workmen

must use safety belts, hand gloves, masks and other devices as may be

necessary for safety of the personnel.

x) The contractor shall provide operating personnel during trial tests and till

the PSS , DSS, lines and equipments etc. are taken over by the Board as

specified in taking over Clause, defined later.

2.4 Unless brought out clearly, the bidder shall be deemed to conform strictly to the

provisions of the bidding documents. All deviations from the specifications shall be

clearly brought out in respective schedule of deviations. Any discrepancy between

specification and bid if not clearly brought out in the schedule, will not be

considered as a valid deviation.

2.5 The respective rights of Board/Purchaser and Bidders /tenderers /contractors shall

be governed by the Tender documents/ contracts signed between the Board &

contractor.

3.0 SCOPE OF WORK

The work is to be taken up on total turnkey basis. This includes engineering,

design, preparation of all drawings, detailed route identification and alignment,

manufacture, testing of the materials at manufacturers works, supply of materials

and equipments as per REC specifications, loading, unloading, transportation,

delivery, storage at works sites, erection and commissioning in all respect of

33/11KV P/S/S, 33KV Line, 11 KV Line, LT line, DSS, BPL connection, Bay

extension and allied works on turnkey basis and handing over of the same to BSEB.

Detailed scope of work is specified in the technical specification which interalia

includes the followings.

For electrification of villages and habitations, a detailed execution programme will

be decided by BSEB prioritizing the pockets of villages/ tolas which are partially

electrified. Priority of work will be decided by the nodal officer in consultation

with Chief Engineer (RE) at the start of execution of work. Also, the redressal of

grievances/ complains/applications already received will be given top priority in

course of electrification work of the villages.

3.1 GENERAL

i) Engineering, design of the project.

Page 12 of 67

ii) Identification of materials and equipments required to execute the works

contemplated in the project.

iii) Procurement of materials and equipment required for the project as per

specification.

iv) Storage of materials received and transport of the materials to the working sites.

v) Execution of the works envisaged in the project as per specifications given in

the tender specification.

vi) Erection, testing & commissioning of contract works.

vii) Preparation of project completion report / closure proposal

viii) Handing over the works to the employer for taking into commercial service.

3.2 DETAILS OF PACKAGE

The details of package has been furnished in the tender specification .The further details, if any, about the

area / villages/ habitations shall be furnished by the Electrical Superintending Engineer of the supply

Circle and Electrical Executive Engineer of the supply Division or such officer as authorized by BSEB

under whom the package have been proposed.

3.3 SERVICES

i) Detailed identification including route alignment, profiling, pole spotting, check

survey for electrification of villages, tolas and to provide BPL service

connections with all necessary materials and labour.

ii) Walk through identification of the electrical network in the project area for

planning the execution of the work.

iii) Preparation of all relevant drawings.

iv) Supply of poles, and all accessories.

v) Supply of all materials required to complete the project including the materials

& equipments specified in the bill of materials.

vi) Supply and erection of Earthing materials as specified.

vii) Erection, stringing, sagging, testing and commissioning of all the lines

specified.

viii) Erection, testing and commissioning of complete works.

ix) Supply & erection of lines with towers or cables for River Crossing locations/

Railway crossing locations/crossing of existing lines/crossing of Roads/

crossing of PTCC lines and other places, wherever required.

Page 13 of 67

x) The Right of way, way leave, crop/tree compensation, forest clearance, if any

will be the responsibility of the contractor. All expenditures to wards the above

shall be borne by the contractor/tenderer. However, BSEB shall extend all

assistance in obtaining the clearances from the Govt. Deptt.

xi) The tenderer will have to carry out the execution of the works as per relevant

standards and codes of practices. Although some guide lines have been given

with regard to the execution of the works, it remains the responsibility of the

contractor to do the works complying to the specifications/ statutory

requirements and to the satisfaction of the engineer, conduct the needed site

checks and tests (apart from factory tests of materials and equipments) before

and after energisation and commissioning of equipment and lines into service

before handing over to the Employer for commercial operation.

3.4 Any other item of work not specifically mentioned above but is required for

erection, testing & commissioning and satisfactory operation of the P/S/S ,

D/S/S, lines, BPL service connections etc. are deemed to be included in the

scope of contractor unless specifically excluded.

3.5 The scope of work shall cover the works in complete conformity with the

tender specification and the works specified.

3.6 All civil works required for completion of the work shall be deemed to be

included in the scope of work.

3.7 Satisfactory and safe operation of the complete P/S/S, D/S/S , lines and BPL

Connections etc. shall be deemed to have been included in the scope of the

work of the contractor.

4.0 ELIGIBILITY CRITERIA

Eligibility of the bidder will be based on meeting the minimum eligibility criteria

specified below regarding the Bidders Technical Experience and financial position as

furnished by the Bidder in the corresponding Bidding schedules. The bidder shall also

be required to furnish the information specified in the specification in their bid.

Tenderer must be a turnkey contractor who is having adequate experience in in-house

engineering and design infrastructure facilities, quality assurance and safety setup to

carry out similar type of work. The bid can be submitted by an individual firm or a joint

venture of two or more firms. Specific requirements are given below:-

4.1 The bidder.

Page 14 of 67

4.1.1 Must have successfully erected, tested & commissioned at least two sub-station

or switchyard of 33 KV class having at least three (3) circuit breaker bays during

last Seven (7) years as on the date of bid opening which must be in satisfactory

operation for at least two (2) years as on the date of bid opening.

OR

Must have successfully erected, tested & commissioned HT lines of aggregate

route length of at least 100 kms of 11 KV and /or 33 KV voltage class during

last Seven (7) years as on the date of bid opening which must be in satisfactory

operation for at least two (2) years as on the date of bid opening and must have

successfully erected, tested & commissioned at least 20 no. of 11/0.4 KV

Distribution transformer in any single year during last Seven (7) years as on the

date of bid opening which must be in satisfactory operation for at least two (2)

years as on the date of bid opening.

[Successful execution of the contract awarded by various customers as well

as number of years of satisfactory operation as on date of bid opening must be

certified by concerned customers failing which the firm will not be considered

eligible to meet the qualifying requirements].

4.1.2 Bids may be submitted by individual firms or Joint Venture firms (having one

partner as lead partner) wherein the partners jointly meet the requirement set

forth in para 4.1.1 above.

4.2 Only reputed and experienced agency or firms having sound financial/ technical

background and management capacity either individually or with associates for

undertaking such works need apply.

4.3 The tenderer must have valid electrical contractor license (H.T) issued by the competent

authority in favour of the tenderer. After award of the contract, the tenderer must have valid

electrical contractor license (H.T) issued by Govt. of Bihar.

4.4 The tenderer should furnish latest Sales Tax Registration and clearance certificate & EP F. code

number & PAN Number.

4.5 To qualify the bidder/ tenderer (single or Joint Venture) must have MAAT (Minimum Average

Annual Turnover ) for best three years out of last five financial years as stipulated below:-

Estimated cost of the project for the district x 1.5

Completion period in year/ years

The same firm or Joint Venture Firms offering bids for more than one district, the requirement of

MAAT shall be cumulative of MAAT of each bid (district) calculated on above basis.

Page 15 of 67

4.6 The bidder/ tenderer (Single or Joint Venture) shall have minimum Liquid Assets (LA) /Credit

Facility as stipulated below:-

Estimated cost of the project for the district x 3

Completion period in months

The same firm or Joint Venture Firms offering bids for more than one districts, the required minimum LA

/credit facility shall be cumulative of minimum LA /credit facility of each bid (district) calculated on

above basis.

In case of bidder being a holding company, MAAT and LA/ Credit Facility shall be that of

holding company only i.e. excluding MAAT and LA/ Credit Facility of its subsidiaries. However,

in case of bidder being a subsidiary company, MAAT and LA/ Credit Facility shall be that of

subsidiary company only, i.e. excluding MAAT and LA/ Credit Facility of its holding company.

4.7 Joint Venture Firms.

4.7.1 In case, a bid is submitted by a Joint Venture (JV) of two or more firms as partners, the Joint

Venture must comply the following minimum criteria:-

I) The lead partner shall meet, not less than 40% of the minimum

criteria as mentioned under Para 4.5 & 4.6 above for MAAT and

LA/ Credit Facility. It should be best out of last three years.

II) Each of the other partner (s) should meet not less than 25% of the

criteria as mentioned under Para 4.5 & 4.6 above for MAAT and

LA/ Credit Facility. It should be best out of last three years.

III) Joint Venture (i.e., all partners) should satisfy collectively the

criteria of MAAT and LA/ Credit Facility. In other words the

relevant figures of MAAT and LA/ Credit Facility of each of the

partners of joint Venture shall be added together to arrive at the

total capacity of Joint Venture.

4.7.2 In case of a Joint Venture, the following conditions shall also apply.

4.7.2.1 The bid and in case of successful bid. the specified form of Agreement

shall be signed so as to be legally binding on all partners (form enclosed.)

4.7.2.2 One of the partners shall be nominated as lead partner, and this authorization shall

be evidenced by submitting a power of attorney signed by legally authorized

signatories of all the partners.

4.7.2.3 The lead partner shall be authorized to incur liabilities and receive instructions for

and on behalf of any and all partners of the Joint Venture, and the entire execution

Page 16 of 67

of the contract, including payment shall be done exclusively with the lead Partner

as per Power conferred to him in the power of Attorney.

4.7.2.4 All partners shall be liable jointly and severally for the execution of the contract in

accordance with the contract terms, and a statement to this effect shall be included

in the authorization mentioned under para 4.7.2.2 above as well as in the bid forms

and in the contract forms (in case of a successful bid).

4.7.2.5 Agreement entered into by the Joint Venture Partners shall be submitted with the

bid

4.8 The bidder shall also furnish following document details with its bid.

i) A certificate from banker (as per the format) indicating various fund

based/non fund based limits sanctioned to the bidder and the extent of

utilisation as on date. Such certificate should have been issued not earlier

than three months prior to the date of bid opening. Whenever necessary

B.S.E.B may make queries with the Bidder's Bankers.

ii) The complete annual reports together with Audited statement of accounts of

the company for last five years of its own (separate) immediately preceding

the date of submission of bid.

4.9 In the event the bidder is not able to furnish the information of its own (i.e.,

separate), being a subsidiary company and its accounts are being consolidated with

its group/holding/parent company, the bidder should submit the audited balance

sheets, income statements, other informations pertaining to it only (not of its

group/Holding/Parent Company) duly certified by anyone of the authority [(i)

Statutory Auditor of the bidder/ (ii) Company Secretary of the bidder or (iii) A

certified Public Accountant] certifying that such informations/documents are based

on the audited account as the case may be.

4.10 Similarly, if the bidder happens to be a Group/Holding /Parent company, the bidder

should submit the above documents/informations of its own (i.e., exclusive of its

subsidiaries) duly certified by anyone of the authority mentioned in para 4.9 above

certifying that these informations /documents are based on the audited accounts as

the case may be.

4.11 The bidder should provide detailed information on any litigation or arbitration

arising out of the contracts completed or under execution by it over the last five

Page 17 of 67

years. A consistent history of awards involving litigation against the Bidder or any

partner of J.V may result in rejection of bid.

4.12 Any firm participating in this bid jointly with one lead partners in any capacity

shall not be associated with any other firm/lead partner quoting for this bid in any

capacity (either as Joint Venture Partner or as a sub contractor) Lead partner is also

not permitted to quote for this bid separately with different partners as a second bid.

This practice means that any lead partner or associate or partner can participate in

one and only one bid.

4.13 The tenderers shall include the following information and documents with their

tenders in the proforma enclosed.

i) Copies of original documents defining the constitution or legal status, place

of registration and principal place of business, written power of attorney of

the authorized signatory of the bidder to submit the tender.

ii) Total annual turnover in electrical construction work performed by the

tenderer in his own name (not by any other company whose name has

subsequently been changed, so as to form the current tenderer) in each of

the last five years.

iii) Experience in executing similar turnkey projects (Nature & Volumes) for

each of the last five years, and details of work in hand and contractual

commitments, clients who may be contacted for further information on

those contracts.

iv) Qualifications and experience of key site management and technical person

proposed for the contract.

v) Reports of financial standing of the Tenderer such as profit and loss

statements and auditor's report for the past five years.

vi) A certificate from a bank or reputable firm of accountants conforming the

liquidity (liquid asset and credit facilities) of the tenderer at a date one

month prior to the last date for submission of tenders.

vii) Evidence of adequacy of working capital for this contract i.e. evidence of

access of line (s) of credit and availability of other financial resources.

viii) Authority to seek references from the Tenderers bankers.

Page 18 of 67

ix) Information regarding any current litigation in which the tenderer is

involved, the parties concerned and disputed amount.

x) Statement of safety policy and safety statistics for the last 5 years.

xi) Copy of QA Certification and associated documentation.

xii) Copy of environmental policy.

4.14 Professional manpower requirement will be as per detail given in para 1.1.8 of

preamble. The tenderer is required to give C.V. of key personnel staff i.e. team

leader, project engineer, quality control engineer and site supervisor details should

be given as per enclosed schedule. The personnel as detailed in the tender para

1.1.8 may be substituted, if needed, but with equivalent or higher qualification and

experience personnel, under intimation to Chief Engineer (RE)

4.15 Notarized affidavit will be submitted by the bidder alongwith the tender that the

bidder has not been black listed by any State Govt./Central Govt. / Govt.

undertaking in India.

5.0 DOCUMENTS ESTABLISHING GOOD ELIGIBILITY AND CONFORMITY

5.1 The Tenderers are requested to furnish a compliance statement along with the technical bid. This statement shall indicate

degree of compliance (Fully compliant, partially compliant or non compliant) to all clauses and sub clauses of both Technical

specifications and General Terms and Conditions and a cross reference with relevant details to their bid shall also be given by

tender.

5.2 The tenderer shall submit a horizontal Bar Chart identifying all major activities,

mile stones and time scales to enable him to meet the Time for Completion. This

should take account of the programme given in this specification and the tenderer

should highlight any difference between this and his proposed programme in his

tender submission.

6.0 BASIS OF BID EVALUATION AND COMPARISON

6.1 Bidder has to quote for the complete scope of work under the package as stated in

this specification. Bid for part of the package will not be accepted. Bidder should

quote in hard copy as well as soft copy (in form of CD) for bid evaluation.

6.2 BSEB will examine the bids to determine whether they are complete, whether any

computational errors have been made, whether required sureties have been

furnished, whether the documents have been properly signed and whether bids are

generally in order.

6.3 (a) Arithmetical errors will be rectified on the following basis:-

If there is a discrepancy between the quoted lump-sum price and the total bid value

Page 19 of 67

obtained by multiplying individual item-wise unit price with their respective quantity,

the unit price of individual item shall prevail and lump-sum price i.e., total bid value

shall stand modified accordingly and the bid will be evaluated on the basis of so arrived

modified lump-sum price. If there is a discrepancy between words and figures, the

amount in words will prevail. If the Bidder does not accept the correction of the errors

as above, his Bid will be rejected and the amount of earnest money will be forfeited.

The work will be awarded on the basis of modified lump-sum price but not on the

basis of quoted price.

(b)The Bidder should ensure that the prices furnished in various price schedules are

consistent with each other. In case of any inconsistency in the price furnished in the

specified price schedules to be identified in Bid Form for this purpose, the Employer

(BSEB) shall be entitled to consider the highest price for the individual item for the

purpose of evaluation and for the purpose of award of the Contract / payment for the

item, use the lowest of the prices in these schedules.

6.4 The quantities of various items, covered under the package as furnished in the

specification is only provisional. For evaluation purpose, the total prices quoted for

complete work under package will be considered. The tenderer shall include in the

total cost of his tender, the cost of supply and erection & Civil work of whole of the

plant, equipments & materials including all types of taxes, duties, freight &

insurance, etc. except State or local taxes like entry tax / octoroi..

Since the quantities of items as set out in various schedules would depend upon

identification of route, the contractor shall be responsible to execute such final

quantities of the items limited to tendered quantity. Upward deviation, if any, will be

done after approval of Chief Engineer (RE) and they shall be paid for such actual

quantities based on the unit rates incorporated in the contract. For this purpose, unit

rates for each items as required in the Bid Proposal sheets are also to be quoted.

6.5 BASIS OF COMPARISON

6.5.1 Bids shall be compared for award on total lump-sum prices for the entire scope of

work under the package and adding capitalization cost of losses of the power

transformers.

Capitalization cost of losses will be evaluated as per Clause 7.0, Chapter-

2, Section-3 for Power Transformer of Volume-II (Technical Specification) of

the tender.

6.5.2 Rebates, if any, offered by any bidder shall be considered in bid evaluation.

However conditional discounts / rebates, if any, offered by the bidder shall not be

taken into consideration for evaluating. It shall, however, be considered in case of

award.

7.0 WORK SCHEDULE & TIME FOR COMPLETION OF THE PROJECT

Page 20 of 67

7.1 The completion period of the total turnkey project including all Power Sub-Stations, DSS, BPL service

connections & lines covered under the package shall be eighteen (18) months from the date of agreement.

The work of completion of PSS and corresponding lines is to be synchronized so that all works are completed

simultaneously.

Simultaneous work should be taken up in all the Power Sub-Stations of the cluster along with associated lines

and other allied works treating them as individual work sites.

7.2 The work shall be considered to be completed only when the Electrical Superintending Engineer under whom

the work is being carried out will issue certificate to this effect.

7.3 Strict adherence to the time schedule for performing the works specified in the tender specifications shall be the

essence of the contract.

7.4 The Board reserves the right to request for a change in the work schedule during pre award discussions with

successful Bidder.

7.5 The contractor shall submit a detailed PERT Network/bar chart within the time frame agreed consisting of

adequate number of activities covering various key phases of the work such as design, Procurement,

manufacturing, shipment and field erection, testing & commissioning activities within 15 (fifteen) days from

the date of agreement of the Contract for approval by Chief Engineer(RE). This network shall also indicate the

inter face facilities to be provided by the Board/owner and dates by which such facilities are needed.

Finalization of the Network/bar charts will be precondition to release of any initial advance payment to the

contractor. During the performance of the contract, if in the opinion of the Engineers, proper progress is not

maintained, suitable changes will be made in the contractor's operations to ensure proper progress without any

cost implication to the Board/owner. The interface facilities to be provided by the Board/owner in accordance

with the agreed network shall also be reviewed while reviewing the progress of the contractor.

7.6 Based on the above-agreed Network/Bar chart, weekly/fortnightly progress report shall be submitted by the

contractor as directed by the Engineer/Board.

7.7 Subsequent to the finalisation of the Network, the contractor shall make available to the Engineer/Board a

detailed programme in line with the agreed Contract Network. Such programme shall be reviewed, up dated

and submitted to the Engineer once every two months thereafter.

7.8 The above bar chart / programme shall be compatible with the owner's computer environment and furnished to

the owner on such media as desired by the owner. The details shall also be furnished on C.D as well.

7.9 Apart from the PERT, Milestone for the different activities under the scope of RGGVY is defined below:-

(i) erection and completion of full works in totality in respect of a village.

(ii) erection and commissioning of PSS and completion of 33 KV lines with all 11 KV lines.

(iii) for R&M works erection commissioning and charging of Power Transformers, VCB and connecting

them with 11 KV feeders.

8.0 LIQUIDATED DAMAGES FOR DELAY IN COMPLETION OF PROJECTS

8.1. If the contractor fails to perform the work within the specified period given

in the letter of award/contract documents, with respect to successful completion of

Page 21 of 67

testing & commissioning of the power substations, Distribution sub-stations, lines,

BPL service connections with allied works, the contractor shall pay to BSEB as

liquidated damages and not as penalty, a sum of half percent (0.5%) of the contract

price for each calendar week of delay or part thereof. However, the amount of

liquidated damages for the Contract shall be limited to a maximum of ten percent

(10%) of the total contract price. For the purpose of LD computation due to delay

in work, the contract price shall be taken as total contract price of the project.

8.2 Liquidated damages for not meeting performance guarantee during the guarantee

period shall be assessed and recovered from the agency as detailed in technical

specifications. Such liquidated damages shall be without any limitations what so

ever and shall be in addition to the damages, if any, payable under any other clause

of conditions of contract.

8.3. Equipment and materials shall be deemed to have been delivered only when all of

its components, parts are also delivered. If certain components are not delivered in

time, the equipments and materials will be considered as delayed until such time,

the missing parts are also delivered.

9.0 PRICE

The prices shall remain "FIRM" for all equipments and materials except cost of

Transformers, Cables and conductors.

The prices for each item as per price schedule should be furnished alongwith the

tender.

Bidders should furnish ex-works price for Transformers, Cables and

Conductors separately only for the purpose of computation of Price

Adjustment.

While quoting the Ex-works price, the due credit under MODVAT scheme, re-

christened as CENVAT scheme, as per relevant Government policies wherever

applicable, has to be taken into account by the bidder.

9.1 General

9.1.1 The price for execution of the entire works covered under the scope

of this Specification shall be quoted by the Bidder in the manner

specified, in the BOQ. The Ex-work price component, less advanced

will be subject to price adjustment, only for

equipment/materials/item of work specifically stated under clause

9.2 below, (for which the bidder shall quote a base price), based on

separate formulae as per price adjustment provisions given herein:

Page 22 of 67

9.1.2 Prices for Ex-work price component for all other equipments/items

except specified at clause 9.2 below, and charge for inland freight &

insurance etc. shall be FIRM and no price adjustment shall be

applicable for these components for the entire duration of the

contract.

9.1.3 No price adjustment shall be applicable on the portion of the

Contract Price payable to the Contractor as advance payment.

9.2 Methodology for price adjustment -

(a) Conductor

The price adjustment of the Ex-works price components, less advance, of

Conductor shall be as follows:-

dEC = EC [ 0.80 x ( A1 A0 ) + 0.05 x (L1 L0) ]

A0 L0

Where,

dEC = Price adjustment amount payable on Ex-work price of Conductor,

shipment-wise (if it works out negative, that would mean the amount

to be recovered by the Employer from the Contractor).

EC = Ex- work price for Conductor, shipmentwise , less advance.

A = Published prices for EC grade aluminium ingots, as published by

CACMAI/ National recognized published index acceptable to

BSEB.

L = All India consumer price index for industrial workers as published

by Labour Bureau, Shimla (Govt. of India)

Fixed portion of the ex- work price component shall be 0.15. This shall not

be subject to any adjustment.

(b) Distribution Transformer/ Station transformer/ Power Transformer

P

1

= P

0

x {0.15 + 0.23 x (C

1

/C

0

) + 0.26 x (ES

1

/ ES

0

) + 0.08 x (IS

1

/ IS

0

) +

0.05 x (IM

1

/ IM

0

) + 0.11 x (TB

1

/ TB

0

) + 0.12 x (L

1

/ L

0

)} P

0

Where,

P

1

= Price

adjustment amount shipmentwise (if it works out negative, that

would mean the amount to be recovered by the Employer from the

Contractor

P

0

= Ex-work price component of Distribution Transformer less advance.

C, ES, IS, IM & L are the price indices for materials and labour as below:

Page 23 of 67

C = Price of Copper Wire Bars, in Rupees per MT, as published by

IEEMA

ES = Price of Electrical Steel Sheets : C&F Price of Electrical Steel sheets

in Rupees per MT, as published by IEEMA

IS (Iron & Steel) = Wholesale Price Index Number for ' Iron & Steel '

(Base 1993-94 =100), as published by IEEMA.

IM ( Insulating Materials) = Price of Insulating materials, as published by

IEEMA

TB = Price of Transformer Oil Base Stock (TOBS) in Rs. / . Ltr., as

published by IEEMA

L = All India average consumer price index number, for Industrial

Workers (base 1982 = 100) as, published by Labour Bureau, Shimla

(Govt. of India)

(C ) Cables

P

1

= P

0

x {0.85 + 0.15 x(A

1

/A

0

)} - P

0

+ ( M

1

- M

0

)

Where,

P

1

= Price Adjustment amount per kilometer of cable ( if it works out

negative, would mean the amount to be recovered by the Employer

from Contractor).

P

0

= Ex- works price per Km of cable, less advance

A = Price index for PVC / XLPE as published by IEEMA

M

1

- M

0

= Change in metal component of the ex- work price of particular

type & size of cable.

M = Weight in MT of metal per Km. of Cable x Published price index of

metals per MT

The bidder has to specify in his bid metal component per Km. for each type

and size of cable.

The total adjustment for Transformer, Conductors and cables shall be

subject to a ceiling of (

+

)20 % of Ex works price.

9.2.1 (i) Subscription '0' refers to indices as on thirty (30) days prior to the date

of opening of bids (referred to as base date indices)

(ii) Subscription '1' refers to indices as on 60 days prior to the date of

shipment.

9.3 For Erection (including civil works) Price Component

9.3.1 The formula for calculation of monthly price adjustments for erection

(including civil works) price component shall be as under:

dER= ER

0

[0.22 (A

1

- A

0

) / A

0

+ 0.58 (L

1

- L

0

) / L

0

Where,

Page 24 of 67

dER = Price adjustment amount payable on Erection price component

(including civil works) for each billing.

ER

0

= Value of Erection work ( including Civil works) done in billing

period as established by the Contract, less advance.

A = Rate for Diesel Oil as published by Indian Oil Corporation which has

jurisdiction over the place of work.

L = Indian field labour index namely All India Consumer Price Index for

Industrial Workers as published by labour Bureau, Simla ( government of

India).

9.3.2 i) Subscription '0' refers to indices as on thirty (30) days prior to the date of

opening of bids

ii) Subscription '1' correspond to the month of billing.

iii) For the purpose of this Clause the billing period shall mean the billing

period as per Contract time schedule i.e. the agreed Bar Chart / PERT

Network or actual period, whichever is earlier.

iv) The billing period for various Erection activities will be as per agreed

erection Bar Chart / PERT Network indicating monthly schedule of erection

activities for completion of works.

9.3.3 The total price adjustment for Erection (including civil works) price

component shall not be subject to any ceiling whatsoever.

9.3.4 A For the purpose of Price Adjustment on ex-works price components of the

equipment, the date of shipment for Goods shall mean schedule date of

shipment or actual date of shipment, whichever is earlier. Scheduled date of

shipment will be ex-works date of dispatch, governed by the accepted PERT

Network/Bar Chart. Similarly, for the purpose of Price Adjustment on

erection (including civil works) price component, the Billing period shall

mean the billing period as per Contract time schedule i.e., the agreed Bar

Chart or actual period, whichever is earlier. The Billing period for various

erection activities will be as per agreed erection Bar Chart indicating

monthly schedule of erection activities for completion of works.

9.3.4 B No price increase shall be allowed beyond the original delivery/ erection

dates unless specially stated in the Time Extension Letter, if any, issued by

the Employer (BSEB). The BSEB will, however, be entitled to any decrease

in the Contract Price which may be caused due to lower price adjustment

amount in case of delivery of Goods/erection beyond the original delivery /

erection dates. Therefore, in case of delivery of Goods erection (including

civil works) beyond the original delivery/ erection dates, the liability of the

Employer shall be limited to the lower of the price adjustment amount

which may work out either on schedule date or actual date of despatch of

Goods / erection (including works).

9.3.5 In case of IEEMA does not publish any of the price indices, as mentioned

above, the bidder shall indices any nationally recognized published index

for respective items and the source of the same shall be furnished in the Bid.

9.3.6 In case of non-publication of applicable indices adjustment purposes, the

published indices prevailing immediately prior to the particular date shall be

applicable.

9.3.7 If the price adjustment amount works out to positive, the same is payable to

the Contractor by the Employer and if works out to be negative, the same is

Page 25 of 67

to be recovered by the Employer (BSEB) from the Contractor.

9.3.8 The Contractor shall promptly submit the price adjustment invoices for the

supplies made/ works done, positively within three (3) months from the date

of shipment/ work done whether it is positive or negative.

Bids shall conform to the price adjustment provisions detailed above, Bids

specifying prices for items mentioned at 9.0 on variable basis run the risk of

rejection. A bid submitted on a fixed price basis will not be rejected but the

price adjustment will be treated as zero.

10.0 EARNEST MONEY

10.1 Tender must be accompanied with an earnest money separately for the package as

detailed in clause 2.3.3 and also given below:-

Sr.no. Name of District Estimated value

(in Rs. Lac.)

Earnest Money

(in Rs. Lac.)

1 Araria 33864.68 677.2936

10.2 The Earnest Money should be deposited in the form of account Payee Bank Draft

drawn in favour of the BSEB, RE Accounts payable at Patna or an irrevocable

Bank Guarantee of equivalent amount issued by any Nationalized Bank of India/

Scheduled Bank in the form specified in the tender document.

10.3 Cheques /fixed deposit receipts are not acceptable towards deposit of Earnest

Money. Tenders accompanied with above (cheques or fixed deposit receipt) on

account of Earnest Money will be considered as without Earnest Money.

10.4 No Earnest Money will be accepted after opening of tender.

10.5 The Earnest Money deposit will be refunded to each of the unsuccessful tenderer. In

the case of the successful tenderer or tenderers it will be retained and no interest on

Earnest Money will be payable.

10.6 After finalizing the tender, LOA will directly be issued to successful tenderer with

30 days time to execute the agreement and to submit a contract performance

guarantee as specified in the tender documents. In the events, the successful

tenderer fails to sign the contract agreement with BSEB within 30 days and fails to

submit the contract performance guarantee as specified in this tender document, 15

days notice will be given and after which LOA may be cancelled.

Earnest Money deposited may be forfeited to compensate damage to Bihar State

Electricity Board. The earnest money may also be forfeited if bidder withdraws the

Page 26 of 67

bid during the period of bid validity specified by the bidder. The Earnest Money of

the successful tenderer shall be returned after furnishing the contract guarantee and

execution of the contract agreement.

10.7 The Earnest Money shall be furnished in a separate sealed cover and shall

accompany the tender/bid.

10.8 Any bid/tender not accompanied by Earnest Money will be rejected as non-

responsive.

10.9 The bidder shall furnish the bank guarantee against the Earnest Money as part of its

bid for the amount as specified above which shall be valid for a period of 14

(fourteen) calendar months from the date of opening of the Part-I i.e. Technical and

Commercial Part of tenders.

10.10 This Earnest Money/B.G/Bid guarantee is required to protect the Board / Owner

against the risk of bidder's conduct which would warrant the guarantee forfeiture

under the conditions detailed in the specification. This guarantee shall be made

payable to the Board/Owner without any condition whatsoever.

10.11 Exemption from depositing of earnest money: - The State Govt/ State Govt.

Undertaking / Central Govt./ Govt. of India Undertaking will be exempted from the

deposit of earnest money.

11. CONTRACT PERFORMANCE GUARANTEE

The successful bidder shall furnish to the Board/Employer a Contract Performance

Guarantee against the contract as per the terms prescribed below.

11.1 The Successful Bidder/tenderer, to whom the work is awarded, shall be required to

furnish a contract performance guarantee from a nationalized bank/ Scheduled

Bank in the approved format of BSEB as a contract performance Security. The

guarantee amount shall be equal to fifteen percent (15%) of the contract value and

it shall guarantee the faithful performance of the contract in accordance with the

terms and conditions as specified in the tender specifications.

11.2 The said bank guarantee shall be valid upto ninety (90) days after expiry of the

Warranty Period.

11.3 The performance guarantee shall cover the following guarantee also, to the

Owner/Board.

Page 27 of 67

11.4 The successful bidder guarantees the successful and satisfactory operation of the

equipment furnished and erected under the contract, as per the tender

specifications.

11.5 The Successful bidder further guarantees that the equipment provided and installed

by him shall be free from all defects in design, material and workmanship and shall

upon written notice from the Owner/Board, fully remedy free of expense to the

Owner/Board such defects as developed under the normal use of the said equipment

within the period of guarantee specified in the tender specifications.

11.6 The contract performance guarantee is intended to secure the performance of the

entire contract. However, it is not to be construed limiting the damages under

performance guarantee clause and damages stipulated in other clauses in the tender

document.

11.7 The performance guarantee will be returned to the Contractor without any interest

at the end of the period mentioned under clause 11.2 above, unless otherwise

specified in the tender specifications.

11.8 The Bank Guarantee shall be issued from a Nationalized Indian Bank/ Scheduled

Bank acceptable to the Board and shall become acceptable to the Board only after

verification by a competent authority/ officials of the Board.

11.9 The successful bidder, after receipt of LOA, will furnish the aforesaid BG within

30 days period prior to execution of the agreement. If there is delay beyond the

specified period in submission of contract performance BG, 15 days notice will be

given and after which BSEB may entail cancellation of letter of award and

forfeiting of Earnest Money/bid guarantee as also detailed under Earnest Money

clause.

12.0 Performance Guarantee:-

12.1 To ensure satisfactory performance of all the equipments supplied and works to be

covered under the contract the contractor shall furnish the contract performance

guarantee, which shall cover the following guarantee also to the Bihar State

Electricity Board:

"The contractor shall warrant successful and satisfactory operation of the power

sub-stations, Distribution sub-stations, lines and allied works with all equipments,

materials and works constructed under the contract, under the condition and for the

service specified. He shall further warrant the power sub-stations, Distribution sub-

Page 28 of 67

stations, lines and allied works with all equipments and works represented and

specified against any and all defects in design, materials and workmanship and

shall upon written notice by the 'Engineer/Owner/ Bihar State Electricity Board,'

Patna fully remedy, free of expense to the Board, such defects as developed under

the normal use of the said equipment within one year of service from the date of

taking over".

12.2 On due performance and execution' of the order in all respects, the BG will be

returned to him without any interest and on presentation of "No Demand

Certificate."

13.0 Payment:-

The payment to the contractor for Part-A and Part- B for the

performance of the contract will be made by Accounts Officer (RE) , Bihar

State Electricity Board, Patna as per the conditions specified hereunder. The

final payment will be made on completion of all works and on fulfillment by

the contractor of all his liabilities under the contract. The Tenderer is

required to submit separate bill for Part-A and Part B as per actual work

done. Proper itemwise accounting has to be maintained for Part- A as well

as Part B.

13.1.1 Advance Payment (Optional):- *

Payment of 15% (Fifteen percent) of the contract value of

ex-works component of supply portion as interest bearing mobilization

advance shall be made after agreement on submission of an irrevocable

Bank Guarantee issued by any Nationalised Bank/ Scheduled bank covering

the advance amount which shall be kept valid till 180 days (six month) after

successful completion of the work. The BG shall be released after

adjustment of principal and interest on prorata basis from successive bills.

The Advance Payment for the contract value of supply (Ex-works) shall be paid as

an interest bearing initial advance on presentation of the following further

documents:

1) Contractors detailed invoice

2) Execution of the agreement by the Contractor

3) Detailed PERT Network/Bar chart and its approval by the Employer.

This payment is an optional payment. The Contractor has the option of

taking the interest bearing advance or otherwise.

Page 29 of 67

In case, the Contractor opts for this interest bearing advance payment, the

same shall be paid to the contractor on fulfillment of above conditions and

interest on monthly outstanding amount of mobilization advance will be

charged considering the rate of interest as per the State Bank Advance Rate

(SBAR) prevailing as on thirty (30) days prior to Bid Opening date. The

monthly outstanding amount for the purpose of calculation of the interest

shall be worked out at the end of each calendar month against the

progressive payment for the work done as per clause no. 13.1 .2 below.

In case, the Contractor opts not to take interest bearing

advance as above, it would be mandatory for him to submit the documents

listed at para 13.1.1 (2) and 13.1.1 (3) above within thirty (30) days of

issuance of Notification of Letter of Award.

13.1.2 Progressive Payment:-

An interim payment of 70% (seventy percent) ** of the ex-works

component of supply portion shall be made on the basis of actual supply

made as per the bill ( separate bill for Part-A and Part B work) duly

verified and admitted by the Engineer-in-Charge and countersigned by the

concerned Electrical Superintending Engineer of electric Supply Circle or

officer authorized by BSEB after deduction / adjustment of the Mobilization

advance and interest on prorata basis and also on submission of documents

indicated herein under subject to the conditions laid down in under noted

sub-para-(i ) to (iv):-

(a) Evidence of dispatch (R/R or L/R)

(b) Contractors detailed invoice & packing list identifying contents of each

shipment.

(c) Insurance policy/certificate

(d) Manufacturers/Contractors guarantee certificate of Quality.

(e) Material Inspection Clearance Certificate (MICC) for dispatch issued by the

Employers representative and the Contractors factory inspection report.

(f) Test certificate

** In case, the Contractor opts not to take interest bearing advance then this

payment shall be 85% instead of 70%. In case the Contractor opts to take

interest bearing advance, after adjustment of principal and interest the interim

payment limit will increase to 85% instead of 70% of ex-works component.

(i) Payment against para 13.1.2 shall be released progressively upto 50% of the cost

Page 30 of 67

of total supply portion of contract price against supply of materials on

certification by engineer-in-charge.

(ii) Thereafter payment against next supply shall only be released upon completion of

40% erection work as per the contract and certification by Engineer-in-charge

regarding completion of 40% erection work in the shape of admitted bills. The

method of calculation of erection work is as detailed below:-

a. In respect of a village, completion of full work in totality will be taken as a

unit. 40% of total erection work will mean 40% of total no. of villages taken

over by BSEB.

b. In respect of a power sub station, completion of civil works, all structures

erection in the power sub- stations for which land has been made available,

complete pole pitching of 33 KV and 11 KV feeders to/from power sub-

station /Grid sub-station.

c. In case of R & M work completion, installation of power transformer and

VCB on the plinth in all the power sub-stations or complete handing over of

R&M work of 40% of total no. of Power sub-stations.

This Payment will be restricted upto 80% of the total supply portion of

contract price against supply of material.

(iii) Further, payment for remaining 20% of total supply portion of contract price

shall be released on completion of 75% of total erection work and

certification by Engineer-in-charge regarding completion of 75% erection

work as per guideline given below:-

a. In respect of a village completion of full work in totality will be taken as a

unit. 75% of total erection work will mean 75% of total no .of villages taken

over by BSEB.

b. In case of Power sub-station installation of power transformers, VCB,

isolator / AB switch of all power sub-stations for which land has been made

available.

c. In case of R&M works complete handing over of 75% of total no. of power

sub-stations.

Further, the erection activities at site shall be strictly matching with the erection

of equipments/materials as mutually agreed.

(iv) Bills for civil works (separate bill for Part- A and Part- B work) shall be raised

Page 31 of 67

separately by the contractor.

13.1.3. Balance Payment:-

The balance 15 % of the ex-works price components shall be paid on submission of

the certificate by the employer representative that the items have been received and

on submission of an unconditional and irrecoverable bank guarantee for full 15 %

amount valid till completion of the work and its taking over by the employer and

shall be extended from time to time till the actual date of successful completion of

testing and commissioning of line and its taking over by the employers. Bills shall

be submitted for such payments only once in three months commencing from the

date of receipt of first lot of materials/ items. The bank guarantee shall be furnished

along with the first invoice of final payment

13.2 Inland Freight & Insurance Charges.

Inland Freight & Insurance Charges ( inclusive all applicable taxes and duties )

shall be paid to the Contractor on pro-rata basis, as per the unit rates indicated in

the letters of Award, after receipt of materials/items at site and on presentation of

the invoices along with supporting documents by the Contractor. However, these

charges will be subject to a limitation that the aggregate of all invoices does not

exceed the total amount indicated in the Letter of Award.

13.3 Erection Price Component (including civil works):

i) Interest bearing Advance Payment (Optional)***: An advance of 10% (ten)

of the total erection price shall be paid as interest bearing initial advance on

submission of documents indicated herein under:

(a) Submission of detailed invoice for advance payment.

(b) Establishment of Contractors site offices, commencement of stub setting

work, and certification by Engineer that satisfactory mobilization for

erection exists.

(c) Submission of an unconditional & irrevocable Bank Guarantee in favour of

BSEB for the equivalent amount of advance and as per proforma attached.

The said Bank Guarantee shall be initially valid up to the end of 180 days

(six months) after the scheduled date for successful completion of

commissioning. The BG shall be released after adjustment of principal and

interest on prorata basis from successive bills.

*** This payment is an optional payment. The Contractor has the option of taking

the interest bearing advance or otherwise.

In case, the Contractor opts for this interest bearing advance payment, the same

Page 32 of 67

shall be paid to the contractor on fulfillment of above conditions and an interest on

monthly outstanding amount will be charged considering the rate of interest as the

State Bank Advance Rate (SBAR) prevailing as on thirty (30) days prior to Bid

Opening date. The monthly outstanding amount for the purpose of calculating the

interest shall be worked out at the end of each calendar month against the

progressive payment for the work done as per para 13.3 (ii) below.

(ii) 80% (eighty percent)*** of the erection price component will be

paid on progressive basis depending on the actual work done as

detailed in para -13.1.2.f. against each completed erection activity

and as per the bill duly verified and admitted by the Engineer-in-

Charge and countersigned by the concerned Electrical

Superintending Engineer of electric Supply Circle and after

deduction / adjustment of the Mobilization advance and interest on

prorata basis. In case of villages payment of erection bill will be

considered after completion of full work in totality and taking over

of a village by BSEB. The assets register is mandatorily to be

submitted along with the bill for capitalization of assets.

*** In case, the contractor opts not to take interest bearing advance then this

payment shall be 90% instead of 80%. In case the Contractor opts to take

interest bearing advance, after adjustment of principal and interest the

interim payment limit will increase to 90% instead of 80% of erection price

component.

(iii) The balance 10% (ten percent) of the erection price component shall be paid after