Documente Academic

Documente Profesional

Documente Cultură

Appd - Reliability and Availability

Încărcat de

chronometryDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Appd - Reliability and Availability

Încărcat de

chronometryDrepturi de autor:

Formate disponibile

Market-Based Advanced Coal Power Systems

APPENDIX D RELIABILITY AND AVAILABILITY The reference plant design presented in this section has reduced redundancy from reference designs produced in the past, yet maintains a high level of availability and reliability. Certain systems in a power plant have a history of causing plant outage or deratings. Table 1 gives the top 40 causes of outages and deratings for coal-fired power plants in the 400 to 599 MWe range. This table is based on information compiled by the North American Electric Reliability Council, in a document titled, Generating Availability Report 1985-1989. Each of the component

availabilities is used to calculate the system availability. The system availabilities are then used to calculate plant availability. Plant availability is a measure of the amount of time a given plant is available to produce power. Through historic data from such sources as the North American Electric Reliability Council, and system availability calculations, the availability for a modern pulverized coal-fired electric power plant is expected to be in the range of 83 to 86 percent, considering planned and forced outages and deratings. The information from the Generating Availability Report and other availability information was utilized in developing system block diagrams to determine the effects of reduced redundancy on system availability. System block diagrams for the coal handling system are included at the end of Appendix D. In Figure 1, a traditional utility type system with a majority of the system having redundant components is illustrated. Figure 2 shows a system as it would be designed today, with the redundancy reduced; however, some items are oversized to provide a margin that would allow the plant to repair a piece of equipment without losing generating capability. In addition, critical components with long mean time to repair times are still redundant (i.e., crushers) to maintain an acceptable availability rate. The differential in availability between Figure 1 and Figure 2 is 0.68 percent. In Figure 3, a low capital cost design is analyzed. This design has eliminated the redundant equipment and reduced availability by 8.88 percent. This is a significant reduction in availability and would not be a recommended design. Major systems can be analyzed by this method to determine the optimum design, considering both capital cost and availability.

D-1

December 1998

Appendix D, Reliability and Availability

Table 1 OUTAGES AND DERATINGS FOR COAL-FIRED POWER PLANTS

System Boiler Overhaul Major Turbine Overhaul Boiler Inspections Furnace Wall Inspection First Reheater Electrostatic Precipitator Problems Economizer Electrostatic Precipitator Fouling Second Superheater Feedwater Pump First Superheater Major Overhaul Rotor Windings Boiler Water Condition (not feedwater water quality) Cyclone Furnace (in cyclone area only) Main Transformer Opacity - Fossil Steam Units High Pressure Heater Tube Leaks Vibration of the Turbine Generator Unit Second Reheater Pulverizer Mills Other Catastrophe Primary Air Heater (regenerative) Stator Windings, Bushings and Terminals Other Tubes Forced Draft Fans Other Steam Turbine Problems Generator Vibration Buckets or Blades Feedwater Pump Drive - Steam Turbine Boiler, Miscellaneous Condenser Tube Leaks Boiler Recirculation Pumps Primary Air Heater Fouling (regenerative) Bearings Combustion/Steam Condition Controls Reheat Steam Piping up to Turbine Stop Valves Induced Draft Fans Mean Time Between Failure, Hours 12,514 36,500 33,692 4,710 87,600 12,167 3,490 13,273 11,526 15,927 4,949 21,366 438,000 292,000 1,321 41,714 25,028 1,665 8,848 13,273 38,087 1,884 438,000 19,909 175,200 62,571 30,207 32,444 43,800 292,000 8,588 12,696 8,588 25,028 27,375 58,400 12,167 219,000 13,905 Mean Down Time, Hours 608.47 850.05 448.14 49.91 452.25 52.98 14.20 40.86 30.12 40.28 12.11 49.91 950.96 707.01 2.63 80.77 47.82 2.91 14.43 19.40 55.15 2.65 599.68 24.88 213.84 73.23 35.87 38.81 52.07 305.42 9.48 13.98 8.59 23.94 25.74 57.07 11.29 210.92 12.54 Availability 0.953631 0.977241 0.986874 0.989515 0.994864 0.995664 0.995948 0.996931 0.997394 0.997477 0.997559 0.997669 0.997834 0.997585 0.998013 0.998067 0.998093 0.998255 0.998372 0.998541 0.998554 0.998595 0.998633 0.998752 0.998781 0.998831 0.998814 0.998805 0.998813 0.998955 0.998897 0.9989 0.999001 0.999044 0.999061 0.999024 0.999073 0.999038 0.999099

December 1998

D-2

Market-Based Advanced Coal Power Systems

Assumptions This reference plant design is based on the following assumptions: Initially a single unit facility is to be constructed including a single pulverized coal-fired boiler connected to a single turbine generator, with an FGD system integrated into the facility. Provisions have been make in the initial unit site layout arrangement to provide for the addition of a future second unit and the necessary support facilities. The circulating water heat sink is a mechanical draft evaporative cooling tower. Makeup and potable water for plant use is filtered and treated on site. Plant and sanitary wastes are held and treated on site.

D-3

December 1998

Appendix D, Reliability and Availability

This page left blank intentionally

December 1998

D-4

Figure 1 Utility Design Availability Analysis (Conceptual)

Coal Handling System Block Diagram

Vibratory Feeder Emergency Coal Hopper Vibratory Feeder Active Pile Reclaim Conveyor 1 Vibratory Feeder Conveyor 2 Coal Stacker Active Pile Reclaim Hopper Vibratory Feeder Feeder Hopper Conveyor 3B Coal Bin With Vent Filter Feeder Granulator Reduction Crusher Impactor Reduction Crusher Conveyor 4B Conveyor 5B Tripper 2 Feeder Feeder Granulator Reduction Crusher Impactor Reduction Crusher Conveyor 4A Conveyor 5A Tripper 1 Feeder Conveyor 3A

Combination Coal Silo, Feeder and Pulverizer Combination Coal Silo, Feeder and Pulverizer Combination Coal Silo, Feeder and Pulverizer Combination Coal Silo, Feeder and Pulverizer Combination Coal Silo, Feeder and Pulverizer Combination Coal Silo, Feeder and Pulverizer

MTBF, hrs MTTR, hrs Availability of each component

Feeder 377.5 24

Conveyor 17520 18

Conveyor 17520 18

Coal Stacker 26280 10

Hopper 12500 74.24

Feeder 377.5 24

Conveyor 17520 18

Bin 2190 8.53

Feeder 377.5 24

Crusher 8760 133

Crusher 8760 133

Conveyor 17520 18

Conveyor 17520 18

Tripper 1752 9

Coal Silo w/Vent Filter 91100 12.45

Feeder 377.5 24

Pulverizer 1884 2.65

0.940224

0.999

0.999

0.99962 Avail. of redundant active pile and Avail. of active/ emergenc y reclaim system

0.9941

0.94

0.999

0.99612

0.94

0.98504

0.98504

0.999

0.999

0.9949 Avai of each Combination Coal Silo, Feeder,

0.999863356

0.940224159

0.998595394

0.99573

0.938775219

Availability of redundant equipment

Need 2 out of 4 Feeders 0.999184 operating

Availability of Coal Handling System 97.98% Available 0.9798061

0.99965

Avail. of redundant crusher trains 0.991

Need 4 out of 6 trains operating

0.996011865

Parson's Power Group, Inc.

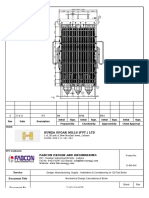

Figure 2 Non Utility Design Availability Analysis (Conceptual)

Coal Handling System Block Diagram

Vibratory Feeder Emergency Coal Hopper Vibratory Feeder Active Pile Reclaim Conveyor 1 Vibratory Feeder Conveyor 2 Coal Stacker Active Pile Reclaim Hopper Feeder Hopper Conveyor Coal Bin With Vent Filter Feeder Granulator Reduction Crusher Vibratory Feeder Impactor Reduction Crusher Conveyor 4B Conveyor 5B Tripper 2 Feeder Feeder Granulator Reduction Crusher Impactor Reduction Crusher Feeder

Combination Coal Silo, Feeder and Pulverizer

Combination Coal Silo, Feeder and Pulverizer Combination Coal Silo, Feeder and Pulverizer

Combination Coal Silo, Feeder and Pulverizer

Combination Coal Silo, Feeder and Pulverizer

Combination Coal Silo, Feeder and Pulverizer

MTBF MTTR Availabilit y of each

Feeder 377.5 24

Conveyor 17520 18

Conveyor 17520 18

Coal Stacker 26280 10

Hopper 12500 74.24

Feeder 377.5 24

Conveyor 17520 18

Bin 2190 8.53

Feeder 377.5 24

Crusher 8760 133

Crusher 8760 133

Conveyor 17520 18

Conveyor 17520 18

Tripper 1752 9

Coal Silo w/Vent Filter 91100 12.45

Feeder 377.5 24

Pulverizer 1884 2.65

0.94022

0.999

0.999

0.99962

0.9941

0.94

0.999

0.99612

0.94

0.98504

0.98504

0.999

0.999

0.994889267 Avail of each combination Coal Silo, Feeder, Pulverizer train

0.999863356

0.940224159

0.999

0.938775219

Avail. of active/ emergenc y reclaim system Availabilit y of redundant equipment Need 2 out of 4 Feeders 0.99918 operating

0.99972

Avail. of redundan t crusher train 0.992

Need 4 out of 6 operating

0.996011865

Availability of Coal Handling System 97.30% Available

0.97303

Parson's Power Group, Inc

Figure 3 Low Capital Cost Design Availability Analysis (Conceptual)

Coal Handling System Block Diagram

Vibratory Feeder y Coal Hopper Vibratory Feeder Feeder

Combination Coal Silo, Feeder and Pulverizer Combination Coal Silo, Feeder and Pulverizer Combination Coal Conveyor Tripper Silo, Feeder and Pulverizer

Conveyor 1 Vibratory Feeder

Conveyor 2

Coal Stacker

Active Pile Reclaim Hopper

Feeder

Conveyo r

Coal Bin With Vent Filter

Feeder

Granulator Reduction Crusher

Impactor Reduction Crusher

Conveyo r

Combination Coal Silo, Feeder and Pulverizer

Vibratory Feeder Combination Coal Silo, Feeder and Pulverizer

Combination Coal Silo, Feeder and Pulverizer

MTBF MDT Availabvility of each component

Feeder 377.5 24

Conveyor Conveyor Coal Stacker 17520 17520 26280 18 18 10

Hopper 12500 74.24

Feeder 377.5 24

Conveyor 17520 18

Bin 2190 8.53

Feeder 377.5 24

Crusher 8760 133

Crusher 8760 133

Conveyor 17520 18

Conveyor 17520 18

Tripper 1752 9

Coal Silo w/Vent Filter 91100 12.45

Feeder 377.5 24

Pulverizer 1884 2.65

0.94022

0.99897

0.99897

0.99962 Avail. of active/ emergency reclaim system

0.9941

0.94

0.999

0.99612

0.9402

0.98504

0.98504

0.999

0.99897

0.9949

0.999863 Avail. of each combination Coal Silo, Feeder, Pulverizer train 0.938775

0.9402

0.998595394

0.99573 Availability of redundant equipment Need 2 out of 4 Feeders 0.99918 operating 0.89102

Need 4 out of 6 trains operating 0.996012

Availablity of Coal Handling system 89.10% Available

Parson's Power Group, Inc.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Orient 300m Professional Diver Watch - A Brief ReviewDocument13 paginiOrient 300m Professional Diver Watch - A Brief ReviewchronometryÎncă nu există evaluări

- Orient 300m Professional Diver Watch - A Brief ReviewDocument13 paginiOrient 300m Professional Diver Watch - A Brief ReviewchronometryÎncă nu există evaluări

- 2012 Asia Pacific District Cooling ForumDocument3 pagini2012 Asia Pacific District Cooling ForumchronometryÎncă nu există evaluări

- High - Pressure Oil Flooded Screw CompressorsDocument6 paginiHigh - Pressure Oil Flooded Screw Compressorschronometry100% (1)

- Methane NumberDocument7 paginiMethane NumberWade ColemanÎncă nu există evaluări

- SST-300 enDocument4 paginiSST-300 enchronometryÎncă nu există evaluări

- Orient CatalogueDocument60 paginiOrient CataloguechronometryÎncă nu există evaluări

- Cg48 - Steam Supply and Condensate Return Line Pipe SizingDocument3 paginiCg48 - Steam Supply and Condensate Return Line Pipe Sizingchronometry100% (1)

- Chapter-Fans and BlowersDocument21 paginiChapter-Fans and BlowersRathish RaghupathyÎncă nu există evaluări

- Zero Discharge ConceptDocument12 paginiZero Discharge ConceptchronometryÎncă nu există evaluări

- SM Resilience 10 2012 EngDocument3 paginiSM Resilience 10 2012 EngchronometryÎncă nu există evaluări

- Siemens Industrial Steam Turbine SST 400 BrochureDocument8 paginiSiemens Industrial Steam Turbine SST 400 Brochurewintermutte100% (1)

- A. Lange & Sohne: Tourbillion and MoonphaseDocument2 paginiA. Lange & Sohne: Tourbillion and MoonphasechronometryÎncă nu există evaluări

- SM Spirit Mk2!11!2012 EngDocument2 paginiSM Spirit Mk2!11!2012 EngchronometryÎncă nu există evaluări

- AW Herapee: User's ManualDocument33 paginiAW Herapee: User's ManualMelocreo Todavia MasÎncă nu există evaluări

- Light Point ProjectDocument1 paginăLight Point ProjectchronometryÎncă nu există evaluări

- Window ViewDocument1 paginăWindow ViewchronometryÎncă nu există evaluări

- Bidder Confirms That The Design and Operation of The HRSG Is Independent of The Dissolved Oxygen Content in Boiler Feed WaterDocument1 paginăBidder Confirms That The Design and Operation of The HRSG Is Independent of The Dissolved Oxygen Content in Boiler Feed WaterchronometryÎncă nu există evaluări

- AW Herapee: User's ManualDocument33 paginiAW Herapee: User's ManualMelocreo Todavia MasÎncă nu există evaluări

- StorkThermeq DeaeratorDocument2 paginiStorkThermeq DeaeratorchronometryÎncă nu există evaluări

- Operation Principle: Typical System SchematicDocument1 paginăOperation Principle: Typical System SchematicchronometryÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Techinical Guide ZF 078 Thru 150 R410A Predator Single Packaged Unitr (Generation 6) - 528194-Ytg-M-0813Document68 paginiTechinical Guide ZF 078 Thru 150 R410A Predator Single Packaged Unitr (Generation 6) - 528194-Ytg-M-0813Rolando VenegasÎncă nu există evaluări

- Training ReportDocument33 paginiTraining ReportMayank KamnaniÎncă nu există evaluări

- Process Description of Gambat South Gas Processing FacilityDocument13 paginiProcess Description of Gambat South Gas Processing FacilitywaheedÎncă nu există evaluări

- Ycas 0130Document204 paginiYcas 0130M100% (1)

- TPS Internship ReportDocument34 paginiTPS Internship Reportmkhalil1148Încă nu există evaluări

- Study Guide Plant Equipment OperatorDocument30 paginiStudy Guide Plant Equipment Operatorluriah100% (2)

- Edta Cleaning PassivationDocument40 paginiEdta Cleaning Passivationsuleman247100% (1)

- High Pressure Boilers: Water Tube vs Fire TubeDocument8 paginiHigh Pressure Boilers: Water Tube vs Fire TubeSanjana ReddyÎncă nu există evaluări

- YorkPackage UnitDocument189 paginiYorkPackage UnitSatya N.GÎncă nu există evaluări

- DESIGN OF Steam DrumDocument40 paginiDESIGN OF Steam Drumshahroze mustafaÎncă nu există evaluări

- Akash RanjanDocument64 paginiAkash RanjanAkash RanjanÎncă nu există evaluări

- HRSG1 (终版)Document120 paginiHRSG1 (终版)Atif KhanÎncă nu există evaluări

- Selection: Semi-Hermetic Screw Compressors HS: Input ValuesDocument5 paginiSelection: Semi-Hermetic Screw Compressors HS: Input ValuesMaka GalalÎncă nu există evaluări

- Classifying and Explaining Common Boiler TypesDocument8 paginiClassifying and Explaining Common Boiler TypesKarthiKeyanÎncă nu există evaluări

- Analysis of Boiler Efficiency CalculationDocument5 paginiAnalysis of Boiler Efficiency CalculationHasan AhmedÎncă nu există evaluări

- Design Exercises - V1.1 - DfgeDocument26 paginiDesign Exercises - V1.1 - DfgeHendrawan Adi SuryaÎncă nu există evaluări

- BOILER PROPER PIDs IntroductionDocument46 paginiBOILER PROPER PIDs IntroductionHai Nguyen100% (1)

- Vector 1550 Series PDFDocument270 paginiVector 1550 Series PDFOtman Othman100% (2)

- WHR ResearchDocument22 paginiWHR ResearchSiddharth ModiÎncă nu există evaluări

- Caire Liberator PDFDocument50 paginiCaire Liberator PDFsterlingco3959Încă nu există evaluări

- Heat Ec ProductsDocument24 paginiHeat Ec Productslhphong021191Încă nu există evaluări

- Bulletin 114 REV032014 PDFDocument20 paginiBulletin 114 REV032014 PDFmul yadiÎncă nu există evaluări

- Dunnair Premium Inverter Rooftop UnitsDocument12 paginiDunnair Premium Inverter Rooftop UnitsSalaar AnsarÎncă nu există evaluări

- Boiler operation-BHELDocument27 paginiBoiler operation-BHELDuggineni RamakrishnaÎncă nu există evaluări

- Heat Transfer and Flow Characteristics of Spiral Fin and Tube Heat ExchangerDocument52 paginiHeat Transfer and Flow Characteristics of Spiral Fin and Tube Heat ExchangerSagarÎncă nu există evaluări

- RefrigerationDocument64 paginiRefrigerationHeat.MotionÎncă nu există evaluări

- 04.section I - Steam, Its Generation & Use, 41 - EdDocument193 pagini04.section I - Steam, Its Generation & Use, 41 - EdMayur Patel100% (1)

- 23XRV Iom 09-2006 EngDocument140 pagini23XRV Iom 09-2006 EngHumaid ShaikhÎncă nu există evaluări

- Principles of Steam Generation: 1.1.2.4 Heat Recovery BoilersDocument3 paginiPrinciples of Steam Generation: 1.1.2.4 Heat Recovery BoilersMohamed El NajjarÎncă nu există evaluări

- Identification of Hazards in Non-Nuclear Power PlantsDocument35 paginiIdentification of Hazards in Non-Nuclear Power PlantsFadi BoustanyÎncă nu există evaluări