Documente Academic

Documente Profesional

Documente Cultură

Designing HSS Connections

Încărcat de

Alexandre BassoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Designing HSS Connections

Încărcat de

Alexandre BassoDrepturi de autor:

Formate disponibile

H

Larry Kloiber, P.E.

ollow structural sections (HSS) are being used more and more often in building construction. A synergy between this increased use and the advances in connection design has resulted in new HSS design specifications and connection design aids. There are two primary reasons to use HSS in building construction: standard structural applications where their use results in cost savings (typical applications are columns or beams that are unbraced and/or bi-axially loaded), and architectural or aesthetic appearance. Both of these applications are primarily the result of the closed shape of the HSS. This closed shape is also what makes HSS connections unique and often challenging to design and fabricate. When HSS are used for architectural applications and appearance becomes a design constraint, it becomes even more challenging to design a connection that is economical to fabricate and erect. Almost all of the current HSS connection design methods and specifications are based on research done outside of the United States. A group of international HSS producers, CIDECT, gathered information and issued Monograph No. 6 in 1986 giving a state of the art approach to welded HSS connections. The International Institute of Welding (IIW) has been working with CIDECT to develop HSS design knowl-

Gapped K Connection

Overlapped K Connection

Figure 1.

Stepped Connection

Figure 2.

Modern Steel Construction / November 2001

edge into a specification format, and their design recommendations form the basis of most specifications. North American research on HSS connections has been lead by Professor J. A. Packer of the University of Toronto. The Canadian Institute of Steel Construction publication, Hollow Structural Section Connections and TrussesA Design Guide by J. A. Packer and J. E. Henderson, is regarded as the primary reference for design information on HSS connections. Until very recently the only specification for design of HSS connections in the United States was found in the American Welding Society (AWS) D1.1 Structural Welding CodeSteel. The AWS provisions for design of tubular connections are similar to IIW/CIDECT recommendations. The AISC Specification for The Design of Steel Hollow Structural Sections published in 1997 along with the AISC Hollow Structural Sections Connection Manual was a major step towards bringing comprehensive HSS connection design information to engineers in the United States. The AISC HSS Connections Manual provides design procedures and a series of connection design tables for a variety of HSS connections. Included are simple shear connections, moment connections, tension and compression connections, cap and base plate connections along with welded truss connections. HSS crosssection properties in the manual are

based on the actual wall thickness being 93% of the nominal thickness per the AISC Specification Section 1.2.2. This reduction in thickness, which is permitted by ASTM A 500, has become standard practice. Connections to HSS almost always require some type of welded connection. Even where bolts are used to make the field connection, it is usually necessary to weld some type of detail material to the HSS. The strength of a connection welded to the face of an HSS is primarily a function of the geometric parameters of the connection and cannot be increased by simply increasing the weld strength. However, the weld strength must be adequate to accommodate the highly non-uniform load distribution along the weld length due to the varying stiffness across the wall of the HSS. Unlike open sections, such as wide flange shapes, it is not possible to add a stiffener to the backside of the connection to provide a more uniform load transfer. Instead, the weld must be designed to ensure that yielding and redistribution will occur in the base metal, thereby allowing the weld to develop the required design load before reaching its ultimate breaking strength. Direct Welded Connections The most common direct welded connections are axially loaded truss type members forming joints in a T, Y or K configuration. The connection

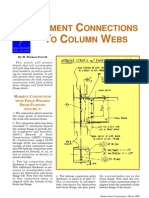

strength, as noted above depends on the geometric parameters of the members, and therefore it is important that the designer choose member sizes with the connection design as part of the selection criteria. The main member or chord should always be checked to make sure the wall thickness is adequate for all of the connection forces delivered by branch member. The joint configuration for K type truss connections can be classed as gapped or overlapped and as stepped or matched as shown in Figures 1, 2 & 3. The AISC HSS Specification currently only provides design rules for gapped type connections. Overlapped connections should only be considered where branch loads are so large they require some type of load transfer directly between branches. Gapped connections are more economical to fabricate because they require only a single bevel cut and the gap allows fit up tolerance. The gap also permits the entire truss to be assembled before welding, which helps to reduce cost. Matched connections require a flare-bevel-groove weld that, depending on the corner radius of the chord, may require some type of steel backing or a special backing weld to close the root of the joint. Flare-bevel-groove welds are relatively inefficient because of the limited effective throats allowed for AWS pre-qualified joints. It is possible to qualify these welds with a much larger effective throat by following the

Matched Connection

Figure 3.

SinglePlate Connection

Figure 4.

November 2001 / Modern Steel Construction

procedure qualification provisions of D1.1. Procedure qualification should be considered if the effective throat of the pre-qualified joint is not adequate for the design loads. Stepped connections are more economical to fabricate than matched connections because they permit the use of fillet welds. The chord and branch member sizes should be selected to allow the fillet welds to be placed on the flat of the chord. The chord width should be approximately the branch width plus four times the chord wall thickness plus two times fillet weld size. If the leg of the fillet weld does extend slightly onto the corner radius, it is still possible to get the required effective throat by modifying the weld profile. Direct welded HSS connections must have enough strength to provide for the non-uniform distribution of load along the weld length at the required load. This can be accomplished by either providing welds that will develop the yield strength of the branch before rupturing or by sizing welds using the effective weld length concept in the AISC HSS Specification section 9.2. The design procedure for developing the branch strength is covered in the AWS D1.1 provisions. The effective weld length procedure is preferred because it is based on actual member loads and results in more economical weld sizes, but it is applicable only to rectangular HSS connections. The effective weld length formulas were developed by Packer and are based on extensive physical tests of HSS joints. More recent work by Packer indicates that the AISC provisions are conservative because they are based on the rectangular dimensions of the HSS in calculating the effective length instead of the actual weld length. The AISC HSS Specification also does not permit the use of the fillet weld increase in strength due to the direction of the load that is allowed by AISC LRFD Specification Appendix J2.4, while Packers work again indicates this increase can be used. The weld strength required is determined by dividing the design load in the member by the effective length calculated per the appropriate formula in Section 9.2. The same strength weld is required around the entire perimeter of

the member even though the effective length maybe substantially less. Fillet welds the preferred weld detail to use for these joints. When detailing fillet welds on surfaces that do not intersect at 90 degrees the weld size or joint detail should be modified to provide the required effective throat. Complete joint penetration (CJP) welds should be avoided in these truss type joints. Except for joints subject to cyclic loading, CJP details are not required. Truss type joints because of the geometry do not permit the use of steel backing. CJP welds that are made without backing require special welder qualifications, special fit-up and require special inspection procedures. It is possible to develop the required connection strength for most HSS using fillets welds and/or partial joint penetration welds. The preferred HSS truss joint is gapped, stepped and fillet welded with the welds sized using the effective weld length procedure. Welded / Bolted Connections The most important advance in HSS connection economy has been the development of the HSS single plate framing connection by Dr. Donald R Sherman of the University of Wisconsin at Milwaukee. The single plate connection shown in Figure 4 is the most economical way to connect a wide flange beam to HSS columns and beams. The fabrication cost of a single plate connection is less than 1/4 the cost of the old through plate connection and substantially less than a WT or a double angle connection. Single plate connections can be used as long as the wall of the HSS is not classed as a slender element. For A500 Grade B material the b/t ratio must be 35 of less. When the reaction is larger than what a single plate connection can carry, the next choice is usually a double angle connection shop welded to the HSS. Stiffened seats welded to the wall of the HSS can also be used. The AISC HSS Connections Manual also gives a procedure for sizing column cap plates supporting beams and joist girders. If the reaction is within the face of the HSS, the load is delivered in direct bearing to the wall of the HSS, and the controlling limit state is either the local yielding or crippling of the

wall of the HSS. Increasing the plate thickness will only increase the bearing length slightly and result in only a minimal increase in strength. Through-bolting of HSS is not very practical. Holes in the HSS have to be manually drilled, the bolt lengths required exceed normal stock lengths and the bolt is difficult to install. When designing through bolts, it is important to remember that the snug tight requirements of the AISC Specification requires all plies in the connection to be in firm contact. This is not possible with an HSS unless some type of interior fill is used. The AISC HSS Specification treats through bolts as pin type connections with reduced bearing values. It is suggested through bolts be used only for erection aids with oversize holes or slots to allow for easier field fit-up. Architecturally Exposed Connections When HSS are used for aesthetic or architectural reasons, the connections are often specified to be welded connections. Connections that are field welded usually require some type of temporary bolted erection aid (connection) to locate and support the member until it can be welded. These connections, including the one shown in Figure 5, are the means and methods of construction and not part of the permanent structure. Therefore, the structural engineer does not normally design these connections or may not even indicate they are required. This can lead to possible conflicts when the fabrication and erection is bid separately. The design drawings should at least indicate that erection aids are to be provided as necessary to allow for the erection and field welding. If it is possible to locate these connections so they can remain and be part of the finished structure the structural engineer should show this on the connection details. Project specifications should reference the Architecturally Exposed Structural Steel (AESS) provisions in the AISC Code of Standard Practice. Often project specifications have provisions that require all welds to be ground. Grinding welds, especially fillet welds, is expensive and usually does not improve the appearance. The AESS provisions require reasonably smooth and uniform welds. Where multi-pass fil-

HSS CONNECTION TIPS The single plate connection shown in Figure 4 is the most economical way to connect a wide flange beam to HSS columns and beams. The design drawings should at least indicate that erection aids are to be provided as necessary to allow for the erection and field welding. Grinding welds, especially fillet welds, is expensive and usually does not improve the appearance.

HSS to HSS Erection Connection

Figure 5. Note: Erection connection is only for locating and supporting HSS member. All field welds must be completed before any other load is applied. After field welding HSS, remove plate connection and grind flush.

let welds are used and a special appearance is required, it is more economical to dress the surface with a plastic filler material like those used in auto repair. The use of a joint mockup is often helpful in establishing reasonable appearance standards for exposed welds. The architect should be required to view the mockup from the same distance he or she will see the finished weld in the structure. This same mockup can be sectioned to verify the effective throats of the various weld details. HSS Connection Design References There have been significant advances in HSS connection design in recent years that make the design process more user-friendly and the fabrication and erection more economical. The HSS connection manuals published by CISC and AISC can be ordered from their web sites: www.cisc-icca.ca and www.aisc.org. In addition to these key references, structural engineers designing truss type connections m ight find a new computer program by the University of Toronto Tube Group helpful. This Windows-based program covers a wide variety of truss connections in metric or U.S. customary units. For more information, e-mail Professor Jeffrey Packer at packer@ecf.utoronto.ca.

Larry Kloiber P.E. is Vice President of Engineering for LeJeune Steel Company in Minneapolis, MN.

HSS Connections SHORT COU RSE

at NASCC 2002Seattle

If you need to know more about the art and science of connection design for hollow structural sections and steel pipe, the 2002 NASCC will feature a short course providing the practical knowledge you need. Whether you design connections or evaluate the connections shown on shop drawings, this course will help you understand the fundamentalsand peculiaritiesof HSS connection design, including welding, bolting and connecting elements. Youll also gain insight into the detailed design of shear, moment, bracing, truss (including HSS-to-HSS) and many other connections in tubular steel structures. When: Saturday, April 27, 8:00 - 1:00 Where: NASCC 2002Seattle, WA Speaker: Donald R. Sherman, Ph.D., P.E., University of Wisconsin, Milwaukee Registration and Cost: Visit www.aisc.org or see the NASCC advance program in the December issue of Modern Steel Construction.

November 2001 / Modern Steel Construction

S-ar putea să vă placă și

- HSS Connection ManualDocument34 paginiHSS Connection Manualtylerlhsmith100% (15)

- HHS Connection DesignDocument3 paginiHHS Connection Designwii2001Încă nu există evaluări

- Article: Wide-Flange Beam To Hss Column Moment ConnectionsDocument3 paginiArticle: Wide-Flange Beam To Hss Column Moment ConnectionsBudi SimatupangÎncă nu există evaluări

- Design of Bearing Stiffeners in Cold Formed Steel C-SectionsDocument151 paginiDesign of Bearing Stiffeners in Cold Formed Steel C-SectionsFabio Saraiva BoxÎncă nu există evaluări

- 112-High Strength Bolting PDFDocument68 pagini112-High Strength Bolting PDFJanesha100% (1)

- AISI Manual Cold-Formed Steel Design 2002 Edition PDFDocument462 paginiAISI Manual Cold-Formed Steel Design 2002 Edition PDFAnonymous WfZmGSUjÎncă nu există evaluări

- Steel Joist IntroDocument11 paginiSteel Joist IntroKrup KolandÎncă nu există evaluări

- AISC DG 37 - Hybrid Steel Frames With CLTDocument116 paginiAISC DG 37 - Hybrid Steel Frames With CLTpeacers100% (1)

- DG 2 EnglishDocument58 paginiDG 2 EnglishÁlló László100% (2)

- Extended End Plate Moment Connections PDFDocument47 paginiExtended End Plate Moment Connections PDFManvitha Reddy100% (1)

- 03 Serviceability Design Considerations For Low-Rise BuildingsDocument27 pagini03 Serviceability Design Considerations For Low-Rise BuildingsLoombardo1996Încă nu există evaluări

- Anchor Rods and Base Plates ExplainedDocument3 paginiAnchor Rods and Base Plates Explainedpenneng0% (2)

- Steel TipsDocument123 paginiSteel TipsEngr AxleÎncă nu există evaluări

- HSS Column Moment ConnectionsDocument49 paginiHSS Column Moment ConnectionsUALU333100% (7)

- Hollow Sections Book WardenierDocument199 paginiHollow Sections Book WardenierANUSSBAUMER100% (3)

- Guía de Fallas en Conexiones HSSDocument57 paginiGuía de Fallas en Conexiones HSSlcorao100% (3)

- Cidect 1Document22 paginiCidect 1susan87Încă nu există evaluări

- Steel Joist CatDocument235 paginiSteel Joist CatEvgeni GenkovÎncă nu există evaluări

- Serviceability Design Considerations: For Steel BuildingsDocument44 paginiServiceability Design Considerations: For Steel BuildingsAnthab MedinaÎncă nu există evaluări

- Cold-Formed Steel Structures To The AISI Specification - 0824792947Document405 paginiCold-Formed Steel Structures To The AISI Specification - 0824792947irdl92% (12)

- HOLLOW STRUCTURAL SECTIONS GUIDEDocument15 paginiHOLLOW STRUCTURAL SECTIONS GUIDECesar BarraganÎncă nu există evaluări

- TD12 CompleteDocument110 paginiTD12 Completemadina1386100% (2)

- SteelDocument56 paginiSteelyoungonhunt100% (15)

- Bolted Beam Column ConnectionsDocument16 paginiBolted Beam Column Connectionslael00Încă nu există evaluări

- Design Guide For Structural Hollow Section ConnectionsDocument213 paginiDesign Guide For Structural Hollow Section ConnectionsAnonymous 8f2veZf83% (6)

- Moment Connections to Column WebsDocument3 paginiMoment Connections to Column WebsAmro Ahmad AliÎncă nu există evaluări

- Composite Steel Joists Including Supplement 1Document282 paginiComposite Steel Joists Including Supplement 1alex.montajeÎncă nu există evaluări

- Buckling Properties of Monosymmetric I-BeamsDocument37 paginiBuckling Properties of Monosymmetric I-Beamsscribd6062100% (1)

- Introduction To Work Station Cranes (Gobel)Document16 paginiIntroduction To Work Station Cranes (Gobel)Yadi KusmayadiÎncă nu există evaluări

- Bracing Connections Green BookDocument29 paginiBracing Connections Green BookLesego MatojaneÎncă nu există evaluări

- P028 Industrial Lattice Frame BuildingDocument100 paginiP028 Industrial Lattice Frame BuildingAnilMohanK100% (12)

- WF To HSS Moment Connections R1 - FINAL PDFDocument7 paginiWF To HSS Moment Connections R1 - FINAL PDFrene_angel1Încă nu există evaluări

- Connecting: Making Connections With HSS Members Is Easier Than You Might Think!Document4 paginiConnecting: Making Connections With HSS Members Is Easier Than You Might Think!PauloAndresSepulvedaÎncă nu există evaluări

- HSS Column Splice Enews v5Document6 paginiHSS Column Splice Enews v5lavignenoeÎncă nu există evaluări

- Steel Interchange: Fillet Weld Terminations Built-Up Column DesignDocument2 paginiSteel Interchange: Fillet Weld Terminations Built-Up Column Designhector diazÎncă nu există evaluări

- Joining Steel MembersDocument1 paginăJoining Steel MemberstierradiegoyahooesÎncă nu există evaluări

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 paginiSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoÎncă nu există evaluări

- Dec11 Si PDFDocument2 paginiDec11 Si PDFspaceheaterÎncă nu există evaluări

- Si 12 2011 PDFDocument2 paginiSi 12 2011 PDFHectorÎncă nu există evaluări

- Steel DetailerDocument3 paginiSteel DetailerKooroshÎncă nu există evaluări

- WF To HSS Moment Connections R1 - FINAL PDFDocument1 paginăWF To HSS Moment Connections R1 - FINAL PDFcecastaÎncă nu există evaluări

- Steel Interchange: How To Specify AESS Gusset Plate DesignDocument2 paginiSteel Interchange: How To Specify AESS Gusset Plate Designhector diazÎncă nu există evaluări

- Steel Interchange: Stability of Beams During Erection Fire Rating of Concrete-Filled HSS MembersDocument2 paginiSteel Interchange: Stability of Beams During Erection Fire Rating of Concrete-Filled HSS Membershector diazÎncă nu există evaluări

- Designing With Structural TubingDocument9 paginiDesigning With Structural TubingJuan Gutier CcÎncă nu există evaluări

- 30 Rules For Good Connections.5Document4 pagini30 Rules For Good Connections.5chipchipperson100% (1)

- Bracing ConnectionDocument16 paginiBracing ConnectionMa N U VenusÎncă nu există evaluări

- Si 01 2012 PDFDocument2 paginiSi 01 2012 PDFAnonymous sfQEKGACgKÎncă nu există evaluări

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 paginiSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoÎncă nu există evaluări

- Galvanized Slip-Critical ConnectionsDocument2 paginiGalvanized Slip-Critical Connectionsaams_sÎncă nu există evaluări

- Steel Framing ConnectioDocument21 paginiSteel Framing ConnectioJamesÎncă nu există evaluări

- 30 Good RulesDocument4 pagini30 Good RulesSamet Karataş100% (1)

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 paginiSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoÎncă nu există evaluări

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 paginiSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoÎncă nu există evaluări

- Connections: Best Tips of The 21st CenturyDocument4 paginiConnections: Best Tips of The 21st Centurysymon ellimac100% (1)

- Simple Shear ConnectionsDocument3 paginiSimple Shear ConnectionsMena M. ZakiÎncă nu există evaluări

- ASIC Steel Interchange - Shear Flow in Plastic DesignDocument2 paginiASIC Steel Interchange - Shear Flow in Plastic DesignMikeÎncă nu există evaluări

- Restrained Beam Astm A307 Bolts: If You'Ve Ever Asked Yourself "Why?"Document2 paginiRestrained Beam Astm A307 Bolts: If You'Ve Ever Asked Yourself "Why?"gv Sathishkumar KumarÎncă nu există evaluări

- Steel Interchange: Drift LimitsDocument2 paginiSteel Interchange: Drift Limitsmaxeytm_839061685Încă nu există evaluări

- Felxural Strength of A Box Section PDFDocument2 paginiFelxural Strength of A Box Section PDFaams_sÎncă nu există evaluări

- Welding of Hollow Structural Sections PDFDocument5 paginiWelding of Hollow Structural Sections PDFManuel Gomez FariasÎncă nu există evaluări

- Horizontal Lifeline ManualDocument8 paginiHorizontal Lifeline ManualjarnebergÎncă nu există evaluări

- Sag CalculationDocument20 paginiSag Calculationrahu111112000Încă nu există evaluări

- The SNR Expert Diagnosis:: Analysis and Recommendations For Optimizing Bearing LifeDocument36 paginiThe SNR Expert Diagnosis:: Analysis and Recommendations For Optimizing Bearing Lifejarneberg100% (3)

- Effects of Bending and Heating On PlateDocument94 paginiEffects of Bending and Heating On PlatejarnebergÎncă nu există evaluări

- Metallurgical Investigation of "Tiger Stripes" On A Carburized High Speed PinionDocument3 paginiMetallurgical Investigation of "Tiger Stripes" On A Carburized High Speed PinionjarnebergÎncă nu există evaluări

- Test Report: IMR KHA Report Number 201416232Document1 paginăTest Report: IMR KHA Report Number 201416232jarnebergÎncă nu există evaluări

- Fault Assessment of Generator Bearing For A 1.5 MW Wind TurbineDocument7 paginiFault Assessment of Generator Bearing For A 1.5 MW Wind TurbinejarnebergÎncă nu există evaluări

- International Material Grade Comparison TableDocument9 paginiInternational Material Grade Comparison Tablenyamuk06100% (4)

- AISI 8620 Case HardeningDocument2 paginiAISI 8620 Case HardeningjarnebergÎncă nu există evaluări

- Sheet Metal Design-Handbook-Rev3 PDFDocument12 paginiSheet Metal Design-Handbook-Rev3 PDFtnchsg100% (1)

- Case Studies in Engineering Failure Analysis: Michael K. BudinskiDocument11 paginiCase Studies in Engineering Failure Analysis: Michael K. BudinskijarnebergÎncă nu există evaluări

- 5127 - Chapter 7 and Case Histories - WEB - 2Document19 pagini5127 - Chapter 7 and Case Histories - WEB - 2jarnebergÎncă nu există evaluări

- Casting Material For Shipyards EtcDocument150 paginiCasting Material For Shipyards EtcjarnebergÎncă nu există evaluări

- Correctio Reissner Paper On Trunion Mounted To Annhjualr PlateDocument2 paginiCorrectio Reissner Paper On Trunion Mounted To Annhjualr PlatejarnebergÎncă nu există evaluări

- Simpson XT Anchor ICBO CertDocument16 paginiSimpson XT Anchor ICBO CertjarnebergÎncă nu există evaluări

- Special Inspection Guidelines Rev 6-6-11Document13 paginiSpecial Inspection Guidelines Rev 6-6-11jarnebergÎncă nu există evaluări

- Hilltie Post Installed Conc Anchor TestDocument20 paginiHilltie Post Installed Conc Anchor TestjarnebergÎncă nu există evaluări

- Test Report: IMR KHA Report Number 201416232Document1 paginăTest Report: IMR KHA Report Number 201416232jarnebergÎncă nu există evaluări

- Correlation of Post Installed by Adhesive Pullout Test To Estimate in Place Concrete StrengthDocument4 paginiCorrelation of Post Installed by Adhesive Pullout Test To Estimate in Place Concrete StrengthjarnebergÎncă nu există evaluări

- Correlation of Post Installed by Adhesive Pullout Test To Estimate in Place Concrete StrengthDocument4 paginiCorrelation of Post Installed by Adhesive Pullout Test To Estimate in Place Concrete StrengthjarnebergÎncă nu există evaluări

- Crosby Clips PG 40Document2 paginiCrosby Clips PG 40jarnebergÎncă nu există evaluări

- Background For Z359 LoadsDocument3 paginiBackground For Z359 LoadsjarnebergÎncă nu există evaluări

- Thread GalingDocument2 paginiThread GalingSpoonful BurnsideÎncă nu există evaluări

- Wire Rope Sling Hand BookDocument28 paginiWire Rope Sling Hand BookJogi Oscar SinagaÎncă nu există evaluări

- Aluminum Bronze OverviewDocument7 paginiAluminum Bronze OverviewjarnebergÎncă nu există evaluări

- Standard Gear Couplings 24330Document52 paginiStandard Gear Couplings 24330jarnebergÎncă nu există evaluări

- Lightweight RopesDocument22 paginiLightweight RopesjarnebergÎncă nu există evaluări

- Belleville Disk Washer FormulaDocument2 paginiBelleville Disk Washer FormulajarnebergÎncă nu există evaluări

- Plate and Box Girder DesignDocument60 paginiPlate and Box Girder DesignKrishna ChandranÎncă nu există evaluări

- 20 Flexible Torsional Behavior of Thin Walled Closed Section Composite Box Beam 14748Document9 pagini20 Flexible Torsional Behavior of Thin Walled Closed Section Composite Box Beam 14748jarnebergÎncă nu există evaluări

- To Engineer Is Human: The Role of Failure in Successful DesignDe la EverandTo Engineer Is Human: The Role of Failure in Successful DesignEvaluare: 4 din 5 stele4/5 (137)

- Advanced Modelling Techniques in Structural DesignDe la EverandAdvanced Modelling Techniques in Structural DesignEvaluare: 5 din 5 stele5/5 (3)

- Modeling and Dimensioning of Structures: An IntroductionDe la EverandModeling and Dimensioning of Structures: An IntroductionÎncă nu există evaluări

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDe la EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsÎncă nu există evaluări

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsDe la EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsÎncă nu există evaluări

- Pocket Guide to Flanges, Fittings, and Piping DataDe la EverandPocket Guide to Flanges, Fittings, and Piping DataEvaluare: 3.5 din 5 stele3.5/5 (22)

- Marine Structural Design CalculationsDe la EverandMarine Structural Design CalculationsEvaluare: 4.5 din 5 stele4.5/5 (13)

- Transmission Pipeline Calculations and Simulations ManualDe la EverandTransmission Pipeline Calculations and Simulations ManualEvaluare: 4.5 din 5 stele4.5/5 (10)

- Built: The Hidden Stories Behind Our StructuresDe la EverandBuilt: The Hidden Stories Behind Our StructuresEvaluare: 4 din 5 stele4/5 (27)

- Design and Construction of Soil Anchor PlatesDe la EverandDesign and Construction of Soil Anchor PlatesEvaluare: 5 din 5 stele5/5 (1)

- Pile Design and Construction Rules of ThumbDe la EverandPile Design and Construction Rules of ThumbEvaluare: 4.5 din 5 stele4.5/5 (15)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingDe la EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingÎncă nu există evaluări

- Piezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringDe la EverandPiezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringÎncă nu există evaluări

- Advanced Design Examples of Seismic Retrofit of StructuresDe la EverandAdvanced Design Examples of Seismic Retrofit of StructuresEvaluare: 1 din 5 stele1/5 (1)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresDe la EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresEvaluare: 1 din 5 stele1/5 (2)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsDe la EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsEvaluare: 4 din 5 stele4/5 (16)

- 3D Concrete Printing Technology: Construction and Building ApplicationsDe la Everand3D Concrete Printing Technology: Construction and Building ApplicationsÎncă nu există evaluări

- Matrix Methods for Advanced Structural AnalysisDe la EverandMatrix Methods for Advanced Structural AnalysisEvaluare: 5 din 5 stele5/5 (1)

- Offshore Pipelines: Design, Installation, and MaintenanceDe la EverandOffshore Pipelines: Design, Installation, and MaintenanceEvaluare: 4.5 din 5 stele4.5/5 (2)

- Pipeline Planning and Construction Field ManualDe la EverandPipeline Planning and Construction Field ManualEvaluare: 5 din 5 stele5/5 (3)

- Experiment and Calculation of Reinforced Concrete at Elevated TemperaturesDe la EverandExperiment and Calculation of Reinforced Concrete at Elevated TemperaturesEvaluare: 5 din 5 stele5/5 (2)