Documente Academic

Documente Profesional

Documente Cultură

Pipe Data: Mason Industries, Inc

Încărcat de

selisenTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pipe Data: Mason Industries, Inc

Încărcat de

selisenDrepturi de autor:

Formate disponibile

MASON INDUSTRIES, Inc.

350 Rabro Drive

Hauppauge, NY 11788

631/348-0282

FAX 631/348-0279

Info@Mason-Ind.com

www.Mason-Ind.com

PIPE

DATA

PIPE, PIPE FITTINGS

AND ACCESSORY

WEIGHTS, AND

THERMAL

EXPANSION

Manufacturers of Vibration Control Products

2101 W. Crescent Ave., Suite D

Anaheim, CA 92801

714/535-2727

FAX 714/535-5738

Info@MasonAnaheim.com

www.MasonAnaheim.com

DATA SHEET DS-500

HANGER SELECTION

When selecting pipe hangers or supports, allowances must be made for Pipe Fittings or Accessories such as valves, strainers, etc. Larger

capacities must be used in these locations. Approximate piping component weights are given in Pipe Fitting and Accessory Weight table.

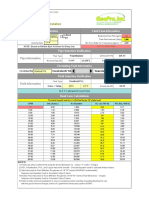

WATER PIPE WEIGHTS (85% MAGNESIA INSULATION)

Max

Insul

Pipe Hanger Pipe ThickSize Spacing Sched- ness

(in)

(ft)

ule (in)

1

7

40 1

7

40 1

11/4

11/2

9

40 1

2

10

40 1

21/2 11

40 1

3

12

40 1

4

14

40 1

5

16

40 11/2

6

17

40 11/2

8

19

40 11/2

10

22

40 11/2

12

23

40 11/2

14

25

30 11/2

16

27

30 11/2

18

28

30 11/2

20

30

20 11/2

24

32

20 11/2

WEIGHT per LENGTH (lbs)

Pipe

Only

1.7

2.3

2.7

3.7

5.8

7.6

11.0

15.0

19.0

29.0

41.0

54.0

55.0

63.0

82.0

79.0

95.0

Water

0.4

0.7

0.9

1.5

2.1

3.2

5.2

8.7

12.4

22.0

34.0

49.0

60.0

79.0

100.0

126.0

184.0

Insulation

0.7

0.8

0.9

1.0

1.2

1.3

1.8

2.9

3.1

4.1

5.2

6.0

7.0

7.5

8.0

8.5

10.0

Total

2.8

3.8

4.5

6.2

9.1

12.1

18.0

26.6

34.5

55.1

80.2

109.0

122.0

150.0

190.0

214.0

289.0

6

17

28

27

37

55

8

22

30

36

50

73

97

144

213

276

440

642

872

10

28

38

45

62

91

121

180

266

345

551

802

1090

1220

1500

1900

2140

2890

12

14

109

145

216

319

414

661

962

1308

1464

1800

2280

2568

3468

252

372

483

771

1123

1526

1708

2100

2660

2996

4046

16

18

20

22

24

26

426

552

882

1283

1744

1952

2400

3040

3424

4624

621

992

1444

1962

2196

2700

3420

3852

5202

1102

1604

2180

2440

3000

3800

4280

5780

1764

2398

2684

3300

4180

4708

6358

2616

2928

3600

4560

5136

6936

3172

3900

4940

5564

7514

28

30

32

4200

5320

5992 6420

8092 8670 9248

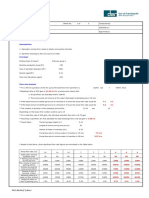

STEAM PIPE WEIGHTS (85% MAGNESIA INSULATION)

Max

Insul

Pipe Hanger Pipe ThickSize Spacing Sched- ness

(in)

(ft)

ule

(in)

1

7

40

11/2

7

40

11/2

11/4

11/2

9

40

11/2

2

10

40

11/2

21/2 11

40

11/2

3

12

40

11/2

4

14

40

11/2

5

16

40

11/2

6

17

40

2

8

19

40

2

10

22

40

2

12

23

40

2

14

25

30

2

16

27

30

2

18

28

30

2

20

30

20

2

24

32

20

2

WEIGHT per LENGTH (lbs)

Pipe

Only

1.7

2.3

2.7

3.7

5.8

7.6

11.0

15.0

19.0

29.0

41.0

54.0

55.0

63.0

82.0

79.0

95.0

Insulation

1.2

1.5

1.8

2.0

2.3

2.1

2.8

3.0

4.6

5.6

7.1

8.1

8.4

9.3

10.4

11.6

13.4

Total

2.9

3.8

4.5

5.7

8.1

9.7

13.8

18.0

23.6

34.6

48.2

62.1

63.4

72.3

92.4

90.6

108.0

6

17

23

27

34

49

8

23

30

36

46

65

78

110

144

189

278

386

497

Pipe

Size

(in)

11/2

2

21/2

3

4

5

6

8

10

12

14

16

18

20

24

FITTINGS

Size Elbows Tee

(in)

(lbs) (lbs)

11/2

15

20

2

20

25

21/2

25

35

3

30

40

4

55

70

5

70

90

6

90

115

8

120

175

10

245

295

12

375

405

14

495

565

16

700

750

18

890

925

20

1140 1180

24

1720 1850

14

193

252

330

484

675

869

888

1012

1294

1268

1512

16

18

20

22

24

26

288

378

554

771

994

1014

1157

1478

1450

1728

425

623

868

1118

1141

1301

1663

1631

1944

692

964

1242

1268

1446

1848

1812

2160

1060

1366

1395

1591

2033

1993

2376

1490

1522

1735

2218

2174

2592

1648

1880

2402

2356

2808

28

30

32

2169

2587

2356 2718

3024 3240 3456

THERMAL EXPANSION OF PIPE

MATERIALS (inches/100 ft. from 70F)

FLANGED 125lb CAST IRON PIPE FITTINGS

AND ACCESSORY WEIGHTS (approximate)

ACCESSORIES

Bonnet Bonnet

Check

Gate Pipe

Strainer Valve Valve

(lbs)

(lbs)

(lbs)

20

25

30

30

25

40

40

35

50

50

45

70

85

80

110

110

120

140

140

155

175

205

305

250

330

455

475

440

675

690

615

885

930

875

1170 1255

1075

1375 1650

1380

1780 1950

2150

2960 3065

10

12

29

38

45

57

81

97

97 116

138 166

180 216

236 283

346 415

482 578

621 745

634 761

723 868

924 1109

906 1087

1080 1296

Flange

(lbs)

3.5

6

8

9

16

20

25

34

53

71

93

120

140

176

255

250 lb. Fittings can be established at approximately 1.8 times

weights shown.

Deg

F

-50

0

50

70

100

150

200

250

300

350

400

450

500

550

600

Carbon, CarbonAustenitic

moly & Low Stainless Steels

Chrome Steel (304, 316, 347) Copper

-0.87

-1.34

-1.32

-0.51

-0.78

-0.79

-0.15

-0.22

-0.22

0.00

0.00

0.00

0.23

0.34

0.34

0.61

0.90

0.91

0.99

1.46

1.51

1.40

2.03

2.08

1.82

2.61

2.67

2.26

3.21

3.27

2.70

3.80

3.88

3.16

4.40

4.49

3.62

5.01

5.12

4.11

5.62

5.74

4.60

6.24

6.39

PVC

-4.00

-2.33

-0.67

0.00

1.00

2.67

ll

ll

ll

ll

ll

ll

ll

ll

ll

Pressure

Deg

F

0

25

50

75

100

125

150

175

200

225

250

275

300

212

267

298

320

338

353

366

378

388

397

406

414

421

Inches per 100 Ft. per 100F in Temperature Range 50-350F:

Carbon, Carbon-moly, Low Chrome Steel:

0.80

Austenitic Stainless Steels (304, 316, 347):

1.14

Copper:

1.16

PVC (varies with type)

3.40"

S-ar putea să vă placă și

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideDe la EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideÎncă nu există evaluări

- Ed34-762 Vrviii 410aDocument746 paginiEd34-762 Vrviii 410aPham van Cuong100% (1)

- Hydroheater Auto Manual VersionDocument45 paginiHydroheater Auto Manual VersionVishal Nawalgaria100% (3)

- 04 - How Does Altitude Affect HVAC UnitsDocument2 pagini04 - How Does Altitude Affect HVAC UnitsMaiccoll OlmÎncă nu există evaluări

- Easyheat s27 - 02 SarcoDocument8 paginiEasyheat s27 - 02 SarcoMarcelo ResckÎncă nu există evaluări

- Lokring I Single Ring 01.07.2013Document58 paginiLokring I Single Ring 01.07.2013Sandra Mabel Leguizamon100% (1)

- The Boiler BookDocument1.140 paginiThe Boiler BookJose Lorenzo ToralÎncă nu există evaluări

- ASTM's Steel Standards GuideDocument63 paginiASTM's Steel Standards GuideNagarjun ReddyÎncă nu există evaluări

- Thermowell Calculation Guide V1.3Document19 paginiThermowell Calculation Guide V1.3AymanelorbanyÎncă nu există evaluări

- p21 006 P 02 (Support Load Data)Document3 paginip21 006 P 02 (Support Load Data)Trishul Nath PallayÎncă nu există evaluări

- Mcquay": Absorption ChillerDocument88 paginiMcquay": Absorption ChillerMuzafar Ali ShahÎncă nu există evaluări

- Troubleshooting A Plate Heat Exchanger - CPE Systems IncDocument7 paginiTroubleshooting A Plate Heat Exchanger - CPE Systems Incrajmohan_kÎncă nu există evaluări

- 6877-SM-LM-99-00-09014-A1A7 Document Number: Merlin Version 2.2 11-JAN-05 15:46:38 Detailed ReportDocument12 pagini6877-SM-LM-99-00-09014-A1A7 Document Number: Merlin Version 2.2 11-JAN-05 15:46:38 Detailed ReportSalimÎncă nu există evaluări

- Mayekawa DOC.2011-200 R5 PDFDocument28 paginiMayekawa DOC.2011-200 R5 PDFadÎncă nu există evaluări

- Flowserve-Ball Valve Technical Manual For AKH3 IOMDocument23 paginiFlowserve-Ball Valve Technical Manual For AKH3 IOMwholenumberÎncă nu există evaluări

- Remote Radiator Systems For Generator SetsDocument2 paginiRemote Radiator Systems For Generator SetsJohn P KÎncă nu există evaluări

- Scroll Compressor Chillers Design TipsDocument1 paginăScroll Compressor Chillers Design TipssajuhereÎncă nu există evaluări

- August 2012 IssueDocument56 paginiAugust 2012 IssueGas, Oil & Mining Contractor Magazine100% (1)

- Volume Control DampersDocument4 paginiVolume Control Dampersdignified34Încă nu există evaluări

- Schimbator de Caldura 2Document1 paginăSchimbator de Caldura 2Dudutz DudutzuÎncă nu există evaluări

- Assessing Stirling Engine Potential in Total Energy SystemsDocument172 paginiAssessing Stirling Engine Potential in Total Energy SystemsAgen KolarÎncă nu există evaluări

- v1.0 Rishabh Engineering CS 37 Piping Stress Analysis Horizontal HeaterDocument4 paginiv1.0 Rishabh Engineering CS 37 Piping Stress Analysis Horizontal HeaterJasonChong212Încă nu există evaluări

- EasiheatDocument12 paginiEasiheatEricOsowskiÎncă nu există evaluări

- IR HL Heatless DryerDocument1 paginăIR HL Heatless DryerYing Kei ChanÎncă nu există evaluări

- 1-Sanitary Drainage SystemsDocument20 pagini1-Sanitary Drainage Systemsraja bharathiÎncă nu există evaluări

- Main Cat 20082009Document321 paginiMain Cat 20082009Liviu Lazar100% (1)

- Design of Fluid Systems PDFDocument66 paginiDesign of Fluid Systems PDFVirendra KumarÎncă nu există evaluări

- Design of Air IDocument5 paginiDesign of Air IInvedeÎncă nu există evaluări

- FlowScanner User GuideDocument137 paginiFlowScanner User GuideJDavid NavaÎncă nu există evaluări

- BOSS™ Pressurisation Units and Expansion Vessels PDFDocument16 paginiBOSS™ Pressurisation Units and Expansion Vessels PDFRIFASÎncă nu există evaluări

- Refrigerant PipingDocument8 paginiRefrigerant PipingfaltuÎncă nu există evaluări

- Increasing Heat Exchanger PerformanceDocument13 paginiIncreasing Heat Exchanger Performanceimtinan mohsinÎncă nu există evaluări

- Clion-Marine Chiller Specs 2017Document1 paginăClion-Marine Chiller Specs 2017Sandy NugrahaÎncă nu există evaluări

- Pipe Insulation - Finding The Optimal ThicknessDocument5 paginiPipe Insulation - Finding The Optimal ThicknessmbsahgÎncă nu există evaluări

- NTN DES 019 Pipe Support SpacingDocument1 paginăNTN DES 019 Pipe Support Spacingjdsa123Încă nu există evaluări

- An Introduction To Wastewater Collection and Pumping R1Document84 paginiAn Introduction To Wastewater Collection and Pumping R1henrysayenÎncă nu există evaluări

- Clesse, Comap, NovacometDocument60 paginiClesse, Comap, NovacometVivek RajanÎncă nu există evaluări

- Hydronic RecoveryDocument4 paginiHydronic RecoveryKhizerÎncă nu există evaluări

- Es Hvacdesigntips0700Document1 paginăEs Hvacdesigntips0700sajuhereÎncă nu există evaluări

- ASME B16.03 - Malleable Iron Threaded Fittings PDFDocument54 paginiASME B16.03 - Malleable Iron Threaded Fittings PDFGrzegorz UrantówkaÎncă nu există evaluări

- Summary of ASME BPVC Section VIII Div 1 (Part 2) - Welding & NDTDocument14 paginiSummary of ASME BPVC Section VIII Div 1 (Part 2) - Welding & NDTTin Aung KyiÎncă nu există evaluări

- High-Rise Fan - Coil - EngineerDocument15 paginiHigh-Rise Fan - Coil - EngineerMIN GUIÎncă nu există evaluări

- PELS Exam For 4311Document9 paginiPELS Exam For 4311Jorge CastilloÎncă nu există evaluări

- 2011 Ref Guide PrintDocument152 pagini2011 Ref Guide Printcesar luis gonzalez rodriguezÎncă nu există evaluări

- Basic Refinery Equipment - Heat Exchanger (E003/1)Document27 paginiBasic Refinery Equipment - Heat Exchanger (E003/1)ebsmsart100% (1)

- Combining Thermal Energy Storage With Buildings-A ReviewDocument21 paginiCombining Thermal Energy Storage With Buildings-A ReviewRisshi AgrawalÎncă nu există evaluări

- Magnatrol Solenoid ValveDocument34 paginiMagnatrol Solenoid ValveWeb LogueandoÎncă nu există evaluări

- Bestline Mining Supplies LTD - 2010 EditionDocument50 paginiBestline Mining Supplies LTD - 2010 EditionTalabarteria RaygozaÎncă nu există evaluări

- Condensate Manual - Gestra PDFDocument176 paginiCondensate Manual - Gestra PDFtrpac100% (1)

- Basco Type 500Document12 paginiBasco Type 500Sebastian OviedoÎncă nu există evaluări

- Ngineering ATA: Temperature & Altitude Effects On FansDocument3 paginiNgineering ATA: Temperature & Altitude Effects On FansMohamed TahounÎncă nu există evaluări

- T Ces Series PDFDocument12 paginiT Ces Series PDFDaniel InostrozaÎncă nu există evaluări

- ASHRAE - The Fundamentals of Expansion Tanks PDFDocument7 paginiASHRAE - The Fundamentals of Expansion Tanks PDFAntonio LebrunÎncă nu există evaluări

- 1083ch1 7Document8 pagini1083ch1 7José GarciaÎncă nu există evaluări

- Vibration Pad Super WMDocument1 paginăVibration Pad Super WMjohndsainÎncă nu există evaluări

- Mason Seismic Restraint Guidelines PDFDocument234 paginiMason Seismic Restraint Guidelines PDFsunmechanical100% (1)

- Heatshrinkable Sheets: Manufacturer Statement & Product Data SheetsDocument15 paginiHeatshrinkable Sheets: Manufacturer Statement & Product Data SheetsariyamanjulaÎncă nu există evaluări

- 3-Inch Flexible Discharge Hose: Protection SystemsDocument1 pagină3-Inch Flexible Discharge Hose: Protection Systemsmax_powerÎncă nu există evaluări

- TDS 09 18Document7 paginiTDS 09 18Mahmoud AglanÎncă nu există evaluări

- Vivek Paul Engineer (Tech.) KLG Systel LTDDocument61 paginiVivek Paul Engineer (Tech.) KLG Systel LTDFirasat AliÎncă nu există evaluări

- Gantt-Chart L2Document7 paginiGantt-Chart L2Elijah JaireÎncă nu există evaluări

- Gantt Chart LDocument8 paginiGantt Chart LAshok PuttaparthyÎncă nu există evaluări

- CdA CalculatorDocument9 paginiCdA CalculatorselisenÎncă nu există evaluări

- Heat loss and fluid temperature calculation for buried insulated and non-insulated oil pipelinesDocument34 paginiHeat loss and fluid temperature calculation for buried insulated and non-insulated oil pipelinesselisenÎncă nu există evaluări

- Heat Exchanger Calculations: Inside Heat Trasfer CoefficientDocument4 paginiHeat Exchanger Calculations: Inside Heat Trasfer CoefficientBimal DeyÎncă nu există evaluări

- HVAC Heater Calculation SheetDocument1 paginăHVAC Heater Calculation SheetselisenÎncă nu există evaluări

- Snowkey Application HandbookDocument160 paginiSnowkey Application HandbookWalter J Naspirán CastañedaÎncă nu există evaluări

- ABCO Heat Exchanger CalculationsDocument1 paginăABCO Heat Exchanger CalculationsselisenÎncă nu există evaluări

- @water & Drainage Equipement DesignDocument46 pagini@water & Drainage Equipement DesignDesigner ForeverÎncă nu există evaluări

- Potable Water Expansion Tank Sizing ProgramDocument2 paginiPotable Water Expansion Tank Sizing ProgramChaosÎncă nu există evaluări

- 02 - Heat ExchangersDocument88 pagini02 - Heat ExchangersDana GuerreroÎncă nu există evaluări

- Cooling Tower. Application - TreybalDocument89 paginiCooling Tower. Application - TreybalPinak ProjectsÎncă nu există evaluări

- The Theory Behind Heat TransferDocument7 paginiThe Theory Behind Heat TransferselisenÎncă nu există evaluări

- @water & Drainage Equipement DesignDocument46 pagini@water & Drainage Equipement DesignDesigner ForeverÎncă nu există evaluări

- Viscosity Vs Temperature CalculatorDocument7 paginiViscosity Vs Temperature CalculatorRafael PerraciniÎncă nu există evaluări

- Processes 09 00939 v2Document19 paginiProcesses 09 00939 v2selisenÎncă nu există evaluări

- Chapter 27: Physical Properties Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument23 paginiChapter 27: Physical Properties Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallselisenÎncă nu există evaluări

- Partially Full Pipe Calculation Tool: US UnitsDocument4 paginiPartially Full Pipe Calculation Tool: US UnitsselisenÎncă nu există evaluări

- 01 Heat Conduction Pipe CalculatorDocument10 pagini01 Heat Conduction Pipe CalculatorselisenÎncă nu există evaluări

- Heat Loss From PipeDocument11 paginiHeat Loss From Pipemlarakahan100% (1)

- Calculation Tool Heat Flux Through A Single Pipe KNOWING Skin TemperaturesDocument5 paginiCalculation Tool Heat Flux Through A Single Pipe KNOWING Skin TemperaturesselisenÎncă nu există evaluări

- Pipe Headloss Calculator: Pipe Selection Fluid Flow InformationDocument1 paginăPipe Headloss Calculator: Pipe Selection Fluid Flow InformationselisenÎncă nu există evaluări

- Domestic Water Booster Pump CalculationsDocument25 paginiDomestic Water Booster Pump CalculationsuddinnadeemÎncă nu există evaluări

- Insulation Thickness Heat Transfer Pipe CalculationsDocument2 paginiInsulation Thickness Heat Transfer Pipe Calculationsrajpal14667% (6)

- Water Properties Calculation ToolDocument2 paginiWater Properties Calculation ToolselisenÎncă nu există evaluări

- Duct Elbow Area PDFDocument14 paginiDuct Elbow Area PDFSakthi.pÎncă nu există evaluări

- Temperature Rise of Centrifugal Pumps at No Flow and Low FlowDocument3 paginiTemperature Rise of Centrifugal Pumps at No Flow and Low FlowselisenÎncă nu există evaluări

- Sump Pit CalculationDocument4 paginiSump Pit CalculationEng Mahmoud Hamdy33% (3)

- Heat Transfer. Heat Loss From A Pipe in An Indoor LocationDocument29 paginiHeat Transfer. Heat Loss From A Pipe in An Indoor LocationselisenÎncă nu există evaluări

- Insulation Thickness Heat Transfer Pipe CalculationsDocument2 paginiInsulation Thickness Heat Transfer Pipe Calculationsrajpal14667% (6)

- Refraction Through Spherical Surfaces and LensesDocument2 paginiRefraction Through Spherical Surfaces and LensesOrbit MBBS PreparationÎncă nu există evaluări

- Chapter 1 Lecture1Document39 paginiChapter 1 Lecture1Anonymous AFFiZnÎncă nu există evaluări

- Molecular Partition Function ExplainedDocument18 paginiMolecular Partition Function ExplainedAnimasahun Olamide HammedÎncă nu există evaluări

- Isolation and Characterization of Degradation Products of Moxidectin PDFDocument20 paginiIsolation and Characterization of Degradation Products of Moxidectin PDFAnonymous 7aE6O6Încă nu există evaluări

- History of Buckling of ColumnDocument10 paginiHistory of Buckling of ColumnSorin Viorel CrainicÎncă nu există evaluări

- Ezy Math Tutoring - Year 9 AnswersDocument144 paginiEzy Math Tutoring - Year 9 AnswersVincents Genesius EvansÎncă nu există evaluări

- Dynamics Lab Sheet 1 - Free Vibration Experiment - PKPDocument3 paginiDynamics Lab Sheet 1 - Free Vibration Experiment - PKPfaqhrulÎncă nu există evaluări

- Iisus A Fost Crucificat La Constantinopole Si Nu La Ierusalim - Partea IVDocument65 paginiIisus A Fost Crucificat La Constantinopole Si Nu La Ierusalim - Partea IVsando khanÎncă nu există evaluări

- Lightweight SUV Frame Design DevelopmentDocument50 paginiLightweight SUV Frame Design DevelopmentAltairEnlightenÎncă nu există evaluări

- Forensic Chemistry ToxicologyDocument139 paginiForensic Chemistry ToxicologyCeasar Estrada94% (18)

- Mock C4 Paper Key ConceptsDocument4 paginiMock C4 Paper Key ConceptsWojtek BażantÎncă nu există evaluări

- Tuned Liquid Dampers for Efficient Tall Building DesignDocument9 paginiTuned Liquid Dampers for Efficient Tall Building Designsukanya12345Încă nu există evaluări

- Appendix G - Soldier Pile and Lagging Wall DesignDocument10 paginiAppendix G - Soldier Pile and Lagging Wall Designbusta299Încă nu există evaluări

- Filter Programs MatlabDocument8 paginiFilter Programs MatlabPreethi Sj100% (1)

- Turbocharger Test GuidelinesDocument13 paginiTurbocharger Test Guidelinespardomu0% (1)

- Static Studies of Magneto-Electro-Elastic 3-D Beam Using ANSYS - FINALDocument8 paginiStatic Studies of Magneto-Electro-Elastic 3-D Beam Using ANSYS - FINALjssrikantamurthyÎncă nu există evaluări

- OAT Bootcamp Physics Equation Sheet PDFDocument11 paginiOAT Bootcamp Physics Equation Sheet PDFjon100% (2)

- Plate Bending Element Formulation and Stiffness Matrix DevelopmentDocument6 paginiPlate Bending Element Formulation and Stiffness Matrix DevelopmentSeyhan ÖzenÎncă nu există evaluări

- Steam Drum Design CalsDocument78 paginiSteam Drum Design Calsabdulrehmandescon100% (1)

- Lahore University of Management Sciences: EE539 - Radar SystemsDocument3 paginiLahore University of Management Sciences: EE539 - Radar SystemsDr-Raghad Al-FahamÎncă nu există evaluări

- Differential Equations and Linear Algebra Lectura NotesDocument96 paginiDifferential Equations and Linear Algebra Lectura NotesClaudioTRodriguesÎncă nu există evaluări

- P Ractical Approaches To Fast Gas Chromatography-Mass Spectrometry Muy BuenoDocument28 paginiP Ractical Approaches To Fast Gas Chromatography-Mass Spectrometry Muy BuenoJavier Joao Lloyd IglesiasÎncă nu există evaluări

- Simulation of Soil Compaction With Vibratory Rollers PDFDocument13 paginiSimulation of Soil Compaction With Vibratory Rollers PDFSandeep KumarÎncă nu există evaluări

- Polar Moment of Inertia ExperimentDocument17 paginiPolar Moment of Inertia Experimentsohail parachaÎncă nu există evaluări

- Standing Waves On A StringDocument6 paginiStanding Waves On A StringamirpouyanÎncă nu există evaluări

- Physics Internal AssessmentDocument14 paginiPhysics Internal AssessmentRachitÎncă nu există evaluări

- Load CalculationsDocument5 paginiLoad Calculationsarif_rubinÎncă nu există evaluări

- CPM cc1 - CH 2 VocabularyDocument3 paginiCPM cc1 - CH 2 Vocabularyapi-252110147Încă nu există evaluări

- PMM WordDocument3 paginiPMM WordShrey R DhanawadkarÎncă nu există evaluări

- Lucia 1995 Rock-FabricPetrophysical Classification of Carbonate Pore SpaceDocument26 paginiLucia 1995 Rock-FabricPetrophysical Classification of Carbonate Pore SpaceMarcos Antonio Romero Arteaga100% (1)