Documente Academic

Documente Profesional

Documente Cultură

Controlador Veloc, Woodward 66728073-DYN1

Încărcat de

ricardo_dionisi2700Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Controlador Veloc, Woodward 66728073-DYN1

Încărcat de

ricardo_dionisi2700Drepturi de autor:

Formate disponibile

User Manual

APECS DYN1-1075X Controllers for DYNA 2000 and 2500 Linear Actuators

DYN1-10752 / DYN1-10753 / DYN1-10754 / DYN1-10756

Manual 36538

WARNINGDANGER OF DEATH OR PERSONAL INJURY

Read this entire manual and all other publications pertaining to the work to be performed before installing, operating, or servicing this equipment. Practice all plant and safety instructions and precautions. Failure to follow instructions can cause personal injury and/or property damage. This publication may have been revised or updated since this copy was produced. To verify that you have the latest revision, be sure to check the Woodward website: www.woodward.com/pubs/current.pdf The revision level is shown at the bottom of the front cover after the publication number. The latest version of most publications is available at: www.woodward.com/publications If your publication is not there, please contact your customer service representative to get the latest copy. The engine, turbine, or other type of prime mover should be equipped with an overspeed shutdown device to protect against runaway or damage to the prime mover with possible personal injury, loss of life, or property damage. The overspeed shutdown device must be totally independent of the prime mover control system. An overtemperature or overpressure shutdown device may also be needed for safety, as appropriate. Any unauthorized modifications to or use of this equipment outside its specified mechanical, electrical, or other operating limits may cause personal injury and/or property damage, including damage to the equipment. Any such unauthorized modifications: (i) constitute "misuse" and/or "negligence" within the meaning of the product warranty thereby excluding warranty coverage for any resulting damage, and (ii) invalidate product certifications or listings.

WARNINGFOLLOW INSTRUCTIONS

WARNINGOUT-OF-DATE PUBLICATION

WARNINGOVERSPEED PROTECTION

WARNINGPROPER USE

CAUTIONPOSSIBLE DAMAGE TO EQUIPMENT OR PROPERTY

CAUTIONBATTERY CHARGING

To prevent damage to a control system that uses an alternator or battery-charging device, make sure the charging device is turned off before disconnecting the battery from the system. Electronic controls contain static-sensitive parts. Observe the following precautions to prevent damage to these parts. Discharge body static before handling the control (with power to the control turned off, contact a grounded surface and maintain contact while handling the control). Avoid all plastic, vinyl, and Styrofoam (except antistatic versions) around printed circuit boards. Do not touch the components or conductors on a printed circuit board with your hands or with conductive devices.

CAUTIONELECTROSTATIC DISCHARGE

death or serious injury. A CAUTION indicates a potentially hazardous situation which, if not avoided, could result in damage to equipment or property. A NOTE provides other helpful information that does not fall under the warning or caution categories.

IMPORTANT DEFINITIONS A WARNING indicates a potentially hazardous situation which, if not avoided, could result in

RevisionsText changes are indicated by a black line alongside the text.

Woodward Governor Company reserves the right to update any portion of this publication at any time. Information provided by Woodward Governor Company is believed to be correct and reliable. However, no responsibility is assumed by Woodward Governor Company unless otherwise expressly undertaken.

Woodward 2006 All Rights Reserved

Manual 36538

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

Contents

ELECTROSTATIC DISCHARGE AWARENESS ............................................................... III CHAPTER 1. GENERAL INFORMATION.........................................................................1 Introduction .......................................................................................................... 1 Switches S1 and S2........................................................................................2 Speed Sensing................................................................................................2 Adjustments ....................................................................................................2 CHAPTER 2. SPECIFICATIONS ....................................................................................3 CHAPTER 3. CALIBRATION ........................................................................................4 Potentiometer Settings & Adjustments ................................................................ 4 S1 and S2 Settings .........................................................................................5 CHAPTER 4. WIRING & INSTALLATION .......................................................................6 Wiring................................................................................................................... 6 CHAPTER 5. TROUBLESHOOTING...............................................................................8 General Checklist................................................................................................. 8 Battery Voltage Check ....................................................................................8 Linkage Check ................................................................................................8 Magnetic Pickup Check ..................................................................................8 Troubleshooting Charts........................................................................................ 9 CHAPTER 6. SERVICE OPTIONS ...............................................................................12 Product Service Options .................................................................................... 12 Returning Equipment for Repair ........................................................................ 13 Replacement Parts ............................................................................................ 14 How to Contact Woodward ................................................................................ 14 Engineering Services ......................................................................................... 15 Technical Assistance ......................................................................................... 16

Woodward

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

Manual 36538

Illustrations and Tables

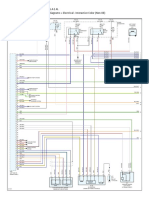

Figure 1. Electronic Control Box Adjustments, Configuration and Typical Wiring Diagram ................................................................................6 Figure 2. Typical Wiring for CE Models..............................................................7

ii

Woodward

Manual 36538

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

Electrostatic Discharge Awareness

All electronic equipment is static-sensitive, some components more than others. To protect these components from static damage, you must take special precautions to minimize or eliminate electrostatic discharges. Follow these precautions when working with or near the control. 1. Before doing maintenance on the electronic control, discharge the static electricity on your body to ground by touching and holding a grounded metal object (pipes, cabinets, equipment, etc.). Avoid the build-up of static electricity on your body by not wearing clothing made of synthetic materials. Wear cotton or cotton-blend materials as much as possible because these do not store static electric charges as much as synthetics. Keep plastic, vinyl, and Styrofoam materials (such as plastic or Styrofoam cups, cup holders, cigarette packages, cellophane wrappers, vinyl books or folders, plastic bottles, and plastic ash trays) away from the control, the modules, and the work area as much as possible. Do not remove the printed circuit board (PCB) from the control cabinet unless absolutely necessary. If you must remove the PCB from the control cabinet, follow these precautions: Do not touch any part of the PCB except the edges. Do not touch the electrical conductors, the connectors, or the components with conductive devices or with your hands. When replacing a PCB, keep the new PCB in the plastic antistatic protective bag it comes in until you are ready to install it. Immediately after removing the old PCB from the control cabinet, place it in the antistatic protective bag.

2.

3.

4.

To prevent damage to electronic components caused by improper handling, read and observe the precautions in Woodward manual 82715, Guide for Handling and Protection of Electronic Controls, Printed Circuit Boards, and Modules.

CAUTIONELECTROSTATIC DISCHARGE

Woodward

iii

Manual 36538

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

Chapter 1. General Information

Introduction

This manual provides information on the following controllers: CE PART NUMBER Previous P/N DYN1-10752-000-0-12 DYN1-10752-000-0-24

YES

INPUT SIGNAL FREQUENCY

Current P/N Replaced by DPG-2201-002 and DPG-2223-002

DYN1-10752-001-0-12 DYN1-10752-001-0-24 DYN1-10753-000-0-12 DYN1-10753-000-0-24 DYN1-10753-001-0-12 DYN1-10753-001-0-24 DYN1-10754-000-0-12 DYN1-10754-000-0-24 DYN1-10754-001-0-12 DYN1-10754-001-0-24 DYN1-10756-000-0-12 DYN1-10756-000-0-24 DYN1-10756-001-0-12 DYN1-10756-001-0-24

250-1200 Hz

YES

Replaced by DPG-2201-002 and DPG-2223-002 8270-1015 8270-1038 8270-1018 8270-1036 8270-1051 Replaced by DPG-2201-002 and DPG-2223-002

1200-2500 Hz

2500-5000 Hz

YES

5000-9000 Hz

YES

NOTE: Select the controller for the correct input signal frequency range generated by the magnetic pickup at the maximum engine speed and for the required DC voltage, 12 or 24.

Description & Features

Woodward DYNA I controllers for DYNA 2000 and 2500 linear actuators provide cost-effective, precision control of diesel, gasoline, or natural gas engines. Separate circuits measure the PROPORTIONAL (amount of OFF speed), INTEGRAL (time of OFF speed), and DERIVATIVE (rate of change of OFF speed) values. These parameters all work together to provide a control that results in fast and stable engine response to load changes while maintaining precise speed regulation.

Woodward

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

Manual 36538

Features

All electric All engine compatible Generator paralleling option Temperature stable High reliability Mounts in any position

Features that can be added at initial installation or when the need arises include: Remote speed setting (DYNS 10000 potentiometer) Isochronous load sharing Automatic synchronizing Ramp generator Single phase load pulse Kw limits

Switches S1 and S2

Switch S1 allows two response ranges for matching either diesel or gas engine dynamics. The diesel version integrates at twice the rate of the gas version. Set S1 to the OFF position for diesel engine applications. Set to the ON position for gas/gasoline engine applications. Switch S2 selects the point at which the actuator coil current level causes the integrator limit to be actuated. This level varies for 12 and 24 volt as shown below. S2 Switch Position OFF ON Model Actuator Part No. DC-10200 DC 10202 DC-10500 DC 10502 Coil Current @: 12V 24V 5.1A 7.2A 2.3A 3.4A

DYNA 2000 DYNA 2500

() Actuators not equipped with a potentiometer feedback transducer.

Typically the engine speed reference signal is obtained from a magnetic pickup mounted in the flywheel housing perpendicular to the ring gear. The number of teeth sensed per revolution is converted into an engine speed signal. Other techniques may be used to obtain speed reference.

Speed Sensing

Adjustments

Speed Setting: 20-turn potentiometer Gain: Single-turn potentiometer. 0 to 100% Integral: Single-turn pot. 0 to 100% Derivative: Single-turn pot. 0 to 100% Droop: Single-turn pot. 0 to 15%

Woodward

Manual 36538

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

Chapter 2. Specifications

Operating Voltage Steady State Speed Band Ambient Operating Temperature Temperature Stability 12 or 24 volts 20% 0.25% -40F to + 180F (-40C to + 85C) Better than 0.5% over temperatures of 40 to +167 (-40 to +75 F F C C) Withstands the following vibration without failure or degraded performance: Mechanical Vibration 0.06 inch double amplitude at 5 to 18 Hz 1 G at 18 to 30 Hz; 0.02 inch double amplitude at 30 to 48 Hz 2.5 G's at 48 to 70 Hz Output Signal Connections Circuit Boards Enclosure Weight PWM current to 6 A max. Terminal strip Heavy conformal coating for moisture and vibration protection Die cast aluminum 1.4 lb (635 g)

Woodward

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

Manual 36538

Chapter 3. Calibration

Potentiometer Settings & Adjustments

Observe that potentiometer settings are adjustable from zero to 100%. Each small division is 10%. The speed potentiometer is 10K, 20-turn. Set the small dip switch (S1) for the correct engine (see Chapter 1: Switches S1 and S2). Set switch S2 in the "OFF" position for actuator DC 10200 and DC 10202 or in the "ON" position for DC 10500 and DC 10502. If a remote speed potentiometer is used for narrow range, set to mid range. Initial Potentiometer Settings: GAIN 20% I 20% D 30% DROOP Zero For isochronous operation, set DROOP counterclockwise to minimum position as shown in Figure 1. For DROOP operation, set DROOP potentiometer clockwise to obtain desired amount of DROOP from no-load to full load. Turning potentiometer clockwise increases DROOP. START ENGINE (NO LOAD) 1. Adjust the controller speed potentiometer for desired engine speed. 2. Adjust the GAIN potentiometer clockwise until the engine begins to hunt. (If the engine remains stable at 100% GAIN, disrupt the actuator linkage by hand.) With the engine hunting, turn the GAIN potentiometer counterclockwise until stable.

A warm engine is normally more stable than a cold one. If the governor is adjusted on a warm engine, turn the adjustment potentiometers counterclockwise 5% (1/2 div.) to ensure a stable engine when started cold. 3. Repeat Step 2 for the "D" setting. 4. Repeat Step 2 for the "I" setting. 5. After calibration, it may be necessary to readjust the speed. 6. If the engine is a diesel, using the above calibration conduct the following test. With the engine operating at rated speed, turn the electric governor off. When engine speed slows to approximately half of rated speed, turn the electric governor back on. Observe the overshoot. If the overshoot is too great, turn the "I" potentiometer counterclockwise to lessen the overshoot. If there is a small hunt at steady state, slightly turn the "I" potentiometer counterclockwise until stable. In some cases, 2 to 5 Hz overshoot may be acceptable. 4 Woodward

NOTE

Manual 36538

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

7. If the engine is an ignition type using compressed fuel such as natural gas or LP, stop the engine and restart in the normal manner to check overshoot. If possible, operate the unit through various load ranges up to 100% to ensure stability.

S1 and S2 Settings

For diesel engine applications set S1 to the OFF position. For gas/gasoline engine applications set S1 to the ON position. When using a DYNA 2000 actuator (DYN1-1020X), set S2 to the OFF position. When using a DYNA 2500 actuator (DYN1-1050X), set S2 to the ON position. To insure accurate setting of ON / OFF switches, simply apply pressure with a small pointed object until the switch clicks into position.

As a safety measure, the engine should be equipped with an independent overspeed shutdown device in the event of failure, which may render the governor inoperative.

CAUTION POSSIBLE DAMAGE TO EQUIPMENT OR PROPERTY

Woodward

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

Manual 36538

Chapter 4. Wiring & Installation

Wiring

Figure 1. Electronic Control Box Adjustments, Configuration and Typical Wiring Diagram NOTES: Cable ADYNK 44-XX (specify length), 90 connector Cable BE26-22 (specify length) Cable CDYNZ 70-4 (specify length) (*) Sheilded Cablecustomer supplied. Should be a cable with a wrapped mylar supported aluminum foil shield with a drain wire. (**) Remote speed potentiometer (DYNS 10000) () The 5K remote speed potentiometer can be wired two ways: 1. As shown by the solid line from the wiper of the 5K pot and then connected to Terminal 9 (no resistor required). Adjustable range is approximately 5% at 1800 rpm. 2. As shown by the dashed line from the wiper of the 5K pot through resistor R and then connected to Terminal 8. Reducing the value of R increases the remote adjustable speed range. 6 Woodward

Manual 36538

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

Figure 2. Typical Wiring for CE Models

To prevent damage to the controller, make sure that it is wired in accordance with the wiring instructions and diagrams in this manual. Do not tin the leads before placing them into the terminals. Ensure the terminals are tightened properly to secure wires.

CAUTION: POSSIBLE DAMAGE TO EQUIPMENT OR PROPERTY

As a safety measure, the engine should be equipped with an independent overspeed shutdown device in the event of failure, which may render the governor inoperative.

CAUTION: POSSIBLE DAMAGE TO EQUIPMENT OR PROPERTY

Woodward

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

Manual 36538

Chapter 5. Troubleshooting

General Checklist

Battery Voltage Check

1. Set multimeter dial to read DC volts. 2. Connect the meter leads across the Red (battery positive) and Black (battery negative) wires of controller. With power to the controller ON, check the voltage during cranking and engine running. Voltage should be within range of engine manufacturers specifications. 3. If voltage is low, check the battery, charging system and/or wiring.

Linkage Check

Many problems can be traced to linkage binding confining motion due to tight settings and/or linkage backlash (backward motion due to loose connections). Linkage must have minimal friction, binding and backlash in order to assure accurate, responsive performance of the application. 1. With engine OFF, check for bent or misaligned linkage. 2. With engine OFF, manually operate linkage to see that it is not sticking, binding or has any backlash. 3. With engine OFF, ensure full travel of the linkage by manually moving it from idle/shutdown to maximum fuel. Travel should be smooth and should not exceed specified actuator stroke. 4. With engine OFF, check for worn out rod end bearings. Hardened steel races are recommended. 5. Correct linkage as needed.

Magnetic Pickup Check

1. Set multimeter dial to read AC volts 2. Connect the meter leads to the magnetic pickup White and Black/White wire of the controller. Check the voltage during cranking and running. Voltage should be 2.5 volts RMS or greater during cranking and running. (AC input impedance of meter must be 5000 ohms/volt or greater). 3. Check the magnetic pickup harness for an open circuit or short. 4. Check for damage to or improper adjustment of magnetic pickup. Replace or readjust. Too large of an air gap between the sensed gear and magnetic pickup could cause a weak signal. Adjust as needed, while avoiding damage to the magnetic pickup (magnetic pickup coming in the sensed gear). 5. Check wiring from the magnetic pickup to the controller. Twisted shielded cable is recommended. The cable should only be grounded at one end of the harness. 6. Check the mounting of the magnetic pickup. Mounting should be rigid; excessive vibration could cause spurious signals and unacceptable performance. 7. Make sure the sensed gear is not missing any teeth. 8. Check coil resistance of the magnetic pickup. Call the manufacturer of the magnetic pickup for specifications. 8 Woodward

Manual 36538

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

Troubleshooting Charts

PROBLEM: System is completely dead. Actuator lever stays at minimum. MEANS OF DETECTION

Check for battery voltage at controller on terminals 1 and 2. Terminal 1 is positive. Check for proper linkage set up. Magnetic pickup signal absent or too low. Measure AC volt across terminals 10 & 11 while cranking the engine. Voltage should be at least 2.5 Vac. NOTE: The voltmeter should have an impedance of 5000 ohms/volts or higher. Measure the resistance of the magnetic pickup coil. This should be from 150 ohms (250 ohms max). Measure the resistance of each pin to the metal case of the magnetic pickup. No continuity should be evident. DC SUPPLY OFF. Place an insulated jumper between terminals 2 & 3 (TP1 & TP2). With DC "ON" the actuator should go to full stroke. DC voltage at terminals 4 & 5 should be within 3 volts of the supply. Measure actuator coil resistance:

CORRECTIVE ACTION

Check battery connections and contacts for turning power "ON" to the controllers. Correct and free linkage. Check pole tip gap over gear tooth. It should be 0.37 0.127mm (0.015" 0.005") or adjusted to obtain 2.5 Vac or greater. Verify magnetic pickup wiring.

If there is an open or shorted coil, replace the magnetic pickup. If there is continuity to case, replace the magnetic pickup.

If the actuator still does not move to full stroke, continue with steps below. If actuator coil is open or shorted to case, replace actuator. If governor still does not operate, continue with steps below. If continuity is detected, replace the actuator.

12 Vdc unit: Coil resistance 1.8 0.2 ohms 24 Vdc unit: Coil resistance 7.3 1.0 ohms

Measuring the resistance of each coil lead to the actuator case should indicate an open circuit on a low scale of the ohmmeter. With the DC to the governor "ON" and the engine "OFF" measure the DC voltage from terminal 6 (+) to 2 (-). Voltage should be approx. 8 Vdc. Between terminal 7 (+) to 2 (-), the voltage should be approximately 4 Vdc. The following should be found when measuring current in series with one of the actuator leads from terminal 4 or 5:

If 8 Vdc is not present, replace the controller.

If 4 Vdc is not present, replace the controller.

12 V actuator--2.5A to 5.9A 24 V actuator--1.0A to 3.0A

(Values may indicate negative if polarity of meter reversed.)

If no output current, replace the controller.

Woodward

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

Manual 36538

PROBLEM: Actuator lever goes to full stroke when DC power is turned ON. (Engine is not operating.) MEANS OF DETECTION

Check magnetic pickup leads for proper shielded wire or open shield. Be sure there is no jumper between terminals 2 & 3. Fail-safe circuit in the controller may be damaged or defective. With DC power "OFF" remove leads at actuator. Check continuity of each terminal to case. There should be no continuity between any terminal and case of the controller. Check for shorted actuator lead. If remote speed potentiometer has been connected to terminals 6, 7 and 8, or 9 of the controller, DISCONNECT THESE LEADS.

Troubleshooting (contd.)

CORRECTIVE ACTION

Verify and correct wiring as necessary. Verify and correct wiring as necessary. Replace controller. If continuity is detected, replace the controller. Correct or replace actuator leads as necessary. Turn DC power to the governor ON if the actuator is now normal. Proceed as follows.

PROBLEM: Improper operation with remote speed potentiometer connected MEANS OF DETECTION

Investigate wiring to remote speed potentiometer for open or shorted circuits. If the leads at terminals 6 & 7 to the remote speed potentiometer are reversed, speed control by the remote speed potentiometer will be reversed. Lead wire to remote speed setting potentiometer should be 3-wire shielded cable. If terminal 7 lead to the remote speed potentiometer is open, engine speed will go high. If wiper lead to remote potentiometer is open, there will be no control by the remote speed potentiometer. If terminal 6 lead to the clockwise terminal of the remote speed potentiometer is open, speed will remain at the value set in the controller.

CORRECTIVE ACTION

Check wiring.

Correct wiring. Verify that the drain shield wire is isolated from ground at the potentiometer. Correct wiring.

Verify and correct wiring.

Verify and correct wiring.

PROBLEM: Erratic governor operation MEANS OF DETECTION

Measure DC voltage at 1 & 2 on controller terminal strip. Nominal battery voltage should be indicated. Battery voltage must be 80% or greater for governor to operate. RFI noise due to incorrect shielding. RFI noise fed through power supply leads.

CORRECTIVE ACTION

If nominal voltage is present, wiring is correct. Check battery and charging system. Correct wiring per applicable wiring diagram. Connect twisted pair power leads direct to the battery.

10

Woodward

Manual 36538

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

PROBLEM: Slow, small amplitude, hunting of speed or frequency MEANS OF DETECTION

Sticking or very loose linkage. Improper linkage arrangement (stroke too short or improper.)

CORRECTIVE ACTION

Correct linkage. See Linkage Check in General Checklist

PROBLEM: Erratic governor operation MEANS OF DETECTION

Measure DC voltage at 1 & 2 on controller terminal strip. Nominal battery voltage should be indicated. Battery voltage must be 80% or greater for governor to operate. RFI noise due to incorrect shielding. RFI noise fed through power supply leads.

CORRECTIVE ACTION

If nominal voltage is present, wiring is correct. Check battery and charging system. Correct wiring per applicable wiring diagram. Connect twisted pair power leads direct to the battery.

PROBLEM: Fast oscillation of governor linkage MEANS OF DETECTION

Verify calibration settings of the controller.

CORRECTIVE ACTION

Readjust settings.

PROBLEM: Engine will not startactuator at full stroke during cranking MEANS OF DETECTION

Make sure fuel is available. Air may be trapped in fuel line. Try to operate engine manually.

CORRECTIVE ACTION

Check fuel to engine and check for correct wiring to shut downs..

Woodward

11

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

Manual 36538

Chapter 6. Service Options

Product Service Options

The following factory options are available for servicing Woodward equipment, based on the standard Woodward Product and Service Warranty (5-01-1205) that is in effect at the time the product is purchased from Woodward or the service is performed: Replacement/Exchange (24-hour service) Flat Rate Repair Flat Rate Remanufacture If you are experiencing problems with installation or unsatisfactory performance of an installed system, the following options are available: Consult the troubleshooting guide in the manual. Contact Woodward technical assistance (see How to Contact Woodward later in this chapter) and discuss your problem. In most cases, your problem can be resolved over the phone. If not, you can select which course of action you wish to pursue based on the available services listed in this section.

Replacement/Exchange

Replacement/Exchange is a premium program designed for the user who is in need of immediate service. It allows you to request and receive a like-new replacement unit in minimum time (usually within 24 hours of the request), providing a suitable unit is available at the time of the request, thereby minimizing costly downtime. This is also a flat rate structured program and includes the full standard Woodward product warranty (Woodward Product and Service Warranty 5-01-1205). This option allows you to call in the event of an unexpected outage, or in advance of a scheduled outage, to request a replacement control unit. If the unit is available at the time of the call, it can usually be shipped out within 24 hours. You replace your field control unit with the like-new replacement and return the field unit to the Woodward facility as explained below (see Returning Equipment for Repair later in this chapter). Charges for the Replacement/Exchange service are based on a flat rate plus shipping expenses. You are invoiced the flat rate replacement/exchange charge plus a core charge at the time the replacement unit is shipped. If the core (field unit) is returned to Woodward within 60 days, Woodward will issue a credit for the core charge. [The core charge is the average difference between the flat rate replacement/exchange charge and the current list price of a new unit.] Return Shipment Authorization Label. To ensure prompt receipt of the core, and avoid additional charges, the package must be properly marked. A return authorization label is included with every Replacement/Exchange unit that leaves Woodward. The core should be repackaged and the return authorization label affixed to the outside of the package. Without the authorization label, receipt of the returned core could be delayed and cause additional charges to be applied.

12

Woodward

Manual 36538

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

Flat Rate Repair

Flat Rate Repair is available for the majority of standard products in the field. This program offers you repair service for your products with the advantage of knowing in advance what the cost will be. All repair work carries the standard Woodward service warranty (Woodward Product and Service Warranty 5-01-1205) on replaced parts and labor.

Flat Rate Remanufacture

Flat Rate Remanufacture is very similar to the Flat Rate Repair option with the exception that the unit will be returned to you in like-new condition and carry with it the full standard Woodward product warranty (Woodward Product and Service Warranty 5-01-1205). This option is applicable to mechanical products only.

Returning Equipment for Repair

If a control (or any part of an electronic control) is to be returned to Woodward for repair, please contact Woodward in advance to obtain a Return Authorization Number. When shipping the item(s), attach a tag with the following information: name and location where the control is installed; name and phone number of contact person; complete Woodward part number(s) and serial number(s); description of the problem; instructions describing the desired type of repair.

To prevent damage to electronic components caused by improper handling, read and observe the precautions in Woodward manual 82715, Guide for Handling and Protection of Electronic Controls, Printed Circuit Boards, and Modules.

CAUTIONELECTROSTATIC DISCHARGE

Packing a Control

Use the following materials when returning a complete control: protective caps on any connectors; antistatic protective bags on all electronic modules; packing materials that will not damage the surface of the unit; at least 100 mm (4 inches) of tightly packed, industry-approved packing material; a packing carton with double walls; a strong tape around the outside of the carton for increased strength.

Woodward

13

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

Manual 36538

Return Authorization Number

When returning equipment to Woodward, please telephone and ask for the Customer Service Department [1 (800) 523-2831 in North America or +1 (970) 482-5811]. They will help expedite the processing of your order through our distributors or local service facility. To expedite the repair process, contact Woodward in advance to obtain a Return Authorization Number, and arrange for issue of a purchase order for the item(s) to be repaired. No work can be started until a purchase order is received.

We highly recommend that you make arrangement in advance for return shipments. Contact a Woodward customer service representative at 1 (800) 523-2831 in North America or +1 (970) 482-5811 for instructions and for a Return Authorization Number.

NOTE

Replacement Parts

When ordering replacement parts for controls, include the following information: the part number(s) (XXXX-XXXX) that is on the enclosure nameplate; the unit serial number, which is also on the nameplate.

How to Contact Woodward

In North America use the following address when shipping or corresponding: Woodward Governor Company PO Box 1519 1000 East Drake Rd Fort Collins CO 80522-1519, USA Telephone+1 (970) 482-5811 (24 hours a day) Toll-free Phone (in North America)1 (800) 523-2831 Fax+1 (970) 498-3058 For assistance outside North America, call one of the following international Woodward facilities to obtain the address and phone number of the facility nearest your location where you will be able to get information and service. Facility Brazil India Japan The Netherlands Phone Number +55 (19) 3708 4800 +91 (129) 230 7111 +81 (476) 93-4661 +31 (23) 5661111

You can also contact the Woodward Customer Service Department or consult our worldwide directory on Woodwards website (www.woodward.com) for the name of your nearest Woodward distributor or service facility.

14

Woodward

Manual 36538

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

Engineering Services

Woodward Industrial Controls Engineering Services offers the following aftersales support for Woodward products. For these services, you can contact us by telephone, by email, or through the Woodward website. Technical Support Product Training Field Service

Contact information: Telephone+1 (970) 482-5811 Toll-free Phone (in North America)1 (800) 523-2831 Emailicinfo@woodward.com Websitewww.woodward.com Technical Support is available through our many worldwide locations or our authorized distributors, depending upon the product. This service can assist you with technical questions or problem solving during normal business hours. Emergency assistance is also available during non-business hours by phoning our toll-free number and stating the urgency of your problem. For technical support, please contact us via telephone, email us, or use our website and reference Customer Services and then Technical Support. Product Training is available at many of our worldwide locations (standard classes). We also offer customized classes, which can be tailored to your needs and can be held at one of our locations or at your site. This training, conducted by experienced personnel, will assure that you will be able to maintain system reliability and availability. For information concerning training, please contact us via telephone, email us, or use our website and reference Customer Services and then Product Training. Field Service engineering on-site support is available, depending on the product and location, from one of our many worldwide locations or from one of our authorized distributors. The field engineers are experienced both on Woodward products as well as on much of the non-Woodward equipment with which our products interface. For field service engineering assistance, please contact us via telephone, email us, or use our website and reference Customer Services and then Technical Support.

Woodward

15

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

Manual 36538

Technical Assistance

If you need to telephone for technical assistance, you will need to provide the following information. Please write it down here before phoning:

General

Your Name Site Location Phone Number Fax Number

Prime Mover Information

Engine/Turbine Model Number Manufacturer Number of Cylinders (if applicable) Type of Fuel (gas, gaseous, steam, etc) Rating Application

Control/Governor Information

Please list all Woodward governors, actuators, and electronic controls in your system:

Woodward Part Number and Revision Letter Control Description or Governor Type Serial Number Woodward Part Number and Revision Letter Control Description or Governor Type Serial Number Woodward Part Number and Revision Letter Control Description or Governor Type Serial Number

If you have an electronic or programmable control, please have the adjustment setting positions or the menu settings written down and with you at the time of the call.

16

Woodward

Manual 36538

APECS DYN1-1075X Controllers for DYNA 2000 & 2500 Actuators

Woodward

17

We appreciate your comments about the content of our publications. Send comments to: icinfo@woodward.com Please include the manual number from the front cover of this publication.

PO Box 1519, Fort Collins CO 80522-1519, USA 1000 East Drake Road, Fort Collins CO 80525, USA Phone +1 (970) 482-5811 Fax +1 (970) 498-3058

Email and Websitewww.woodward.com Woodward has company-owned plants, subsidiaries, and branches, as well as authorized distributors and other authorized service and sales facilities throughout the world. Complete address / phone / fax / email information for all locations is available on our website.

06/6/M

S-ar putea să vă placă și

- Follow - Up Steering Control AmplifierDocument24 paginiFollow - Up Steering Control AmplifierBozo Basic100% (1)

- Tib 0055 - r450 Avr Replacing The r448 AvrDocument7 paginiTib 0055 - r450 Avr Replacing The r448 AvrKelvin FaneyteÎncă nu există evaluări

- DSE8680 Operators ManualDocument51 paginiDSE8680 Operators ManualSon DoÎncă nu există evaluări

- GPU 2 Manual de InstalaciónDocument75 paginiGPU 2 Manual de InstalaciónjjcanoolivaresÎncă nu există evaluări

- 785CE Operation - Atlantis Marine PowerDocument90 pagini785CE Operation - Atlantis Marine PowerBeto SansÎncă nu există evaluări

- Auto Syn Woodward ManualDocument71 paginiAuto Syn Woodward ManualMary HarrisonÎncă nu există evaluări

- Control-Repeater Panel M 4.3 M en 2018 HDocument5 paginiControl-Repeater Panel M 4.3 M en 2018 HTURARAMA100% (1)

- Load Sharing Module WoodwardDocument36 paginiLoad Sharing Module WoodwardgusgifÎncă nu există evaluări

- Electronics: Automatic Voltage RegulatorDocument7 paginiElectronics: Automatic Voltage RegulatorOleksandr Cheban-Lianka50% (2)

- Simrad Repeaters Instruction Manual PDFDocument40 paginiSimrad Repeaters Instruction Manual PDFBeneDict Ben DÎncă nu există evaluări

- DSE7110MKII DSE7120 MKII Wiring Diagram PDFDocument3 paginiDSE7110MKII DSE7120 MKII Wiring Diagram PDFNave GanteÎncă nu există evaluări

- Configuration Manual Easygen 2000 SeriesDocument341 paginiConfiguration Manual Easygen 2000 SeriesGilberto Nunes Dualdo Junior100% (8)

- DYN110754 Technical Bulletin PDFDocument6 paginiDYN110754 Technical Bulletin PDFMaksim PanfilovÎncă nu există evaluări

- APECS Controllers For DYNA 2000 and 2500 Linear Actuators: User ManualDocument22 paginiAPECS Controllers For DYNA 2000 and 2500 Linear Actuators: User ManualwymjlbÎncă nu există evaluări

- Easy 3000 Installation ManualDocument52 paginiEasy 3000 Installation ManualHalit Yalçınkaya100% (1)

- Smartfind M5 Class A / Inland AIS Installation and Maintenance ManualDocument104 paginiSmartfind M5 Class A / Inland AIS Installation and Maintenance ManualRoyson Joseph0% (1)

- Digital Booklet - Bach ConcertosDocument14 paginiDigital Booklet - Bach Concertosppopgod33% (3)

- The SAGE Handbook of Digital JournalismDocument497 paginiThe SAGE Handbook of Digital JournalismK JÎncă nu există evaluări

- Speed Relay spr-p06Document3 paginiSpeed Relay spr-p06Elect Yan Lumoso100% (2)

- Aec 63-7 Avr 9273300990Document8 paginiAec 63-7 Avr 9273300990Bontha RajuÎncă nu există evaluări

- Smartpack II UMDocument32 paginiSmartpack II UMAnonymous jnG2gQEbHÎncă nu există evaluări

- mdc-2900 Ime Rev07 PDFDocument110 paginimdc-2900 Ime Rev07 PDFcostinosÎncă nu există evaluări

- Technical Manual for Norselight XS 1000 R10 SearchlightDocument20 paginiTechnical Manual for Norselight XS 1000 R10 SearchlightAlex Bombay100% (1)

- Inflatable Packers enDocument51 paginiInflatable Packers enDavid LuhetoÎncă nu există evaluări

- EGCP-2 Engine Generator Control PackageDocument64 paginiEGCP-2 Engine Generator Control PackageErick RojasÎncă nu există evaluări

- Follow - Up Steering Control Amplifier (Analog Version) : Type 139 - 153 E01Document24 paginiFollow - Up Steering Control Amplifier (Analog Version) : Type 139 - 153 E01Dharan NarayananÎncă nu există evaluări

- What Are The Reasons For Reverse Power To Occur in Generators While RunningDocument4 paginiWhat Are The Reasons For Reverse Power To Occur in Generators While Runningwaleed mohi100% (1)

- 01-Azeotropic Distillation (IL Chien)Document35 pagini01-Azeotropic Distillation (IL Chien)Shivam Vinoth100% (1)

- Cat Dcs Sis ControllerDocument2 paginiCat Dcs Sis ControllerЮрий Шариков100% (5)

- (Woodward) DPG-2201-001 Digital Governor - User ManualDocument40 pagini(Woodward) DPG-2201-001 Digital Governor - User ManualAbdulrahman Al HuribyÎncă nu există evaluări

- Compound ManualDocument28 paginiCompound ManualoveladoÎncă nu există evaluări

- Woodward MFR 13Document91 paginiWoodward MFR 13OryaÎncă nu există evaluări

- Quezon City Department of The Building OfficialDocument2 paginiQuezon City Department of The Building OfficialBrightNotes86% (7)

- New PDFDocument24 paginiNew PDFGolbert GolbiÎncă nu există evaluări

- Powertron Motor Starter Manual ENAD Ver5Document24 paginiPowertron Motor Starter Manual ENAD Ver5Aruljyothy PCÎncă nu există evaluări

- BTS 4000 PDFDocument43 paginiBTS 4000 PDFBf Ipanema100% (1)

- Sx460 Automatic Voltage Regulator (Avr)Document4 paginiSx460 Automatic Voltage Regulator (Avr)rajan_2002eee100% (1)

- 721 Speed ControlDocument102 pagini721 Speed Controlbondan_pertamaxÎncă nu există evaluări

- 21st Century LiteraciesDocument27 pagini21st Century LiteraciesYuki SeishiroÎncă nu există evaluări

- Banas Dairy ETP Training ReportDocument38 paginiBanas Dairy ETP Training ReportEagle eye0% (2)

- Masterpact M m32h1 STR38Dmerlin Gerin-2Document1 paginăMasterpact M m32h1 STR38Dmerlin Gerin-2Zoran NesicÎncă nu există evaluări

- Controllers For Stanadyne Pumps Using DC-70025 Integrated Actuators PDFDocument16 paginiControllers For Stanadyne Pumps Using DC-70025 Integrated Actuators PDFO mecanicoÎncă nu există evaluări

- Specifications of Avr - SMR (Mosfet)Document4 paginiSpecifications of Avr - SMR (Mosfet)Александр ЩеблыкинÎncă nu există evaluări

- Installation Manual Inmarsat-C Mes Felcom18: ModelDocument62 paginiInstallation Manual Inmarsat-C Mes Felcom18: Modelsrinu19840% (1)

- Woodward SPM ADocument32 paginiWoodward SPM AChristos Apostolopoulos100% (1)

- Old Steering CalibrateDocument1 paginăOld Steering Calibratejrj82Încă nu există evaluări

- Generator Voltage Regulator ManualDocument48 paginiGenerator Voltage Regulator ManualvjÎncă nu există evaluări

- SS350 Manual PDFDocument6 paginiSS350 Manual PDFCarlos GuareguaÎncă nu există evaluări

- Cosimat N+ PDFDocument38 paginiCosimat N+ PDFmass72Încă nu există evaluări

- Esd5111 enDocument4 paginiEsd5111 enMahdi Dehghankar100% (1)

- DSE555 Data SheetDocument4 paginiDSE555 Data SheetFabio JuniorÎncă nu există evaluări

- AD-100 Operator's Manual Ver U 8-20-04Document32 paginiAD-100 Operator's Manual Ver U 8-20-04BeneDict Ben DÎncă nu există evaluări

- BCM Battery Chargers Technical SpecificationDocument4 paginiBCM Battery Chargers Technical Specificationbbpncb100% (1)

- Catalogue of Permanent Company PDFDocument8 paginiCatalogue of Permanent Company PDFJaimeCoelloÎncă nu există evaluări

- EPQ96-2 Users Manual-Installation Note 4189320025 UKDocument17 paginiEPQ96-2 Users Manual-Installation Note 4189320025 UKСергей ГудинÎncă nu există evaluări

- DPG-2201-00X Digital Controllers: User ManualDocument50 paginiDPG-2201-00X Digital Controllers: User ManualPatrick CreighÎncă nu există evaluări

- InteliNano-AMF-1.5 - Fast User GuideDocument2 paginiInteliNano-AMF-1.5 - Fast User GuideGiangDo100% (3)

- Marine Master-Slave Clock Instruction ManualDocument7 paginiMarine Master-Slave Clock Instruction ManualFront Crown100% (1)

- Deepsea SettingDocument44 paginiDeepsea SettingPamungkas100% (1)

- Calibrating Dyn1 10794 Controllers for Stanadyne PumpsDocument4 paginiCalibrating Dyn1 10794 Controllers for Stanadyne PumpsGolbert GolbiÎncă nu există evaluări

- Deep Sea Electronics: DSE8660 MKII Configuration Suite PC Software ManualDocument155 paginiDeep Sea Electronics: DSE8660 MKII Configuration Suite PC Software ManualKG GeradoresÎncă nu există evaluări

- M060279-Deep Sea 5510 Insufficient Capacity Protection UpgradeDocument8 paginiM060279-Deep Sea 5510 Insufficient Capacity Protection UpgradelilyricardoseamanÎncă nu există evaluări

- Delomatic 3, SCM-1, Synchronising-Measuring Module 4921240056 UKDocument3 paginiDelomatic 3, SCM-1, Synchronising-Measuring Module 4921240056 UKВупсень ПупсеньÎncă nu există evaluări

- XSH - 0 - 2 Iss3 Type 1801 External Seahorse' Pantograph WiperDocument12 paginiXSH - 0 - 2 Iss3 Type 1801 External Seahorse' Pantograph WipertylerdurdaneÎncă nu există evaluări

- Fire Detector ED 820 InstalacionDocument6 paginiFire Detector ED 820 InstalacionluchobaiaÎncă nu există evaluări

- Paralleling PCC 2100 in Droop Mode Using Aux101 ModuleDocument2 paginiParalleling PCC 2100 in Droop Mode Using Aux101 ModuleGeneral Projects and Electric, C.A GEPECAÎncă nu există evaluări

- EPG Electrically Powered Governors With Single Phase Droop: Installation and Operation ManualDocument32 paginiEPG Electrically Powered Governors With Single Phase Droop: Installation and Operation ManualInter Home AguinzaÎncă nu există evaluări

- "60 Tips On Object Oriented Programming" BrochureDocument1 pagină"60 Tips On Object Oriented Programming" BrochuresgganeshÎncă nu există evaluări

- 2006-07 (Supercupa) AC Milan-FC SevillaDocument24 pagini2006-07 (Supercupa) AC Milan-FC SevillavasiliscÎncă nu există evaluări

- Operation Roman Empire Indictment Part 1Document50 paginiOperation Roman Empire Indictment Part 1Southern California Public RadioÎncă nu există evaluări

- CORE Education Bags Rs. 120 Cr. Order From Gujarat Govt.Document2 paginiCORE Education Bags Rs. 120 Cr. Order From Gujarat Govt.Sanjeev MansotraÎncă nu există evaluări

- Royal Enfield Market PositioningDocument7 paginiRoyal Enfield Market PositioningApoorv Agrawal67% (3)

- SyllabusDocument4 paginiSyllabusapi-105955784Încă nu există evaluări

- ADSLADSLADSLDocument83 paginiADSLADSLADSLKrishnan Unni GÎncă nu există evaluări

- MN AG v. SANOFI - 3:18-cv-14999 - Defendants' Joint Motion To Dismiss - 2019-08-12Document124 paginiMN AG v. SANOFI - 3:18-cv-14999 - Defendants' Joint Motion To Dismiss - 2019-08-12The Type 1 Diabetes Defense FoundationÎncă nu există evaluări

- MsgSpec v344 PDFDocument119 paginiMsgSpec v344 PDFqweceÎncă nu există evaluări

- Engine Controls (Powertrain Management) - ALLDATA RepairDocument4 paginiEngine Controls (Powertrain Management) - ALLDATA Repairmemo velascoÎncă nu există evaluări

- L-1 Linear Algebra Howard Anton Lectures Slides For StudentDocument19 paginiL-1 Linear Algebra Howard Anton Lectures Slides For StudentHasnain AbbasiÎncă nu există evaluări

- SAP PS Step by Step OverviewDocument11 paginiSAP PS Step by Step Overviewanand.kumarÎncă nu există evaluări

- SAP ORC Opportunities PDFDocument1 paginăSAP ORC Opportunities PDFdevil_3565Încă nu există evaluări

- Philippine Architecture, Film Industry EvolutionDocument4 paginiPhilippine Architecture, Film Industry EvolutionCharly Mint Atamosa IsraelÎncă nu există evaluări

- Mayor Byron Brown's 2019 State of The City SpeechDocument19 paginiMayor Byron Brown's 2019 State of The City SpeechMichael McAndrewÎncă nu există evaluări

- Mba Assignment SampleDocument5 paginiMba Assignment Sampleabdallah abdÎncă nu există evaluări

- Elementary School: Cash Disbursements RegisterDocument1 paginăElementary School: Cash Disbursements RegisterRonilo DagumampanÎncă nu există evaluări

- BAM PPT 2011-09 Investor Day PDFDocument171 paginiBAM PPT 2011-09 Investor Day PDFRocco HuangÎncă nu există evaluări

- Impact of Coronavirus On Livelihoods of RMG Workers in Urban DhakaDocument11 paginiImpact of Coronavirus On Livelihoods of RMG Workers in Urban Dhakaanon_4822610110% (1)

- Diagnostic Information For Database Replay IssuesDocument10 paginiDiagnostic Information For Database Replay IssuesjjuniorlopesÎncă nu există evaluări

- Gaspardo Operation Manual Campo 22-32-2014 01 f07011089 UsaDocument114 paginiGaspardo Operation Manual Campo 22-32-2014 01 f07011089 UsaМихайленко МиколаÎncă nu există evaluări

- Shoib CV Scaffold EngineerDocument3 paginiShoib CV Scaffold EngineerMohd Shoib100% (1)

- Weka Tutorial 2Document50 paginiWeka Tutorial 2Fikri FarisÎncă nu există evaluări