Documente Academic

Documente Profesional

Documente Cultură

Structural Upgrade of Reinforced Concrete Column-Tie Beam Assembly Using FRP Composites

Încărcat de

ram_babu_59Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Structural Upgrade of Reinforced Concrete Column-Tie Beam Assembly Using FRP Composites

Încărcat de

ram_babu_59Drepturi de autor:

Formate disponibile

SP-2584

Structural Upgrade of Reinforced Concrete Column-Tie Beam Assembly using FRP Composites

by A.S. Mosallam

Synopsis: The paper discusses the potential use of fiber reinforced polymer composites for repair and retrofit of existing reinforced concrete (RC) column-tie beam assemblies. Results of an experimental program performed on large-scale specimens repaired and strengthened with two types of wet lay-up composite systems are presented. Each column-tie beam assembly specimen was subjected to a constant axial load simulating gravity loads, and incremental cyclic lateral loads simulating potential seismic forces. Displacements, strains and loads were continuously monitored and recorded during all tests. Evaluations of the observed strength and ductility enhancements of the strengthened specimens are made and limitations of such retrofit methods are highlighted for design purposes. Experimental results indicated that the two composite systems used in this study succeeded in enhancing the strength, stiffness and the ductility of the column-tie beam assembly. As compared to the unstrengthened specimens, the strengths of the retrofitted specimens were 152% and 154% for carbon/epoxy and E-glass/epoxy composite systems, respectively.

Keywords: FRP composites; moment connections; seismic

57

58

Mosallam

Ayman S. Mosallam is a Professor in Resident and Director of the Structural Engineering Testing Hall and the Director of Advanced Composites & Nano Technology Laboratory at the Civil & Environmental and Engineering Department, University of California, Irvine. He is a registered Structural Professional Engineer. He has published over 250 technical papers, chapters, and reports on structural performance of structural systems. He is a member of ACI Committee 440, Fiber Reinforced Polymer Reinforcement. INTRODUCTION Over the years, several seismic repair and retrofitting techniques, including pressure epoxy injection, epoxy impregnation [1], external steel plating [2], and concrete jacketing [3] have been investigated. However, there are a number of drawbacks associated with these techniques. The 1995 Federal Emergency Management Agency (FEMA)-97 Report questions the effectiveness of the pressure injection technique in completely restoring the bond between the reinforcement and concrete. The epoxy impregnation method, while able to overcome the problem of the creation of voids in small-scale tests, is extremely difficult to apply on large practical scales. The use of bonded steel plates has several disadvantages, including high cost, possibility of corrosion of the steel at the bond-line interface (which can lead to premature bond failure), and the requirement for specialized heavy equipment at the job site. As compared to steel jacketing, the use of polymer composites repair and retrofit systems provide several unique advantages. The key advantage of composites in these applications is its tailorability, which enables the engineer to decouple stiffness and strength (stiffer columns would attract more forces during the earthquake which are not included in the original design). In the last decade or so, the use of fiber reinforced polymer (FRP) in repair and rehabilitation of different reinforced concrete members has been widely accepted by the structural engineering community. Some of the early successful application of FRP composites was in the repair and retrofit of reinforced concrete highway bridge columns that started in California and now is considered to be standard accepted procedures by different departments of transportation in USA and other countries. This application was extended to buildings and other constructed facilities where hundreds or may be thousands of repair and rehabilitation projects have been successfully executed. The use of these materials was shown to be also effective in repair and rehabilitation of reinforced concrete girders, slabs, shear walls as well as masonry wall structures [4, 5]. One of the recent applications of composites is repair and rehabilitations of different types of reinforced concrete joints including shear capacity upgrade of beam-column joints [6, 7] moment frame connections and column-tie connections [8, 9] as described in this paper. The major influence of connections details on the structural integrity and seismic performance of reinforced concrete structures has more evident after the 1989 Loma Prieta, the 1994 Northridge and 1999 Kocaeli (Turkey) earthquakes. Post earthquake reports of the Loma Prieta indicated that one of the main reasons behind the collapse of the Cypress Viaduct, and the damage of the China Basin and the I-80 Freeway is the failure of connections. As the result of 1994 Northridge earthquake, several parking structures collapsed mainly due to severe damage of beam-column and column-base connections (see Figure 1). During more recent events such as the 1999 Kocaeli (Turkey) earthquake, it was observed that beam-column joint failures contributed to the severe damage and collapse of many reinforced concrete buildings [10] (see Figure 2). Column-tie connections are found in many structures including space frames that are commonly used in oil refineries and petrochemical facilities (see Figure 3) and some parts of moment frame buildings (see Figure 4). For this special connections, no gravity loads are applied to the tie beam (no floor slabs), except of its own weight, and all vertical loads are transferred via columns as shown in Figures 3 and 4. In this case, the joint is exposed to minimum shear and relatively higher moments and axial loads in the column region. In this paper, a pilot study on repair and rehabilitation of this type of joint using two types of FRP composites is presented. EXPERIMENTAL PROGRAM In this study, two composite strengthening systems for column-tie beam connections were evaluated, that included i) carbon/epoxy wet layup system and, ii) E-glass/epoxy wet layup system. Table (1) presents the average values of the mechanical properties of the two FRP composites systems. The values presented in Table (1) were obtained from coupon specimens that were tested in accordance to ASTM D-3039 Standard Test Method for Tensile Properties of Fiber-Resin Composites.

Sesmic Strengthening of Concrete Buildings

Loading History

59

The loading regimes used in all evaluation tests described herein adhered to the ICC AC125 requirements as shown in Figure (5). In this loading scenario, the effect of seismic forces was simulated by applying reversed cyclic loading to the tip of the beam member while maintaining a constant axial load to the column. Per the ICC-AC 125 requirement, the lateral reversal load and displacement histories were divided into two phases. Initially, the tests were conducted under a load control mode until the yielding load of the connection steel reinforcements. At this stage, a displacement control mode was utilized. The test setup was designed such that the specimens are subjected to constant axial load and cyclic vertical loads. An axial load was applied to each horizontal member just before the test. The peak forces controlled the initial loading cycles until the specimen developed the force corresponding to the first yield of longitudinal steel, Vy. Then, the test was stopped and the yield displacement was calculated from the following equation:

y

Vi Vy

(1)

where 1 is the average of the measured peak displacements corresponding to the first-yield lateral load, Vy, in the push and pull directions. The ideal flexural lateral load capacity, Vi, is computed based on the extreme concrete compressive strain of 0.004 (0.005 for retrofitted specimens) and on measured material properties. After the specimen developed the first yield capacity, loading cycles were controlled by the peak displacement till failure. Displacement Ductility Displacement ductility factor , was used in defining the loading history. The ductility factor is defined as the ratio of the applied displacement ( ) over the displacement at first yielding of the connection steel reinforcements ( y). The yield displacement is defined by the following equation:

M if

My

(2)

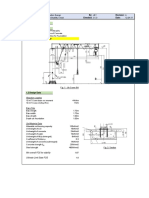

where 1 is the average measured displacement corresponding to the first yielding moment capacity, My, in the push/pull direction. The ideal flexural moment capacity, Mif, is calculated based on the concrete compressive strain and the measured materials properties. Test Specimens A total of four full-scale reinforced concrete column-tie beam assemblies tested under sustained axial column load and full lateral reversed cyclic loading conditions. The specimen represents a typical construction similar to those shown in Figures (3) and (4). The ends of the columns were pinned simulating inflection points. The columntie beam assemblies were configured to induce moment limit-states and related failure modes. As shown in Figure (6) extremes of dimensions and weak reinforcement details were employed per the recommendations of section 5.3.1 of the ICC-ES AC 125 [11]. Specimens Lay-up As it was mentioned earlier, two lay-up schedules were used for the carbon/epoxy and E-glass/epoxy systems. The general fiber architecture for both systems was similar and the only difference was in the number of plies in some directions. The general lamination concept is to strengthen the joint portion with quasi-isotropic laminate [0o/90o/45o] and the beam and the column portion with cross-ply laminate [0o/90o]. However, wrapping the 90olaminate was only applied to the column portion above and below the floor level (beams upper and lower faces) since wrapping the beam (which is desirable) is not practical in building applications because of the presence of the floor slab. To account for possible obstruction of the slab that will exist in an actual building, unstrengthened depth of 4 (101.6 mm), simulating the depth of the floor slab was maintained.

60

Mosallam

Control (Unstrengthened) Moment Frame Joints Tests In order to develop a baseline for comparing and quantifying the contributions of the composite strengthening systems, two identical control (unstrengthened) joint specimens were tested. Figure (6) shows the dimensions and reinforcement details for an unstrengthened interior column-tie beam joint (refer to Figures 3 and 4). The typical test setup for all specimens is shown in Figure (7). In performing this test, the loading history shown in Figure (5) was employed. Initially, load-control regime was adopted until the first yield, after which displacement-control loading was used. Figure (8) shows the control specimens during testing and the progression of failure. The load-deflection hysteresis curve for one of the unstrengthened control specimen is shown in Figure (9). The failure of the control specimen was brittle with an average ultimate lateral load of 19.55 kips that is corresponds to a moment capacity of 36.90 kip-ft (50 kN-m) and a maximum rotational angle of 0.03 radiant. The average idealized yield displacement of the control specimens was 0.34 (8.64 mm). Table (2) presents a summary for the average experimental values obtained from the control joints tests. Carbon/Epoxy Moment Frame Joints Tests Initially, the connection exhibited high stiffness which lasted for the first four cycles and up to a lateral displacement of about 1 (25.4 mm). At this stage, the joint reached its maximum load capacity of 29.85 kips (132.8 kN) which corresponds to a maximum flexural capacity of 55.10 kip-ft (74.71 kN-m). In the following cycles, gradual degradation in both stiffness and strength was noticed as shown in Figure (10). The idealized yield displacement was 0.67 (17 mm) and the ultimate displacement was 2.23 (56.64 mm). The joint relative rotation measured using the four LVDTs at the ultimate load was 0.041 rad. The maximum calculated ductility of this specimen was 3.6. Test results indicated that the flexural strength of the column-tie beam assemblies strengthened with the carbon/epoxy system was 1.53 times the average strength of the unstrengthened as-built specimen (29.85 kips (133 kN) vs. 19.55 kips (87 kN)). The ultimate lateral displacement at failure for the strengthened specimen was 1.24 times the corresponding displacement of the unstrengthened specimen (2.32 (59 mm) vs. 1.87 (47.5 mm)). In addition, test results indicated that the use of the carbon/epoxy FRP system resulted in an appreciable stiffness enhancement to the strengthened specimen as compared to the control one. The initial rotational stiffness has been increased to 15,000 kip-ft/rad (20,317 kN-m/rad) as compared to only 4,175 kip-ft/rad (5,655 kN-m/rad) for the control joint specimen with gain in the initial rotational stiffness of 260%. The ultimate failure of this specimen was a combination of spalling of the unstrengthened concrete portion of the joint that was extended to the top side of the tie beam (refer to Figure 11). This local joint damage resulted in a large joint rotation followed by a rupture of columns steel rebars at joint location as shown in Figure (11). The maximum-recorded FRP laminate strain was 0.68% which is about 60% of the rupture strain of the carbon/epoxy composite system. E-Glass/Epoxy Column-Tie Beam Joints Tests Similar to the previous evaluation test, the objective of this test was to demonstrate the structural performance and the effectiveness of the E-glass/epoxy composite system in enhancing the cyclic performance of a deficient reinforced concrete moment frame joints. The FRP lamination schedule for this specimen was similar to the carbon/epoxy strengthened specimens described earlier. After applying the composites, the composites material was allowed to cure for at least 72 hours under the laboratory environment. Strain gages at different critical locations and in different fiber directions were bonded to the external composite laminate as well as to the internal steel rebars. Figure (12) shows the P- hysteresis loops for the E-glass/epoxy composite strengthened joint specimen. Similar to the carbon/epoxy joint specimen, the joint exhibited a relatively high stiffness which lasted for the first five load levels (fifteen cycles), after which a gradual degradation in both stiffness and strength was observed. At this stage, the joint reached its maximum average load capacity of 32.7 kips (145.5 kN) which corresponds to a maximum flexural capacity of 60.36 kip-ft (81.51 kN-m). As shown in Figure (12), the strength degradation following the fifth cycle was very moderate (only 9% drop). The idealized yield displacement for this specimen was

Sesmic Strengthening of Concrete Buildings

61

0.65 (16.51 mm) and the ultimate displacement was 2.52 (64 mm). The joint relative rotation measured using the four LVDTs at the ultimate load was 0.045 rad. As shown in Figure (13), the ultimate ductility of this specimen was 3.9. Damage progression and ultimate failure are illustrated in Figure (14). The maximum laminate strain measured during this test was 2.15% which is about 95% of the rupture strain of the E-glass/epoxy composite system. Test results indicated that the strength of the column-tie beam joint assembly strengthened with E-glass/epoxy composite system is 1.54 times the average flexural strength of the unstrengthened control specimen (30.10 kips/133.9 kN vs. 19.55 kips/87 kN). The ultimate lateral displacement at failure for the strengthened specimen was 1.34 times the corresponding displacement of the unstrengthened specimen (2.52 (64 mm) vs. 1.87 (47.5 mm)). SUMMARY & CONCLUSIONS Experimental results indicated that the two FRP composite systems succeeded in enhancing the strength, stiffness and the ductility of the seismically-deficient reinforced concrete column-tie beam connections. As compared to the unstrengthened joint specimens, the strengths of the strengthened specimens were 152% and 154% for the carbon/epoxy and E-glass/epoxy composite systems, respectively. Figure (14) presents a graphical comparison between the strength capacity of the strengthened and the average strength capacity of the as-built (control) joint specimens. In addition, test results indicated that the use of the FRP composite strengthening systems resulted in an appreciable increase in the maximum lateral (floor) displacement at the cyclic ultimate load (20% increase for the carbon/epoxy and 35% for the E-glass/epoxy). Figure (15) presents the load-displacement envelopes for strengthened and unstrengthened (control) test specimens. As shown in this figure, both the strength and stiffness of the strengthened specimens were upgraded. This figure also indicates that the FRP strengthened specimens have a lower rate of strength deterioration and higher ductility up to failure (increased up to 35%) as well as higher initial stiffness as compared to the as-built specimen. ACKNOWLEDGEMENT The experimental program was sponsored by Structural Composites Construction, Inc (SCCI) as a part of an ICC-ES evaluation program. All composite materials evaluated in this paper were supplied by SCCI. REFERENCES Wolfgram French, C., Thorp, G. A. and Tsai, W., (1990). Epoxy Repair Techniques for Moderate Earthquake Damage. ACI Structural Journal July-August, pp. 416-424. 2. Flexural Retrofit of Rectangular Reinforced Concrete Bridge Columns by Steel Jacketing: Experimental Studies, Report No. SSRP-93/01, Department of Applied Mechanics and Engineering Sciences, University of California at San Diego, San Diego, CA, USA, 215p. 3. Alcocer, S. M., and Jersa, J.O. (1993). Strength of Reinforced Concrete Frame Connections Rehabilitated by Jacketing. ACI Structural Journal, Vol. 90, No. 3, pp. 249-261. 4. Mosallam, A.S. (2002), Composites in Construction, Chapter 45, Materials Handbook, John Wiley Publishing Co., NY, USA, 53 ps. 5. Mosallam, A.S. (2000), Innovative Seismic Repair & Rehabilitation Systems Proceedings, Technomic publishing Co., Pennsylvania. 6. Said, A., and Nehdi, M., 2004, Use of FRP for RC Frames in Seismic Zones: Part I. Evaluation of FRP BeamColumn Joint Rehabilitation Techniques, Journal of Applied Composite Materials, Vol. 11, No. 4, pp. 205-226. 7. Pantelides, C.P., and Gergely, J. (2002). Carbon-Fiber-Reinforced Polymer Seismic Retrofit of RC Bridge Bent: Design and In-Situ Validation. ASCE Journal of Composites in Construction, 6(1), 52-60. 8. Mosallam, A.S., et al. (1999). "Concrete Connections," Civil Engineering Magazine, January, pp. 43-45. 9. Mosallam, A.S. (2000). Strength and Ductility of Reinforced Concrete Moment Frame Connections Strengthened with Quasi-Isotropic Laminates, Composites Part B: Engineering, 31, 481-497. 10. Sezen, H., Elwood, K., Whittaker, A., Mosalam, K.M., Wallace, J., and Stanton, J. (2000), Structural Engineering Reconnaissance of the August 17, 1999, Kocaeli (Izmit), Turkey, Earthquake, PEER 2000/09, Pacific Earthquake Engineering Research Center, University of California, Berkeley, California. 1.

62

Mosallam

11. Acceptance Criteria for Concrete and Reinforced and Unreinforced Masonry Strengthening Using Externally Bonded Fiber-Reinforced Polymer (FRP) Composite Systems, AC125, January, 2007, International Code Council Evaluation Service (ICC-ES), Whittier, California.

Table 1 Properties of the Composites Materials

System Carbon/epoxy E-glass/epoxy Thickness (t) inch [mm] Ultimate Strength ksi [MPa] 154 [1,061] 74 [510] Strain at Ultimate (-strain) 0.012 0.022 Modulus of Elasticity ksi [GPa] 14 X103 [96.5] 3.5 X 103 [24.2]

0.045 [1.14] 0.045 [1.14]

Table 2 Average Experimental Values for the two Control Specimens

Ultimate Load, kips (kN) 19.55 (87) Average Moment Capacity, kipsin (kN-m) 443 (50) Average Lateral Displacement, in (mm) 1.7 (43.18) Average Relative Rotation, rad 0.03 Rotational Stiffness, kip-in/rad (kN-m/rad) 50,100 (5,655)

Figure 1 Local Failure of Beam-Column Connections during Northridge Earthquake, California, 1994. [8]

Sesmic Strengthening of Concrete Buildings

63

Figure 2 Building Collapse Due To Failure of RC BeamColumn Joints during 1999 Kocaeli Earthquake. [10]

No Slab

ColumnTie Beam Joint

Figure 3 Condenser and Elevated Tank Frame in Oil Refineries.

Figure 4 Typical Column-Tie Beam Joint in RC Buildings.

64

Mosallam

Figure 5 Typical Lateral Loading History. [Source: Fig. 1 ICC-ES AC 125]

Figure 6Dimensions and Reinforcement Details for Interior Control (Unstrengthened) Moment Frame Joints.

Figure 7Typical Test Setup.

Sesmic Strengthening of Concrete Buildings

65

Figure 8Control Column-Tie Beam Assemblies Test Setup and Progression of Failure.

Figure 9 Experimental Load-deflection Hysteresis for Unstrengthened Specimens.

66

Mosallam

Floor Displacement (mm)

-100 40 30 20 -75 -50 -25 0 25 50 75 100 160 120 80 Carbon/Epoxy Quasi-Isotropic Beam-Column Retrofitted Specimen

Seismic Load (kips)

10 0 -5 -4 -3 -2 -1 0 1 2 3 4

Push

5

40 0

-10 -20 -30 -40 -50 -4

Pull

Ductility

-40 -80

-120 -160 -200 -3 -2

Lateral Displacement (inch)

Floor Displacement (inch)

-1

Figure 10 Experimental Load-deflection Hysteresis for Carbon/Epoxy Retrofitted Specimens.

Figure 11 Ultimate Failure Mode of Carbon/Epoxy Retrofitted Specimen.

Seismic Load (KN)

Sesmic Strengthening of Concrete Buildings

67

Floor Displacement (mm)

-100 40 30 20 -75 -50 -25 0 25 50 75 100 160 120 80 E-Glass/Epoxy Quasi-Isotropic Beam-Column Retrofitted Specimen

Seismic Load (kips)

10 0 -5 -4 -3 -2 -1 0 1 2 3 4

Push

5

40 0 -40 -80

-10 -20 -30 -40 -50 -4

Pull

Ductility

-120 -160 -200 -3 -2

Floor Lateral Displacement (inch)

-1

Figure 12 P- Hysteresis Loops for E-Glass/Epoxy Retrofitted Specimen.

Figure 13 Damage Progression and Failure Mode of the E-Glass/Epoxy Retrofitted Specimen.

Seismic Load (KN)

68

Mosallam

Control (Average)

Carbon/Epoxy

E-glass/Epoxy

Figure 14Strength Comparison between Strengthened and Unstrengthened (As-Built) Column-Tie Beam Joint Specimens.

F lo o r D isp lacem en t (m m )

40 30 20 -75 -60 -45 -30 -15 0 15 30 45 60 75 160 120 80

Seismic Load (kips)

10 0 -10 -20 -30 -40 -50 -3.0

P u sh P u ll

40 0 -40 -80

-120

C o n tro l S p e cim en C a rbo n /E po xy R e tro fitte d S pe cim en E -G la ss/E p o xy R etro fitte d S p e cim e n

-160 -200 3.0

-2.5

-2.0

-1.5

-1.0

F lo o r D isp lacem en t (in ch )

-0.5

0.0

0.5

1.0

1.5

2.0

2.5

Lateral Displacement (inch)

Figure 15 Comparison between Load-Displacement Envelopes for Strengthened and Unstrengthened (Control) Test Specimens.

Seismic Load (KN)

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Downtime Data Collection and Analysis for Valid Simulation ModelsDocument7 paginiDowntime Data Collection and Analysis for Valid Simulation Modelsram_babu_59Încă nu există evaluări

- A Study On Trend of Export of Natural Stones From India To Various Countries PDFDocument20 paginiA Study On Trend of Export of Natural Stones From India To Various Countries PDFram_babu_59Încă nu există evaluări

- Chapalu in TeluguDocument2 paginiChapalu in TeluguRaj Yalla0% (3)

- E Program Files An ConnectManager SSIS TDS PDF Interplus 256 Eng HK A4 20091005Document4 paginiE Program Files An ConnectManager SSIS TDS PDF Interplus 256 Eng HK A4 20091005ram_babu_59Încă nu există evaluări

- ABC's of Spray Painting PDFDocument30 paginiABC's of Spray Painting PDFram_babu_59100% (1)

- 3.2 Classification of Costs 3.3 Definitions 3.4 Fixed Costs 3.5 Operating Costs 3.6 Labor Costs 3.7 Variable Effort Cycles 3.8 Animal Rates 3.9 ExamplesDocument17 pagini3.2 Classification of Costs 3.3 Definitions 3.4 Fixed Costs 3.5 Operating Costs 3.6 Labor Costs 3.7 Variable Effort Cycles 3.8 Animal Rates 3.9 Examplesram_babu_59Încă nu există evaluări

- Accurate Solutions DispensingDocument3 paginiAccurate Solutions Dispensingram_babu_59Încă nu există evaluări

- Jib Foundation Sizing and Stability AnalysisDocument4 paginiJib Foundation Sizing and Stability AnalysisChiedu Okondu50% (2)

- 2 GbcengDocument2 pagini2 Gbcengram_babu_59Încă nu există evaluări

- 7 Questions - How Do You Create Clarity in Your Job and Those of Your Employees? The Importance of A Good Employee-Manager RelationshipDocument6 pagini7 Questions - How Do You Create Clarity in Your Job and Those of Your Employees? The Importance of A Good Employee-Manager Relationshipram_babu_59Încă nu există evaluări

- A Facility Layout Problem in A Marble Factory ViaDocument9 paginiA Facility Layout Problem in A Marble Factory Viaram_babu_59Încă nu există evaluări

- PDFDocument10 paginiPDFJim TsikasÎncă nu există evaluări

- Bp2 Sitemaint and Qryclosure 052511Document12 paginiBp2 Sitemaint and Qryclosure 052511ram_babu_59Încă nu există evaluări

- Commute Sampleletter2Document1 paginăCommute Sampleletter2Mudassar KhanÎncă nu există evaluări

- Polishing Knowledge: A Study of Marble and Granite ProcessingDocument21 paginiPolishing Knowledge: A Study of Marble and Granite Processingram_babu_59Încă nu există evaluări

- Corrosion and Metalworking FluidsDocument5 paginiCorrosion and Metalworking Fluidsram_babu_59Încă nu există evaluări

- FulltextDocument63 paginiFulltextram_babu_59Încă nu există evaluări

- Best lubricants for gantry crane gearsDocument1 paginăBest lubricants for gantry crane gearsram_babu_59Încă nu există evaluări

- Level StaffDocument4 paginiLevel Staffram_babu_59Încă nu există evaluări

- Evergreen Engineering Inc.: P.O. Box 21530 Eugene, Oregon 97402-0409 (541) 484-4771 Fax (541) 484-6759Document5 paginiEvergreen Engineering Inc.: P.O. Box 21530 Eugene, Oregon 97402-0409 (541) 484-4771 Fax (541) 484-6759ram_babu_59Încă nu există evaluări

- Vpanel Brochure PDFDocument6 paginiVpanel Brochure PDFram_babu_59Încă nu există evaluări

- 3481e Catalogue BhagwatiDocument4 pagini3481e Catalogue Bhagwatiram_babu_59Încă nu există evaluări

- mpc03 152Document61 paginimpc03 152ram_babu_59Încă nu există evaluări

- AB 01 Model PDFDocument1 paginăAB 01 Model PDFram_babu_59Încă nu există evaluări

- Daily Work PlanDocument2 paginiDaily Work Planram_babu_59Încă nu există evaluări

- Workers' Accommodation: Processes and StandardsDocument38 paginiWorkers' Accommodation: Processes and StandardsIFC Sustainability50% (2)

- Column FootingDocument57 paginiColumn Footingnuwan01100% (7)

- Plaster Quantity: SL - No Description Quantity UnitDocument2 paginiPlaster Quantity: SL - No Description Quantity Unitram_babu_59Încă nu există evaluări

- P.B1 Plan Section A-B Rings PB1-750X800: Existing RCC BeamDocument1 paginăP.B1 Plan Section A-B Rings PB1-750X800: Existing RCC Beamram_babu_59Încă nu există evaluări

- DPRDocument2 paginiDPRSyed Adnan AqibÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Formula Michigan 2018 Event GuideDocument76 paginiFormula Michigan 2018 Event GuideGonzaloÎncă nu există evaluări

- Spandex Fiber: Dorlastan.) Invista, Radicispandex CorporationDocument20 paginiSpandex Fiber: Dorlastan.) Invista, Radicispandex CorporationShantnu MittalÎncă nu există evaluări

- Chassis, Aerodynamics and FeaDocument25 paginiChassis, Aerodynamics and FeaSivaPrasad Chekri100% (1)

- Manufacturing of Light Weight Composite Parts For Automotive ApplicationsDocument84 paginiManufacturing of Light Weight Composite Parts For Automotive ApplicationsvkrishnarajÎncă nu există evaluări

- Technical Programme ACMFMS2012DElhiDocument19 paginiTechnical Programme ACMFMS2012DElhiSwarnava GhoshÎncă nu există evaluări

- Shin2015Document9 paginiShin2015Riston SinagaÎncă nu există evaluări

- Dr. Yasir Nawab CVDocument6 paginiDr. Yasir Nawab CVYasir NawabÎncă nu există evaluări

- Concrete Silos: Failures, Design Issues and Repair/Strengthening MethodsDocument26 paginiConcrete Silos: Failures, Design Issues and Repair/Strengthening MethodsVenkatesh HebbarÎncă nu există evaluări

- Ameron GREDocument398 paginiAmeron GREnas_mech8208Încă nu există evaluări

- Thermoformable Composites PDFDocument26 paginiThermoformable Composites PDFd3bil0% (1)

- Cut Resistant Property of Weft Knitting StructureDocument14 paginiCut Resistant Property of Weft Knitting StructureHaider AliÎncă nu există evaluări

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument28 paginiWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsBRIGHT TECH INDUSTRIALS INDIA PVT LTDÎncă nu există evaluări

- 023 Morgano Clasico PDFDocument15 pagini023 Morgano Clasico PDFLaura Sandoval AcevedoÎncă nu există evaluări

- Journal of Building Engineering: Majid M.A. Kadhim, Akram R. Jawdhari, Mohammed J. Altaee, Ali Hadi AdheemDocument14 paginiJournal of Building Engineering: Majid M.A. Kadhim, Akram R. Jawdhari, Mohammed J. Altaee, Ali Hadi AdheemHùngÎncă nu există evaluări

- List of Papers - ICCEA - 2019Document7 paginiList of Papers - ICCEA - 2019akanagesÎncă nu există evaluări

- Design and Analysis of A Propeller Shaft of A Toyoto QualisDocument118 paginiDesign and Analysis of A Propeller Shaft of A Toyoto QualisSyed Hasan100% (2)

- Overview of Gearbox Development For Formula One: 2.2. Required PerformanceDocument6 paginiOverview of Gearbox Development For Formula One: 2.2. Required PerformanceBlaze123xÎncă nu există evaluări

- 614460-Multi-Objective Material Selection For Wind Turbine Blade and Tower - Ashby's Approach - 10Document12 pagini614460-Multi-Objective Material Selection For Wind Turbine Blade and Tower - Ashby's Approach - 10Erika Kawakami VasconcelosÎncă nu există evaluări

- Composite MaterialsDocument170 paginiComposite MaterialsAnonymous M0tjyW100% (1)

- Aircraft BRAKE SystemsDocument3 paginiAircraft BRAKE SystemsMuhammad KashifÎncă nu există evaluări

- Parker PTFE Fluid Power Seals PDFDocument116 paginiParker PTFE Fluid Power Seals PDFTaufan Arif100% (1)

- CM Seminar Topics PDFDocument2 paginiCM Seminar Topics PDFraviÎncă nu există evaluări

- HySpan 6500 CatalogDocument16 paginiHySpan 6500 CatalogdragasaniÎncă nu există evaluări

- Formulastudent2014 PDFDocument27 paginiFormulastudent2014 PDFDionisis SpiliopoulosÎncă nu există evaluări

- Biomedical Applications of Composite MaterialsDocument30 paginiBiomedical Applications of Composite MaterialsRita Singh50% (2)

- MBrace Lam PDFDocument2 paginiMBrace Lam PDFFrancois-Încă nu există evaluări

- Inderdeep Singh Mar 25 PDFDocument25 paginiInderdeep Singh Mar 25 PDFAakashSamaddarÎncă nu există evaluări

- Ch22-Materials Selection and Design ConsiderationDocument29 paginiCh22-Materials Selection and Design ConsiderationBryan de GuiaÎncă nu există evaluări

- PDFDocument25 paginiPDFMuddu AlaparthiÎncă nu există evaluări

- Retrofitting Chandaria Warehouse StructureDocument9 paginiRetrofitting Chandaria Warehouse Structuremusiomi2005Încă nu există evaluări