Documente Academic

Documente Profesional

Documente Cultură

Standardiso Fops 3449

Încărcat de

Anil Kumar KnDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Standardiso Fops 3449

Încărcat de

Anil Kumar KnDrepturi de autor:

Formate disponibile

ISO Standard 3449

Earth Moving Machinery Falling Object Protective Structures (FOPS) Laboratory Tests and Performance Requirements

Scope and Application: This international standard provides performance criteria for falling-object protective structures (FOPS). It recognizes that there are various classes and sizes of machines that operate in a variety of environmental conditions. It is intended to assure operators of reasonable protection from falling objects of different sizes and masses. This international standard specifies laboratory tests for measuring the structural characteristics of, and gives performance requirements in a representative test for, falling-object protective structures (FOPS) intended for use on ride-on earth-moving machines as defined in ISO 6165. It is applicable to both FOPS supplied as an integral part of the machine and those supplied separately for attachment to the machine. It is not intended to apply to FOPS for use on landfill compactors, excavators, rollers, trenchers, pipe layers, for the additional seat for operation of an attachment (e.g. attachment backhoe), or on machines with a power rating of less than 15 kW. The laboratory tests are a means of evaluating the characteristics of the structures used to protect the operator from localized impact penetration and, indirectly, of the loadcarrying capacity of the supporting structure to resist impact loading. This standard establishes a consistent, repeatable means of evaluating characteristics of FOPS under loading and prescribes performance requirements for these structures under such loading in a representative test. (For similar tests on FOPS for excavators and excavator based machines, see ISO 10262.) Note: This International Standard can be used to provide guidance to the manufacturers of roll-over or falling-object protective structures should it be decided to provide such protection for these or other machines for a particular application. Definitions: Falling-Object Protective Structure (FOPS) system of structural members arranged in such a way as to provide operators with reasonable protection from falling objects (trees, rocks, small concrete blocks, hand tools etc.) Roll-Over Protective Structure (ROPS) system of structural members whose primary purpose is to reduce the possibility of a seat-belted operator being crushed should the machine rollover. Note: Structural members include any sub frame, bracket, mounting, socket, bolt, pin, suspension or flexible shock absorption used to secure the system to the machine frame, but exclude mounting provisions that are integral with the machine frame. Deflection Limiting Volume DLV - orthogonal approximation of a large male, seated operator wearing normal clothing and a hard hat. Level I Impact Protection impact strength for protection from small falling objects (e.g. bricks, small concrete blocks, hand tools) encountered in operations such as highway maintenance, landscaping and other construction site services. Level II Impact Protection impact strength for protection from heavy fallingobjects (e.g. trees, rocks) for machines involved in site clearing, overhead demolition or forestry. Representative Test test of a specimen whose material, dimensional and processing requirements are typical of production FOPS. This standard goes on to discuss Laboratory Tests, Performance Requirements, Labelling and Reporting of Test Results.

(Over)

(contd) Labelling: A label shall be applied to every FOPS. When the structure meets the performance requirements for both the FOPS and ROPS, the ROPS labelling shall be in accordance with ISO 3471. The label shall be of a permanent type and permanently attached to the structure. The label and its contents shall be of a size that is legible. The label shall be located on the structure so that it can easily be read and so that it is protected from defacing by the weather. The labelling shall provide the following, minimum information: a) name and address of the manufacturer or constructor of the FOPS; b) FOPS identification number, if any; c) machine make, model(s), or product identification number(s) the structure is designed to fit; d) International Standard number(s) for which the structure meets all of the performance requirements and the level being met (national regulations may be included); e) Year of construction for FOPS, supplied separately for attachment to a machine. A combined FOPS/ROPS label shall include information from a) and c) of this clause. The manufacturer may include such other information as deemed appropriate (e.g. installation, repair or replacement information). The standard also discusses test reports and results of the tests. A typical test report format is annexed in the standard.

This bulletin contains a summary of excerpts taken from the Standard, for general information purposes only. This bulletin is not reflective of the complete requirements that the Standard prescribes.

Note: Manitoba Regulation M.R. 217/2006 Section 1.4 inconsistency: If there is an inconsistency between this regulation and a requirement contained in a publication, code or standard referenced in this regulation, the provisions in this regulation prevail.

S-ar putea să vă placă și

- What ROPS FOPS Certification MeansDocument8 paginiWhat ROPS FOPS Certification MeansJose Morales100% (1)

- Erecting Altering Dismantling Scaffolding Prefabricated Steel Modular Scaffolding Industry Safety Standard 2373Document32 paginiErecting Altering Dismantling Scaffolding Prefabricated Steel Modular Scaffolding Industry Safety Standard 2373madhav0303Încă nu există evaluări

- CFM56-5B: Lufthansa Technik AG Engine Parts & Accessories Repair (EPAR)Document154 paginiCFM56-5B: Lufthansa Technik AG Engine Parts & Accessories Repair (EPAR)özkanNeşeliÎncă nu există evaluări

- A-Plus Study Notes: CFA 2013 Level I CertificationDocument687 paginiA-Plus Study Notes: CFA 2013 Level I CertificationNguyễn Quốc Thắng100% (1)

- HRM Practice in ACIDocument19 paginiHRM Practice in ACIChakma Manson100% (1)

- Cms Guide To The Fidic 2017 Suite: Cms - Lawtax - Negative - 28-100.epsDocument44 paginiCms Guide To The Fidic 2017 Suite: Cms - Lawtax - Negative - 28-100.epsДенис КовалевÎncă nu există evaluări

- Ihc S 500Document2 paginiIhc S 500hk089Încă nu există evaluări

- As 2317-1998 Collared EyeboltsDocument8 paginiAs 2317-1998 Collared EyeboltsSAI Global - APACÎncă nu există evaluări

- Gear Non-Standard Tooth ProportionsDocument9 paginiGear Non-Standard Tooth Proportionsluis_dominguezeÎncă nu există evaluări

- SK FAQsDocument88 paginiSK FAQsLindsey MarieÎncă nu există evaluări

- Regulation of The Legal ProfessionDocument31 paginiRegulation of The Legal Professionlegalmatters100% (5)

- 1 - 2012 - Cranes - Wheels and Tracks Copy-TRDocument28 pagini1 - 2012 - Cranes - Wheels and Tracks Copy-TRmehmet türeÎncă nu există evaluări

- BS en Iso 7096-2008Document30 paginiBS en Iso 7096-2008marksuseÎncă nu există evaluări

- Design of Protective Structure of Operator Cabin Against Falling Object (FOPS)Document9 paginiDesign of Protective Structure of Operator Cabin Against Falling Object (FOPS)saravananjaiÎncă nu există evaluări

- Fork Extensions Crepa-22Document13 paginiFork Extensions Crepa-22Jogi Oscar SinagaÎncă nu există evaluări

- Horizontal Lifeline Systems GuidelineDocument4 paginiHorizontal Lifeline Systems GuidelinemohanÎncă nu există evaluări

- Deepak Project On Jaw CrusherDocument96 paginiDeepak Project On Jaw CrusherAnil Kumar KnÎncă nu există evaluări

- FTP 2004-2009Document81 paginiFTP 2004-2009Mayank Jain100% (1)

- Hammer MillDocument6 paginiHammer MillKamil Irfani100% (1)

- NR 26 Safety SignallingDocument6 paginiNR 26 Safety SignallingMarcia Rezende AntonioÎncă nu există evaluări

- International Standard: Fans - Performance Testing Using Standardized AirwaysDocument19 paginiInternational Standard: Fans - Performance Testing Using Standardized AirwaysviniciusschwabÎncă nu există evaluări

- Obligations and Contracts NotesDocument14 paginiObligations and Contracts NotesAys0% (1)

- Iso 3874Document34 paginiIso 3874BRIJITHÎncă nu există evaluări

- Standards Update Notice (Sun) ISSUED: July 8, 2020Document3 paginiStandards Update Notice (Sun) ISSUED: July 8, 2020jklelvis100% (1)

- Standardcsa Platform b354!2!2001 r2006Document3 paginiStandardcsa Platform b354!2!2001 r2006nodolaemailÎncă nu există evaluări

- As 7240.21-2006 Fire Detection and Alarm Systems Routing EquipmentDocument7 paginiAs 7240.21-2006 Fire Detection and Alarm Systems Routing EquipmentSAI Global - APACÎncă nu există evaluări

- Lever Hoist ManualDocument40 paginiLever Hoist Manualbeshoy100% (1)

- Iso 3449 2005 en PDFDocument8 paginiIso 3449 2005 en PDFkrlos_SW2009Încă nu există evaluări

- Iso 24023 2 2020Document9 paginiIso 24023 2 2020fÎncă nu există evaluări

- TUVME Profile 05 2014Document142 paginiTUVME Profile 05 2014Илгар НахматовÎncă nu există evaluări

- LEEA-062 Series Guidance To The Manufacturer of Lifting Equipment To The Development of Instructions For Use - V1 April 2015Document105 paginiLEEA-062 Series Guidance To The Manufacturer of Lifting Equipment To The Development of Instructions For Use - V1 April 2015Fariz SafarullaÎncă nu există evaluări

- Standardiso Rops 3471Document2 paginiStandardiso Rops 3471Gaurav AgarwalÎncă nu există evaluări

- En 131-2-2010+a2-2017Document6 paginiEn 131-2-2010+a2-2017Ibrahim shaik100% (1)

- Rollover Protective Structures (ROPS)Document3 paginiRollover Protective Structures (ROPS)hazopmanÎncă nu există evaluări

- Iso 188 2011Document11 paginiIso 188 2011Muhammad Kamran AsgharÎncă nu există evaluări

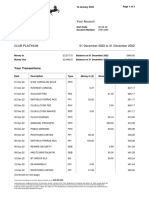

- Statement 2022 12Document3 paginiStatement 2022 12GustavoÎncă nu există evaluări

- BS 361-2002 Personal Protective Equipment Against Falls From A Height - Full Body Harnesses PDFDocument14 paginiBS 361-2002 Personal Protective Equipment Against Falls From A Height - Full Body Harnesses PDFRashid AliÎncă nu există evaluări

- List of BS CodeDocument8 paginiList of BS CodeCC OoiÎncă nu există evaluări

- 17E Taper Ring Guage STDDocument28 pagini17E Taper Ring Guage STDNPD QualityÎncă nu există evaluări

- En Iso 14122-3 (2001)Document20 paginiEn Iso 14122-3 (2001)Generosa FerreiraÎncă nu există evaluări

- ANSI/BHMA A156.1-2016: American National Standard For Butts and HingesDocument1 paginăANSI/BHMA A156.1-2016: American National Standard For Butts and HingesBui Chi TamÎncă nu există evaluări

- En 10204Document9 paginiEn 10204Uthayan SPÎncă nu există evaluări

- IS 17043 Part 1 2024 Shoes For ServicesDocument22 paginiIS 17043 Part 1 2024 Shoes For ServicesAvinash MishraÎncă nu există evaluări

- 558 Servo Pneumatic Universal Testing Machine For Resilient ModulusDocument6 pagini558 Servo Pneumatic Universal Testing Machine For Resilient ModulusRajesh KumarÎncă nu există evaluări

- Katalog Wampfler Narazniky EN PDFDocument34 paginiKatalog Wampfler Narazniky EN PDFpich222100% (1)

- EN 15151-1 enDocument1 paginăEN 15151-1 enMulyana Ibex100% (1)

- prEN ISO 3471-1.2 - 2006 - EDocument2 paginiprEN ISO 3471-1.2 - 2006 - EMontineriÎncă nu există evaluări

- Appendix A Rev 0Document3 paginiAppendix A Rev 0Afsal AchoosÎncă nu există evaluări

- En 341Document6 paginiEn 341Ariane Bronkow100% (1)

- Bash-P General CatalogueDocument123 paginiBash-P General CatalogueAri Rizki RivaldoÎncă nu există evaluări

- Datasheet For Gate ValveDocument1 paginăDatasheet For Gate ValveSudheepÎncă nu există evaluări

- Examination SchemesDocument2 paginiExamination SchemesegyinspectoryahooÎncă nu există evaluări

- MOM Inspection Requirements Lifting EquipmentDocument1 paginăMOM Inspection Requirements Lifting EquipmentLew MingÎncă nu există evaluări

- EN 12277 enDocument1 paginăEN 12277 enDean WilyÎncă nu există evaluări

- ANSI Standard A14.3-2000Document3 paginiANSI Standard A14.3-2000Jairo WilchesÎncă nu există evaluări

- Iso 9969 2007 Determining The Ring Stiffness ValueDocument14 paginiIso 9969 2007 Determining The Ring Stiffness ValueMICHAEL SCOTTY100% (1)

- MST Leak Test GRPDocument2 paginiMST Leak Test GRPmohd hyderÎncă nu există evaluări

- Sist en 14579 2004Document9 paginiSist en 14579 2004AnelÎncă nu există evaluări

- Gear Box No Load Run Test ReportDocument1 paginăGear Box No Load Run Test ReportPRABHUDAYAL SHARMAÎncă nu există evaluări

- Astm D4385-10Document7 paginiAstm D4385-10roshniÎncă nu există evaluări

- AppeDocument9 paginiApperadu_pop_52Încă nu există evaluări

- Light Weight Deflectometer For The Dynamic Plate Load Test Instruction Manual H-4119A - H-4129A PDFDocument96 paginiLight Weight Deflectometer For The Dynamic Plate Load Test Instruction Manual H-4119A - H-4129A PDFManuelÎncă nu există evaluări

- Usepa - 3051 ADocument30 paginiUsepa - 3051 Awrangel_2Încă nu există evaluări

- Non-Destructive Testing (NDT) For Determining The Integrity of Seams Used in Joining Flexible Polymeric Sheet GeomembranesDocument2 paginiNon-Destructive Testing (NDT) For Determining The Integrity of Seams Used in Joining Flexible Polymeric Sheet GeomembranesLeudy UtriaÎncă nu există evaluări

- TURNBUCKLEDocument2 paginiTURNBUCKLEAnonymous cljdRqO8Încă nu există evaluări

- Astm-F1759 - Hdpe Mahole DesignDocument12 paginiAstm-F1759 - Hdpe Mahole DesignSusanta PanigrahyÎncă nu există evaluări

- Classification of Equipment Lifting Machinery Dec 2009 enDocument7 paginiClassification of Equipment Lifting Machinery Dec 2009 enisrael.cayado5861Încă nu există evaluări

- DS - en 1997-2 DK Na - 2011 eDocument9 paginiDS - en 1997-2 DK Na - 2011 ep_meulendijks108Încă nu există evaluări

- Surface Vehicle Standard: Issued APR1998Document14 paginiSurface Vehicle Standard: Issued APR1998anupthattaÎncă nu există evaluări

- MSH SB 126Document5 paginiMSH SB 126Dandung Yunianto123Încă nu există evaluări

- New 3Document10 paginiNew 3qwrasdfÎncă nu există evaluări

- 1LE1503-2BB03-4AA4 Datasheet enDocument1 pagină1LE1503-2BB03-4AA4 Datasheet enAnil Kumar KnÎncă nu există evaluări

- Wilfley Table LabDocument3 paginiWilfley Table LabAnil Kumar Kn0% (1)

- Jaw Crushers and Disk Mills: FritschDocument20 paginiJaw Crushers and Disk Mills: FritschAnil Kumar KnÎncă nu există evaluări

- 15 X 21 Batch Ball MillDocument12 pagini15 X 21 Batch Ball MillAnil Kumar KnÎncă nu există evaluări

- Revvo Motor Catalogue 2021Document32 paginiRevvo Motor Catalogue 2021Anil Kumar KnÎncă nu există evaluări

- VCM 100 and VCM 400Document2 paginiVCM 100 and VCM 400Anil Kumar KnÎncă nu există evaluări

- Jaw Crushers and Disk Mills: FritschDocument20 paginiJaw Crushers and Disk Mills: FritschAnil Kumar KnÎncă nu există evaluări

- Vol37No1ManTIOgedengbeJul2014 PDFDocument6 paginiVol37No1ManTIOgedengbeJul2014 PDFAnil Kumar KnÎncă nu există evaluări

- ChancadoDocument17 paginiChancadokevin guaoÎncă nu există evaluări

- Jaw Crushers and Disk Mills: FritschDocument20 paginiJaw Crushers and Disk Mills: FritschAnil Kumar KnÎncă nu există evaluări

- DesignAndAnalysisOfRototShaftAssemblyOfHammerMillCrusher (22 30) PDFDocument9 paginiDesignAndAnalysisOfRototShaftAssemblyOfHammerMillCrusher (22 30) PDFAnil Kumar KnÎncă nu există evaluări

- Fibrous MatDocument8 paginiFibrous MatAnil Kumar KnÎncă nu există evaluări

- Brochure DFZK Vertica Hammer Mill enDocument4 paginiBrochure DFZK Vertica Hammer Mill enAnil Kumar KnÎncă nu există evaluări

- Brochure DFZK Vertica Hammer Mill enDocument4 paginiBrochure DFZK Vertica Hammer Mill enAnil Kumar KnÎncă nu există evaluări

- Design Fabrication and Testing of A Laboratory Size Hammer Mill1Document11 paginiDesign Fabrication and Testing of A Laboratory Size Hammer Mill1Esteban San Martín MaulénÎncă nu există evaluări

- Hammer MillDocument4 paginiHammer MillAnil Kumar KnÎncă nu există evaluări

- Core Splitter Brochure 1 1 14Document2 paginiCore Splitter Brochure 1 1 14Anil Kumar KnÎncă nu există evaluări

- ChancadoDocument17 paginiChancadokevin guaoÎncă nu există evaluări

- 13 Series Industrial Grinder - BrochureDocument2 pagini13 Series Industrial Grinder - BrochureAnil Kumar KnÎncă nu există evaluări

- Prater HammermillsDocument2 paginiPrater HammermillsAnil Kumar KnÎncă nu există evaluări

- FB Pellet Dies and Roll Shells en DataDocument4 paginiFB Pellet Dies and Roll Shells en DataAnil Kumar KnÎncă nu există evaluări

- Sales Template - PBM - 1Document2 paginiSales Template - PBM - 1Anil Kumar KnÎncă nu există evaluări

- C CatalogDocument16 paginiC CatalogAnil Kumar KnÎncă nu există evaluări

- Jaw Crusher BrochureDocument2 paginiJaw Crusher BrochureAnil Kumar KnÎncă nu există evaluări

- Userfiles File N26AtlasAutoPressDocument2 paginiUserfiles File N26AtlasAutoPressAnil Kumar KnÎncă nu există evaluări

- Jaw Crusher Brochure PDFDocument2 paginiJaw Crusher Brochure PDFAnil Kumar KnÎncă nu există evaluări

- Industrial Electrical SymbolsDocument4 paginiIndustrial Electrical Symbols최우혁Încă nu există evaluări

- Law 203 First Semester NoteDocument12 paginiLaw 203 First Semester NoteAhmad IbÎncă nu există evaluări

- Celex 52020PC0596 enDocument18 paginiCelex 52020PC0596 enJózsef PataiÎncă nu există evaluări

- Revenue Generation Strategies in Sub Saharan African Universities Compatibility ModeDocument15 paginiRevenue Generation Strategies in Sub Saharan African Universities Compatibility ModeLakim ArsenalÎncă nu există evaluări

- Certificate No.: Room # 908, Uni Plaza, I. I. Chundrigar Road, Karachi PakistanDocument1 paginăCertificate No.: Room # 908, Uni Plaza, I. I. Chundrigar Road, Karachi PakistanSyed Mohammad Ali MehdiÎncă nu există evaluări

- Fixing Ownership of A Patent After The FactDocument12 paginiFixing Ownership of A Patent After The Factbodong408100% (1)

- Prohibited and Restricted Substances: Suppliers GuideDocument7 paginiProhibited and Restricted Substances: Suppliers GuideAlprecoÎncă nu există evaluări

- Application Form Electrical Installation PermitDocument5 paginiApplication Form Electrical Installation PermitStephen Amachi Chisati100% (1)

- Test 1 - 2 All Law PapersDocument26 paginiTest 1 - 2 All Law PapersShrikant RathodÎncă nu există evaluări

- Aashish ContractsDocument28 paginiAashish ContractsAshish MittalÎncă nu există evaluări

- StatconDocument334 paginiStatconjaikaÎncă nu există evaluări

- Petition 143 of 2014Document9 paginiPetition 143 of 2014Andrew OkoitiÎncă nu există evaluări

- Ifrs For SmesDocument2 paginiIfrs For SmesChristieJoyCaballesParadelaÎncă nu există evaluări

- McAfee Et Al. - What Is A Barrier To EntryDocument5 paginiMcAfee Et Al. - What Is A Barrier To EntryBenjamín Lingay OsesÎncă nu există evaluări

- Corporate Social and Environmental Responsibility A Short Report On IKEA B.VDocument8 paginiCorporate Social and Environmental Responsibility A Short Report On IKEA B.VbrazzrÎncă nu există evaluări

- IPPA1 SampleDocument6 paginiIPPA1 SamplePV PalmaÎncă nu există evaluări

- Force MajeureDocument11 paginiForce MajeuremrlobboÎncă nu există evaluări

- Bancassurance-FinalDocument61 paginiBancassurance-Finalprabs9869Încă nu există evaluări

- Project Study Format GuideDocument3 paginiProject Study Format GuideTemoteo L. Pupa IIIÎncă nu există evaluări

- Government of Karnataka: ST STDocument7 paginiGovernment of Karnataka: ST STraghavendhraaÎncă nu există evaluări

- SAKINAH LA RINE A1M218019 - Task 3 Critical ReadingDocument2 paginiSAKINAH LA RINE A1M218019 - Task 3 Critical ReadingMarwan AlfarisÎncă nu există evaluări