Documente Academic

Documente Profesional

Documente Cultură

1937 - 0856

Încărcat de

seafire47Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

1937 - 0856

Încărcat de

seafire47Drepturi de autor:

Formate disponibile

FLIGHT.

APRIL I , 1937.

A prominent feature on the starboard side of the Major 150 is the flame-trap. The design allows the whole induction system to be removed in-a few minutes by disconnecting the spring-loaded ball joints of the controls, slackening a steady bracket on the flame-trap and undoing eight locating dome nuts. This and the simple fitting of the exhaust stubs allow quick removal of cylinder heads. As none of the accessories has a particular gear positioning any one may be removed singly from the rear cover without disturbing the timing. On considering the full equipment and sturdy construction of the Major 150 the weight strikes one as being creditably low, for with flame-trap, cooling chute, cylinder baffles, airscrew hub and spinner, dual Amal pump and its flexible copper piping, exhaust stubs and new Cirrus Minor type rubber mountings and rigid metal feet the ratio is 2.16 lb. per h.p. The weight of the complete engine, but without the full equipment, is 300J lb. A 12-volt, 60-watt generator, with drive and housing, an inertia starter and all other equipment, increases the total weight to 351^ lb. + or 5 lb. I t is intended to supply a combined manifold-silencer for the exhaust stubs. To add to the general clean and smart appearance of the engine all external polished parts are plated or stove enamelled. A kit of tools for running adjustments is supplied and the engine is designed to run on any first-grade A cylinder billet, the rough turned cylinder and motor car fuel of 70 octane value. a cylinder finned and flanged but awaiting final The suppliers of the various grinding operations.

-:-: ^IjjHHjl

clearly from the induction side, is located in a well formed at the rear of the main crankcase. A return main oil-pipe, a pressure pipe from a nipple on the main casting, a flexible petrol pipe and the carburettor and ignition controls and intercontrols remain for connection to complete this part of the installation. Petrol and oil filters are seen to be very conveniently placed for inspection and cleaning, and air scoop windows, not shown in the photographs, will give ready access to the K.L.G. sparking plugs on production engines.

On the left is the crankcase with main bearing caps in position (note " shrunk-in " pressure feed pipe and scavenge pipe) ; above are a connecting rod, partly machined, showing the jig pins, and a rough and a finished piston together with a Lord resilient mounting in a bearer foot; and below is the crankshaft with its front ball race.

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shor BRQS.: of RochesterDocument1 paginăShor BRQS.: of Rochesterseafire47Încă nu există evaluări

- Gtsac : Flight Engineering SectionDocument1 paginăGtsac : Flight Engineering Sectionseafire47100% (1)

- "Mercury" Makes GoodDocument1 pagină"Mercury" Makes Goodseafire47Încă nu există evaluări

- 7 Moundsville Lone Eagle 94Document9 pagini7 Moundsville Lone Eagle 94seafire47Încă nu există evaluări

- 203 Sample ArticleDocument8 pagini203 Sample Articleseafire47Încă nu există evaluări

- 598 Flight.: DECEMBER I 6, 1937Document1 pagină598 Flight.: DECEMBER I 6, 1937seafire47Încă nu există evaluări

- SB2U VindicatorDocument11 paginiSB2U Vindicatorseafire47100% (1)

- North American P-51D in Detail (Revisited) - FuselagesDocument10 paginiNorth American P-51D in Detail (Revisited) - Fuselagesseafire47Încă nu există evaluări

- Splash 1Document4 paginiSplash 1seafire47100% (1)

- North American P-51D in Detail (Revisited) - Wings and TailsDocument10 paginiNorth American P-51D in Detail (Revisited) - Wings and Tailsseafire47100% (2)

- Modeller's Guide To Late P-51 Mustang VariantsDocument17 paginiModeller's Guide To Late P-51 Mustang Variantsseafire47100% (1)

- Seversky P-35 in DetailDocument10 paginiSeversky P-35 in Detailseafire47100% (1)

- Modeller's Guide To Early P-51 Mustang VariantsDocument10 paginiModeller's Guide To Early P-51 Mustang Variantsseafire47100% (3)

- Rockforo Round-Up: UhmnmmrkitDocument1 paginăRockforo Round-Up: Uhmnmmrkitseafire47Încă nu există evaluări

- Grumman f3f 2Document14 paginiGrumman f3f 2seafire47100% (1)

- Big Deal From BEDEDocument1 paginăBig Deal From BEDEseafire47Încă nu există evaluări

- Nene Jet Engines of The Two XF9F-2 Prototypes Were Replaced in Production F9F-2s by PrattDocument8 paginiNene Jet Engines of The Two XF9F-2 Prototypes Were Replaced in Production F9F-2s by Prattseafire47Încă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Evolution 900 NF 5W40 TDS PDFDocument1 paginăEvolution 900 NF 5W40 TDS PDFFlorinFlorinÎncă nu există evaluări

- A-COVER 1-CD-F479 P.S.C.C.H.Co Comm.15.13Document5 paginiA-COVER 1-CD-F479 P.S.C.C.H.Co Comm.15.13Islam AttiaÎncă nu există evaluări

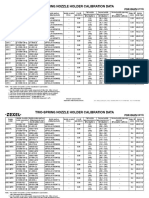

- Zexel Two Spring Nozzle Holder Calibration DataDocument63 paginiZexel Two Spring Nozzle Holder Calibration DataИльнур Султанов100% (6)

- SRKR Engineering College (A), Bhimavaram: Department of Mechanical EngineeringDocument22 paginiSRKR Engineering College (A), Bhimavaram: Department of Mechanical Engineeringsarath chandra satuluriÎncă nu există evaluări

- 903K 909K 953K 959K Espec Dka5004 - 12-06Document20 pagini903K 909K 953K 959K Espec Dka5004 - 12-06coelhoclaudiosÎncă nu există evaluări

- 10R80 Adaptive Learning Drive CycleDocument1 pagină10R80 Adaptive Learning Drive CyclemedicaluvÎncă nu există evaluări

- Minimum Height For Use of Either Autopilot or Flight DirectorDocument2 paginiMinimum Height For Use of Either Autopilot or Flight DirectorCarlos CuartasÎncă nu există evaluări

- 712563Document3 pagini712563Brian RugglesÎncă nu există evaluări

- Titan XD: Up To 3,000-lb Payload 48-Volt Powertrain Seats Up To Four PassengersDocument6 paginiTitan XD: Up To 3,000-lb Payload 48-Volt Powertrain Seats Up To Four PassengersForklift Systems IncorporatedÎncă nu există evaluări

- Massey Ferguson MF7600 Technician Workshop ManualDocument798 paginiMassey Ferguson MF7600 Technician Workshop Manualgavcin100% (5)

- SR220 SR250 SV250 SV300 - GBDocument2 paginiSR220 SR250 SV250 SV300 - GBXavier WalhemÎncă nu există evaluări

- Puc Certificate New 5794Document1 paginăPuc Certificate New 5794dilip polutionÎncă nu există evaluări

- Trip SheetDocument3 paginiTrip SheetHari KrishnaÎncă nu există evaluări

- Cluster 206 PDFDocument5 paginiCluster 206 PDFecutronicssÎncă nu există evaluări

- Hydraulic BrakeDocument5 paginiHydraulic BrakenvjkhfghfÎncă nu există evaluări

- 2013 Pb-Eng-M-L126tih - 950106-01210Document428 pagini2013 Pb-Eng-M-L126tih - 950106-01210Cristian Sepulveda100% (4)

- JH 600Document22 paginiJH 600Joel MoralesÎncă nu există evaluări

- Nissan Note Power Control SystemDocument106 paginiNissan Note Power Control SystemDaniel Aguirre100% (1)

- The Ten Forklift Safety RulesDocument10 paginiThe Ten Forklift Safety RulesAlexandra johnÎncă nu există evaluări

- (Engine Control Module) - Me7.9.9 (Fam Ii 2Document25 pagini(Engine Control Module) - Me7.9.9 (Fam Ii 2jorge luis guevara martinezÎncă nu există evaluări

- Application: 1990 Chevrolet Celebrity 1990 Chevrolet CelebrityDocument78 paginiApplication: 1990 Chevrolet Celebrity 1990 Chevrolet CelebritySimon Enrique GuzmanÎncă nu există evaluări

- Despiece Susp. Post. 980e-4Document2 paginiDespiece Susp. Post. 980e-4Andersson Campos VásquezÎncă nu există evaluări

- Strategic Management by Ford Motor CompanyDocument12 paginiStrategic Management by Ford Motor CompanyAbdul Hakim75% (4)

- Isuzu Axiom 2002 ManualDocument2.100 paginiIsuzu Axiom 2002 Manualgasman11195% (19)

- Skoda Kodiaq Body Repairs Exterior EngDocument248 paginiSkoda Kodiaq Body Repairs Exterior EngСергей ДаниловÎncă nu există evaluări

- Aggregate Transportation With Diffrent LeadsDocument25 paginiAggregate Transportation With Diffrent LeadsRavi ValakrishnanÎncă nu există evaluări

- 2015 Ford 6.7L Diesel F 250 550 Supplement Version 1 - 60l6d - EN US - 02 - 2014 PDFDocument84 pagini2015 Ford 6.7L Diesel F 250 550 Supplement Version 1 - 60l6d - EN US - 02 - 2014 PDFtonomart79Încă nu există evaluări

- PD5 - Vermeer INCADORADocument2 paginiPD5 - Vermeer INCADORAErik RodriguezÎncă nu există evaluări

- All-New: Kia Motors Corporation 231 Yangjae-Dong, Seocho-Gu, Seoul, 137-938, KoreaDocument14 paginiAll-New: Kia Motors Corporation 231 Yangjae-Dong, Seocho-Gu, Seoul, 137-938, KoreaJuan Gabriel Celis SalgueroÎncă nu există evaluări

- Spesifikasi Teknis Isuzu FRR 90 Q Bus (Chassis) : Items SpecificationDocument1 paginăSpesifikasi Teknis Isuzu FRR 90 Q Bus (Chassis) : Items SpecificationEneng RismawatiÎncă nu există evaluări