Documente Academic

Documente Profesional

Documente Cultură

Valve Mounting Height PDF

Încărcat de

grisham018Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Valve Mounting Height PDF

Încărcat de

grisham018Drepturi de autor:

Formate disponibile

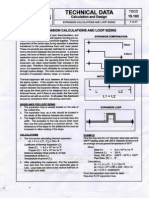

DEP 30.00.60.13-Gen. April 2009 Page 19 B.3.

2 Position indicators Valves equipped with valve position indicators shall be installed so that the indicators status is directly visible from a normal vantage point (e.g. adjacent to walkway) when opening or closing the valve. For valves fitted for remote control, an independent indicator showing whether the valve is open or closed shall be provided on or adjacent to the control that is visible from the operators normal standing position. B.3.3 B.3.3.1 Mounting heights Handwheel operated valves Valve handwheels shall be mounted in the Preferred or Acceptable vertical and horizontal locations as shown in Figures B.1 and B.2, depending on valve stem orientation and maximum force requirements as stated in (B.2.1) and (B.2.2). See notes and exceptions to these dimensions at the bottom of the figures.

Unacceptable

1300 mm (51 in)

Preferred

455 mm (18 in) Acceptable 150 mm (6 in)

455 mm (18 in)

Grade/deck Max. horizontal distance from obstruction or operators front

NOTES:

1. Distances or heights are measured to handwheel centreline. For gear-operated valves with a handwheel provided with a spinner handle, maximum horizontal distance is measured to the edge of the handwheel furthest from the operator. 2. Heights are to be to the maximum extension of valve stem for rising stem valves. 3. These dimensions are appropriate male and female personnel worldwide from 5th to 95th percentile, except that the top limit for the Preferred choice location should be reduced by 100 mm (4 in) to accommodate male and female populations in regions such as West Africa, Southeast Asia, Southern China, parts of Latin America, India and Japan. 4. For valves located below 455 mm (18 in), sufficient clearance of at least 1300 mm (51 in) should be provided behind the operator to accommodate a bending or kneeling posture.

Figure B.1

Mounting heights for hand-wheel operated valves with vertical stems

DEP 30.00.60.13-Gen. April 2009 Page 20

Min. 610 mm (24 in) between

any obstruction and hand wheel/valve stem

Unacceptable 1830 mm (72 in)

Preferred

610 mm (24 in) Acceptable 230 mm (9 in)

Grade/deck

455 mm (18 in)

Max. horizontal distance from obstruction, or operators front

NOTES:

1. Distances or heights are measured to handwheel centreline. For gear-operated valves with a handwheel provided with a spinner handle, maximum horizontal distance is measured to the edge of the handwheel furthest from the operator. 2. These dimensions are appropriate for personnel worldwide, from the 5th percentile of the female population to the 95th percentile of the male population, except that the top limit should be set at 1755 mm (69 in) for 5th percentile males and 66 in (1675 mm) for 5th percentile females in regions such as West Africa, Southeast Asia, Southern China, parts of Latin America, India and Japan. 3. For valves located below 455 mm (18 in), sufficient clearance of at least 1300 mm (51 in) should be provided behind the operator to accommodate a bending or kneeling posture.

Figure B.2 B.3.3.2

Mounting heights for handwheel operated valves with horizontal stems

Lever operated valves Valve levers shall be mounted in the locations as shown in Figures B.3 and B.4, depending on valve stem orientation and maximum force requirements (B.2.1). No valve handles shall protrude into walkways or work areas when the valve is in the closed position.

DEP 30.00.60.13-Gen. April 2009 Page 21

760 1300 mm (30 51 in)

Grade/deck

NOTE:

These dimensions are appropriate for personnel worldwide, from the 5th percentile of the female population to the 95th percentile of the male population, except that the top limit should be reduced to 1145 mm (45 in) to accommodate 5th percentile females in regions such as West Africa, Southeast Asia, Southern China, parts of Latin America, India and Japan.

Figure B.3

Mounting heights for lever-operated valves with vertical stems

A) Max. height to top of handle when handle rotates up from the centreline = 1905 mm (75 in)

A) Max. height to top of handle when handle rotates down from the centerline = 1905 mm (75 in)

Above 1300 mm (51 in) or between 150 760 mm (6 30 in)

Grade/deck

NOTE:

These dimensions are drawn for North American males, and are therefore appropriate for other regions such as Northern Europe, Australia, UK, and Central Europe. These dimensions should be reduced to 1805 mm (71 in) for 5th percentile males in areas such as West Africa, Southeast Asia, Southern China, parts of Latin America, India and Japan, and 1725 mm (68 in) for 5th percentile females in West Africa, Southeast Asia, Southern China, parts of Latin America, India and Japan. To accommodate the same international population of 5th percentile females, horizontal stem valves should be located at least 1145 mm (45 in) above the standing surface, rather than 1300 mm (51 in) as shown.

Figure B.4

Mounting heights for lever-operated valves with horizontal stems

Valves oriented with the stem in a horizontal position are preferred when the lever is located between 150 mm and 760 mm (6 in and 30 in), or more than 1300 mm (51 in) above the deck as shown in Figure B.4. However, the maximum height above the deck to the valve tip should not exceed 1905 mm (75 in). The valve handle is not permitted to rotate down from centreline if there is a walking surface directly underneath.

DEP 30.00.60.13-Gen. April 2009 Page 22 Valves in a vertical section of the pipe e.g., located in a manifold or at battery limit, shall be oriented with all the stems on the same side as shown in Figures B.5 and B.6, with a 75 mm (3 in) clearance maintained between the lever and any obstruction.

X = 75 mm (3 in) minimum

All levers oriented in same direction when open/closed

Y see Table B.2

Grade/deck

Figure B.5

Manifold or battery limit valves with 75 mm (3 in) minimum gap between lever-end and the nearest flange/obstruction

X = 75 mm (3 in) minimum X X

All levers oriented in same direction when open/closed

Y see Table B.2

Grade/deck

Figure B.6

Manifold or battery limit valves with 75 mm (3 in) minimum gap between front face of levers outer surface and nearest flange/obstruction

DEP 30.00.60.13-Gen. April 2009 Page 23 Table B.2 Height of valve lever end above grade/deck Height (Y) of valve lever end above grade/deck Preferred Acceptable Unacceptable B.3.3.3 610 mm to 1905 mm (24 in to 75 in) 230 mm to 610 mm (9 in to 24 in) < 230 mm or > 1905 mm (< 9 in or > 75 in)

Valves operated from vertical ladders Category 1 (C-1) valves shall not be located so that they have to be operated from a ladder (caged or uncaged) Other valves should not be located so that they have to be operated from a ladder, but if this is unavoidable the following requirements shall apply: The handwheel or lever shall be located between 150 mm (6 in) and 610 mm (24 in) from the edge of the ladder stringer in order to open and close the valves, as shown in Figures B.7 and B.8; Valve location, orientation, and actuator type shall be selected to enable opening or closing with one-hand only.

150 mm (6 in) min

150 mm (6 in) min

Vessel

Vertical stem valve

Horizontal stem valve

LT

LG

610 mm (24 in) max

610 mm (24 in) max

Figure B.7

Required lateral reach distances (minimum and maximum) for level instruments, gauge nozzles or valves on the side of a vessel; lever/handle operated

B.3.4 B.3.4.1

Valve Maintenance Considerations Access The minimum distance between valve flanges and any obstruction shall be the bolt length plus 25 mm (1 in) to allow access for hand tools and torquing of bolts. Where standing room is required for maintenance access to valve flanges, the clearance between a flange and a wall, structural steel, or guardrail shall not be less than 460 mm (18 in).

DEP 30.00.60.13-Gen. April 2009 Page 24

150 mm (6 in) min

150 mm (6 in) min

Vessel

Vertical stem valve

Horizontal stem valve

LT

LG

610 mm (24 in) max

610 mm (24 in) max

Figure B.8

Required lateral reach distances (minimum and maximum) for level instruments, gauge nozzles or valves on the side of a vessel; handwheel operated.

B.3.4.2

Valve mass and lifting aids Valves with a mass less than 23 kg (50 lb) shall be located so that they can be lifted by one person without risking injury through poor lifting posture. Valves with a mass less than 45.5 kg (100 lb) shall be located so that they can be lifted by two persons, provided the valve can be lifted without having to reach over or around items between the persons and the valve.

NOTE: The 23 kg (50 lb) limit is the lifting equation load constant in NIOSH 94-110. The recommended mass limit assumes a single lift and optimum lift-height, lift-distance and body position. For any repetitive type lifting or non-optimal body positioning, the lift height or distance, and other relevant handling factors, a regional HFE Specialist shall be consulted.

For all valves in excess of the above weight limits and lifting heights that must be lifted for repair, replacement or maintenance, permanent or portable assisted lifting devices (e.g. chain-falls, lever chain puller/hoist) shall be provided to aid the lifting or moving. If such devices are provided, space for them and the personnel who use and manoevre them shall be provided. Assisted lifting devices provided to assist in lifting or moving equipment should be able to be located (e.g. by means of pad eyes or beam clamps) directly over the item to be lifted so the lift is vertical to prevent swinging loads when the items are raised or lowered. Two lifting aids may be used simultaneously, one on each side of the valve, if a vertical lift is not feasible. Hoisting areas should be free of obstacles such as cable trays, HVAC ducting, structural components, piping, and other equipment within a radius of at least 305 mm (12 in) at the point of hookup to the device. There shall be sufficient clearance above each valve to attach the lifting device and pull the valve or valve operating mechanism, or to complete all maintenance tasks in place without removing the valve.

Last page of this DEP

S-ar putea să vă placă și

- Pig Launcher+receiverDocument3 paginiPig Launcher+receiverwong_949618676Încă nu există evaluări

- Flange Bolt Tightening ProcedureDocument5 paginiFlange Bolt Tightening ProcedureArya100% (1)

- ASME B16 Welding EndsDocument2 paginiASME B16 Welding Endsf_riseÎncă nu există evaluări

- Bondstrand Series 7000 M Installation ManualDocument84 paginiBondstrand Series 7000 M Installation ManualPavel Vicentiu0% (1)

- GussetDocument3 paginiGussetSeungmin PaekÎncă nu există evaluări

- How to include instruments in AutoCAD Plant 3D isometric BOMDocument4 paginiHow to include instruments in AutoCAD Plant 3D isometric BOMvitinrjÎncă nu există evaluări

- Minimum Distance Between Two Circumferential PipeDocument7 paginiMinimum Distance Between Two Circumferential PipeAbdulrahmanÎncă nu există evaluări

- 13.date Sheet For Gate ValveDocument2 pagini13.date Sheet For Gate ValveMrinal Kanti BhaduriÎncă nu există evaluări

- 7-12-0025 Rev 5Document2 pagini7-12-0025 Rev 5cynideÎncă nu există evaluări

- Spe 77-105 Gate Globe and Check Valves To Bs 5154Document9 paginiSpe 77-105 Gate Globe and Check Valves To Bs 5154awisakipÎncă nu există evaluări

- QuillsDocument4 paginiQuillsajostosÎncă nu există evaluări

- MSS SP 80 PDFDocument35 paginiMSS SP 80 PDFMuhamed AneeshÎncă nu există evaluări

- NPT Thread DimensionsDocument1 paginăNPT Thread DimensionsRamnandan MahtoÎncă nu există evaluări

- Dimensions and Weights of Spades (Paddle Blank) and Ring Spacers (Paddle Spacer) ASME B16.47 For Installation Between ASME B16.47 Series A Flanges. 26 Inch To 60 InchDocument6 paginiDimensions and Weights of Spades (Paddle Blank) and Ring Spacers (Paddle Spacer) ASME B16.47 For Installation Between ASME B16.47 Series A Flanges. 26 Inch To 60 InchPozii Ziipunii PaulÎncă nu există evaluări

- Catalogo - TechlokDocument30 paginiCatalogo - Techlokorea1Încă nu există evaluări

- API 6D Overview - Pipeline & Piping ValvesDocument3 paginiAPI 6D Overview - Pipeline & Piping ValvesNilesh MistryÎncă nu există evaluări

- DC 950045 001Document1 paginăDC 950045 001Abu Anas M.SalaheldinÎncă nu există evaluări

- Pipe Fitting Weight ChartDocument1 paginăPipe Fitting Weight Chartab5918590Încă nu există evaluări

- Piping Calculation Program For ASME B31 1 CodeDocument3 paginiPiping Calculation Program For ASME B31 1 CodeAMIT100% (2)

- b16 47Document65 paginib16 47Gustavo FamaÎncă nu există evaluări

- Pig Launcher & ReceiverDocument4 paginiPig Launcher & ReceiverMEHDI100% (1)

- Vector Techlok BrochureDocument34 paginiVector Techlok BrochureRobert Murray100% (2)

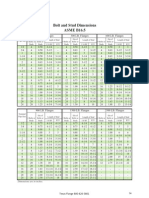

- Expansion Calculation and Loop Sizing001Document2 paginiExpansion Calculation and Loop Sizing001Joseph R. F. DavidÎncă nu există evaluări

- Api 598Document13 paginiApi 598SurachaiAumongkolÎncă nu există evaluări

- Thickness Calculation For PipeDocument7 paginiThickness Calculation For PipeNAYEEM100% (5)

- Pig ValvesDocument3 paginiPig ValvesteacgÎncă nu există evaluări

- Guides For Storage Tanks Nozzles OrientationDocument5 paginiGuides For Storage Tanks Nozzles OrientationGeethaÎncă nu există evaluări

- Din Flange PDFDocument45 paginiDin Flange PDFVineeth MuraleedharanÎncă nu există evaluări

- Branch Reinforcement Pad Requirement CalculationDocument1 paginăBranch Reinforcement Pad Requirement Calculations.mladinÎncă nu există evaluări

- List Shell Dep Amp Mesc Spe PDFDocument9 paginiList Shell Dep Amp Mesc Spe PDFAzhar Ahmad100% (1)

- Grayloc Nozzle SpecificationsDocument58 paginiGrayloc Nozzle SpecificationsAhrian BenaÎncă nu există evaluări

- Bolt and Stud DimentionDocument1 paginăBolt and Stud DimentionwhngomjÎncă nu există evaluări

- ASTM A333 Grade 6 SpecificationDocument9 paginiASTM A333 Grade 6 SpecificationmaldonadohansÎncă nu există evaluări

- A1a PMSDocument5 paginiA1a PMSS.selvakumarÎncă nu există evaluări

- ET Subsea Ball ValvesDocument9 paginiET Subsea Ball ValvesAndrew BaileyÎncă nu există evaluări

- LS Furmanite OyMDocument26 paginiLS Furmanite OyMDanny Carrasco Vicharra0% (2)

- OPERATING & SERVICE MANUAL AZ-1-107-NL SERIES PUMPDocument16 paginiOPERATING & SERVICE MANUAL AZ-1-107-NL SERIES PUMPREZA ASGARIÎncă nu există evaluări

- Pipe Support As Per Asme 31.1Document1 paginăPipe Support As Per Asme 31.1udaysaichand kollipara100% (1)

- Branch Reinforcement Pad Requirement CalculationDocument2 paginiBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- Pipe Spacing Dimensions ChartDocument4 paginiPipe Spacing Dimensions ChartAlfredo Rafael Acosta100% (1)

- Tie in PointsDocument1 paginăTie in Pointsrenjithv_4Încă nu există evaluări

- Piping Line List Template 2018-05-29Document1 paginăPiping Line List Template 2018-05-29Trevor KanodeÎncă nu există evaluări

- PIG TRAP DESIGN GUIDEDocument6 paginiPIG TRAP DESIGN GUIDEDouGPhillips999100% (1)

- Knife Gate Valve - For Reference OnlyDocument16 paginiKnife Gate Valve - For Reference Onlysj_scribdÎncă nu există evaluări

- Insulation BOQ Piping DocumentDocument1 paginăInsulation BOQ Piping DocumentRasool Shaik100% (1)

- The Torque Calculation Method For Ball ValvesDocument2 paginiThe Torque Calculation Method For Ball ValvesZakky Ibnu Fadjrie100% (2)

- Datasheet DBB Ball ValvesDocument1 paginăDatasheet DBB Ball ValvesVivi Oktavianti100% (1)

- Anti Blow Out StemDocument48 paginiAnti Blow Out StemimthiyazmuhammedÎncă nu există evaluări

- API 6A Type 6B & 6BX FlangesDocument31 paginiAPI 6A Type 6B & 6BX FlangesEason NgÎncă nu există evaluări

- Torque values for ICP flange insulation gasketsDocument2 paginiTorque values for ICP flange insulation gasketsYasser MahmoudÎncă nu există evaluări

- Valve Material ApplicationDocument16 paginiValve Material Applicationswapneel_kulkarniÎncă nu există evaluări

- API 650 PageDocument2 paginiAPI 650 PageGerry Dan ChanliongcoÎncă nu există evaluări

- VMS PaliDocument61 paginiVMS Palichintan100% (2)

- Tie in & Hot TappingDocument2 paginiTie in & Hot TappingKarthik P MuraliÎncă nu există evaluări

- Vertical clearance requirementsDocument90 paginiVertical clearance requirementsMichael RobinsonÎncă nu există evaluări

- Jabsco Y-Valve: Model 45490-1000Document4 paginiJabsco Y-Valve: Model 45490-1000Michał BorzemskiÎncă nu există evaluări

- Beltway Scale Manual 2009Document56 paginiBeltway Scale Manual 2009morris_timÎncă nu există evaluări

- Is 13591 1992 PDFDocument13 paginiIs 13591 1992 PDFslamienkaÎncă nu există evaluări

- ASME A18 1 Rev 10 5 2017 ED 1 16 2019Document6 paginiASME A18 1 Rev 10 5 2017 ED 1 16 2019Fausto Castro JaramilloÎncă nu există evaluări

- Link Belt HC248 Crane SpecificationsDocument8 paginiLink Belt HC248 Crane SpecificationsJhony Espinoza PerezÎncă nu există evaluări

- Minimum System Requirements PlantDocument11 paginiMinimum System Requirements PlantManny MendozaÎncă nu există evaluări

- Isogen PDFDocument2 paginiIsogen PDFgrisham018Încă nu există evaluări

- Minimum System Requirements PlantDocument11 paginiMinimum System Requirements PlantManny MendozaÎncă nu există evaluări

- Minimum System Requirements PlantDocument11 paginiMinimum System Requirements PlantManny MendozaÎncă nu există evaluări

- AWS Welding Symbol ChartDocument1 paginăAWS Welding Symbol Chartgrisham018Încă nu există evaluări

- Shinjuku Kawaguchiko ScheduleDocument2 paginiShinjuku Kawaguchiko SchedulesetyoÎncă nu există evaluări

- Minimum System Requirements PlantDocument11 paginiMinimum System Requirements PlantManny MendozaÎncă nu există evaluări

- Shinjuku Kawaguchiko ScheduleDocument2 paginiShinjuku Kawaguchiko SchedulesetyoÎncă nu există evaluări

- Fire Protection in MalaysiaDocument37 paginiFire Protection in MalaysiaCastiel Arumugam50% (2)

- Aquos Manual 202011 PDFDocument36 paginiAquos Manual 202011 PDFgrisham018Încă nu există evaluări

- Quick Disconnect Couplings & Hydraulic ValvesDocument14 paginiQuick Disconnect Couplings & Hydraulic Valvesgrisham018Încă nu există evaluări

- CAMC Trucks Service Manual PDFDocument535 paginiCAMC Trucks Service Manual PDFchuck absulio100% (1)

- BMW E39Document20 paginiBMW E39RenatÎncă nu există evaluări

- Instrument Procedures Handbook: U.S. Department of Transportation Federal Aviation AdministrationDocument12 paginiInstrument Procedures Handbook: U.S. Department of Transportation Federal Aviation AdministrationWachirarat Ton ChomchomeÎncă nu există evaluări

- Ground Proximity Warning ReceiverDocument16 paginiGround Proximity Warning ReceivermaniÎncă nu există evaluări

- R4a 51Document4 paginiR4a 51marneilrivera96Încă nu există evaluări

- Dynapac Cp2700 t3 Spare Parts CatalogueDocument20 paginiDynapac Cp2700 t3 Spare Parts Cataloguemartina100% (47)

- Crane Spec SheetDocument6 paginiCrane Spec Sheetrifki centilÎncă nu există evaluări

- SBGR Ils-T-Rwy-28r Iac 20220908Document1 paginăSBGR Ils-T-Rwy-28r Iac 20220908jcndrckz4qÎncă nu există evaluări

- 08 Stopping Sight DistanceDocument38 pagini08 Stopping Sight Distancesherifgeb1Încă nu există evaluări

- Design Calculation for Horizontal Filter VesselDocument4 paginiDesign Calculation for Horizontal Filter VesselHasmukh DaveÎncă nu există evaluări

- Namma Kalvi 6th Science and Social Science Text Book EM Term 3Document224 paginiNamma Kalvi 6th Science and Social Science Text Book EM Term 3Priya DharshiniÎncă nu există evaluări

- Corporate Office: Lahore Office: Islamabad Office: Faisalabad Office: Multan Office: Hyderabad OfficeDocument1 paginăCorporate Office: Lahore Office: Islamabad Office: Faisalabad Office: Multan Office: Hyderabad OfficeshahzadtecÎncă nu există evaluări

- Buffer Spring: FeaturesDocument2 paginiBuffer Spring: FeaturesqusayÎncă nu există evaluări

- Void Void: 6081-42-24-50 09-24-21 03-24-22 2016 KIA Forte KNAFK4A62G5540409Document2 paginiVoid Void: 6081-42-24-50 09-24-21 03-24-22 2016 KIA Forte KNAFK4A62G5540409Jessica GuyadeenÎncă nu există evaluări

- BMW E90 Suspension GuideDocument17 paginiBMW E90 Suspension GuideWeiso Chen100% (1)

- Advanced vocabulary homeworkDocument8 paginiAdvanced vocabulary homeworkSanÎncă nu există evaluări

- Latihan Bab 3Document12 paginiLatihan Bab 3Hasnah GhaniÎncă nu există evaluări

- An Analysis Report of Implementation of Smart Parking System Using Internet of ThingsDocument4 paginiAn Analysis Report of Implementation of Smart Parking System Using Internet of ThingskhalidÎncă nu există evaluări

- Carrileadora JD WRDocument108 paginiCarrileadora JD WRVladimirCarrilloÎncă nu există evaluări

- Chennai Mofussil Bus Terminal: D E S S T K U T D O Y P Sheet NoDocument8 paginiChennai Mofussil Bus Terminal: D E S S T K U T D O Y P Sheet Nonithin rasureÎncă nu există evaluări

- Naskah Soal US SD BHS INGGRIS 2020-2021Document17 paginiNaskah Soal US SD BHS INGGRIS 2020-2021Fransisca KartikawatiÎncă nu există evaluări

- Chapter 1. IntroductionDocument57 paginiChapter 1. Introductionsisay gemÎncă nu există evaluări

- New 2024 Chevy Silverado EVDocument2 paginiNew 2024 Chevy Silverado EVluxury life wishesÎncă nu există evaluări

- Jadual Wim - Penjajaran Coptpa Cu, Wa, PPMPP, PPMPB Dan JPWDocument10 paginiJadual Wim - Penjajaran Coptpa Cu, Wa, PPMPP, PPMPB Dan JPWBakal JenazahÎncă nu există evaluări

- Unit 12 Urban Life Literal ListeningDocument3 paginiUnit 12 Urban Life Literal ListeningMoh Alfian HabibullohÎncă nu există evaluări

- Traffic Study Report for Bogotá-Cartagena Highway CorridorDocument147 paginiTraffic Study Report for Bogotá-Cartagena Highway CorridorOscar Alberto Montes de OcaÎncă nu există evaluări

- Risk Appetite GuideDocument50 paginiRisk Appetite GuideAmlan Kumar SahuÎncă nu există evaluări

- A Comparitive Study On Consumer Perception of Online Cab Services (Project Report) Vardaan SrivastavaDocument59 paginiA Comparitive Study On Consumer Perception of Online Cab Services (Project Report) Vardaan SrivastavaFinancial Basket100% (1)

- Coil Springs: Technical ListingDocument24 paginiCoil Springs: Technical ListingturboguzziÎncă nu există evaluări

- Dheeraj Singh Yadav ResumeDocument3 paginiDheeraj Singh Yadav Resumesatyamtomer2014Încă nu există evaluări

- Advanced Modelling Techniques in Structural DesignDe la EverandAdvanced Modelling Techniques in Structural DesignEvaluare: 5 din 5 stele5/5 (3)

- An Architect's Guide to Construction: Tales from the Trenches Book 1De la EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1Încă nu există evaluări

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDe la EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationEvaluare: 4 din 5 stele4/5 (18)

- A Place of My Own: The Architecture of DaydreamsDe la EverandA Place of My Own: The Architecture of DaydreamsEvaluare: 4 din 5 stele4/5 (241)

- To Engineer Is Human: The Role of Failure in Successful DesignDe la EverandTo Engineer Is Human: The Role of Failure in Successful DesignEvaluare: 4 din 5 stele4/5 (137)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDe la EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionEvaluare: 4.5 din 5 stele4.5/5 (2)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDe la EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedEvaluare: 5 din 5 stele5/5 (1)

- Civil Engineer's Handbook of Professional PracticeDe la EverandCivil Engineer's Handbook of Professional PracticeEvaluare: 4.5 din 5 stele4.5/5 (2)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsDe la EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsEvaluare: 4.5 din 5 stele4.5/5 (6)

- Building Construction Technology: A Useful Guide - Part 2De la EverandBuilding Construction Technology: A Useful Guide - Part 2Evaluare: 5 din 5 stele5/5 (1)

- Nuclear Energy in the 21st Century: World Nuclear University PressDe la EverandNuclear Energy in the 21st Century: World Nuclear University PressEvaluare: 4.5 din 5 stele4.5/5 (3)

- Building Construction Technology: A Useful Guide - Part 1De la EverandBuilding Construction Technology: A Useful Guide - Part 1Evaluare: 4 din 5 stele4/5 (3)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDe la EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialÎncă nu există evaluări

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseDe la EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseEvaluare: 5 din 5 stele5/5 (3)

- Markup & Profit: A Contractor's Guide, RevisitedDe la EverandMarkup & Profit: A Contractor's Guide, RevisitedEvaluare: 5 din 5 stele5/5 (11)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsDe la EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsÎncă nu există evaluări

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDe la EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsÎncă nu există evaluări

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDe la EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsEvaluare: 3.5 din 5 stele3.5/5 (3)

- Field Guide for Construction Management: Management by Walking AroundDe la EverandField Guide for Construction Management: Management by Walking AroundEvaluare: 4.5 din 5 stele4.5/5 (3)

- How to Write Construction Programmes & SchedulesDe la EverandHow to Write Construction Programmes & SchedulesEvaluare: 4 din 5 stele4/5 (9)

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsDe la EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsEvaluare: 1 din 5 stele1/5 (4)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDe la Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideEvaluare: 3.5 din 5 stele3.5/5 (7)

- Real Life: Construction Management Guide from A-ZDe la EverandReal Life: Construction Management Guide from A-ZEvaluare: 4.5 din 5 stele4.5/5 (4)