Documente Academic

Documente Profesional

Documente Cultură

Derbi Rambla 125 (En)

Încărcat de

ManuallesTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Derbi Rambla 125 (En)

Încărcat de

ManuallesDrepturi de autor:

Formate disponibile

DERBI

NACIONAL MOTOR, S.A.U. Derbi

INDEX OF TOPICS

CHARACTERISTICS TOOLING MAINTENANCE ELECTRICAL SYSTEM ENGINE FROM VEHICLE ENGINE SUSPENSIONS BRAKING SYSTEM COOLING CHASSIS PRE-DELIVERY

CHAR TOOL MAIN ELE SYS ENG VE ENG SUSP BRAK SYS COOL SYS CHAS PRE DE

SYSTEM

INDEX OF TOPICS

CHARACTERISTICS

CHAR

Characteristics

Rules Safety rules

GENERAL PRECAUTIONS AND INFORMATION When repairing, dismantling and reassembling the vehicle, follow the recommendations given below carefully.

CAUTION

USE OF NAKED FLAMES IS FORBIDDEN DURING ALL TYPES OF OPERATION. BEFORE STARTING ANY MAINTENANCE OPERATION OR INSPECTION ON THE VEHICLE, SWITCH OFF THE ENGINE AND REMOVE THE KEY. WAIT UNTIL THE ENGINE AND THE EXHAUST SYSTEM ARE COLD, IF POSSIBLE, RAISE THE VEHICLE USING A SUITABLE TOOL ON FIRM AND LEVEL GROUND. TO AVOID BURNS PAY SPECIAL CARE WITH HOT ENGINE AND EXHAUST SYSTEM PARTS. DO NOT HOLD ANY MECHANICAL OR OTHER SCOOTER PARTS WITH YOUR MOUTH: SCOOTER COMPONENT ARE NOT EDIBLE, ON THE CONTRARY SOME OF THEM ARE HARMFUL AND EVEN TOXIC. CARBON MONOXIDE If you need to keep the engine running in order to carry out any procedure, please ensure that you do so in an open or very well ventilated area. Never let the engine run in an enclosed area. If you do work in an enclosed area, make sure to use a smoke-extraction system.

CAUTION

EXHAUST EMISSIONS CONTAIN CARBON MONOXIDE, A POISONOUS GAS WHICH CAN CAUSE LOSS OF CONSCIOUSNESS AND EVEN DEATH. FUEL

CAUTION

FUEL USED TO DRIVE EXPLOSION ENGINES IS HIGHLY FLAMMABLE AND CAN BECOME EXPLOSIVE UNDER SPECIFIC CONDITIONS. IT IS THEREFORE RECOMMENDED TO CARRY OUT REFUELLING AND MAINTENANCE PROCEDURES IN A VENTILATED AREA WITH THE ENGINE SWITCHED OFF. DO NOT SMOKE DURING REFUELLING AND NEAR FUEL VAPOURS, AVOIDING ANY CONTACT WITH NAKED FLAMES, SPARKS OR OTHER SOURCES WHICH MAY CAUSE THEM TO IGNITE OR EXPLODE.

CAUTION

DO NOT DISPOSE OF FUEL INTO THE ENVIRONMENT.

CAUTION

KEEP OUT OF THE REACH OF CHILDREN. HIGH-TEMPERATURE COMPONENTS CHAR - 6

Characteristics

The engine and the components of the exhaust system can get very hot and remain hot for some time even after the engine has been switched off. Before handling these components, make sure that you are wearing insulating gloves or wait until the engine and the exhaust system have cooled down. TRANSMISSION OIL AND USED FORK OIL

CAUTION

IT IS ADVISABLE TO WEAR LATEX GLOVES WHEN CARRYING OUT SERVICE WORK. THE TRANSMISSION OIL MAY CAUSE SKIN DAMAGE IF HANDLED FREQUENTLY AND FOR LONG PERIODS. WASH YOUR HANDS CAREFULLY AFTER HANDLING OIL. HAND THE OIL OVER TO OR HAVE IT COLLECTED BY THE NEAREST USED OIL RECYCLING COMPANY OR THE SUPPLIER. IT IS ADVISABLE TO WEAR LATEX GLOVES WHEN CARRYING OUT SERVICE WORK.

CAUTION

DO NOT DISPOSE OF OIL INTO THE ENVIRONMENT.

CAUTION

KEEP OUT OF THE REACH OF CHILDREN. BRAKE FLUID

CAUTION

THE BRAKE FLUID MAY DAMAGE PAINTED, PVC OR RUBBER SURFACES. WHEN SERVICING THE BRAKE SYSTEM, PROTECT THESE COMPONENTS WITH A CLEAN CLOTH. ALWAYS WEAR PROTECTIVE GOGGLES WHEN SERVICING THE BRAKE SYSTEM. THE BRAKE FLUID IS EXTREMELY DANGEROUS TO THE EYES. IN THE EVENT OF ACCIDENTAL CONTACT WITH THE EYES, RINSE THEM IMMEDIATELY WITH ABUNDANT COLD, CLEAN WATER AND SEEK MEDICAL ADVICE.

CAUTION

KEEP OUT OF THE REACH OF CHILDREN. HYDROGEN GAS AND BATTERY ELECTROLYTE

CAUTION

THE BATTERY ELECTROLYTE IS TOXIC, CORROSIVE AND AS IT CONTAINS SULPHURIC ACID, IT CAN CAUSE BURNS WHEN IN CONTACT WITH THE SKIN. WHEN HANDLING THE BATTERY ELECTROLYTE, WEAR TIGHT-FITTING GLOVES AND PROTECTIVE APPAREL. IF THE ELECTROLYTIC FLUID GETS INTO CONTACT WITH THE SKIN, WASH WITH ABUNDANT COOL WATER. IT IS PARTICULARLY IMPORTANT TO PROTECT THE EYES BECAUSE EVEN TINY AMOUNTS OF BATTERY ACID MAY CAUSE BLINDNESS. IF IT COMES INTO CONTACT WITH THE EYES, CHAR - 7

Characteristics

RINSE THEM CAREFULLY WITH WATER FOR FIFTEEN MINUTES, THEN SEE AN EYE SPECIALIST AS SOON AS POSSIBLE. IF IT IS ACCIDENTALLY SWALLOWED, DRINK LARGE QUANTITIES OF WATER OR MILK, FOLLOWED BY MILK OF MAGNESIA OR VEGETAL OIL, AND SEEK MEDICAL ADVICE IMMEDIATELY. THE BATTERY RELEASES EXPLOSIVE GASES. KEEP IT AWAY OF FLAMES, SPARKS, CIGARETTES OR ANY OTHER HEAT SOURCE. ENSURE ADEQUATE VENTILATION WHEN SERVICING OR RECHARGING THE BATTERY.

CAUTION

KEEP OUT OF THE REACH OF CHILDREN.

CAUTION

THE BATTERY LIQUID IS CORROSIVE. DO NOT POUR OR SPILL IT, PARTICULARLY ON PLASTIC COMPONENTS. ENSURE THAT THE ELECTROLYTIC ACID IS COMPATIBLE WITH THE BATTERY TO BE ACTIVATED.

Maintenance rules

GENERAL PRECAUTIONS AND INFORMATION When repairing, dismantling and reassembling the vehicle, follow the recommendations given below carefully.

CAUTION

UNLESS OTHERWISE INDICATED, REFIT THE UNIT FOLLOWING THE REMOVAL STEPS BUT IN REVERSE ORDER. THE POSSIBLE OVERLAPPING OF OPERATIONS REFERRED TO IN THE OTHER CHAPTERS MUST BE CARRIED OUT LOGICALLY, AVOIDING ANY UNNECESSARY REMOVAL OF COMPONENTS. DO NOT POLISH MATT PAINTWORK WITH ABRASIVE PASTES. NEVER USE FUEL AS SOLVENT FOR CLEANING THE SCOOTER. DO NOT USE ALCOHOL, PETROL OR SOLVENTS TO CLEAN RUBBER AND PLASTIC PARTS AND THE SADDLE. USE ONLY WATER AND NEUTRAL SOAP INSTEAD. DISCONNECT THE NEGATIVE CABLE (-) OF THE BATTERY IF YOU INTEND TO CARRY OUT ELECTRICAL WELDING WORK. BEFORE REMOVING COMPONENTS Before dismantling components, remove dirt, mud, dust and foreign bodies from the vehicle. Use the special tools designed for this scooter, as required. REMOVAL OF COMPONENTS Do not loosen and/or tighten screws and nuts using pliers or other tools than the specially designed wrench. Mark positions on all connection joints (pipes, cables etc.) before separating them, and identify them with distinctive symbols. Each component needs to be clearly marked in order to be identified during reassembly. Clean and wash the dismantled components carefully using a low-flammability detergent.

CHAR - 8

Characteristics

Keep coupled parts together since they have "adjusted" to each other due to normal wear and tear. Some components must be used together or replaced altogether. Keep away from heat sources. REASSEMBLING COMPONENTS

CAUTION

NEVER REUSE A CIRCLIP; IF A CIRCLIP HAS BEEN REMOVED, IT MUST BE REPLACED WITH A NEW ONE. WHEN INSTALLING A CIRCLIP, ENSURE THAT ITS ENDS ARE NOT STRETCHED MORE THAN IS NECESSARY TO FIT IT ONTO THE SHAFT. AFTER INSTALLING THE CIRCLIP, CHECK THAT IT IS FULLY AND CLEANLY INSTALLED IN ITS SEAT. DO NOT USED COMPRESSED AIR TO CLEAN BEARINGS.

NOTE

BEARINGS MUST BE ABLE TO ROTATE FREELY, WITHOUT JAMMING AND/OR NOISE, OTHERWISE THEY NEED REPLACING. Use only ORIGINAL Derbi SPARE PARTS. Comply with lubricant and consumables usage guidelines. Lubricate parts (whenever possible) before refitting them. When tightening nuts and screws, start from the ones with the largest section or from the internal ones, moving diagonally. Tighten nuts and screws in successive steps before applying the tightening torque. Always replace self-locking nuts, washers, sealing rings, circlips, O-rings, split pins and screws with new ones if their tread is damaged. When fitting bearings, make sure to lubricate them well. Check that each component is fitted correctly. After a repair or routine maintenance procedure, carry out pre-ride checks and test the vehicle on private grounds or in an area with low traffic density. Clean all coupling surfaces, oil guard rims and washers before refitting them. Apply a light layer of lithium-based grease on the oil guard rims. Reassemble the oil guards and the bearings with the brand or lot number facing outward (visible side). ELECTRIC CONNECTORS Electric connectors must be disconnected as described below as non-compliance with the procedure so described causes irreparable damage to both the connector and the cable harness: Press the relevant safety hooks, if any.

CAUTION

TO DISCONNECT THE TWO CONNECTORS, DO NOT PULL THE CABLES. Grip the two connectors and disconnect them by pulling them in opposite directions.

CHAR - 9

Characteristics

In presence of dirt, rust, humidity etc., clean the connector's internal parts carefully, using a pressurised air jet. Make sure that the cables are correctly linked to the connector's internal terminal ends.

NOTE

THE TWO CONNECTORS CONNECT ONLY FROM ONE SIDE; CONNECT THEM THE RIGHT WAY ROUND. Then fit the two connectors making sure that they couple correctly (if the relevant hooks are provided, you will hear them "click" into place). TIGHTENING TORQUE

CAUTION

DO NOT FORGET THAT TIGHTENING TORQUES OF ALL FASTENING ELEMENTS ON WHEELS, BRAKES, WHEEL SPINDLES AND OTHER SUSPENSION COMPONENTS PLAY A KEY ROLE IN ENSURING THE VEHICLE'S SAFETY AND MUST COMPLY WITH SPECIFIED VALUES. CHECK THE TIGHTENING TORQUES OF FASTENING PARTS ON A REGULAR BASIS AND ALWAYS USE A TORQUE WRENCH TO REASSEMBLE THESE COMPONENTS. IF THESE RECOMMENDATIONS ARE NOT COMPLIED WITH, ONE OF THE COMPONENTS MAY BECOME LOOSE AND EVEN DETACHED, THUS BLOCKING A WHEEL, OR OTHERWISE COMPROMISING THE VEHICLE'S MANOEUVRABILITY. THIS CAN LEAD TO FALLS, WITH THE RISK OF SERIOUS INJURY OR DEATH. BRAKE FLUID

CAUTION

DO NOT USE FLUIDS OTHER THAN THOSE PRESCRIBED AND DO NOT MIX DIFFERENT LIQUIDS WHEN TOPPING UP IN ORDER NOT TO DAMAGE THE BRAKE SYSTEM. DO NOT USE BRAKE FLUID TAKEN FROM OLD CONTAINERS OR FROM CONTAINERS THAT HAVE BEEN OPEN FOR A PROLONGED TIME. SUDDEN CHANGES IN THE PLAY OR ELASTIC RESISTANCE IN THE BRAKE LEVERS ARE DUE TO FAULTS IN THE HYDRAULIC CIRCUIT. MAKE ESPECIALLY SURE THAT BRAKE DISCS AND THE FRICTION MATERIAL ARE NOT SMEARED OR GREASY, PARTICULARLY AFTER CARRYING OUT MAINTENANCE AND INSPECTION OPERATIONS. CHECK THAT BRAKE WIRES ARE NOT TWISTED OR WORN. ENSURE THAT WATER OR DUST DO NOT INGRESS INADVERTENTLY INTO THE CIRCUIT. IT IS ADVISABLE TO WEAR LATEX GLOVES WHEN SERVICING THE HYDRAULIC CIRCUIT. DISC BRAKE

CAUTION

ANY OIL OR OTHER LIQUIDS ON A DISC WILL SOIL THE BRAKE PADS. SOILED PADS MUST BE REMOVED AND REPLACED. A SOILED DISC OR A DISC WITH TRACES OF OIL MUST BE CLEANED WITH A TOP QUALITY DEGREASING AGENT. IF THE SCOOTER IS USED CLOSE TO WATER OR ON DUSTY OR UNSURFACED ROADS, OR IF IT IS USED FOR SPORTS APPLICATION, HALVE THE SERVICE INTERVALS. COOLANT The cooling of the engine is by forced liquid circulation. The coolant liquid is made up of 50% de-ionised water and antifreeze solution in a base of ethylene glycol and corrosion inhibitors. The product recommended in the 'Recommended products table' is already mixed and ready to use.

CHAR - 10

Characteristics

For the best functioning of the engine the temperature of the coolant fluid should register in the central zone of the appropriate gauge. If the needle enters the red zone, stop the engine, allow it to cool, and check the level of the fluid; if it is normal, contact an Official Derbi Dealer.

CAUTION

DO NOT USE YOUR VEHICLE IF THE COOLANT LEVEL IS BELOW THE MINIMUM LEVEL MARKED "MIN".

CAUTION

COOLANT IS TOXIC IF INGESTED; CONTACT WITH YOUR EYES OR SKIN MAY CAUSE IRRITATION. IF THE FLUID GETS IN CONTACT WITH THE EYES OR SKIN, RINSE REPEATEDLY WITH PLENTY OF WATER AND SEEK MEDICAL ADVICE. IF SWALLOWED, INDUCE VOMITING, RINSE MOUTH AND THROAT WITH PLENTY OF WATER AND SEEK MEDICAL ADVICE IMMEDIATELY.

CAUTION

DO NOT REMOVE THE EXPANSION TANK PLUG WHEN THE ENGINE IS HOT, SINCE COOLANT IS UNDER PRESSURE AND VERY HOT. CONTACT WITH SKIN OR CLOTHES MAY CAUSE SEVERE BURNS AND/OR INJURIES. TYRES

CAUTION

CHANGING, REPAIR, MAINTENANCE AND BALANCING ARE IMPORTANT OPERATIONS THAT ARE CARRIED OUT BY QUALIFIED PERSONNEL USING SUITABLE TOOLS. THE NEW TYRES MAY BE COVERED WITH A THIN LAYER OF PROTECTIVE COATING THAT IS SLIPPERY. DRIVE CAREFULLY FOR THE FIRST FEW KILOMETRES (MILES). NEVER USE RUBBER TREATMENT AGENTS OF ANY KIND ON THE TYRES. IN PARTICULAR ENSURE THAT THE TYRES DO NOT COME INTO CONTACT WITH LIQUID FUEL THAT WOULD CAUSE A RAPID DETERIORATION OF THE RUBBER. A TYRE THAT HAS BEEN IN CONTACT WITH OIL OR PETROL MUST BE REPLACED AND NOT SIMPLY CLEANED. DO NOT FIT TYRES WITH INNER TUBES ON RIMS FOR TUBELESS TYRES AND VICE VERSA.

Vehicle identification

Chassis number The chassis number is stamped on the chassis central bar. Remove the indicated cap placed inside the front glove-box in order to read this number.

CHAR - 11

Characteristics

Engine number The engine number is stamped near the rear shock absorber lower support.

CAUTION ALTERING IDENTIFICATION NUMBERS CAN BE SERIOUSLY PUNISHED BY LAW, PARTICULARLY MODIFYING THE CHASSIS NUMBER WILL IMMEDIATELY INVALIDATE THE WARRANTY.

Dimensions and mass

SIZES

Specification Max. length Max. length (to brake levers (to mirrors)) Max. height (to the rear-view mirrors) Saddle height Wheelbase Minimum ground clearance Kerb weight Desc./Quantity 1965 mm 720 mm (890 mm) 1.143 mm 790 mm 1360 mm 130 mm 148 kg

Engine

ENGINE

Specification Engine model Engine type Valve quantity Cylinder quantity Overall engine capacity Bore/stroke Compression ratio MAX power MAX. torque Start-up Engine revs at idle speed Clutch Lubrication system Cooling Valve clearance Carburettor model (125): Carburettor model (200): Supply Fuel IGNITION Ignition advance (125)

TECHNICAL DATA

Desc./Quantity M281M (125) M282M (200) Single-cylinder, 4-stroke, 4 valves, wet sump forced lubrication system, overhead camshaft. 4 1 124 cm (125) 198 cm (200) 57 mm / 48.6 mm (125) 72 mm / 48.6 mm (200) 12.0 0.5 : 1 (125) 11.5 0.5 : 1 (200) 11 kW at 10,000 rpm (125) 14 kW at 8,500 rpm (200) 11.7 Nm at 7,500 rpm (125) 19 Nm at 6,500 rpm (200) Electric 1600 100 rpm Automatic centrifugal dry clutch Wet sump forced lubrication system. forced-circulation air cooling driven by a centrifugal pump Inlet: 0.10 Outlet: 0.15 CVK7 30 Keihin CVK7 30 Keihin WVF7 29 WALBRO Vacuum pump Use premium unleaded petrol only, with minimum octane rating of 95 (NORM) and 85 (NOMM). Capacitive discharge ignition, variable advance Variable ignition advance by microprocessor:

CHAR - 12

Characteristics

Specification

Ignition advance (200)

Spark plug Spark plug electrode gap

Desc./Quantity 10 1 to 2,000 rpm 34 1 from 4,500 to 10,000 rpm Variable (before TDC) from: 10 1 to 2,000 rpm 32 1 to 6,500 rpm NGK CR7EB 0.7 - 0.8 mm

Transmission

TRANSMISSION

Specification Gear Primary drive Secondary Engine/wheel total ratio Minimum ratio for continuos transmission Maximum ratio for continuos transmission Desc./Quantity continuous and automatic variator V-belt With gears 1/6.36 (125) 1/6.54 (200) 36.5 (125) 22.36 (200) 10.95 (125) 7.88 (200)

Capacities

CAPACITY

Specification Fuel (reserve included) Fuel reserve Engine oil - engine oil change and engine oil filter replacement Transmission oil Fork oil Depth of fork oil level from the rim / without spring / fork included Coolant Seats Vehicle max. load (rider + passenger + luggage) Desc./Quantity 9l 1.5 l 1100 cm 250 cm 135 1 cm per stem 99 1.5 mm 1.5 l (50% water + 50% ethylene glycol antifreeze fluid) 2 210 kg

Electrical system

BULBS/WARNING LIGHTS

1 2 3 4 5 6 7 8 9 10 11 12 Specification High-/low-beam bulb Tail light bulb Front turn indicator bulbs Rear turn indicator bulbs Rear tail light /stop light bulb License plate light bulb Instrument panel lighting bulb Turn indicator warning light High-beam warning light Low fuel warning light Engine oil pressure warning light High coolant temperature gauge warning light Desc./Quantity 12 V - 55 W - H7 12V - 5W 12 V - 10 W (Amber) 12 V - 10 W (White) 12 V - 5/21 W (Red) 12V - 5W LED LED LED LED LED LED

ELECTRICAL SYSTEM

Specification Battery Desc./Quantity 12V - 10 Ah

CHAR - 13

Characteristics

Specification (Permanent magnet) Generator

Desc./Quantity 12V - 180W

Frame and suspensions

CHASSIS AND SUSPENSIONS

Specification Size "A" Size "B" Trail Chassis type Steering inclination angle Front suspension Front suspension travel Rear suspension Rear suspension travel Desc./Quantity 423.5 mm 479 mm 86.2 mm High-strength steel tubular chassis, single spar at the front, superimposed double cradle at the rear. 26.5 Hydraulic action telescopic fork 100 mm hydraulic action double-acting shock absorber, adjustable preloading 80 mm

Brakes

BRAKES

Specification Front brake Rear brake Desc./Quantity 260-mm disc brake with hydraulic transmission 220-mm disc brake with hydraulic transmission

Wheels and tyres

WHEELS AND TYRES

Specification Wheel rims Front wheel rim Rear wheel rim Tyres Front tyre Rear tyre Rear tyre standard inflation pressure Front tyre standard inflation pressure Front tyre standard inflation pressure with passenger Rear tyre standard inflation pressure with passenger Desc./Quantity Made of light alloy 2.75 x 15" 3.00 x 15" Without inner tube (Tubeless) 120/70 - 15'' 56P 130/80 - 15'' 63P 200 kPa (2.0 bar) 200 kPa (2.0 bar) 200 kPa (2.0 bar) 230 kPa (2.3 bar)

CHAR - 14

Characteristics

Carburettor

KEY: 1. Minimum jet 2. Maximum jet 3. Idle air set screw 4. Tapered pin 5. Throttle valve return spring 6. Float chamber assy 7. Starter cover 8. Cover 9. Screw 10. Screw 11. Fuel closing float needle 12. Diaphragm 13. Float kit 14. Complete automatic starter 15. Spring 16. Cap 17. Washer 18. Seeger ring 19. Spring CHAR - 15

Characteristics

20. Washer 21. Acceleration pump kit

125cc Version Kehin

CARBURETTOR 125 CC

Specification Model Diffuser Engine-side coupling Float Petrol inlet valve needle seat Start-up air inlet hole Start-up jet Minimum jet Idle air screw open in turns Minimum air hole Maximum air hole Maximum jet Throttle valve Sprayer Tapered pin Notch Desc./Quantity CVK7 30 Keihin 29 mm 40 mm 1.2 150 42 35 2 130 70 105 Standard 2.8 mm NDVA

200cc Version Kehin

CARBURETTOR 200 CC

Specification Model Diffuser Engine-side coupling Float Petrol inlet valve needle seat Start-up air inlet hole Start-up jet Minimum jet Idle air screw open in turns Minimum air hole Maximum air hole Maximum jet Throttle valve Sprayer Tapered pin Notch Desc./Quantity CVK7 30 Keihin 29 mm 40 mm 1.2 150 42 38 2 115 70 100 Standard 2.8 mm NDVA

Tightening Torques

HANDLEBAR

Name Handlebar to fork retainer Torque in Nm 4820%

CHAR - 16

Characteristics

Name Safety screw Steering set nut Steering series fixing lock nut Instrument panel support to handlebar retainer Mirror supports to handlebar retainer Mirrors retainer

Torque in Nm 2020% 1520% 11020% 620% 5220% 2520%

CHASSIS

Name License plate holder curved support to chassis retainer Passenger grab handle to chassis retainer Horn to chassis retainer Regulator to chassis retainer Switch to chassis retainer Fuel tank to chassis retainer Helmet compartment to chassis retainer Air deflector to chassis retainer Coil to chassis retainer Torque in Nm 2520% 2520% 1020% 1020% 1020% 1020% 520% 520% 520%

ELECTRICAL SYSTEM

Name Starter motor cable retainer Battery to relay retainer Starter motor on relay retainer Battery cable harness ground lead retainer Torque in Nm 520% 420% 420% 1020%

SADDLE

Name Hinge on saddle retainer Torque in Nm 720%

LOCKS

Name Glove-box lock on cover retainer Saddle lock on right and left half-tail sections retainer Saddle lock on helmet compartment retainer Torque in Nm 420% 320% 520%

INSTRUMENT PANEL

Name Instrument panel to rear panel retainer Instrument panel to instrument panel support retainer Rear panel to handlebar retainer Front panel to lower clamp retainer Front panel to rear panel retainer Lower clamp to rear panel retainer Left and right tool holder retainer Torque in Nm 0.820% 4.520% 120% 120% 320% 120% 520%

REAR BODYWORK

Name Retroreflector to license plate holder retainer License plate to license plate holder retainer Rear taillight to right and left half-tail sections retainer Front retainer for right and left half-tail sections on helmet compartment Rear retainer for right and left half-tail sections on helmet compartment Rear light cover on license plate holder retainer Rear light cover on helmet compartment retainer Rear light cover on tail sections retainer License plate holder on right and left half-tail sections retainer License plate holder on rear mudguard chassis retainer Luggage carrier cover on luggage carrier retainer Torque in Nm 1.520% 120% 120% 420% 120% 120% 6 120% 320% 520% 120%

CHAR - 17

Characteristics

Name Retainer between passenger grab handle cover and passenger grab handle Right and left half-tail sections on helmet compartment retainer Fuel probe lid on helmet compartment retainer Retainer for lower lock of right and left half-tail sections on right and left half-tail sections

Torque in Nm 120% 120% 120% 320%

CENTRAL BODYWORK

Name Central inspection cover on helmet compartment retainer Central inspection cover on right and left fairings retainer Left side inspection cover retainer Right side inspection cover retainer Battery cover retainer Footrest retainer Right and left lower shield retainer Glove-box lid on internal legshield retainer Internal legshield to external legshield retainer Glove-box net on internal legshield retainer Glove-box lid reinforcing retainer Bag hook retainer Air intake on internal legshield retainer Torque in Nm 120% 320 320% 320% 320% 320% 320% 120% 120% 120% 120% 120% 120%

FRONT AND REAR BRAKE

Name Calliper on fork retainer Calliper on muffler plate retainer Pipe cable guide on link rod retainer Pipe cable guide on air deflector retainer Right and left pump on handlebar retainer Rear calliper support to muffler plate retainer Rear calliper support on muffler plate retainer Front pipe cable guide on fork retainer Torque in Nm 2520% 2520% 1020% 520% 1020% 2520% 2520% 1020%

FRONT BODYWORK

Name Right and left air intake on shield retainer Right and left turn indicators on external legshield retainer Front headlamp on external legshield retainer External legshield on cover retainer External legshield on shield retainer Front mudguard clamp on fork retainer External legshield on under-footrest retainer Front mudguard on clamps retainer Case on internal legshield retainer Torque in Nm 120% 120% 120% 120% 120% 120% 320% 520% 220%

FILTER CASING

Name Sleeve on carburettor retainer Sleeve on filter housing retainer Filter housing on engine retainer Torque in Nm 220% 220% 820%

COOLING UNIT

Name Thermal switch retainer Head pipe on radiator retainer Pump pipe on radiator retainer Radiator on bulkhead retainer Electric fan on radiator retainer Expansion tank on air deflector retainer Torque in Nm 2020% 220% 220% 720% 120% 420%

CHAR - 18

Characteristics

FRONT WHEEL

Name Pin retainer Safety screw retainer Torque in Nm 5020% 1020%

LINK ROD

Name Connecting rod to chassis retainer Connecting rod to engine retainer Chassis connecting rod on engine connecting rod retainer Silent-block on chassis retainer Torque in Nm 6020% 4020% 6020% 5020%

EXHAUST

Name Manifold to engine retainer Muffler to manifold retainer Muffler on plate retainer Protection on muffler retainer Torque in Nm 1520% 1620% 2520% 720%

REAR WHEEL

Name Rear wheel retainer Speed sensor screw retainer Speed sensor on muffler plate retainer Torque in Nm 11020% 1020% 1020%

STAND

Name Stand to engine retainer Torque in Nm 2720%

ENGINE

Name Muffler plate on engine Fuel breather pipe cable guide on crankcase Anti-vibration roller Driven pulley shaft nut Clutch assembly nut on driven pulley Driving pulley nut Flywheel nut Oil filter fitting on crankcase Minimum oil pressure sensor engine oil drainage plug/mesh filter oil pump driving crown gear screw Timing chain tensioner support screw Engine crankcase coupling screws Rear hub cover screws Oil pump cover screws Transmission cover screws Oil sump screws Screws fixing oil pump to crankcase Stator unit screws () Starter motor screws Screws for engine crankcase internal bulkhead (transmissionside half shaft) Torque in Nm 2520% 1020% 12 16 54 60 55 60 75 83 54 60 27 33 12 14 24 30 10 14 11 13 11 13 24 27 0.7 0.9 11 13 10 14 56 34 11 13 46

REAR SUSPENSION

Name Right and left shock absorber to chassis retainer Shock absorber on engine bracket retainer Shock absorber on muffler plate retainer Shock absorber bracket on engine retainer Torque in Nm 2520% 4020% 4020% 2520%

CHAR - 19

Characteristics

FUEL SUPPLY SYSTEM

Name Probe to tank retainer Fuel coupling clamp retainer Tank to helmet compartment retainer Petrol pump on helmet compartment retainer Torque in Nm 1.520% 120% 220% 220%

Overhaul data Assembly clearances Cylinder - piston assy.

125 cm Version

COUPLING CATEGORIES

Name Cylinder Cylinder Piston Piston Cylinder 1st Oversize Cylinder 1st Oversize Piston 1st Oversize Piston 1st Oversize Cylinder 2nd Oversize Cylinder 2nd Oversize Piston 2nd Oversize Piston 2nd Oversize Cylinder 3rd Oversize Initials A B C D A1 B1 C1 D1 A2 B2 C2 D2 A3 Cylinder 56.997 57.004 57.004 57.011 57.011 57.018 57.018 57.025 57.197 57.204 57.204 57.211 57.211 57.218 57.218 57.225 57.397 57.404 57.404 57.411 57.411 57.418 57.418 57.425 57.597 57.604 Piston 56.945 56.952 56.952 56.959 56.959 56.966 56.966 56.973 57.145 57.152 57.152 57.159 57.159 57.166 57.166 57.173 57.345 57.352 57.352 57.359 57.359 57.366 57.366 57.373 57.545 57.552 Play on fitting 0.045 - 0.059 0.045 - 0.059 0.045 - 0.059 0.045 - 0.059 0.045 - 0.059 0.045 - 0.059 0.045 - 0.059 0.045 - 0.059 0.045 - 0.059 0.045 - 0.059 0.045 - 0.059 0.045 - 0.059 0.045 - 0.059

CHAR - 20

Characteristics

Name Cylinder 3rd Oversize Piston 3rd Oversize Piston 3rd Oversize

Initials B3 C3 D3

Cylinder 57.604 57.611 57.611 57.618 57.618 57.625

Piston 57.552 57.559 57.559 57.566 57.566 57.573

Play on fitting 0.045 - 0.059 0.045 - 0.059 0.045 - 0.059

200 cm Version

COUPLING CATEGORIES (WITH ALUMINIUM CYLINDER)

Name Cylinder/Piston Cylinder/Piston Cylinder/Piston Cylinder/Piston Initials A B C D Cylinder 71.990 71.997 71.997 72.004 72.004 72.011 72.011 72.018 Piston 71.953 71.960 71.960 71.967 71.967 71.974 71.974 71.981 Play on fitting 0.030 - 0.044 0.030 - 0.044 0.030 - 0.044 0.030 - 0.044

COUPLING CATEGORIES (WITH CAST-IRON CYLINDER)

Name Cylinder/Piston Cylinder/Piston Cylinder/Piston Cylinder/Piston Initials M N O P Cylinder 72 72.007 72.007 72.014 72.014 72.021 72.021 72.026 Piston 71.953 71.960 71.960 71.967 71.967 71.974 71.974 71.981 Play on fitting 0.040 - 0.054 0.040 - 0.054 0.040 - 0.054 0.040 - 0.054

Piston rings

125 cm Version

CHAR - 21

Characteristics

ENGINE SEALING RINGS

Name Compression ring Oil scraper ring Oil scraper ring Description Dimensions 57 x 1 57 x 1 57 x 2.5 Initials A A A Quantity 0.15 0.30 0.10 0.30 0.15 0.35

ENGINE SEALING RINGS (1 ST OVERSIZE)

Name Compression ring 1st Oversize Oil scraper ring 1st Oversize Oil scraper ring 1st Oversize Description Dimensions 57.2 x 1 57.2 x 1 57.2 x 2.5 Initials A A A Quantity 0.15 0.30 0.10 0.30 0.15 0.35

ENGINE SEALING RINGS (2 ND OVERSIZE)

Name Compression ring 2nd Oversize Oil scraper ring 2nd Oversize Oil scraper ring 2nd Oversize Description Dimensions 57.4 x 1 57.4 x 1 57.4 x 2.5 Initials A A A Quantity 0.15 0.30 0.10 0.30 0.15 0.35

ENGINE SEALING RINGS (3 RD OVERSIZE)

Name Compression ring 3rd Oversize Oil scraper ring 3rd Oversize Oil scraper ring 3rd Oversize Description Dimensions 57.6 x 1 57.6 x 1 57.6 x 2.5 Initials A A A 0.15 0.35 Quantity 0.15 0.30

200 cm Version

CHAR - 22

Characteristics

ENGINE SEALING RINGS

Name Compression ring Oil scraper ring Oil scraper ring Description Dimensions 72x1.5 72 x 1 72 x 2.5 Initials A A A Quantity 0.15 0.30 0.10 0.40 0.20 0.40

Crankcase - crankshaft - connecting rod

CRANKSHAFT HALF-BEARINGS

Name Crankshaft half-bearings Crankshaft half-bearings Crankshaft half-bearing Description Dimensions Initials B Type - blue C Type - yellow E Type - green Quantity 1.973 1.976 1.976 1.979 1.979 1.982

CRANKCASE - CRANKSHAFT COUPLINGS

Name Crankshaft type 1Crankcase type 1 Crankshaft type 1 Crankcase type 2 Crankshaft type 2 Crankcase type 1 Crankshaft type 2 Crankcase type 2 Description Dimensions Initials E-E C-C C-C B-B Quantity

CRANKSHAFT - CRANKCASE

Name Crankshaft Crankshaft Crankcase Crankcase Description Dimensions Initials Class 1 Class 2 Class 1 Class 2 Quantity 28.998 29.004 29.004 29.010 32.959 32.965 32.953 32.959

CHAR - 23

Characteristics

Fitting clearances Crankshaft/crankcase axial clearance (H): 0.15 0.40 mm (when cold)

CHAR - 24

Characteristics

CRANKSHAFT / CRANKCASE AXIAL CLEARANCE

Name Half shaft, transmission side Half shaft, flywheel side Connecting rod Spacer tool Description Dimensions 16.6 +0-0.05 16.6 +0-0.05 18 -0.10 -0.15 51.4 +0.05 Initials A B C E Quantity D = 0.20 0.50 D = 0.20 0.50 D = 0.20 0.50 D = 0.20 0.50

Slot packing system

125 cm Version

Characteristic

Compression ratio 12 0.5 : 1

Distance A to be measured is a value of piston protrusion, it indicates how deep the piston crown protrudes out of the plane formed by the cylinder crown. The further the piston protrudes out of the cylinder, the thicker the base gasket to be used should be (to compensate the compression ratio) and vice versa.

NOTE

DISTANCE A, MEASURED WITH THE PISTON AT THE TOP DEAD CENTER, MUST BE TAKEN WITH NO GASKET FITTED BETWEEN THE CRANKCASE AND CYLINDER AND AFTER RESETTING THE DIAL GAUGE, WITH ITS SUPPORT ON A GROUND SURFACE.

CHAR - 25

Characteristics

METAL HEAD GASKET (0.3)

Name Shimming - Cylinder 67.8 - Head gasket 0.3 - Base gasket 0.4 Shimming - Cylinder 67.8 - Head gasket 0.3 - Base gasket 0.6 Measure A 1.40 1.65 1.65 1.90 Thickness 0.4 0.05 0.6 0.05

200 cm Version

Characteristic

Compression ratio 11.5 0.5: 1

Distance A to be measured is a value of piston protrusion, it indicates how deep the piston crown protrudes out of the plane formed by the cylinder crown. The further the piston protrudes out of the cylinder, the thicker the base gasket to be used should be (to compensate the compression ratio) and vice versa.

NOTE

DISTANCE A, MEASURED WITH THE PISTON AT THE TOP DEAD CENTER, MUST BE TAKEN WITH NO GASKET FITTED BETWEEN THE CRANKCASE AND CYLINDER AND AFTER RESETTING THE DIAL GAUGE, WITH ITS SUPPORT ON A GROUND SURFACE.

METAL HEAD GASKET (0.3)

Name Shimming - Cylinder 67.8 - Head gasket 0.3 - Base gasket 0.4 Shimming - Cylinder 67.8 - Head gasket 0.3 - Base gasket 0.6 Measure A 2.50 2.40 2.40 2.20 Thickness 0.4 0.05 0.6 0.05

CHAR - 26

Characteristics

Name Shimming - Cylinder 67.8 - Head gasket 0.3 - Base gasket 0.8

Measure A 2.20 2.10

Thickness 0.8 0.05

Products

RECOMMENDED PRODUCTS TABLE

Product AGIP RACING 4T, SAE 10W-40 AGIP GEAR SYNTH SAE 75W-90 AGIP FORK 7.5W AGIP FILTER OIL AGIP BRAKE 4 SPECIAL AGIP PERMANENT fluid Description Engine oil Gearbox oil Fork oil Oil for air filter sponge Brake fluid Coolant Specifications 10W-40 API GL4, GL5 FMVSS DOT4+ Biodegradable coolant, ready for use, with "long life" technology and characteristics (pink). Freezing protection up to -40. According to CUNA 956-16 standard. NLGI 2

AGIP GREASE SM2

NEUTRAL GREASE OR PETROLEUM JELLY

Lithium grease with molybdenum for bearings and other points needing lubrication Battery poles

Neutral grease or petroleum jelly.

CHAR - 27

INDEX OF TOPICS

TOOLING

TOOL

Tooling

SPECIFIC TOOLS

Stores code 020622Y Description Transmission-side oil seal punch

020565Y

Flywheel lock calliper spanner

001467Y013

Calliper to extract 15-mm diameter bearings

001467Y035

Bell for OD 47-mm bearings

020150Y

Air heater support

020151Y

Air heater

TOOL - 29

Tooling

Stores code 020193Y

Description Gauge for oil pressure check

020262Y

Crankcase splitting strip

020263Y

Sheath for fitting the driven pulley

020287Y

Ring to assemble piston on cylinder

020306Y

Punch for fitting the valve sealing rings

020329Y

Vacuum pump Mity-Vac

TOOL - 30

Tooling

Stores code 020331Y

Description Digital multimeter

020357Y

32x35 mm punch

020359Y

42 x 47 mm punch

020360Y

Adaptor 52x54 mm

020363Y

Crankshaft oil seal punch D 20 mm

020368Y

driving pulley lock wrench

TOOL - 31

Tooling

Stores code 020375Y

Description 28x30 mm punch

020376Y

Adapter handle

020382Y

Tool for removing valve cotters fitted with part 012

020382Y011

adaptor for valve removing tool

020393Y

Piston fitting ring

020412Y

Clutch oil seal punch D 15 mm

TOOL - 32

Tooling

Stores code 020423Y

Description Driven pulley lock wrench

020424Y

Punch for fitting driven pulley roller casing

020425Y

Punch for flywheel side oil seal

020430Y

Tool for fitting the pin snap rings

020434Y

Fitting for oil pressure check

020444Y011

adaptor ring

TOOL - 33

Tooling

Stores code 020444Y009

Description 46 x 55 wrench

020444Y010

adaptor ring

020442Y

Pulley lock wrench

020444Y

Tool for fitting/removing the clutch on the driven pulley

020455Y

10-mm guide for oil seal on water pump shaft

020456Y

24 mm adaptor

TOOL - 34

Tooling

Stores code 020454Y

Description Tool to fit pin snap rings (200 - 250)

020477Y

37-mm Adaptor

020483Y

30 mm guide

020489Y

Stud bolt set for hub cover support

TOOL - 35

INDEX OF TOPICS

MAINTENANCE

MAIN

Maintenance

Maintenance chart

ROUTINE

MAINTENANCE TABLE

I: INSPECT AND CLEAN, ADJUST, LUBRICATE OR REPLACE IF NECESSARY C: CLEAN, R: REPLACE, A: ADJUST, L: LUBRICATE * Check level every 3,000 km ** Replace every 2 years *** Replace every 4 years km x 1,000 Driven pulley roller casing Safety locks Spark plug driving belt Throttle control Brake disc Air filter SAS filter Engine oil filter Valve clearance Electrical system and battery Braking systems Light circuit Brake control levers Brake fluid ** Coolant level** Exhaust muffler/ silencer Engine oil* Hub oil Headlight aiming adjustment Brake pads Sliding blocks / Variable speed rollers Vehicle test drive Radiator Idle speed Wheels/tyres Suspensions Steering Transmissions Fuel pipes *** 1 I I I A I I C R A I I I I I R I I I I 6 12 L I R R A I C C R I I I L I I I R I A I R I A I I I L I 18 24 L I R R A I C C R I I I L I I I R R A I R I A I I I L I 30 36 L I R R A I C C R A I I I L I I I R I A I R I C A I I I L I 42 48 L I R R A I C C R I I I L I I I R R A I R I A I I I L I 54 60 L I R R A I C C R I I I L I I I R I A I R I A I I I L I

I I I C R A I I I I I R I I I I C I

I I I C R I I I I I R I I I I

I I I C R I I I I I R I I I I

I I I C R A I I I I I R I I I I C I

R I I I L I I R R I I A I I

Spark plug

CAUTION

WAIT SOME MINUTES UNTIL THE ENGINE AND THE EXHAUST SYSTEM ARE COLD. Check and/or replace the spark plug at the intervals shown in the scheduled maintenance table. To reach the spark plug: Remove the central cover of the chassis. Undo the indicated screw and remove the spark plug inspection cover.

MAIN - 37

Maintenance

Disconnect the tube. Unscrew the spark plug.

Characteristic

Spark plug electrode gap 0.7 -0.8 mm Spark plug NGK CR7EB

To refit, carry out removal operations but in reverse order

Hub oil

Ride a few kilometres until the regular working temperature is reached, then shut off the engine.

NOTE

USE RECOMMENDED OIL ONLY. REFER TO THE RECOMMENDED PRODUCTS TABLE.

Check

Park the vehicle on firm and level ground. Rest the vehicle on its centre stand. Unscrew and pull out the measuring cap-dipstick. Clean the area in contact with oil with a clean cloth. Screw the cap-dipstick fully down into its tube. Pull out the cap-dipstick again and read the level the oil reaches on the dipstick. The level is correct when it is close to the first notch above the little round mark. Top-up if necessary.

CAUTION WAIT SOME MINUTES UNTIL THE ENGINE AND THE EXHAUST SYSTEM ARE COLD.

TOP-UP Pour a small quantity of oil through the fill opening and wait about one minute so that the oil flows evenly into the crankcase. MAIN - 38

Maintenance

Check the oil level and top up, if required. Top-up with small quantities of oil, until the recommended level is reached. At the end of the operation, screw and tighten the cap-dipstick.

NOTE

RIDING THE VEHICLE WITH INSUFFICIENT LUBRICATION OR CONTAMINATED OR NOT RECOMMENDED LUBRICANTS ACCELERATES THE WEAR AND TEAR OF MOVING PARTS AND CAN CAUSE IRRETRIEVABLE DAMAGE

Replacement

Park the vehicle on firm and level ground. Rest the vehicle on its centre stand. Stop the engine and let it cool down. This will allow the oil to settle into the crankcase and cool down.

CAUTION

WAIT SOME MINUTES UNTIL THE ENGINE AND THE EXHAUST SYSTEM ARE COLD. Unscrew and pull out the measuring cap-dipstick.

Place a +300 cm (18.3 cu.in) capacity container under the drain screw. Unscrew and remove the drain screw and let the oil drain off completely. Screw and tighten the drain screw. Add oil through the transmission oil fill opening. Screw and tighten the measuring capdipstick. Start the engine and let it run for several minutes. Stop the engine and let it cool down. Check the transmission oil level.

CAUTION USED OIL CONTAINS SUBSTANCES THAT ARE HARMFUL TO THE ENVIRONMENT. DISPOSE OF USED OIL ACCORDING TO THE REGULATIONS IN FORCE.

MAIN - 39

Maintenance

Air filter

Clean and check the air filter following the indications specified in the scheduled maintenance table. Carry out the maintenance procedures more frequently if the vehicle is used in rainy or dusty areas, or off road. In this case, the air filter can be partially cleaned after travelling along these kinds of roads.

CAUTION

PARTIAL AIR FILTER CLEANING DOES NOT EXCLUDE NOR POSTPONE AIR FILTER REPLACEMENT. DO NOT START THE ENGINE WITHOUT THE AIR FILTER. DO NOT USE PETROL OR SOLVENTS TO CLEAN THE FILTERING ELEMENT; THE FUEL SUPPLY SYSTEM MAY CATCH FIRE POSING A GREAT RISK FOR PEOPLE AND THE VEHICLE ITSELF. Remove the filter. Wash the filtering element with clean, non-flammable or high-volatility solvents, and let it dry properly. Apply a specific filter oil over all the surface.

CAUTION PARTIAL AIR FILTER CLEANING DOES NOT EXCLUDE NOR POSTPONE AIR FILTER REPLACEMENT. DO NOT START THE ENGINE WITHOUT THE AIR FILTER. DO NOT USE PETROL OR SOLVENTS TO CLEAN THE FILTERING ELEMENT; THE FUEL SUPPLY SYSTEM MAY CATCH FIRE POSING A GREAT RISK FOR PEOPLE AND THE VEHICLE ITSELF.

Check the lower part of the bleed pipes 1 for dirt. Remove any deposit coming from the filter housing found inside the bleed pipe. Proceed as follows: Remove the caps 2. Drain the content in a container; then, send it to a recycling bank.

WARNING

NEVER REUSE A FILTER. Replace the air filter with a new one of the same type.

Engine oil

MAIN - 40

Maintenance

Replacement

Rest the vehicle on its centre stand. Shut off the engine and let it cool down, so that the crankcase oil drains out and cools off. Unscrew and pull out the cap-dipstick 1. Place a container under the filter to collect the engine oil.

NOTE PARK THE VEHICLE ON SAFE AND LEVEL GROUND. CAUTION WAIT SOME MINUTES UNTIL THE ENGINE AND THE EXHAUST SYSTEM ARE COLD.

Unscrew and remove the cartridge engine oil filter 4. Unscrew and remove the oil drainage plug 3 and then drain all the engine oil into the collecting container. Fit a new oil cartridge filter 4 and take special care to lubricate the filter sealing O-rings with oil. Screw and tighten the engine oil drainage plug 3. Add oil through the transmission engine oil fill opening. Screw and tighten the measuring capdipstick 1. Start the engine and let it run for several minutes. Stop the engine and let it cool down. Check the engine oil level.

CAUTION USED OIL CONTAINS SUBSTANCES THAT ARE HARMFUL TO THE ENVIRONMENT. DISPOSE OF USED OIL ACCORDING TO THE REGULATIONS IN FORCE.

Check

Park the vehicle on firm and level ground. Rest the vehicle on its centre stand. MAIN - 41

Maintenance

CAUTION

WAIT SOME MINUTES UNTIL THE ENGINE AND THE EXHAUST SYSTEM ARE COLD. Stop the engine and let it cool down. This will allow the oil to settle into the crankcase and cool down.

NOTE

FAILURE TO FOLLOW THESE OPERATIONS MAY RESULT IN AN INCORRECT READING OF THE ENGINE OIL LEVEL. Unscrew and take out the measuring cap-dipstick 1. Clean the area in contact with oil with a clean cloth. Screw the cap-dipstick 1 fully down into its tube 2. Pull out the cap-dipstick again 1 and read the level the oil reaches on the dipstick: MAX = maximum level. MIN = minimum level. The level is correct when it is close to "MAX" level, marked on the measuring dipstick. Top up if necessary.

WARNING DO NOT GO BEYOND THE "MAX" OR BELOW THE "MIN" LEVEL MARKS TO AVOID SEVERE ENGINE DAMAGE.

ENGINE OIL TOP-UP Pour a small quantity of oil through the fill opening 2 and wait about one minute so that the oil flows evenly into the crankcase. Check the oil leveland top-up,if required. Top-up with small quantities of oil, until the recommended level is reached. At the end of the operation, screw and tighten the cap-dipstick 1.

NOTE

RIDING THE VEHICLE WITH INSUFFICIENT LUBRICATION OR CONTAMINATED OR NOT RECOMMENDED LUBRICANTS ACCELERATES THE WEAR AND TEAR OF MOVING PARTS AND CAN CAUSE IRRETRIEVABLE DAMAGE.

NOTE

DO NOT EXCEED THE "MAX" MARK WHEN TOPPING-UP ENGINE OIL.

Cooling system Level check

CAUTION

MAIN - 42

Maintenance

WAIT FOR THE ENGINE TO COOL DOWN BEFORE CHECKING OR TOPPING-UP THE COOLANT LEVEL.

CAUTION

PARK THE VEHICLE ON SAFE AND LEVEL GROUND. Shut off the engine and wait until it cools off. Undo the indicated screw on both sides and remove the front case.

Make sure that the liquid level in the expansion tank is between "MIN" and "MAX" references. Otherwise, top-up.

DO NOT ADD ADDITIVES OR OTHER SUBSTANCES TO THE OIL.

TOP-UP Loosen but do not remove the coolant reservoir cap. Wait for some seconds so that possible pressure may be purged. Unscrew and remove the cap Top up with the recommended product until the liquid approximately reaches the "MAX" level. Refit the fuel tank cap.

CAUTION

IF THERE IS AN EXCESSIVE CONSUMPTION OF COOLANT OR WHEN THE EXPANSION TANK REMAINS EMPTY, CHECK THAT THERE ARE NO LEAKS IN THE CIRCUIT. Radiator cleaning Remove the front case. Wash the radiator with a pressurised water jet. Blow the radiator with compressed air.

NOTE

IT IS NOT NECESSARY TO REMOVE THE RADIATOR MAIN - 43

Maintenance

Braking system

The following operations refer to both braking systems.

CAUTION

PURGE THE AIR IN THE SYSTEM IN CASE OF EXCESSIVE TRAVEL OF THE BRAKE LEVER, EXCESSIVE ELASTICITY OR AIR BUBBLES IN THE CIRCUIT. DO NOT USE OR MIX DIFFERENT SILICON- OR PETROLEUM-BASED COOLANT TYPES. PAY UTMOST ATTENTION THAT NO WATER OR DUST INADVERTENTLY GETS INTO THE CIRCUIT.

Level check

Park the vehicle on its centre stand. Turn the handlebar so that the fluid in the brake fluid reservoir is parallel to the MIN reference mark indicated on the sight glass 1. Check that the level in the reservoir is over the MIN reference mark indicated on the sight glass 1. MIN = minimum level. If the fluid does not reach at least the MIN reference mark:

CAUTION BRAKE LEVEL DECREASES GRADUALLY AS BRAKE PADS WEAR DOWN.

Check brake pads and disc for wear. If the pads and/or the disc do not need replacing, top-up the fluid.

Top-up

Remove the front handlebar cover. Undo and remove the four screws indicated.

CAUTION RISK OF BRAKE FLUID SPILLS. DO NOT PULL THE FRONT BRAKE LEVER WHEN THE SCREWS ARE LOOSE OR, MAINLY, WHEN THE BRAKE FLUID RESERVOIR COVER HAS BEEN REMOVED. PLACE A CLOTH UNDER THE BRAKE FLUID RESERVOIR TO PROTECT IT FROM ANY FLUID LEAKS.

MAIN - 44

Maintenance

Remove the cover and top up the reservoir with the recommended liquid until the correct level is reached

CAUTION DO NOT SHAKE THE VEHICLE TO AVOID BRAKE FLUID SPLASHING DURING TOP-UP. CAUTION AVOID PROLONGED AIR EXPOSURE OF THE BRAKE FLUID. BRAKE FLUID IS HYGROSCOPIC AND ABSORBS MOISTURE WHEN IN CONTACT WITH AIR. LEAVE THE BRAKE FLUID RESERVOIR OPEN ONLY FOR THE TIME NEEDED TO COMPLETE THE TOPPING UP PROCEDURE. CAUTION DO NOT FILL UP THE TANK TO THE MAXIMUM, BUT JUST OVER THE ''MIN'' LEVEL. TOP-UP TO MAXIMUM LEVEL MARK ONLY WHEN BRAKE PADS ARE NEW. BRAKE LEVEL DECREASES GRADUALLY AS BRAKE PADS WEAR DOWN. IT IS ADVISABLE NOT TO TOP-UP TO THE MAX LEVEL MARK WHEN THE BRAKE PADS ARE WORN BECAUSE YOUR RISK SPILLING FLUID WHEN CHANGING THE BRAKE PADS.

Headlight adjustment

For a quick check of the correct direction of the front light beams, place the vehicle ten metres from a vertical wall and make sure the ground is level. Turn on the low-beam light, sit on the vehicle and check that the light beam projected to the wall is a little below the headlight horizontal straight line (about 9/10 of the total height). To adjust the light beam: Use a screwdriver to act on the corresponding screws 1 on the front wheel housing. SCREW it (clockwise) to raise the light beam. UNSCREW it (anticlockwise) to lower the light beam.

MAIN - 45

INDEX OF TOPICS

ELECTRICAL

SYSTEM

ELE SYS

Electrical system

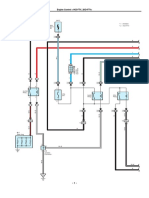

KEY: 1. Multiple connectors 2. Fuel Level Sensor 3. Instrument panel 4.Thermistor 5.Speed sensor 6. MODE Button 7. Horn 8. Key switch 9. Front stop switch 10. Rear stop switch 11.Light switch 12. Left rear turn indicator 13. Twin tail light/stop light bulb 14. Right rear turn indicator 15. Rear light assembly 16. License plate light 17. Stop light relay 18. Turn indicators switch 19. Start-up relay ELE SYS - 47

Electrical system

20. Starter motor 21. Main fuses 22. Auxiliary fuses 23. Plug socket 24. Battery 25. HV coil 26. Spark plug 27. Automatic starter 28. CDI Control Unit 29. Connection for oil sensor (USA only) 30. Oil pressure sensor 31. Pick-up 32. Generator 33. Voltage regulator 34. Thermometric switch 35. Fan 36. Glove-box light 37. Glove-box light switch 38. Right front turn indicator 39. - Headlamp tail light 40. High-beam bulb 41. Low-beam bulb 42. Left front turn indicator 43. Complete front headlamp 44. Blinker (USA only) 45.Kit for blinker (USA only) 46. Horn button 47.Start button 48. Engine stop switch CABLE COLOURS Ar orange Az sky blue B blue Bi white G yellow Gr grey M brown N black ELE SYS - 48

Electrical system

R red V green Vi purple Ro pink

Components arrangement

1. Fan 2. Thermometric switch Remove the legshield to reach it.

ELE SYS - 49

Electrical system

3. Horn 4. Voltage regulator Remove the front wheel housing to reach it.

Electric characteristic

No-load recharge voltage 13 15 V at 5000 rpm

5. Battery 6. Fuses Remove the battery cover on the footrest to reach them.

7. Start-up relay 8. Stop light relay Remove the footrest to reach it.

9. Speed sensor It is placed on the rear wheel.

ELE SYS - 50

Electrical system

10. Magneto flywheel 11. Automatic starter Remove the tail section to reach connectors.

Electric characteristic

Permanent magnet generator 12V - 180W Stator winding resistance 0.11 Ohm at 20 C (68 F) Off-load generated voltage > 50 V at 5000 RPM Pick-up winding resistance 10510% Ohm at 20 C (68 F) Starter resistance ~30 Ohm at 20 C (68 F) 12. Control unit Remove the tail section to reach it.

13. Fuel Level Sensor Remove the plastic cover under the saddle to reach it.

Electric characteristic

Full tank 10010% Ohm Empty tank 120010% Ohm

ELE SYS - 51

Electrical system

14. Thermistor Remove the helmet compartment to reach it.

Electric characteristic

Resistance at 100 C (212F) 144 Ohm Resistance at 80 C (176F) 262 Ohm Resistance at 60 C (140F) 512 Ohm Resistance at 40 C (104F) 1090 Ohm 15. HV coil Remove the rear central cover to reach it.

Electric characteristic

Secondary resistance 290010% Ohm at 20 C (68 F) Primary resistance 0.210% Ohm at 20 C (68 F)

ELE SYS - 52

Electrical system

Front side

ELE SYS - 53

Electrical system

ELE SYS - 54

Electrical system

KEY 1.Push through the hole 2. Long black clamps (290x4.5) 3.Push through the hole

ELE SYS - 55

Electrical system

KEY 1. Medium black clamps (180x4.5)

ELE SYS - 56

Electrical system

KEY 1. Medium black clamps (180x4.5)

ELE SYS - 57

Electrical system

KEY 1. Long black clamps

ELE SYS - 58

Electrical system

KEY 1.Long black clamps (290x4.5)

ELE SYS - 59

Electrical system

ELE SYS - 60

Electrical system

ELE SYS - 61

Electrical system

KEY 1. Long black clamps (290x4.5)

ELE SYS - 62

Electrical system

ELE SYS - 63

Electrical system

Back side

KEY 1. Medium black clamps (180x4.5)

ELE SYS - 64

Electrical system

KEY 1. Small black clamps (98x2.5)

ELE SYS - 65

Electrical system

KEY 1. Rubber cap 2.Medium black clamps (180x4.5)

ELE SYS - 66

Electrical system

KEY 1. Small black clamps (98x2.5)

ELE SYS - 67

Electrical system

KEY 1. Small black clamps (98x2.5) 2. Cable guide

ELE SYS - 68

Electrical system

KEY 1. Long black clamps (290x4.5)

ELE SYS - 69

Electrical system

KEY 1.Long black clamps (290x4.5)

ELE SYS - 70

Electrical system

KEY 1. Long black clamps (290x4.5)

ELE SYS - 71

Electrical system

KEY 1.Small black clamps (98x2.5)

ELE SYS - 72

Electrical system

KEY 1.Medium black clamps (180x4.5)

ELE SYS - 73

Electrical system

Conceptual diagrams Ignition

KEY: 8. Key switch 21. Main fuses 22. Auxiliary fuses 24.Battery 25. HV coil 26.Spark plug 28. CDI Control Unit 31. Pick-up 48. Engine stop switch

ELE SYS - 74

Electrical system

Battery recharge and starting

KEY: 8. Key switch 9.Front stop switch 10. Rear stop switch 19. Start-up relay 20. Starter motor 21. Main fuses 22. Auxiliary fuses 24. Battery 32. Generator 33. Voltage regulator 47. Start button 48. Engine stop switch

ELE SYS - 75

Electrical system

Level indicators and enable signals section

KEY: 1. Multiple connectors 2. Fuel Level Sensor 3.Instrument panel 4.Thermistor 5.Speed sensor 8.Key switch 21. Main fuses 22. Auxiliary fuses 24.Battery 29. Connection for oil sensor (USA only) 30.Oil pressure sensor

ELE SYS - 76

Electrical system

Devices and accessories

KEY: 3.Instrument panel 6.MODE Button 7. Horn 8.Key switch 21. Main fuses 22. Auxiliary fuses 23. Plug socket 24. Battery 27.Automatic starter 28. CDI Control Unit 34.Thermometric switch 35.Fan 46. Horn button

ELE SYS - 77

Electrical system

Lights and turn indicators

KEY: 3.Instrument panel 8.Key switch 9.Front stop switch 10. Rear stop switch 11. Light switch 12.Left rear turn indicator 13. Twin tail light/stop light bulb 14. Right rear turn indicator 15.Rear light assembly 16.License plate light 17. Stop light relay 18. Turn indicator switch 21. Main fuses 22. Auxiliary fuses 24.Battery 28.CDI Control Unit 38.Right front turn indicator

ELE SYS - 78

Electrical system

39. -Front headlamp tail light 40. High-beam bulb 41. Low-beam bulb 42. Left front turn indicator 43.Complete front headlamp 44. Blinker (USA only) 45. Kit for blinker (USA only) 48.Engine stop switch

Checks and inspections Ignition circuit No spark plug

CAUTION

THE CONTINUITY TEST SHOULD BE PERFORMED WITH THE RELATIVE CONNECTORS DISCONNECTED. Check spark plug for correct conditions, clean it and remove deposits. Replace it, if necessary.

Pick-Up Check With engine off disconnect the control unit connector. Measure the resistance present between terminals No. 6 (Blue-Yellow cable) and No. 8 (Blue cable). If the value measured is incorrect, repeat the check directly on the component.

ELE SYS - 79

Electrical system

Disconnect the Pick-Up connector and measure the resistance between the pin corresponding to the Blue-Yellow cable of the wiring and the ground connection on the engine. If the value measured is correct, check wiring continuity.

Electric characteristic

Pick-up winding resistance 10510% Ohm at 20 C (68 F) Coil primary check: Disconnect the connector of the control unit. Measure the resistance present between terminals No. 3 (White-Purple cable) and No. 8 (Blue cable). If the measured value is incorrect, repeat the check between the positive and negative terminals of the coil. If a correct value is measured, check wiring continuity.

Electric characteristic

Primary resistance 0.210% Ohm at 20 C (68 F) Coil secondary check Disconnect the spark plug cap from the coil cable and measure the resistance between the cable end and the coil green negative terminal.

Electric characteristic

Secondary resistance 290010% Ohm at 20 C (68 F)

Battery recharge circuit

With engine running at high revs, measure the voltage present at the battery poles.

Electric characteristic

No-load recharge voltage ELE SYS - 80

Electrical system

13 15 V at 5000 rpm

Stator check

Checking the stator winding

WARNING

THE CHECK-UP CAN BE MADE WITH THE STATOR PROPERLY INSTALLED. 1) Remove the front wheel housing. 2) Disconnect the voltage regulator connector. 3) Measure the resistance between each of the yellow terminals and the other two.

Electric characteristic

Stator winding resistance 0.11 Ohm at 20 C (68 F)

4) Check that there is insulation between the each yellow cable and the earth. 5) If incorrect values are detected, repeat the check directly on the stator and control cable harnesses if necessary.

Recharge system voltage check

Connect the ammeter induction clamp to the voltage regulator positive terminal (Red-Orange). Measure the battery voltage and turning on the vehicle lights, with engine off, wait for the voltage to set at about 12 V. Start the engine and measure the current generated by the system with lights on and a high running engine.

Characteristic

Generated current: 6A at 6000 rpm ELE SYS - 81

Electrical system

Start up system check

KEY: 1. Key switch 2.Front stop switch 3.Rear stop switch 4. Start button 5.Engine stop switch 6. Start-up relay 7. Starter motor 8.Battery 9. Main fuses 10. Auxiliary fuses

CAUTION

THE CONTINUITY TEST SHOULD BE PERFORMED WITH THE RELATIVE CONNECTORS DISCONNECTED.

ELE SYS - 82

Electrical system

1) Check fuses No. 1 and 4. 2) Check key switch and engine stop switch contacts. 3) Check stop switches and start button contacts. 4) Try to start up and check for voltage between the Yellow-Red cable and the Blue cable of the start-up relay (see figure). 5) If voltage is not detected, check cable harness continuity. 6) Check the start-up relay. 7) Check the integrity and the connections of the Red cable that connects the battery to the start-up relay. 8) Repeat the check with the Red cable that connects the start-up relay and the starter motor (see figure).

Horn control

KEY: 1. Horn button ELE SYS - 83

Electrical system

2. Key switch 3. Horn 4.Battery 5.Main fuses 6.Auxiliary fuses

CAUTION

THE CONTINUITY TEST SHOULD BE PERFORMED WITH THE RELATIVE CONNECTORS DISCONNECTED. 1) Check fuses No. 1 and 3. 2) Check key switch and horn button contacts. 3) With the key switch set to ON, check for voltage between the Green cable of the horn button and ground. If voltage is not detected, check cable harness continuity. 4) Check the integrity and the connections of the Grey cable of the horn and the horn ground lead (Blue cable).

Choke Inspection

KEY: 1.CDI Control Unit ELE SYS - 84

Electrical system

2. Key switch 3.Main fuses 4.Battery 5.Auxiliary fuses 6.Automatic starter

CAUTION

THE CONTINUITY TEST SHOULD BE PERFORMED WITH THE RELATIVE CONNECTORS DISCONNECTED. 1) Keep the connector connected to the system and check for voltage between both terminals of the starter when the engine is on. 2) If no voltage is detected, check the continuity of the Green-Red cable with fuse No. 4 and that of the Green-Black cable with the control unit (pin 7).

Electric characteristic

Starter resistance ~30 Ohm at 20 C (68 F)

Turn signals system check

KEY: 1. Instrument panel ELE SYS - 85

Electrical system

2.Turn indicators switch 3. Left rear turn indicator 4.Right rear turn indicator 5.CDI Control Unit 6.Right front turn indicator 7.Left front turn indicator

CAUTION

THE CONTINUITY TEST SHOULD BE PERFORMED WITH THE RELATIVE CONNECTORS DISCONNECTED. 1) Check that bulbs and their ground connection are in working conditions (Blue cables). 2) Check the continuity of the Blue-Black cable connecting the control unit (pin 1) and the turn indicator switch. 3) Check the contacts of the turn indicator switch. 4) Check the integrity and the connections of the bulbs cable harnesses (Sky blue and Red cables) to the turn indicator switch.

level indicators

KEY: 1.Fuel Level Sensor 2.Instrument panel

CAUTION

ELE SYS - 86

Electrical system

THE CONTINUITY TEST SHOULD BE PERFORMED WITH THE RELATIVE CONNECTORS DISCONNECTED. 1) Measure the resistance in the fuel level sensor ends in the different conditions. 2) If the resistance values are correct, but the indication on the instrument panel is incorrect, check the integrity and the connections of the cable harnesses (Brown cable with pin 7 of the instrument panel connector and Grey-Green cable with pin 12 of the instrument panel connector.)

Electric characteristic

Full tank 10010% Ohm Empty tank 120010% Ohm

Lights list

KEY: 1.Instrument panel 2. Light switch ELE SYS - 87

Electrical system

3.Key switch 4.Twin tail light/stop light bulb 5.License plate light 6. Battery 7. Main fuses 8.Auxiliary fuses 9. High-beam bulb 10. Front headlamp tail lights 11.Low-beam bulb

BULBS/WARNING LIGHTS

1 2 3 4 5 6 7 8 9 10 11 12 CAUTION Specification High-/low-beam bulb Tail light bulb Front turn indicator bulbs Rear turn indicator bulbs Rear tail light /stop light bulb License plate light bulb Instrument panel lighting bulb Turn indicator warning light High-beam warning light Low fuel warning light Engine oil pressure warning light High coolant temperature gauge warning light Desc./Quantity 12 V - 55 W - H7 12V - 5W 12 V - 10 W (Amber) 12 V - 10 W (White) 12 V - 5/21 W (Red) 12V - 5W LED LED LED LED LED LED

THE CONTINUITY TEST SHOULD BE PERFORMED WITH THE RELATIVE CONNECTORS DISCONNECTED. Tail lights line check 1) Check that bulbs and their ground connection are in working conditions (Blue cables). 2) Check fuses No. 1 and 3. 3) Check key switch contacts. 4) Check the integrity and the connections of the bulbs cable harnesses (Green cables) with fuse No. 3. High-beam/low-beam lights line check 1) Check that bulbs and their ground connection are in working conditions (Blue cables). 2) Check fuses No. 1 and 3. 3) Check key switch and light switch contacts. 4) With the key switch set to ON, check for voltage between the light switch Green cables and ground. If voltage is not detected, check cable harness continuity. 5) Check that the connections between bulb cable harnesses (White cable and Black cable) and the light switch are in good conditions.

ELE SYS - 88

Electrical system

Fuses

CAUTION

DO NOT REPAIR FAULTY FUSES. NEVER USE FUSES OTHER THAN THE ONES SPECIFIED. A SHORT CIRCUIT MAY DAMAGE THE ELECTRICAL SYSTEM OR EVEN CAUSE A FIRE. NOTE IF THE SPARE FUSE IS USED, REPLACE WITH ONE OF THE SAME TYPE IN THE CORRESPONDING FITTING.

FUSE DISTRIBUTION

1 Specification Fuse No. 1 Desc./Quantity Capacity: 20A Protected circuits: Key switch, instrument panel, fan and recharge circuit. Capacity: 15 A Protected circuits: From battery to plug socket. Capacity: 15 A Protected circuits: From key switch to tail lights, stop lights, high-beam light, low-beam light, horn and instrument panel. Capacity: 7.5A Protected circuits: From key switch to automatic starter, ignition and start-up circuit.

2 3

Fuse No. 2 Fuse No. 3

Fuse No. 4

Dashboard

KEY 1. Blue high-beam warning light 2. Green turn indicators warning light 3. Fuel gauge 4. Orange low fuel warning light ELE SYS - 89

Electrical system

5. Speedometer 6. Coolant high temperature warning light 7. Coolant temperature gauge 8. Red oil pressure warning light. 9. ABS warning light (Activated on ABS versions only) 10. Multifunction indicator: total odometer (ODO) / two trip odometers (ODO I - ODO II) / battery voltage 11. Warning light not active 12. Digital clock

Km or miles selection Quickly press the MODE button, select the battery voltage measurement function. Hold down the MODE button for more than 10 seconds to change from km to mile reading for the odometer. For the first 5 seconds the button is held down, there will be no instrument panel indication, but for the next 5 seconds, the legend of the unit of measurement (km or miles) currently in use will flash at a frequency of 1 Hz. If the button is released before 10 seconds elapse, the unit of measurement does not vary.

Data check function

WARNING

THE SERVICE WARNING LIGHT IS NOT ACTIVE. WHEN THE KEY IS INSERTED, THE SERVICE COUPONS ICON SHALL BE ON FOR TWO SECONDS ONLY AFTER REACHING 50,000 KM. CARRY OUT THE RESET SERVICE TO ELIMINATE THE SERVICE COUPONS ICON IGNITION. RESET Hold the MODE button down.

Turn the key to ''ON'' and wait 10 seconds. During this operation the service icon flashes at a 1 Hz frequency.

ELE SYS - 90

Electrical system

Sealed battery

Commissioning sealed batteries (without maintenance) In case the vehicle fits a sealed battery, the maintenance is limited to the loading state and to an eventual recharge. These operations should be carried out before delivering the vehicle, and on a six-month basis while the vehicle is stored in open circuit. Besides upon pre-delivery, it is therefore necessary to check the battery charge and recharge it, if required, before storing the scooter and afterwards every 6 months. INSTRUCTIONS FOR BATTERY REFRESH AFTER OPEN CIRCUIT STORAGE 1. Voltage check 2. Before installing the battery on the vehicle, check the open circuit voltage with a standard tester. If voltage is over 12.60V, the battery can be installed without any refresh. If voltage is below 12.60 V, a renewal recharge is required as explained in 2). 3. Constant-voltage battery charge mode 4. Constant-voltage charge equal to 14.4014.70V Initial charge current equal to 0.30.5 of the battery rated capacity Charge time: 10 to 12 h recommended Minimum 6 h Maximum 24 h 5. Constant-current battery charge mode 6. Charge current equal to 1/10 of the battery rated capacity

Dry-charge battery

Commissioning dry charge battery (with maintenance)

WARNING

BATTERY ELECTROLYTE IS POISONOUS AS IT MAY CAUSE SERIOUS BURNS. IT CONTAINS SULPHURIC ACID. AVOID CONTACT WITH YOUR EYES, SKIN AND CLOTHING. IF IT ACCIDENTALLY COMES INTO CONTACT WITH YOUR EYES OR SKIN, WASH WITH ABUNDANT WATER FOR APPROX. 15 MIN. AND SEEK IMMEDIATE MEDICAL ATTENTION. IF ACCIDENTALLY SWALLOWED, IMMEDIATELY DRINK LARGE QUANTITIES OF WATER OR MILK FOLLOWED BY MAGNESIUM MILK, BEATEN EGG OR VEGETABLE OIL. SEEK IMMEDIATE MEDICAL ATTENTION. BATTERIES PRODUCE EXPLOSIVE GASES; KEEP CLEAR OF NAKED FLAMES, SPARKS OR CIGARETTES; VENTILATE THE AREA WHEN RECHARGING INDOORS. ALWAYS WEAR EYE PROTECTION WHEN WORKING IN THE PROXIMITY OF BATTERIES. KEEP OUT OF THE REACH OF CHILDREN

ELE SYS - 91

Electrical system

Remove the short closed tube and the caps, then pour sulphuric acid into the cells, using the type specified for batteries, with a specific gravity of 1.26, corresponding to 30 B, at a minimum temperature of 15C until the upper level is reached. Leave to rest for at least 2 hours, then restore the level with sulphuric acid. Within the following 24 hours, recharge with the specific battery charger at an intensity of about 1/10 of the battery nominal capacity and until the acid density is about 1.27, corresponding to 31 B, and these values are stabilised. Once the charge is complete, level the acid (by adding distilled water). Close and clean carefully. Once the above operations have been performed, install the battery on the vehicle ensuring that it is connected properly. 1 Hold the tube upright 2 Inspect visually 3 The float must be freed Electrolyte level check The electrolyte level must be checked frequently and must reach the upper level. Only use distilled water to restore this level. If it is necessary to add water too frequently, check the vehicle electrical system: the battery works overcharged and is subject to quick wear. Charge status check After topping-up the electrolyte level, check its density using an appropriate densitometer. With the battery charged, a density of 3032 B, corresponding to a specific weight of 1.261.28, must be at a minimum temperature of 15 C. A density reading below 20 B indicates that the battery is completely flat and must therefore be recharged. If the vehicle is not be used for a certain time (1 month or more), the battery needs to be recharged periodically. ELE SYS - 92

Electrical system

The battery runs down completely in about three months. Should the battery be fitted on a vehicle, be careful not to invert the connections, keeping in mind that the ( black) ground wire marked (-) is connected to the - negative terminal while the other two red wires marked (+) are connected to the + positive terminal. Battery recharge

WARNING

BEFORE RECHARGING THE BATTERY, REMOVE THE CAPS OF EACH CELL. KEEP NAKED FLAMES OR SPARKS AWAY FROM THE BATTERY WHILE CHARGING. First detach the negative terminal before removing the battery from the vehicle. Normal bench charging must be performed using the special battery charger, setting the battery charge selector to the type of battery that requires recharging (that is, at a current equal to 1/10 of the battery rated capacity). Connections to the power supply source must be implemented by connecting corresponding poles (+ to + and - to -). The battery should always be kept clean, especially its top side, and the terminals should be coated with petroleum jelly.

CAUTION

NEVER USE FUSES WITH A CAPACITY HIGHER THAN THE RECOMMENDED CAPACITY. USING A FUSE OF UNSUITABLE RATING MAY SERIOUSLY DAMAGE THE VEHICLE OR EVEN CAUSE A FIRE.

CAUTION

ORDINARY DRINKING WATER CONTAINS MINERAL SALTS THAT ARE HARMFUL TO THE BATTERY. CONSEQUENTLY, ONLY USE DISTILLED WATER.

CAUTION

TO ENSURE MAXIMUM PERFORMANCE, THE BATTERY MUST BE CHARGED BEFORE USE. INADEQUATE CHARGING OF THE BATTERY BEFORE BEING PUT INTO OPERATION SHORTENS BATTERY LIFE.

ELE SYS - 93

Electrical system

Connectors

ENGINE CONNECTOR 1. Stator phase (Yellow) 2.Not connected 3.Stator phase (Yellow) 4. Oil pressure sensor (Purple) 5.Stator phase (Yellow) 6.Pick-up (Blue-Yellow)

VOLTAGE REGULATOR CONNECTOR 1. Magneto flywheel (Yellow) 2.Magneto flywheel (Yellow) 3.Magneto flywheel (Yellow) 4. Battery positive (Red-Orange) 5. Not connected 6. Ground (Blue)

ECU

1.Turn indicators switch (Blue-Black) 2.Not connected 3.HV coil (White-Purple) 4.Not connected 5.Live supply (White-Black) 6.Pick-up (Blue-Yellow) 7.Automatic starter (Green-Black) 8.Ground (Blue)

ELE SYS - 94

Electrical system

Dashboard

1.Oil pressure sensor (Purple) 2. MODE Button (Pink) 3. Left turn indicator warning light (Sky Blue) 4. Right turn indicator warning light (Red) 5.High-beam warning light (White) 6. Not connected 7. Fuel level sensor (Brown) 8. Speed sensor negative (Yellow-White) 9. Not connected 10. Speed sensor positive (Orange-Black) 11. Not connected 12. Fuel level sensor (Yellow-Green) 13.Thermistor (White-Blue) 14. Speed sensor signal (Blue-Orange) 15. Not connected 16. Ground (Blue) 17. Ground (Blue) 18. Not connected 19. Live supply (Green) 20. Battery-powered (Red-Orange)

ELE SYS - 95

INDEX OF TOPICS

ENGINE FROM VEHICLE

ENG VE

Engine from vehicle

Exhaust assy. Removal

CAUTION

ALLOW ENGINE AND EXHAUST SILENCER TO COOL OFF. Remove the rear central cover. Undo and remove the two fixing nuts of the exhaust manifold

Undo and remove the three fixing screws of the exhaust silencer. Remove the exhaust system.

Silencer removal Rest the vehicle on its centre stand. Loosen the clamp (1) fixing the exhaust silencer to the manifold. Undo and remove the three fixing screws (2). Remove exhaust silencer.

Removal of the engine from the vehicle

Remove the saddle. Remove the luggage rack. Remove the side fairings. Remove the tail section. Remove the helmet compartment.

ENG VE - 97

Engine from vehicle

Remove the rear brake calliper and release the pipes from the engine by unscrewing the indicated screw.

Remove the speed sensor by undoing the fixing screw.

Remove the spark plug tube.

Remove the pipe connecting the radiator to the water pump and empty the system.

ENG VE - 98

Engine from vehicle

Remove the fuel inlet and delivery pipes from the fuel pump.

Remove the fuel manifold from the carburettor.

Remove the coolant temperature sensor connector.

Remove the starter motor power supply cable and the ground lead to release cable harnesses.

ENG VE - 99

Engine from vehicle

Remove the automatic starter connector and the generator connector.

Remove the throttle grip transmission and release it.

Loosen the swinging arm fixing nut in the engine.

Slide off the pin and remove the engine from the vehicle.

When refitting the engine onto the scooter, carry out the removal operations but in reverse order and respect the tightening torques shown in the Specifications Chapter. Check the engine oil level and, if necessary, top it up with the recommended type. Fill up and bleed the cooling circuit. Check the functioning of the accelerator and the electrical devices.

CAUTION

ENG VE - 100

Engine from vehicle

PAY SPECIAL ATTENTION WHEN POSITIONING THE THROTTLE CONTROL TRANSMISSION PROPERLY.

ENG VE - 101

INDEX OF TOPICS

ENGINE

ENG

Engine

This section describes the operations to be carried out on the engine and the tools required.

Automatic transmission Transmission cover

- To remove the transmission cover, it is necessary to remove the plastic cover first by inserting a screwdriver in the slotted holes. Using the clutch bell lock wrench shown in the figure, remove the driven pulley shaft nut and washer.

Specific tooling

020423Y Driven pulley lock wrench - Pull out the cap/dipstick from the engine oil filling tube. - Remove the 10 screws. - Now remove the transmission cover. If this operation is carried out directly on the vehicle, remove the cooling air supply sleeve of the transmission housing.

ENG - 103

Engine

Air duct

125 VERSION Remove the 4 screws and the small casing.

200 VERSION - Remove the 5 screws on the two different levels, as well as the small casing

ENG - 104

Engine

Air duct filter

To remove the intake throat on the transmission cover, just remove the 2 fixing screws indicated in the figure.

Removing the driven pulley shaft bearing

- Remove the Seeger ring from the inside of the cover. - Remove the bearing from the crankcase by means of:

Specific tooling

020376Y Adapter handle 020375Y 28 x 30 mm adaptor 020412Y 15 mm guide

Refitting the driven pulley shaft bearing

- Slightly heat the crankcase internal side so as not to damage the coated surface. - Insert the bearing in its housing. - Refit the Seeger ring.

CAUTION REST THE COVER ON A SUITABLE SURFACE TO AVOID DAMAGING THE COVER COAT. NOTE ALWAYS REPLACE THE BEARING WITH A NEW ONE AT EVERY REFIT

Specific tooling

020376Y Adapter handle 020357Y 32 x 35 mm adaptor 020412Y 15 mm guide

Baffle roller Removal

Belt support roller (only 200 cc version) ENG - 105

Engine

- Check that the roller shows no signs of abnormal wear and that it rotates freely. - Remove the special fixing screw and the roller with the bearing.

Refitting

- Heat up the roller and insert the bearing by using the specific punch: Specific tools:

Specific tooling

020455Y 10 mm guide

ENG - 106

Engine

- Refit the roller with the special screw. - Tighten to the specified torque. - Refit the intake throat with the O-Ring, the sealing gasket for the sump and the closing casing for the fan.

Locking torques (N*m)

Anti-vibration roller 12 16

Removing the driven pulley

- Remove the spacer, the clutch bell and the whole driven pulley assembly.

NOTE THE ASSEMBLY CAN ALSO BE REMOVED EVEN IF THE DRIVING PULLEY IS MOUNTED.

Inspecting the clutch drum

Checking the bell working surface eccentricity - Fit the bell on a driven pulley shaft with 2 bearings (inside diameter: 15 and 17 mm). - Lock with the original spacer and nut. - Place the bell/shaft assembly on the support to check the crankshaft alignment.

- Make sure that the clutch bell is not worn or damaged. - Measure the clutch bell inside diameter.

Characteristic

ENG - 107

Engine

Clutch bell max. value Max. value: 134.5 mm Clutch bell standard value Standard value: 134 134.2 mm

Inspecting the clutch

- Check the thickness of the clutch mass friction material. - The masses must exhibit no traces of lubricants; in that case, check the driven pulley unit seals.

NOTE

UPON RUNNING-IN, THE MASSES MUST EXHIBIT A CENTRAL FAYING SURFACE AND MUST NOT BE DIFFERENT FROM ONE ANOTHER. DIFFERENT CONDITIONS MAY CAUSE CLUTCH TEARING.

CAUTION

DO NOT USE TOOLS TO OPEN THE MASSES TO AVOID VARIATION IN THE RETURN SPRING LOAD.

Characteristic

Check minimum thickness 1 mm

ENG - 108

Engine

Removing the clutch

Removing the clutch (125cc H2O) - Prepare the specific tool to compress the driven pulley spring with the medium-length pins in position F screwed from the tool inner side. - Insert the adaptor ring No. 8 in the pins. - Fit the driven pulley unit on the tool by inserting the nail heads in the adaptor ring. - Make sure that the clutch is perfectly inserted into the adapter ring before proceeding to tighten the clutch nut. - With the specific 46x55 wrench, component No. 9, remove the clutch fixing nut. - Disassemble the driven pulley into its components (Clutch, fan and spring with plastic fitting).

CAUTION

THE TOOL MUST BE FIRMLY FIXED IN THE VICE AND THE CENTRAL SCREW MUST TOUCH THE TOOL. EXCESSIVE TORQUE MAY DEFORM THE SPECIFIC TOOL.

Specific tooling

020444Y009 46 x 55 wrench 020444Y010 adaptor ring

ENG - 109

Engine

- Prepare the specific tool to compress the driven pulley spring with the medium-length pins in position C screwed from the tool inner side. - Insert the adaptor ring No.11 with the chamfering facing the tool inner side. - Fit the driven pulley unit on the tool by inserting the three pins in the ventilation holes in the ground holder support. - Make sure that the clutch is perfectly inserted into the adapter ring before carrying out the clutch nut locking/release operations. - With the specific 46x55 wrench, component No. 9, remove the clutch fixing nut. - Disassemble the driven pulley into its components (Clutch and spring with plastic fitting).

CAUTION

THE TOOL MUST BE FIRMLY FIXED IN THE VICE AND THE CENTRAL SCREW MUST TOUCH THE TOOL. EXCESSIVE TORQUE MAY DEFORM THE SPECIFIC TOOL.

Specific tooling

020444Y009 46 x 55 wrench 020444Y011 adaptor ring

ENG - 110

Engine

Pin retaining collar

- Simultaneously turn and pull the collar manually to remove it.

NOTE

USE 2 SCREWDRIVERS IN CASE OF ANY DIFFICULTY.

NOTE

BE CAREFUL NOT TO PUSH THE SCREW DRIVERS IN TOO FAR TO AVOID DAMAGING THE ORING SEAL.

ENG - 111

Engine

Removing the driven half-pulley bearing

- Check there are no signs of wear and/or noise; otherwise, replace it. - Remove the snap ring using two flat blade screwdrivers. - Place pulley bushing on the threaded side adequately on a wood support. - Using a hammer and pin, knock the ball bearing out as shown in the figure.

- Properly support the pulley by means of the specific bell shown in figure.

Specific tooling

001467Y035 Bell for 47-mm outside diameter bearings

ENG - 112

Engine

- Remove the roller bearing using the modular punch.

Specific tooling

020376Y Adapter handle 020456Y 24 mm adaptor 020363Y 20 mm guide

Inspecting the driven fixed half-pulley

- Measure the outside diameter of the pulley bushing. - Check the contact surface with the belt to make sure there are no signs of abnormal wear. - Check the riveted joints are functional. - Check the evenness of the belt contact surface.

Characteristic

Half-pulley minimum diameter Minimum diameter allowed: 40.96 mm Half-pulley standard diameter Standard diameter: 40.985 mm Wear limit 0.3 mm

ENG - 113

Engine

Inspecting the driven sliding half-pulley