Documente Academic

Documente Profesional

Documente Cultură

Las 3 R Del Acero Sostenible

Încărcat de

Gerdau en ChileTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Las 3 R Del Acero Sostenible

Încărcat de

Gerdau en ChileDrepturi de autor:

Formate disponibile

Fact sheet The three Rs The three Rs of sustainable steel

Reduce, reuse and recycle are the three Rs of sustainability. For decades, the steel industry has been reducing the need for raw materials and encouraging reuse of existing products. Steel is the worlds most recycled material.

The world steel industry applies the principles of reduction, reuse and recycling in many ways, in order to improve the sustainability of the industry. This fact sheet outlines the achievements that the industry has made in each of the three Rs: reduce, reuse and recycle.

Dramatically reduced need for raw materials

In the 1970s and 1980s, modern steel plants needed an average of 144 kg of raw materials to produce 100 kg of steel. With investments in research, technology improvements and good planning, the steel industry today uses only 115 kg of inputs to make 100 kg of steel a 21% reduction.1 In 2008, the world steel industry produced over 1.3 billion tonnes of steel. It used 1.48 billion tonnes of raw materials, or 470 millions tonnes less than would have been needed to make the same volume of steel in the 1970s.2 This equates to a saving of 1.12 billion tonnes of CO2 emissions in 2008 alone.3

Source: worldsteel, AISI, JISF and JFE, Global steel sectoral approach, presentation in Washington, 2008

These improvements were achieved through: enhanced energy efficiency in the steelmaking process, the result of significant investments in R&D continuous efforts to implement incremental advances shared best practices more recycling of steel-containing products and better quality of recycled steels more use of by-products from steelmaking and yield increases.

Thinner, stronger steels reduce emissions

Steel industry innovation continues to produce new grades of steel, many of which are thinner but still offer the strength needed for the most demanding product applications. These new steels, called Advanced and Ultra High-Strength steels (AHSS and UHSS), allow customers, particularly automotive manufacturers to reduce mass of the vehicles by 17% to 25% while maintaining safety standards.4,5 Less mass means lower emissions from driving the vehicle. If the body structure of all cars produced worldwide (approximately 71 million in 20086) were made of AHSS instead of conventional steel, this would result in total lifetime emission saving of 156 million tonnes CO2 equivalents. The vehicles are lighter because they use thinner and stronger steel grades. Today, more than 50% of the steel components in a vehicle are new high-strength steels. This reduced material need lowers emissions from steel production.

Reuse extends a products life

Reuse is a key aspect of sustainability.7 It applies to all materials, but the durability of steel makes reuse particularly relevant. Steel reuse can be described as any process where end-of-life steel is not re-melted but rather enters a new product use phase. Many items made from steel are easily reused. For example, paper clips are used over and over again in homes and offices all over the world. Steel barrels, or drums, have a typical life of six months. If they are used 10 times, however, that lifespan can be extended to five years. It is the durability of the steel that enables these products to be reused.

Reducing energy use

From 1975 to 2005, the average energy consumption per tonne of crude steel produced decreased by about 50%.

worldsteel.org

worldsteel Fact sheet

In North America approximately 33% of the straight rail (sections of straight railway track) purchased comes from used rail that is disassembled at redevelopment sites. In 2007, approximately 1.4 million tonnes of steel rail were shipped to customers across the US.8 Based on railroad industry reports, an estimated 1.46 million tonnes of straight rail were put into service, thus over 340,000 tonnes of straight rail were reused during this period. Eliminating the need to produce 340,000 tonnes of new rail products equates to saving of 811,600 tonnes of CO2.

Table 1: STeel

induSTry recycling raTeS

Construction Machinery Automotive

Market

2007 (est.)

85% 85%

2050 Target

90% 95%

Total

Containers

Appliances

90% 50% 83% 69%

95%

75% 90% 75%

The worlds most recyled material

Of the three Rs, recycling is probably the most recognised attribute of steel. Steel scrap is re-melted and used to make new steel. In 2008, more than 475 million tonnes of steel scrap9 was moved from the waste stream into the recycling stream. This is more than the combined reported totals for other recyclable materials, including paper, plastic, glass, copper, lead, and aluminum.10 Steel recycling began in the major cities of the 19th century. In the industrial centres of London, Hong Kong and New York, peddlers collected pots, pans and other metal products that contained valuable steel and sold them on for use in steel plants. This has evolved into the recycling infrastructure that services the world today. The World Steel Association has estimated the recycling rates for products that contain a significant portion of steel, and identified target rates for 2050 (see Table 1).

These goals, when accomplished, will result in an additional 38 million tonnes of steel being recycled worldwide by 2050. This equates to 54 million tonnes less CO2. Steel recycling accounts for significant raw material and energy savings. Over 1,400 kg of iron ore, 400 kg of coal, and 55 kg of limestone are saved for a tonne of steel scrap used. From an environmental point of view, steel recycling has an enormous impact on the reduction of CO2 emissions. If 450 million tonnes of hot rolled steel were produced from 100% scrap rather then new materials, the total CO2 savings would be approximately 634 million tonnes in one year.

The impact of the three Rs on climate change

This fact sheet demostrates how the steel industry is taking action to minimise its environmental footprint. The industry continues to evolve and aims to make steel the most innovative and sustainable material of the 21st century.

Last updated: March 2010

Footnotes 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. www.sustainable-steel.org/matefficiency.html, accessed 28 September 2009 World Steel in Figures 2009, World Steel Association Derived from the life cycle inventory (LCI) for steel, 2000 update, World Steel Association ULSAB research (WorldAutoSteel), carmakers own body structure designs Determination of Weight Elasticity of Fuel Economy for Conventional ICE Vehicles, Hybrid Vehicles and Fuel Cell Vehicles, fka, June 2007 www.ioca.net, accessed 28 September 2009 Recycling, reuse and the sustainability of steel, Louis Brimacombe, Nick Coleman and Colin Honess in Millennium Steel, 2005 American Iron and Steel Institute statistics World Steel in Figures 2009, World Steel Association Steel recycling on the rise, World Business Council on Sustainable Development, 2009

worldsteel.org

S-ar putea să vă placă și

- La Industria Del Acero Como Socio Del Desarrollo SustentableDocument60 paginiLa Industria Del Acero Como Socio Del Desarrollo SustentableGerdau en ChileÎncă nu există evaluări

- Gerdau: Informe Anual Edición 2012Document43 paginiGerdau: Informe Anual Edición 2012Gerdau en ChileÎncă nu există evaluări

- El Libro Blanco Del Acero (Ingles)Document50 paginiEl Libro Blanco Del Acero (Ingles)Gerdau en ChileÎncă nu există evaluări

- World Steel - Providing The Basis For LCA Studies 6 April 2011Document18 paginiWorld Steel - Providing The Basis For LCA Studies 6 April 2011Gerdau en ChileÎncă nu există evaluări

- Contribucion Acero Bajas Emisiones CarbonoDocument6 paginiContribucion Acero Bajas Emisiones CarbonoGerdau en ChileÎncă nu există evaluări

- World Steel Commitment CharterDocument1 paginăWorld Steel Commitment CharterGerdau en ChileÎncă nu există evaluări

- Excellence Recognition 2011Document12 paginiExcellence Recognition 2011Gerdau en ChileÎncă nu există evaluări

- Chile's Environmental Management FrameworkDocument79 paginiChile's Environmental Management FrameworkGerdau en Chile100% (1)

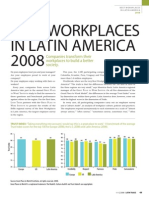

- 2008 Best Companies in Latin AmericaDocument6 pagini2008 Best Companies in Latin AmericaGerdau en ChileÎncă nu există evaluări

- Guias para Construcciones Menores Sin IngenieríaDocument154 paginiGuias para Construcciones Menores Sin IngenieríaGerdau en ChileÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- DY-1-20 Scrap Tires Recycling Pyrolysis Oil Plant of Doing GroupDocument3 paginiDY-1-20 Scrap Tires Recycling Pyrolysis Oil Plant of Doing GrouppyrolysisoilÎncă nu există evaluări

- Value Chain Analysis of CokeDocument4 paginiValue Chain Analysis of CokeDeepak YadavÎncă nu există evaluări

- Shweta Prakash PDFDocument79 paginiShweta Prakash PDFdona biswasÎncă nu există evaluări

- Business Presentation - Ekt Uganda 2020Document23 paginiBusiness Presentation - Ekt Uganda 2020Herbert BusharaÎncă nu există evaluări

- Directions: Read The Following Statements. Choose The Letter of The Correct AnswerDocument2 paginiDirections: Read The Following Statements. Choose The Letter of The Correct AnswerJorie Aguilar Velasco0% (1)

- Voice 1 Voice 2 Voice 1: The Story of PaperDocument5 paginiVoice 1 Voice 2 Voice 1: The Story of PaperAnDrew DGÎncă nu există evaluări

- Environmental and Social Issues For ManagementDocument27 paginiEnvironmental and Social Issues For ManagementJhon Gonzales100% (1)

- 2 Guangco English8Document14 pagini2 Guangco English8MICHELLE MARIE GUANGCOÎncă nu există evaluări

- Nov 11Th: Next IssueDocument40 paginiNov 11Th: Next IssuemwmccarthyÎncă nu există evaluări

- ThesDocument397 paginiThesR JÎncă nu există evaluări

- School Solid Waste ManagementDocument2 paginiSchool Solid Waste ManagementJonathan L. MagalongÎncă nu există evaluări

- An Overview of Deconstruction With A Focus On: Community Development OpportunitiesDocument19 paginiAn Overview of Deconstruction With A Focus On: Community Development OpportunitiesNikolaÎncă nu există evaluări

- Examination Paper Term 2, 2021/2022: Read These Instructions FirstDocument23 paginiExamination Paper Term 2, 2021/2022: Read These Instructions FirstOMANA NAIR A/P PRABHAKARANÎncă nu există evaluări

- Import Export PageDocument3 paginiImport Export PageCheech ParrÎncă nu există evaluări

- Terra CycleDocument7 paginiTerra CycleAngela de Mesa100% (1)

- Ninth Development Plan - Chapter 32 - Municipal AffairsDocument16 paginiNinth Development Plan - Chapter 32 - Municipal AffairsHamza AhmadÎncă nu există evaluări

- Seasonal and Geographical Characterizations of Municipal SDocument13 paginiSeasonal and Geographical Characterizations of Municipal Ssishu21Încă nu există evaluări

- Electronic Waste Recycling and Reprocessing For A Sustainable Future Maria E Holuszko Full ChapterDocument51 paginiElectronic Waste Recycling and Reprocessing For A Sustainable Future Maria E Holuszko Full Chaptermary.roy331100% (4)

- Lesson Plan in Handicraft Production Grade 7Document2 paginiLesson Plan in Handicraft Production Grade 7Stephanie Kcel PilapilÎncă nu există evaluări

- Recent Case Studies of Engineering Thermosets For Under-The-Hood ApplicationsDocument8 paginiRecent Case Studies of Engineering Thermosets For Under-The-Hood ApplicationsLeventÎncă nu există evaluări

- Texts Bi Paper 1Document72 paginiTexts Bi Paper 1PIRULETA100% (6)

- Smart Task 01 (Waste To Energy) Rahul KundiyaDocument16 paginiSmart Task 01 (Waste To Energy) Rahul KundiyaRahul Kundiya100% (1)

- Reverse Vending Machine Pilot ProjectDocument4 paginiReverse Vending Machine Pilot ProjectICT WalaÎncă nu există evaluări

- 2nd Summative Q1Document15 pagini2nd Summative Q1Aiza BartoloÎncă nu există evaluări

- Coca-Cola Beverages Philippines, Inc (CSR)Document17 paginiCoca-Cola Beverages Philippines, Inc (CSR)Stephanie Cristy LacanguloÎncă nu există evaluări

- M800-M80-E80 Series Maintenance Manual Ib1501273enghDocument224 paginiM800-M80-E80 Series Maintenance Manual Ib1501273enghsunhuynhÎncă nu există evaluări

- S1q1 Esp, Scie, EngDocument6 paginiS1q1 Esp, Scie, EngLouise Gerard De VegaÎncă nu există evaluări

- BBU 6201 MaintenanceDocument19 paginiBBU 6201 MaintenancemarhoumeÎncă nu există evaluări

- CF ArmaFlex Rail - Brochure.EN - US.2019Document20 paginiCF ArmaFlex Rail - Brochure.EN - US.2019NelmarÎncă nu există evaluări

- Degree EPR For Textiles Decree ENDocument33 paginiDegree EPR For Textiles Decree ENRita CaetanoÎncă nu există evaluări