Documente Academic

Documente Profesional

Documente Cultură

Ikssss

Încărcat de

Vikas GowdaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ikssss

Încărcat de

Vikas GowdaDrepturi de autor:

Formate disponibile

Sulzer Metco

Material Product Data Sheet Nickel Chromium Aluminum Thermal Spray Powders

Thermal Spray Powder Products: Metco 443NS, Amdry 960, Amdry 510

Introduction

Metco 443NS and Amdry 960 are aluminum clad nickel chromium alloyed powders that undergo an exothermic reaction when sprayed. The reaction is vigorous enough to assure more consistent bonding to the substrate and better interparticle bonding than that obtained non-exothermic materials. Plasma-sprayed Metco 443NS and Amdry 960 coatings are self-bonding and can be used for high temperatures oxidation and corrosion resistant coatings. They are recommended as a bond coat for ceramic top coats and for salvage and buildup of worn or mismachined parts made of nickel, nickel alloys or machinable corrosionresistant steels. Thermosprayed Metco 443NS and Amdry 960 coatings are not self-bonding. They should only be used on surfaces that have been properly prepared using a standard method of surface preparation. These coatings are recommended as abradable coatings for high temperature performance in machine element clearance control applications and as a bond coat for ceramic top coats.

Morphology of Metco 443NS, a mechanically clad powder

Amdry 510 is a gas atomized NiCrAl alloyed powder. Coatings sprayed with Amdry 510 have a long service life against spallation and exhibit superior resistance to oxidation and corrosive gas attack.

1.1

Typical Uses and Applications:

Quick Facts Classification Chemistry Manufacture Morphology Apparent Density Purpose Composite or alloy, nickel-based NiCrAl Mechanically clad or gas atomized Irregular or spheroidal 1.4 4 g/cm3 Wear and corrosion protection Atmospheric plasma spray, combustion powder Thermospray or HVOF

DSMTS-0091.1 2012 Sulzer Metco

Bond coat for thermal barrier coatings in turbine engine components and heat treating fixtures Abradable coatings for machine element clearance control and turbine engine components Salvage and restoration of worn or mismachined nickel, nickel alloy or machinable corrosion-resistant steel substrates

Service Temperature 980 C (1800 F) Process

NiCrAl Powders

1/6

Sulzer Metco

2 2.1

Material Information Chemical Composition Chemical Composition (nominal wt. %) Ni Bal. Bal. Bal. Cr 15.5 21.5 16.0 21.0 19.0 25.0 Al 4.0 8.0 4.5 7.0 8.0 12.0 Others (max) 7.0 7.0 2.0 Organics (max) 4.0 4.0 ---

Product Metco 443NS Amdry 960 Amdry 510

2.2

Particle Size Distribution and Other Characteristics Nominal Particle Size Distribution (m) -125 +45 -125 +45 -44 +22 Morphology Irregular Irregular Spheroidal Manufacturing Method Mechanically Clad Mechanically Clad Gas Atomized

Product Metco 443NS Amdry 960 Amdry 510

Particle size equal to or above 45 m determined by sieve analysis; below 45 m by laser diffraction (Microtrac). Other particle size distributions are available on request.

2.3

Key Selection Criteria Amdry 510 has a fine particle size distribution and can be applied using HVOF when low porosity and low oxide content are required in the coatings. Coatings sprayed with Amdry 510 provide better oxidation resistance, corrosion resistance and longer service life than Metco 443 and Amdry 960.

Choose the product that meets the required customer material specification Metco 443NS and Amdry 960 have coarse particle size distributions and can be applied using atmospheric plasma spray (APS) or combustion powder Thermospray. APS coatings of these powders are self-bonding.

NiCrAl Powders

2/6

DSMTS-0091.1 2012 Sulzer Metco

Sulzer Metco

2.4

Related Products low shrink, good wear and excellent corrosion resistance properties for hard bearing applications. Coating of Metco 444 are self-bonding without thickness limits. However, the maximum service temperature of coatings of Metco 444 is 870 C (1600 F), lower than that of the plasma-sprayed Metco 443NS and Amdry 960 coatings. Metco 442 is also a self-bonding stainless composite powder that produces coatings having a high macrohardness of 39 HRC as a result of precipitation hardening. However, the service temperature of coatings with Metco 442 is up to 760 C (1400 F). Metco 461NS is a patented, nickel chroumium-alumnium-cobalt-yttria composite powder designed to produce self-bonding coatings that can be used for oxidation and corrosion resistant applications at temperatures up to 980 C (1800 F). The formation of Al2O3-Y2O3 during spraying improves high temperature cohesive strength within the coating and aids in applications where flexing is important.

Coatings plasma-sprayed with nickel-chromium alloyed powder, such as Metco 43C-NS, Metco 43FNS, and Metco 43VF-NS can also be used ro resist oxidation and corrosive gases up to 980 C (1800 F). However, coatings of Metco 443 and Amdry 960 are self-bonding and have better oxidation resistance, can be applied thicker, have equivalent as-sprayed surface roughness as bond coats for ceramics and are more easily machined. Metco 450NS and Amdry 956 are mechanically clad composite materials of nickel and aluminum, exhibit an exothermic reaction during the spray process and self-bond to steel substrates. The are often used for salvage and buildup. However, the service temperatures of these coatings are lower (max. 800 C, 1475 F) compared to those sprayed using the products in this data sheet. Metco 444 is a nickel, chromium, molybdenum, aluminum composite powder. It was especially developed to produce machinable stainless type coatings with

NiCrAl Powders

3/6

DSMTS-0091.1 2012 Sulzer Metco

Sulzer Metco

2.5

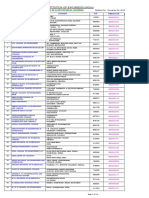

Customer Specifications Customer Specification Avio 4800M/12 Canada Pratt & Whitney CPW 369 CFM International CP 6006 Chromalloy BZ-003 Type 4 GE B50A890 GE B50TF119, Cl A Honeywell 91547-M3956 Honeywell EMS 57748, Type I, Cl 2 Honeywell FP 5045, Type XVIII MTU MTS 1077 Pratt & Whitney PWA 1347 Rolls-Royce Corporation EMS 56772 Rolls-Royce OMAT 3/135 Rolls-Royce plc MSRR 9507/14 Snecma DMR 33.018 Volvo MTL 116 Volvo PM 819-47 Williams WIMS 646 CFM International CP 6006 GE B50A890 GE B50TF119, Cl A Honeywell 91547-M3956 Honeywell EMS 57748, Type I, Cl 2 MTU MTS 1077 Pratt & Whitney PWA 1347 Rolls-Royce OMAT 3/135 Rolls-Royce plc MSRR 9507/14 Snecma DMR 33.018 Volvo MTL 116 Volvo PM 819-47 Williams WIMS 646

Product Metco 443NS

Amdry 960

NiCrAl Powders

4/6

DSMTS-0091.1 2012 Sulzer Metco

Sulzer Metco

3 3.1

Coating Information Key Thermal Spray Coating Information

Data is provided is typical and variability can be expected. Changes in spray process, spray equipment or spray parameters can significantly change coating results. Typical Data Metco 443NS and Amdry 960 Atmospheric plasma spray or combustion powder Thermospray HRB DPH300 vol. % vol. % m in m in m in MPa psi 80 90 200 260 <5 1 20 8.9 20.3 350 800 0.5 1.5 20 60 5 20 0.1 0.5 51.7 68.9 7500 10000 Amdry 510 Atmospheric plasma spray or HVOF

Specification Recommended Process Macrohardness Microhardness Porosity Oxide Content Surface Roughness Ra as sprayed machined ground (60 grit SiC) Bond Strength *

* Using FM 1000 Epoxy Tape

3.2

Available Coating Parameter Sheets: Process Atmospheric Plasma Thermospray HVOF Spray Guns 3MB, 9MB, F4MB-XL TriplexPro 5P-II, 6P-II DiamondJet, WokaJet, WokaStar

Coating parameters for the following spray guns are available to Sulzer Metco customers. Please note that parameters may not be available for all material / gun combinations. Please contact your local Sulzer Metco Account Representative. Support for specific application requirements are available through Sulzer Metco Coating Solutions Centers.

NiCrAl Powders

5/6

DSMTS-0091.1 2012 Sulzer Metco

Sulzer Metco

4 4.1

Commercial Information Ordering Information and Availability Order No. 1000300 1000596 1001051 1002396 Package Size 5 lb (approx. 2.25 kg) 25 lb (approx 11 kg) 5 lb (approx. 2.25 kg) 10 lb (approx. 4.5 kg) Availability Stock Stock Stock Special Order Distribution Global Global Global Global

Product Metco 443NS Amdry 960 Amdry 510

4.2

Handling Recommendations Open containers should be stored in a drying oven to prevent moisture pickup. Remove desiccant prior to use, if applicable.

Store in the original container in a dry location. Tumble contents gently prior to use to prevent segregation.

4.3

Safety Recommendations Product Metco 443NS Amdry 960 Amdry 510 MSDS No. 50-173 50-173 50-424

See the MSDS (Materials Safety Data Sheet) in the localized version applicable to the country where the material will be used. MSDS are available from the Sulzer web site at www.sulzer.com (Resources Online Tools).

www.sulzer.com info@sulzermetco.com

Sulzer Metco (US) Inc. 1101 Prospect Avenue Westbury NY 11590 USA Tel. +1 516 334 1300 Fax +1 516 338 2414 Sulzer Metco (Japan) Ltd. 4-2 Hikawadai 3-Chome, Nerima-ku, Tokyo 179-0084 Japan Tel. +81 359 203 302 Fax +81 359 203 512 Sulzer Metco Europe GmbH Spreestrasse 2 65451 Kelsterbach Germany Tel. +49 6142 6033 0 Fax +49 6142 6033 400 Sulzer Metco AG (Switzerland) Rigackerstrasse 16 5610 Wohlen Switzerland Tel. +41 56 618 81 81 Fax +41 56 618 81 01 Sulzer Metco (Singapore) Pte. Ltd. 2 Loyang Lane # 06-02 Singapore 508913 Tel. +65 6545 0870 Fax +65 6545 0816

Information is subject to change without prior notice

NiCrAl Powders

6/6

DSMTS-0091.1 2012 Sulzer Metco

S-ar putea să vă placă și

- Quality of SurfaceDocument8 paginiQuality of SurfaceNexhat QehajaÎncă nu există evaluări

- 1st Unit Engineering EconomicsDocument17 pagini1st Unit Engineering EconomicsVikas GowdaÎncă nu există evaluări

- 7 Tips For Materials TestingDocument11 pagini7 Tips For Materials TestingGiuseppe GoriÎncă nu există evaluări

- Metal Coating Processes GuideDocument9 paginiMetal Coating Processes GuideIrfan IslamyÎncă nu există evaluări

- MtechDocument10 paginiMtechVikas GowdaÎncă nu există evaluări

- Module 3 Lecture 6 FinalDocument12 paginiModule 3 Lecture 6 FinalChima C. UgwuegbuÎncă nu există evaluări

- BecbcsDocument16 paginiBecbcsbobca117Încă nu există evaluări

- Hot Metal Dipping PDFDocument6 paginiHot Metal Dipping PDFnishanth124acharyaÎncă nu există evaluări

- IEI List of Institutional MembersDocument14 paginiIEI List of Institutional MembersVikas GowdaÎncă nu există evaluări

- Production Engineering-M IIIDocument13 paginiProduction Engineering-M IIIalext1985nÎncă nu există evaluări

- Faculty Members Personal File Content SheetDocument23 paginiFaculty Members Personal File Content SheetVikas GowdaÎncă nu există evaluări

- DR - Nair SpresentationDocument40 paginiDR - Nair SpresentationsachinguptachdÎncă nu există evaluări

- SAR Criteria Checklist 25.03.2019Document1 paginăSAR Criteria Checklist 25.03.2019Vikas GowdaÎncă nu există evaluări

- Faculty Members Personal File Content SheetDocument1 paginăFaculty Members Personal File Content SheetVikas GowdaÎncă nu există evaluări

- Mech Vii Engineering Economics (10me71) SolutionDocument30 paginiMech Vii Engineering Economics (10me71) SolutionVikas Gowda100% (1)

- ECo NotesDocument14 paginiECo NotesVikas GowdaÎncă nu există evaluări

- PlasmaDocument2 paginiPlasmaVikas GowdaÎncă nu există evaluări

- Module 4: Present, Future, Annual Worth ProblemsDocument4 paginiModule 4: Present, Future, Annual Worth ProblemsVikas GowdaÎncă nu există evaluări

- What Are The Advantages of Plasma Spraying?: Frequently Asked QuestionsDocument1 paginăWhat Are The Advantages of Plasma Spraying?: Frequently Asked QuestionsVikas GowdaÎncă nu există evaluări

- Interaction and Main Effects of Wear and CofDocument2 paginiInteraction and Main Effects of Wear and CofVikas GowdaÎncă nu există evaluări

- Centricpartsglossaryrev - 3 15 11Document16 paginiCentricpartsglossaryrev - 3 15 11Vikas GowdaÎncă nu există evaluări

- SS304 304L Data SheetDocument2 paginiSS304 304L Data SheetPrakash KumarÎncă nu există evaluări

- 14 3-4Document11 pagini14 3-4Vikas GowdaÎncă nu există evaluări

- Influence of Material Condition On The Dry Sliding Wear Behavior of Spring Steels by K. V. Arun and K.V. SwethaDocument2 paginiInfluence of Material Condition On The Dry Sliding Wear Behavior of Spring Steels by K. V. Arun and K.V. SwethaVikas GowdaÎncă nu există evaluări

- HtyDocument7 paginiHtyVikas GowdaÎncă nu există evaluări

- What Are The Advantages of Plasma Spraying?: Frequently Asked QuestionsDocument1 paginăWhat Are The Advantages of Plasma Spraying?: Frequently Asked QuestionsVikas GowdaÎncă nu există evaluări

- Interaction and Main Effects of Wear and CofDocument2 paginiInteraction and Main Effects of Wear and CofVikas GowdaÎncă nu există evaluări

- Literature Work2Document5 paginiLiterature Work2Vikas GowdaÎncă nu există evaluări

- Robust Design Experiments For Better Products TaguchiDocument30 paginiRobust Design Experiments For Better Products TaguchiVikas GowdaÎncă nu există evaluări

- 3849 5902 1 PBDocument9 pagini3849 5902 1 PBVikas GowdaÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Rate Data Collection and AnalysisDocument18 paginiRate Data Collection and AnalysisLê MinhÎncă nu există evaluări

- B.sc. Electronics Honours SyllabusDocument10 paginiB.sc. Electronics Honours Syllabussiddhartharay007Încă nu există evaluări

- Transducer AssignmentDocument5 paginiTransducer AssignmentdagemÎncă nu există evaluări

- Failure analysis of bilge keels reveals stresses lead to cracksDocument6 paginiFailure analysis of bilge keels reveals stresses lead to cracksBrizamar AguiarÎncă nu există evaluări

- Nooter Eriksen HRSG AdvantagesDocument3 paginiNooter Eriksen HRSG Advantagesaliscribd46Încă nu există evaluări

- KPPSC SDO Test QuestionsDocument3 paginiKPPSC SDO Test Questionssalman khattakÎncă nu există evaluări

- Unit 1 EmmDocument40 paginiUnit 1 EmmNagaaswin SÎncă nu există evaluări

- Stability Analysis of Soil Slope Subjected To Blast Induced Vibrations Using FLACDocument11 paginiStability Analysis of Soil Slope Subjected To Blast Induced Vibrations Using FLACResmi RosaliniÎncă nu există evaluări

- 07 Theory of ShearingDocument33 pagini07 Theory of ShearingSûhâs KS IyengarÎncă nu există evaluări

- Chapter 10 Shell energy balances and temperature distributions in solid and laminar flowDocument43 paginiChapter 10 Shell energy balances and temperature distributions in solid and laminar flowCecilia CelineÎncă nu există evaluări

- Manual Bombas Berkeley PDFDocument24 paginiManual Bombas Berkeley PDFxavifoxÎncă nu există evaluări

- Shotcrete Nozzleman Basics - Vertical Wall ConstructionDocument4 paginiShotcrete Nozzleman Basics - Vertical Wall ConstructionFroilan AngbengcoÎncă nu există evaluări

- Sample Problem Part 7 Mech Fluid PDF FreeDocument10 paginiSample Problem Part 7 Mech Fluid PDF FreeJim LeeÎncă nu există evaluări

- Behavior of Concrete Beams Reinforced With ASTM A1035 Grade 100 Stirrups Under ShearDocument8 paginiBehavior of Concrete Beams Reinforced With ASTM A1035 Grade 100 Stirrups Under ShearTrong Tuan TranÎncă nu există evaluări

- Chapter 02 - Mechanism and Linkages - Part ADocument81 paginiChapter 02 - Mechanism and Linkages - Part ASyahrul Nizam AnuarÎncă nu există evaluări

- Refrigerant Selection and Environmental ImpactsDocument67 paginiRefrigerant Selection and Environmental Impactsdamola2realÎncă nu există evaluări

- Lecture 11 - Multiple Reactions 2Document14 paginiLecture 11 - Multiple Reactions 2Sabrina AzharÎncă nu există evaluări

- DESIGN and OPTIMIZATION OF SHELL and TUBE HEAT EXCHANGRDocument4 paginiDESIGN and OPTIMIZATION OF SHELL and TUBE HEAT EXCHANGRMoon Choon-GeunÎncă nu există evaluări

- Quasi One Dimensional FlowDocument17 paginiQuasi One Dimensional FlowtemprasÎncă nu există evaluări

- Antenna Datasheet Am 2 Freq CircDocument9 paginiAntenna Datasheet Am 2 Freq CircĐỗ Quang HuyÎncă nu există evaluări

- Protocol-XRD XRF SEM OE PDFDocument16 paginiProtocol-XRD XRF SEM OE PDFShyamÎncă nu există evaluări

- filedate_858Download ebook Shigleys Mechanical Engineering Design 11Th Ed Pdf full chapter pdfDocument67 paginifiledate_858Download ebook Shigleys Mechanical Engineering Design 11Th Ed Pdf full chapter pdfjeremy.collins128100% (21)

- Chapter Two: Fundamentals of Damages Theory (McEng 5142Document34 paginiChapter Two: Fundamentals of Damages Theory (McEng 5142Mikias TeferaÎncă nu există evaluări

- Welding TestDocument21 paginiWelding TestryantoÎncă nu există evaluări

- Study Materials Level 3Document6 paginiStudy Materials Level 3Krishna Vacha50% (2)

- James B. Hartle Department of Physics University of California Santa Barbara, CA 93106Document25 paginiJames B. Hartle Department of Physics University of California Santa Barbara, CA 93106huevonomar05Încă nu există evaluări

- Automotive Air Conditioning SystemDocument46 paginiAutomotive Air Conditioning SystemHimanshu Katara80% (5)

- Struc Ex Pro Rectangular Beam Design CalculationDocument1 paginăStruc Ex Pro Rectangular Beam Design Calculationpobre3nga3bataÎncă nu există evaluări

- SR Physics - Chapter Wise Important QuestionsDocument11 paginiSR Physics - Chapter Wise Important Questionsgitha71% (248)

- Handout 1Document11 paginiHandout 1Adefris FikireÎncă nu există evaluări