Documente Academic

Documente Profesional

Documente Cultură

Conformal Coating Inspection Technical Bulletin Mar 09

Încărcat de

Lee HitchensDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Conformal Coating Inspection Technical Bulletin Mar 09

Încărcat de

Lee HitchensDrepturi de autor:

Formate disponibile

Technical Bulletin Mar 09

Conformal Coating Inspection

In the process of conformal coating, one of the most critical areas is conformal coating inspection. There

are several purposes for coating inspection including the assessment of the conformal coating quality

applied to the PCB. This assessment is measured against standards, whether internal, national or

international, and the criteria defined in the standards of what is acceptable and unacceptable,

ultimately help determine the long term reliability of the circuit board.

Conformal Coating Inspection and the IPC A 610 Acceptance Standards Summary

International Standards Class 1, 2, 3

With standards it’s important to distinguish between • Completely cured and homogeneous

application and selection of coating, and qualification

• Coating only in those areas where coating is

and manufacture of coating. Generally, the first is for

required

the user of the conformal coating in production and

the second is for the manufacturer of the conformal • Loss of adhesion adjacent to masking

coating. • No bridging of adjacent lands or conductive

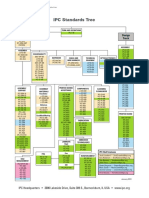

The Interconnections & Packaging Conference (IPC) surfaces from:

standards are very good for both these areas and their 1. loss of adhesion

details can be found on www.ipc.org . 2. voids or bubbles

For manufacturing conformal coating the standard 3. de-wetting

IPC-CC-830B details the manufacturer’s requirements to 4. cracks

self-certify the quality of their product. 5. ripples

6. fisheyes or orange peel

In the case of production the IPC A -610 standard is an

ideal starting point. The IPC-A-610 gives some minor • Foreign material does not violate minimum

references which are of limited help except for electrical clearance between components,

specifying acceptance criteria. This standard also is a lands or conductive surfaces

self-regulatory document. • Coating is thin but still coats component /

device edges

These Acceptance criteria are taken from the

IPC-A-610 standard.

The references the IPC standard makes to the

defects can be checked against the recent

technical bulletins and FAQs on Conformal

Coating Failure Mechanisms contained on the

SCH website.

Using these two information sources, this enables

the acceptance criteria to be drawn up and a

work instruction produced for conformal coating

A conformal coated PCB under UVA ultraviolet light inspection.

to aid inspection

SCH Technologies is a Trading Name of SCH Services Limited

Newburgh Building, McLintock Way, Barnsley, South Yorkshire. S70 6BF

Tel: +44 (0)1226 297711 Fax: +44 (0)1226 297733

www.conformalcoating.co.uk SCH Technologies are ISO9001 and ISO14001 certified

IPC A 610 Defects Standards Summary Automated Conformal Coating Inspection

Defect - Class 1, 2, 3 It is now possible to automate the inspection

• Coating is not cured (exhibits tackiness) process with the ACCIS Automated Conformal

Coating Inspection System.

• Coating is not applied to required areas

• Coating is on areas required to be free of

coating

• Any bridging of adjacent lands or conductive

surfaces from:

7. loss of adhesion (mealing)

8. voids or bubbles

9. de-wetting

10. cracks

11. ripples

12. fisheyes or orange peel The ACCIS, developed by SCH, eliminates many of

the problems associated with conformal coating

• Any foreign material that bridges lands or

inspection including

adjacent conductive surfaces, exposes circuitry

or violates minimal electrical clearance • Operator error due to manual process

between components, lands or conductive • Different standards between operators

surfaces • Time consuming process

• Discolouration or loss of transparency • No traceable recording of inspection

• Coating wicking into connector housing Contact SCH for details or check the website.

• Coating wicking into mating surfaces

These Acceptance criteria are taken from the IPC-

A-610 standard.

SCH Technologies offer

Mil-I-46058C • Conformal coating Subcontract Services

Another standard often mentioned is Mil-I-46058C • Global supply of Conformal Coating

which is an old military standard from which the Application Equipment

IPC committee developed the IPC-CC-830

standard and is related to materials. • Humiseal Conformal Coatings

This standard is relevant where the conformal • Conformal Coating Training courses

coating material must be qualified for military Consultation & troubleshooting

approval and placed on a Qualified Product List PLEASE CHECK OUR WEBSITE FOR DETAILS

(QPL) which is constantly updated.

www.conformalcoating.co.uk

Future Bulletins

• Automated Conformal coating inspection. How effective is it?

• Conformal coating CTI (Comparative Tracking Index).

SCH Technologies is a Trading Name of SCH Services Limited

Newburgh Building, McLintock Way, Barnsley, South Yorkshire. S70 6BF

Tel: +44 (0)1226 297711 Fax: +44 (0)1226 297733

www.conformalcoating.co.uk SCH Technologies are ISO9001 and ISO14001 certified

S-ar putea să vă placă și

- PCB Reliability1Document45 paginiPCB Reliability1Prasad KulkarniÎncă nu există evaluări

- Ipc Oem Stds A4 English 1111 OnlineDocument4 paginiIpc Oem Stds A4 English 1111 OnlineAnonymous nMavFhZÎncă nu există evaluări

- IPC SpecTree Jan13 PDFDocument1 paginăIPC SpecTree Jan13 PDFbabshuag100% (1)

- Random Solder Balls: Definition: After Reflow, Small Spherical Particles WithDocument2 paginiRandom Solder Balls: Definition: After Reflow, Small Spherical Particles WithŞahin AktürkÎncă nu există evaluări

- 610E Training Material List For CIT CDDocument1 pagină610E Training Material List For CIT CDdruids2000Încă nu există evaluări

- Panasonic OperatorDocument28 paginiPanasonic Operatorapi-3760998100% (2)

- All SMD Soldering RecommendationsDocument3 paginiAll SMD Soldering RecommendationsbehzadÎncă nu există evaluări

- Introduction To Surface Mount Technology 24 April 2002 Helen HolderDocument38 paginiIntroduction To Surface Mount Technology 24 April 2002 Helen HolderbercincÎncă nu există evaluări

- Solving Conformal Coating Problems in The Application ProcessDocument30 paginiSolving Conformal Coating Problems in The Application ProcessMael Azmi100% (1)

- Houston Impact of J-STD-001F and IPC-A-610F ChangesDocument36 paginiHouston Impact of J-STD-001F and IPC-A-610F Changeswayneseal1Încă nu există evaluări

- Conformal Coating Inspection and Defects.21JUL16Document35 paginiConformal Coating Inspection and Defects.21JUL16kwangjin1980Încă nu există evaluări

- J STD 004bwam1Document4 paginiJ STD 004bwam1cdealmeida0% (2)

- SMT Stencil DesignDocument34 paginiSMT Stencil DesignVinceDeSilva100% (2)

- Nasa - Workmanship Standard For Surface Mount Technology - Nasa Technical Standard - Nasa-Std-8739.2 - ManualDocument84 paginiNasa - Workmanship Standard For Surface Mount Technology - Nasa Technical Standard - Nasa-Std-8739.2 - Manualhbpr9999100% (1)

- Ipc 6013aDocument10 paginiIpc 6013abenmen73Încă nu există evaluări

- MAXXI 6 Sales Presentation 04-2016Document33 paginiMAXXI 6 Sales Presentation 04-2016Marty SchreckÎncă nu există evaluări

- Ipc Policies and Procedures Cis General Module Rev 2 4-2016Document47 paginiIpc Policies and Procedures Cis General Module Rev 2 4-2016kddjjdi100% (1)

- Best Practices FactoryDocument207 paginiBest Practices FactorysmtdrkdÎncă nu există evaluări

- SMT Troubleshooting GuideDocument20 paginiSMT Troubleshooting GuideMarlon Sepillo100% (1)

- Printed Circuit Board: CharacteristicsDocument23 paginiPrinted Circuit Board: CharacteristicsSai Gautam100% (1)

- E-Book Proof of Design DFM and Concurrent EngineeringDocument425 paginiE-Book Proof of Design DFM and Concurrent Engineeringsmtdrkd100% (7)

- Spec TreeDocument1 paginăSpec TreePiyush Vishwakarma0% (1)

- RUSH PCB INC PresentationDocument23 paginiRUSH PCB INC PresentationRUSH PCB IncÎncă nu există evaluări

- IPC Specification TreeDocument1 paginăIPC Specification Treeshoker4Încă nu există evaluări

- The Solder Paste Printing Process: Critical Parameters, Defect Scenarios, Specifications, and Cost ReductionDocument14 paginiThe Solder Paste Printing Process: Critical Parameters, Defect Scenarios, Specifications, and Cost ReductionNurul KhomariyahÎncă nu există evaluări

- IPC 2223 Design Standard For Flex and Rigid Flex CircuitsDocument19 paginiIPC 2223 Design Standard For Flex and Rigid Flex CircuitsMariano DiazÎncă nu există evaluări

- Solder Balls or Solder Balling On A PCB - Wave Soldering DefectsDocument5 paginiSolder Balls or Solder Balling On A PCB - Wave Soldering DefectsasdfÎncă nu există evaluări

- SMT Line Capacity CalculationsDocument4 paginiSMT Line Capacity Calculationssmtdrkd100% (3)

- DFM Training Course-2Document6 paginiDFM Training Course-2Mauricio CastroÎncă nu există evaluări

- 4412A Amendment 1 (3 07)Document7 pagini4412A Amendment 1 (3 07)Aani MazharÎncă nu există evaluări

- Ipc/jedec 9703Document46 paginiIpc/jedec 9703metaballinÎncă nu există evaluări

- Board Design Guidelines 2003 Rev-ADocument53 paginiBoard Design Guidelines 2003 Rev-Agre_test_takerÎncă nu există evaluări

- Intro To SMTDocument38 paginiIntro To SMTShelly NandalÎncă nu există evaluări

- InTech-Automatic Optical Inspection of SolderingDocument56 paginiInTech-Automatic Optical Inspection of SolderingTeoTyJayÎncă nu există evaluări

- Design For Manufacturing Course - by DFRDocument257 paginiDesign For Manufacturing Course - by DFRhlgc63100% (2)

- 10 Manufacturing KPIs. Must WatchDocument14 pagini10 Manufacturing KPIs. Must WatchAura100% (1)

- IPC-TM-650 Test Methods Manual: Association Connecting Electronics IndustriesDocument4 paginiIPC-TM-650 Test Methods Manual: Association Connecting Electronics IndustriesVenkateswaran venkateswaranÎncă nu există evaluări

- Solder Paste Stencil Design R. 00Document17 paginiSolder Paste Stencil Design R. 00edwin100% (1)

- PCB GuideDocument35 paginiPCB Guidesmtdrkd100% (12)

- IPC SpecTree 1Document1 paginăIPC SpecTree 1Vuong Tran LeÎncă nu există evaluări

- Ipc Standards - Everything You Need From Start To Finish: End-ProductDocument1 paginăIpc Standards - Everything You Need From Start To Finish: End-ProductRidwan100% (1)

- Flex Circuits Design GuideDocument32 paginiFlex Circuits Design Guideluat1983Încă nu există evaluări

- IPC-TM-650-MDP-A: 2020 - March IPC Test Method Development PacketDocument14 paginiIPC-TM-650-MDP-A: 2020 - March IPC Test Method Development PacketJohnÎncă nu există evaluări

- Project Report On Taguchi Method 9tqm Project) by Sudeshna DashDocument17 paginiProject Report On Taguchi Method 9tqm Project) by Sudeshna DashODISHA FOOD ZONE & LIFE STYLEÎncă nu există evaluări

- Workmanship Standards QE SeminarDocument73 paginiWorkmanship Standards QE SeminarJuanPabloJimenezÎncă nu există evaluări

- Lean Manufacturing in Digital EraDocument7 paginiLean Manufacturing in Digital Eradian saharÎncă nu există evaluări

- Ipc Checklist For Rigid Pcba Revision August 1 2014 High ResDocument21 paginiIpc Checklist For Rigid Pcba Revision August 1 2014 High ResWim Op 't VeldÎncă nu există evaluări

- Printed Circuit BoardDocument22 paginiPrinted Circuit BoardMahiÎncă nu există evaluări

- Aim Lead Free Guide PDFDocument60 paginiAim Lead Free Guide PDFBruno DebonnetÎncă nu există evaluări

- Aperture and Area Ratio CalculationsDocument26 paginiAperture and Area Ratio Calculationssmtdrkd100% (1)

- Nasa STD 8739 2 PDFDocument84 paginiNasa STD 8739 2 PDFRanjitha BÎncă nu există evaluări

- Houston Impact of J-STD-001F and IPC-A-610F ChangesDocument36 paginiHouston Impact of J-STD-001F and IPC-A-610F Changes安靖Încă nu există evaluări

- IPC J-STD-004C en 2022 Requirements For Soldering FluxesDocument16 paginiIPC J-STD-004C en 2022 Requirements For Soldering FluxescdmingÎncă nu există evaluări

- IPC-7351A & PCBL Land Pattern Naming ConventionDocument6 paginiIPC-7351A & PCBL Land Pattern Naming ConventionSri ramÎncă nu există evaluări

- Ipc Skill ChallengeDocument38 paginiIpc Skill ChallengeShashidhara SSÎncă nu există evaluări

- X Ray Inspection and The IPC 7095 A SpecificationDocument1 paginăX Ray Inspection and The IPC 7095 A SpecificationoroxcooÎncă nu există evaluări

- Printed Circuit Board AcceptibilityDocument5 paginiPrinted Circuit Board AcceptibilityAnn Marian CadaoÎncă nu există evaluări

- Fiber Optic Polishing HandbookDocument12 paginiFiber Optic Polishing HandbookWey TongÎncă nu există evaluări

- Subcontract Conformal Coating and Parylene ServicesDocument1 paginăSubcontract Conformal Coating and Parylene ServicesLee HitchensÎncă nu există evaluări

- SCH Technical Bulletin Setting Up A Conformal Coating Production Line PDFDocument5 paginiSCH Technical Bulletin Setting Up A Conformal Coating Production Line PDFLee HitchensÎncă nu există evaluări

- Conformal Coating Masking Technical Bulletin PDFDocument3 paginiConformal Coating Masking Technical Bulletin PDFLee Hitchens100% (1)

- Conformal Coating Masking TapesDocument1 paginăConformal Coating Masking TapesLee HitchensÎncă nu există evaluări

- MG Chemicals Epoxy Compounds SCH BrochureDocument1 paginăMG Chemicals Epoxy Compounds SCH BrochureLee HitchensÎncă nu există evaluări

- Parylene Coating MachineDocument1 paginăParylene Coating MachineLee HitchensÎncă nu există evaluări

- UV200 UV Cure ConveyorDocument2 paginiUV200 UV Cure ConveyorLee HitchensÎncă nu există evaluări

- ACR Inline and Batch Conformal Coating Dip SystemDocument1 paginăACR Inline and Batch Conformal Coating Dip SystemLee HitchensÎncă nu există evaluări

- Humiseal 1R32 Conformal Coating English TdsDocument2 paginiHumiseal 1R32 Conformal Coating English TdsLee HitchensÎncă nu există evaluări

- MG Chemicals SCH BrochureDocument1 paginăMG Chemicals SCH BrochureLee HitchensÎncă nu există evaluări

- Global Coating ServicesDocument1 paginăGlobal Coating ServicesLee HitchensÎncă nu există evaluări

- MG Chemicals SCH BrochureDocument1 paginăMG Chemicals SCH BrochureLee HitchensÎncă nu există evaluări

- Consultancy SCH BrochureDocument1 paginăConsultancy SCH BrochureLee HitchensÎncă nu există evaluări

- Consultancy Troublshooting SCH BrochureDocument1 paginăConsultancy Troublshooting SCH BrochureLee HitchensÎncă nu există evaluări

- MACCS 400 Version 2 Multi Axis Conformal Coating System For Application of Conformal Coating MaterialsDocument1 paginăMACCS 400 Version 2 Multi Axis Conformal Coating System For Application of Conformal Coating MaterialsLee HitchensÎncă nu există evaluări

- Conformal Coating Spraying Complete Coverage Technical Bulletin July 09Document2 paginiConformal Coating Spraying Complete Coverage Technical Bulletin July 09Lee Hitchens100% (1)

- Technical Bulletin 1 Selective Robotic Conformal Coating Application Issues 250412Document1 paginăTechnical Bulletin 1 Selective Robotic Conformal Coating Application Issues 250412Lee HitchensÎncă nu există evaluări

- Humiseal 1A33 Conformal Coating English TdsDocument2 paginiHumiseal 1A33 Conformal Coating English TdsLee HitchensÎncă nu există evaluări

- Conformal Coating UV Curing Technical Bulletin June 09Document2 paginiConformal Coating UV Curing Technical Bulletin June 09Lee HitchensÎncă nu există evaluări

- Conformal Coating Dipping Technical Bulletin May 09Document2 paginiConformal Coating Dipping Technical Bulletin May 09Lee Hitchens100% (1)

- Humiseal 1R32A 2 Conformal Coating English TdsDocument2 paginiHumiseal 1R32A 2 Conformal Coating English TdsLee HitchensÎncă nu există evaluări

- Humiseal UV40 UV Cure Conformal Coating English TdsDocument4 paginiHumiseal UV40 UV Cure Conformal Coating English TdsLee HitchensÎncă nu există evaluări

- Humiseal 1B31 English TdsDocument2 paginiHumiseal 1B31 English TdsLee HitchensÎncă nu există evaluări

- ACCIS Automated Conformal Coating Inspection System Workshop Flyer 100209Document1 paginăACCIS Automated Conformal Coating Inspection System Workshop Flyer 100209Lee HitchensÎncă nu există evaluări

- Conformal Coating Viscosity Conversion TableDocument1 paginăConformal Coating Viscosity Conversion TableLee HitchensÎncă nu există evaluări

- Conformal Coating Curing and Drying Technical Bulletin Apr 09Document2 paginiConformal Coating Curing and Drying Technical Bulletin Apr 09Lee HitchensÎncă nu există evaluări

- Working Safely With Conformal Coatings - A Guide To Safe Working PracticesDocument4 paginiWorking Safely With Conformal Coatings - A Guide To Safe Working PracticesLee HitchensÎncă nu există evaluări

- WS100 Conformal Coating Wet Stripping System Technical Brochure 160209Document2 paginiWS100 Conformal Coating Wet Stripping System Technical Brochure 160209Lee Hitchens100% (1)

- ACCIS Automated Conformal Coating Inspection System Single Page Brochure 100209Document1 paginăACCIS Automated Conformal Coating Inspection System Single Page Brochure 100209Lee HitchensÎncă nu există evaluări

- General CNC InformationDocument63 paginiGeneral CNC InformationCristopher EntenaÎncă nu există evaluări

- Analog Electronics Module-2Document15 paginiAnalog Electronics Module-2Sourabh HalagekarÎncă nu există evaluări

- 04 Vibro V1000 Vs068en EnglischDocument36 pagini04 Vibro V1000 Vs068en EnglischFlerasgard0% (1)

- Tia Eia-607 PDFDocument40 paginiTia Eia-607 PDFChris Lex100% (1)

- K Factor TransformersDocument6 paginiK Factor Transformerssumitsharma2010Încă nu există evaluări

- ABS551T Service ManualDocument48 paginiABS551T Service ManualvovchickÎncă nu există evaluări

- 111ec0179 - Vishal Mishra - Baseband Transmission TechniquesDocument8 pagini111ec0179 - Vishal Mishra - Baseband Transmission Techniquesvsmishra1992Încă nu există evaluări

- CSE - 610 Lecture # 1Document35 paginiCSE - 610 Lecture # 1zaidÎncă nu există evaluări

- Evolution of TelevisionDocument18 paginiEvolution of TelevisionArianne AtilasÎncă nu există evaluări

- Grp4 - PN Sequence Spectra and Noise GenerationDocument18 paginiGrp4 - PN Sequence Spectra and Noise GenerationJohn Matthew Taule OboÎncă nu există evaluări

- Research ProposalDocument31 paginiResearch ProposalRaselle EbojoÎncă nu există evaluări

- Very Simple DIY Battery Tester - Schematics & ConstructionDocument5 paginiVery Simple DIY Battery Tester - Schematics & Constructionbnc1Încă nu există evaluări

- DET Tronics: Unitized UV/IR Flame Detector U7652Document2 paginiDET Tronics: Unitized UV/IR Flame Detector U7652Julio Andres Garcia PabolaÎncă nu există evaluări

- Study On Shure SM57 and Neumann TLM102Document11 paginiStudy On Shure SM57 and Neumann TLM102leoÎncă nu există evaluări

- Power Electronics Lab Assignment-X: Simulation of Half Bridge InverterDocument4 paginiPower Electronics Lab Assignment-X: Simulation of Half Bridge InverterAurang ZaibÎncă nu există evaluări

- 9355 SpecDocument1 pagină9355 SpecTrung DangÎncă nu există evaluări

- An H64Document4 paginiAn H64Hugo RojasÎncă nu există evaluări

- Accurate Measurement of Dynamic ON-Resistance in GaN Transistors at Steady-StateDocument6 paginiAccurate Measurement of Dynamic ON-Resistance in GaN Transistors at Steady-StateMin WANÎncă nu există evaluări

- Ae-6b Service Manual 488Document52 paginiAe-6b Service Manual 488fontanieroÎncă nu există evaluări

- Lampiran C.3 Spesifikasi Bahan LedakDocument3 paginiLampiran C.3 Spesifikasi Bahan LedakanisyahÎncă nu există evaluări

- JJRC X1 User ManualDocument8 paginiJJRC X1 User ManualManuelÎncă nu există evaluări

- Automated Drip Irrigation System Using Cloud Computing: Prof. P. S. Bangare, Ruturaj Patil, Zia Khatib, Indrajit KaduDocument4 paginiAutomated Drip Irrigation System Using Cloud Computing: Prof. P. S. Bangare, Ruturaj Patil, Zia Khatib, Indrajit Kaduzia khatibÎncă nu există evaluări

- Electronics: Fully Integrated Low-Ripple Switched-Capacitor DC-DC Converter With Parallel Low-Dropout RegulatorDocument16 paginiElectronics: Fully Integrated Low-Ripple Switched-Capacitor DC-DC Converter With Parallel Low-Dropout RegulatorBadraa BatorgilÎncă nu există evaluări

- Product Specifications Product Specifications: LDXX LDXX - 6515DS 6515DS - VTM VTMDocument6 paginiProduct Specifications Product Specifications: LDXX LDXX - 6515DS 6515DS - VTM VTMTumpal PasaribuÎncă nu există evaluări

- Ansi Tia 607 C 2015Document92 paginiAnsi Tia 607 C 2015DamiánÎncă nu există evaluări

- Monitor Module S-A4042Document2 paginiMonitor Module S-A4042Ashiq Salman100% (1)

- MCCB Elcb MCBDocument60 paginiMCCB Elcb MCBLUATÎncă nu există evaluări

- Okuma Manuals 2771Document96 paginiOkuma Manuals 2771kkcm100% (1)

- Grid Connected Inverter SpcificationDocument2 paginiGrid Connected Inverter Spcificationdh24992499Încă nu există evaluări

- MDA MDA: Automatic Start UnitDocument2 paginiMDA MDA: Automatic Start Unitluat1983Încă nu există evaluări