Documente Academic

Documente Profesional

Documente Cultură

244 251

Încărcat de

patrik710Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

244 251

Încărcat de

patrik710Drepturi de autor:

Formate disponibile

Service performance of refractories in connection with pusher reheating furnaces in Bhilai Steel Plant

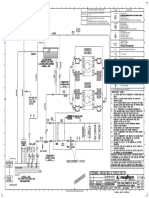

Maheshwari Singh, R. S. Dahiya, Rajat Sen Er Bhilai Steel Plant, Bhilai Bhilai Steel Plant comprises of three finishing mills, which are equipped with continuous pusher reheating furnaces to heat blooms & billets from the blooming & billet mill at 2.5 M. T. stage. Reheating furnaces of rail & structural mill and merchant mill are of same design with three zones having 20 burners in each furnace (7 burners in top & bottom zone & 6 burners in soaking zone). The wire rod mill has got only one reheating furnace with 2 zones having 14 burners in each zone. The merchant mill is equipped with 3 pusher type and charging, discharging reheating furnaces of overall length 26000 mm. & width 18000 mm. The length & breadth of active hearth of each furnace is 6500 mm and 20,000 mm respectively. The furnace is heated with a mixture of coke oven & blast furnace gas of the calorific yak; a 1500 K Cal/M3. The furnace pressure under soaking zone roof Is upto 2.5 rr; -n of water column. These furnaces are equipped with ceramic & metallic recuperators for pre-heating of air and gas upto 700 & 300C respectively. The capacity of each furnace is 60 T/hr.

A.

K. Singh

Seven continuous pusher reheating furnaces are installed in 2.5 million tonne stage in the R & S. Mill, Merchant Mill and Wires & Rod Mill at Bhilai Steel Plant to cater the need of rolling of various finished products. In this paper, attempts have been made to brief out the service performance of refractories in various elements of the furnaces. The replacement of better refractory material and installation over original "design in order to strengthen the weak link for continuous service ability of the furnace has also been discussed in brief.

Three reheating furnaces are installed in rail & structural mill each cf 72 TI hr. capacity to fulfill the demand of rolling and these tired kith a mixfurnace ture of coke oven &

gas of calorific value 1500 K Cal/M3 Air for combustion 1- preheated to 500C in ceramic recuperators of 200M3 usefull volume and the gas is preheated to 250C 11 metallic recuperators of 620 11 2 surface area. Tie soaking temperatur-a is between 1280

244

to 1300C and, the soaking time is normally 2 hc Jrs. The furnace is maintained at sightly positive pressure ( 2 mm watt.- gauge). The active hearth Is 6.7 M wide and 29 M long. There are 2G burners in each furnace, distributed threa zones. 7 in top zone, 7 in bo.tom zone and 6 in soaking zone. Automatic control devices have bri-an provided in the furnace to ensure the effective burning of the gas and combustion products of all the three furnaces are discharged by a common chimney of 5 M dia & 90 M height. There is only one continuous reheating furnace in wire rod mill with a sloping hearth, 18 M long & 12.6 M wide having side charging & discharging of the billets. The furnace capacity is 120 T/hr. The furnace is heated by means of a mixture of coke oven & blast furnace gas of calorific value 1500 K/113. The gas is preheated to 250C in metallic recuperators & air is preheated in ceramic recuperators to a temperature approximately 500C. The pressure of the gas in the furnace is about 1500 mm of water gauge. Combustion products of the furnace are disposed off through a chimney 3.5 M dia & 75 M height.

roof and hearth (mainly on ejector axis of soaking zone). Standard chrome magnesite bricks of size 230 x 115 x 65 mm are laid on edge in the heard . Erosion of these chrome magnesite bricks In the hearth, specially in the ejector axis of soaking zone, causes uneven surface and pits are formed In the hearth. Billets which are to be pushed out of the furnace when falls in these pits, they are at lower level than the water cooled ejector ram which is supposed

to push these billets out of the furnace.

This ejector ram some times misses these billets completely which are in these pits, and travels on top of the billets. Ultimately discharging of the billets out of the furnace becomes a problem. These pits are formed mainly because of continuous abrasion of ejector ram and hydration of chromemagnesite bricks during discalling by spraying water on the ejector axis. To avoid this scale formation high alumina bricks (88% M203) from Indigenous suppliers with high alumina mortar, were used as these bricks had high abrasion resistance & other favourable properties. But use of these bricks were not at all satisfactory as the errosion & pit formation was much more higher than chrome magnesite bricks. Recently electrocast corundum blocks have been used in the ejector axis which is providing excellent performance. Abrasion of these blocks & pit formation are practically nil and descaling operation is much more easier. It has been reported that at the Cherepovets Works, U. S. S R.

Wire rod mill reheating furnace This furnace is of two zone continous side charging & discharging with curvilinear bottom having capacity 120 T/hr. The refractory failure In wire rod mill Is mostly in burners, curved

245

hearth, with corundum blocks has been extended upto average 2 years instead of 6 months in continuous furnace. There Is a proposal of using corundum blocks In heating zone also, in wire rod mill The chemical composition of corundum blocks used in wire rod mill at. Bhilai Steel Plant is given in Table No. I. TABLEI Specification of electrocast corundum blocks A1203 Sio2 Tio2 Fe2O3 Other Oxides P C. E. R. U. L. ta B. D. of Bhilai Steel Plant.

the mean life of the

refractory failure) Is another bottle neck In reheating furnaces. In the begining burners were laid with shaped bricks of ten different shapes, which are leading to following Inconveniences. .. I ) More Inventory due to different shapes.

li ) Non-availability of one or more

shapes resulting difficulty In laying of burners.

lil ) Heavy in weightswhich was

causing Inconveniency in transportation and laying of burners. To avoid above problems, rammlr,g masses of different types have been tried in casting of burners in reheating furnaces. The main types are air setting and hydraulic setting ramming masses of different composition, General compositions of air and hydraulic setting ramming masses are given

90-95% 2-5% 0.5% 0.7% 30 / 0 1950C 1700C 3.0 gm/cc

The heating zone consists of partly uncooled solid skids and partly chrome, magnesite brick work. Invariably, it has been observed that, the erosion of chrome magnesite bricks is maximum when the billets leave uncooled solid skids and ride on chrome magnesite bottom. It has been experienced in other plants that the use of corundum blocks In this load transformation region also can increase the life of the furnaces considerably by avoiding Intermediate stoppage of the furnace for the repair of hearth at this region. Failure of the water cooled burners (refractories) & turner heads (mechanical failure which ultimately causes

in Table No. II. It has been observed TABLEII The properties of ramming masses used in burner of reheating furnaces.

Parameters

Hydraulic setting ramming masses 36-40 01er 1700C (0-5) r.:'.1

Air-setting ramming masses

1. A1203, % 2. Refractories 3. Grading. 95% Min will be below the maximum grain size

60-65 Over 1740C

(0--5)MM

246

that air 1._.ting ramming masses cf higher aIJAna content -(60% A1203) have taken up hightr thermal load than hydraulic setting ramming masses whereas hydraulic setting ramming masses are easy to ram, have good green strength, provide a smooth profile of the turner. However, the shrinkage after firing of hydraulic setting masses is high. Some times this shrinkage causes such wide cleavages and burners ultimately collapse. The air setting masses have less shrinkage after firing but they have slightly less green strength and their surface profile is week if ramming is not done very carefully. The life of rammed burner is about 18-20 months. The main reason of burner failure is due to the failure of burner heads. Generally there are two types of failures In burners. First one Is flame shoot out at the back of the burner head, & the other one is failure of water cooled burner heads & subsequent water leakage on the ramming mass. As shown In figures before ramming, steel plates are welded at the back of burner for the ramming mass. If this steel plate provides sufficient room for ramming at the back of the

burner head, the ramming mass sort of locks the burner head from the back and this ultimately arrest any escape route of flame at the back of burner head (Fig. 2). When the steel plate Is nearer to the burner head there is not much of space for the rammer to operate smoothly and ramming at the back Is weak which is not strong enough to arrest shooting out of flames from the back side (Fig, I ). Water leakages from water cooed burner heads on rammed burner and roof underneath to makes It wet which imparts severe thermal shock and ultimately burner of roof fails. In case of burner it may be due to pressure of steam which Is developed by water leakage Inside the ramming mass. Attempts were taken to cool the burne heads with chilled air, but it was also not very much successful as this process had its own limitation. The curved roof or pre-regime roof of wire rod mill is of high alumina category refractory bricks (A1203 54%) and has an average life of 18 months, Mostly curved roof fails (beside the

n5 -2,

Burner blocks Fig, 1. Before modification and Fig, 2. After modification.

247

refractory failure of unknown reason) because of leakage water from burner head dripping on it. During weekly repair day when the temperature of the furnace Is brought down, these bricks which had cracked due to thermal shock caused by leakage water, are not able to take further thermal shock and fall down. The existing reheating furnace design of B. S. P. does not permit any replacement of curved roof bricks & from out side. The damaged portion is patched up by gunniting from Inside but this also causes a opera. tional problem as portion of gunniting mass which falls on the billets restricts proper heating cf billets even though raking is done.

in rail & structural mill and merchant mill Is mostly in burners, water cooled skids, side walls, roof, hearth & discharging end lintel. Burners are rammed in the same way as described previously in wire rod mill section of the article. Reasons of failure are same as discussed above. However, some modifications were done to hold the ramming mass togecher with water cooled burner heads by welding anchor rods or wire nets arround the head as shown In the figures. But It was not very much successful as anchor roils (Fig. 3) were causing following inconveniences. I ) They were an obstacle for smooth

The side walls and roof of heating and soaking zone are of high grog fireclay bricks which imparts quite satisfactory performance. Recuperator of wire rod mill has not given any problem so far. False checkers are there before the recupera tors which restricts flue dust to go Into the recuperator. These are cleaned during the capital repair of the furnace. The expected life of the recuperator Is about 15 years.

operation of rammer. II ) There ends were very near to the surface of ramming mass. Hence during operation they were highly heated up or were directly exposed to the flame & ultimately their purpose were not solved. Further, wire net welded to burner head ( Fig. 4) Is not much effective in holding ramming mass at burner mouth. Skid insulation is a bottle neck in reheating furnaces of rail & stauctural mill and merchant mill The life of skid Insulation was found out to be 4-6 months In Rail & structural mill and 6-10 months In that of Merchant Mill. In reality life & capacity of skid insulation is the major factor in achieving low heat loss to the cooling members. This heat loss depeles upon the quality

Rail, structural and merchant mill reheating furnace There are three zones and charging and sloping discharging continuous type furnaces. The average Ile of rail & structural mill reheating furnace is 6 to 8 months & that of merchant mill Is 10-12 months. The refractory failure

248

Fig. 3 ramming nx of burner with anchor rod. Fig. 4. Ramming mass of burn,..)r . , -rith wire net. of tht , Insulating material, their installation techniqu_ and service condition of the furntce. The skids insulating material has to serve at a temperatures of 1250CI350C with the reaction of mill scale at this elevated temperature. It also should have resistance to thermal shock and mechanical shock due to a number of operational problems. Following are the types of skid failure actually observed in rail & structural and merchant mill of Bhliai Steel Plant. I ) Skid Insulation rallure Problems occur when the pins welded to the skid are not perfect In size and protrude out of the ramming mass after the skid insulation come in direct contact of the flame and fall very III ) Sagging of skid Skids are generally Insulated by hydraulic setting ramming masses of different verity from different manushortly and the hold on ramming mass after the skid insulation or pins are not firmly welded to the skid, Pins protruding out of the insulation come In facturers. Old insulation sticking to the skids Is removed and then small pins or studs are welded on three sides of the skids for anchoring the ramming mass. Wooden scaffoldings are fixed around the skids, part by part, and then thick slurry of ramming mass is poured in these scaffoldings. Scaffoldings are removed when the material sets perfectly as shown in Fig. 5 to 9.

ii ) Puncture of skid

Fig. 5r -Fig. 3. Various modifications of insulating ramming mass for skid rails

249

direct contact of the flame and fail very shortly and the hold on ramming mass is very weak which slowly falls. Further, pin welding on old skids Is not strong enough as the fused insulating material of last campaign adheres to the skid. This is not easy to remove completely and hence the welding is not proper. This ultimately causes failure of the insulation. When Insulation of the skid fails, skid is In direct exposer of flame and many a time it punctures The cooling water through that puncture falls on chrome magnesite bottom of bottom zone hearth, which crumbles Immediately. This further causes sinking of bottom and side walls which ultimately cause gap in side walls. Water cooled skids rest on separation walls. They are aligned and st.pported from bottom by tightening grooved castings below them (Fig. 10 & I I.) Due to the service condition chase skids are not In perfect straight line.

If the castings below the skids are not tightened perfectly or If the arches above the flue has sunk little bit, this causes tightened castings to become loose, then there is a gap between the skid and castings. The heavy stock which is travelling on these skids Impart hammering effect on the loose castings or wall below it (Fig. 12) and wall collapses. This effect is more prominent If there is any variation in the distribution of load, This effect Is less in the merchant mill reheating furnace, as stock travelling on the skids Is lighter. As brick tightening below the castings was not giving good life, using air modification was done by setting ramming mass above the arches., This was favourable as ramming mass goes into every corner around & below the castings and provides better holding. Ser ice performance and bricl.:s used in the curved roof, straight roof and side walls of reheating furnaces of rail & structural mill & merchant mill are same as discussed in case of wire rod

STIIFiNER. LONGITUDINAL BRICK

r I G hICrrIO

BRICKS TIGHTENED LINDER THE 4k1D

am . 0s 6111111111111111=161 witammurrearimm II/AKIM111111M1111111111111 411 !.. ..drimilINN=1111111111111111 s 1 ... ... s s --...miumnimi minit

01MEW "'Nom= ......-s s .4ts

Fs 11: A-1414 ;:E Ti

HAMMtRloG EFF6cro

AND CASTING.

Iii

CAsTIMG , ..

eiG.

11.

FIG.

12

Fig. 10-12. Setting of skid and failure'of the refractories. 250

mill. The life of ..rve&roof Is about 2 yaxs. Soaking one and bottom zone hearth nt,1

with the chrome magnesite or any other brick with expected life of 2 years. 3. Refractories used In curved roof and in soaking zone roof should be of high alumina type with 54% A1203 range and remaining portion of the roof may be continued with 38-42% A1203 brick. 4. Monolithic refractories must be upgraded to suit the demand of at least 2 years from 18 months which is the present life. 5. To achieve economy by reducing heat loss In the skids, it is urgent to develop refractories and its application technique to match with the service condition. Instead of ramming, shaped bricks and insulating rings may be used to achieve life of atleast I year. 6. Curved roof should be designed/ modified so that any emergency repair may be taken up from outside the furnace. 7. The shape of the lintel brick should be changed so that It is more stronger as desired by the service conditions.

s ere Cnuch pro..

blem. Soaking zon3 learth also gives average ific of 2 yeart. Charging and lintel has a life of 3-4 months. The shaped brick used here are or firec;ay (Fig. 13). These bricks are hanged to water cooled lintel by means of channels welded to the lintel. Due to Improper distribution or pushing of the stock going inside the furnace, stock overlap and tilt the lintel brickwork and the lintel is damaged. As the temperature of this zone Is not very high no serious damage is done to the furnace structure even after the failure of the lintel brick work. However, there should be some modification In brick shape or design to achieve more life. Conclusion I. It is advisable to use electro-cast refractories in critical areas of the curvilinear bottom of wire rod mill reheating furnace, i.e., in ejector axis of soaking zone & at load transformation point of the heating zone. 2. Solid skids should be replaced by electro-cast refractories, and soaking hearth should be continued

WATER COOLED

LINTEL.

6-1

I 6- 1 J-6 -

7-.51827 FIG. 13

LINTEL-

RICKS.

CHANNELS WELDED TO HATER coo( VD LINTEL Fpft HANCIN6 tiArnORICAs

Fig. 13. Fireclay shapes used for lintel Fig 14. Fireclay shapes with welded channels

251

S-ar putea să vă placă și

- Hardness Shore C C MN MN Si P S Ni CRDocument2 paginiHardness Shore C C MN MN Si P S Ni CRpatrik710Încă nu există evaluări

- Rev - 00 - Open Loop Water Circuit - 3250kwDocument1 paginăRev - 00 - Open Loop Water Circuit - 3250kwpatrik710Încă nu există evaluări

- List of ContractorDocument1 paginăList of Contractorpatrik710Încă nu există evaluări

- If Your Actions Inspire Others To Dream MoreDocument3 paginiIf Your Actions Inspire Others To Dream Morepatrik710Încă nu există evaluări

- Bearing 6202 and 6203 ConsumptionDocument2 paginiBearing 6202 and 6203 Consumptionpatrik710Încă nu există evaluări

- Ring FormationDocument5 paginiRing Formationpatrik710Încă nu există evaluări

- BookletDocument1 paginăBookletpatrik710Încă nu există evaluări

- Organgram of Shyam MetalicDocument1 paginăOrgangram of Shyam Metalicpatrik710Încă nu există evaluări

- Shut DownDocument1 paginăShut Downpatrik710Încă nu există evaluări

- PO Box 1010, Liverpool L70 1NL, United KingdomDocument2 paginiPO Box 1010, Liverpool L70 1NL, United Kingdompatrik710Încă nu există evaluări

- Po Sel PIPEDocument2 paginiPo Sel PIPEpatrik710Încă nu există evaluări

- Tata SteelDocument32 paginiTata Steelpatrik710Încă nu există evaluări

- Observation ChartDocument5 paginiObservation Chartpatrik710Încă nu există evaluări

- Po Sel PIPEDocument2 paginiPo Sel PIPEpatrik710Încă nu există evaluări

- Crompton Greaves LetterDocument1 paginăCrompton Greaves Letterpatrik710Încă nu există evaluări

- SafetyDocument1 paginăSafetypatrik710Încă nu există evaluări

- Electrical MotorsDocument6 paginiElectrical Motorspatrik710Încă nu există evaluări

- Based On Liquids Not Exceeding 200 CST Viscosity and 70Document1 paginăBased On Liquids Not Exceeding 200 CST Viscosity and 70patrik710Încă nu există evaluări

- Sti 2062Document6 paginiSti 2062patrik710Încă nu există evaluări

- Facility of Pipe PlantDocument3 paginiFacility of Pipe Plantpatrik710Încă nu există evaluări

- Crompton Greaves LetterDocument1 paginăCrompton Greaves Letterpatrik710Încă nu există evaluări

- Based On Liquids Not Exceeding 200 CST Viscosity and 71Document2 paginiBased On Liquids Not Exceeding 200 CST Viscosity and 71patrik710Încă nu există evaluări

- VMHDocument6 paginiVMHpatrik710Încă nu există evaluări

- Gear Teeth Chemical CompositionDocument1 paginăGear Teeth Chemical Compositionpatrik710Încă nu există evaluări

- Crompton Greaves LetterDocument1 paginăCrompton Greaves Letterpatrik710Încă nu există evaluări

- Efficient Furnace Operation1Document7 paginiEfficient Furnace Operation1patrik710Încă nu există evaluări

- Misc Pipe and Grade For Iph & OphDocument1 paginăMisc Pipe and Grade For Iph & Ophpatrik710Încă nu există evaluări

- V Pully DimensionDocument1 paginăV Pully Dimensionpatrik710Încă nu există evaluări

- Hydrolic Cylinder Dspec DetaDocument1 paginăHydrolic Cylinder Dspec Detapatrik710Încă nu există evaluări

- The Steel Pipe Data Chart Below Can Be Used To Find Pipe SizesDocument6 paginiThe Steel Pipe Data Chart Below Can Be Used To Find Pipe Sizespatrik710100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Inventaa Hollow WallsDocument6 paginiInventaa Hollow WallsSumedh GuptaÎncă nu există evaluări

- Sample Report Standard Quality On Crawlspace EplansDocument1 paginăSample Report Standard Quality On Crawlspace EplansRyan De Vera PagalÎncă nu există evaluări

- R1 Designing A School Public ToiletDocument18 paginiR1 Designing A School Public ToiletIrish Barte100% (1)

- Cristobal, Rowela - Research Work #1Document8 paginiCristobal, Rowela - Research Work #1rowela cristobalÎncă nu există evaluări

- The Problem and Its BackgroundDocument4 paginiThe Problem and Its BackgroundSuzaku KururugiÎncă nu există evaluări

- Technical Data Handbook of TK CorporationDocument172 paginiTechnical Data Handbook of TK CorporationGerard Adrian Bautista AnonuevoÎncă nu există evaluări

- Acoustic Insulation Under FloorDocument11 paginiAcoustic Insulation Under FloorMiteshaÎncă nu există evaluări

- 301 Stainless SteelDocument1 pagină301 Stainless SteelDanielÎncă nu există evaluări

- Reducing Field Sample of Aggregate To Test Sample ASTM C 702, D75Document16 paginiReducing Field Sample of Aggregate To Test Sample ASTM C 702, D75Shekh AbdullahÎncă nu există evaluări

- Difference Between Up Milling and Down MillingDocument4 paginiDifference Between Up Milling and Down MillingT. VeerabhadraiahÎncă nu există evaluări

- TSPP8Document76 paginiTSPP8Ian Naylor100% (1)

- Set 8-3 PDFDocument56 paginiSet 8-3 PDFAek JayÎncă nu există evaluări

- Juk MS-191 261 261JDocument38 paginiJuk MS-191 261 261JRHoskaÎncă nu există evaluări

- 32mm Thick Flush Doors Rs 140Document9 pagini32mm Thick Flush Doors Rs 140lkovijayÎncă nu există evaluări

- Lab Manual - Mech 1051 Ay 2021-2022 EvenDocument10 paginiLab Manual - Mech 1051 Ay 2021-2022 EvenKoushik DebnathÎncă nu există evaluări

- Consumable Spec Rev 12Document24 paginiConsumable Spec Rev 12megastar0604Încă nu există evaluări

- CemfixDocument2 paginiCemfixpravi3434100% (1)

- PVA Fibre Reinforced High-Strength Cementitious Composite For 3D Printing Mechanical Properties and DurabilityDocument12 paginiPVA Fibre Reinforced High-Strength Cementitious Composite For 3D Printing Mechanical Properties and Durabilityhamed sadaghianÎncă nu există evaluări

- Pricelist - TABLE TOP - Chennai - 2020 AbinDocument2 paginiPricelist - TABLE TOP - Chennai - 2020 AbinShivaji RamaniÎncă nu există evaluări

- IxawDocument4 paginiIxawyuvaraja 2219Încă nu există evaluări

- Damascus SteelDocument6 paginiDamascus SteelAkram FaisalÎncă nu există evaluări

- Temporary Structure (Food Plaza)Document5 paginiTemporary Structure (Food Plaza)Gunjan UttamchandaniÎncă nu există evaluări

- Concrete Mix Design PQC M40Document5 paginiConcrete Mix Design PQC M40Pirpasha Ujede50% (2)

- 2fd9c443-8a5c-41e2-9aad-48cdd9dc151dDocument2 pagini2fd9c443-8a5c-41e2-9aad-48cdd9dc151dmelsabaeÎncă nu există evaluări

- MFDP2 - L04 - Deep Drawing and Stretch Drawing - ENIM 2021-22Document43 paginiMFDP2 - L04 - Deep Drawing and Stretch Drawing - ENIM 2021-22Alaa RmidaÎncă nu există evaluări

- Cement: Is A Complex Mixture of Dicalcium Silicate (C2S)Document18 paginiCement: Is A Complex Mixture of Dicalcium Silicate (C2S)Pratik AgajÎncă nu există evaluări

- Lista Preturi Pardoseli 1iulie2020Document42 paginiLista Preturi Pardoseli 1iulie2020elyeliza2000Încă nu există evaluări

- RESUME - 044 BD Ceiling Polystyrene 1x1800 - 2016-07-18: Implementare in 1x1800mm Numar Articole: 15Document7 paginiRESUME - 044 BD Ceiling Polystyrene 1x1800 - 2016-07-18: Implementare in 1x1800mm Numar Articole: 15johnÎncă nu există evaluări

- D10414410a Fmea CastingDocument7 paginiD10414410a Fmea CastingSuraj RawatÎncă nu există evaluări

- Fork Head DIN 71752 Fork Joints GN 751Document2 paginiFork Head DIN 71752 Fork Joints GN 751Anonymous HPlNDhM6ejÎncă nu există evaluări